Академический Документы

Профессиональный Документы

Культура Документы

Mac

Загружено:

alwar_shi262068Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mac

Загружено:

alwar_shi262068Авторское право:

Доступные форматы

PRODUCT MIX DECISION

Q.

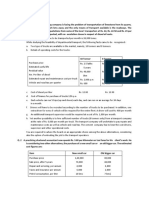

Aramis Aromatics company produces & sells its product AA100 to well known cosmetics companies for $940 per ton. The marketing manager is considering the possibility of refining AA100 further into finer perfumes before selling them to the cosmetics companies. Product AA101 is expected to command a price of $1,500 per ton & AA102 a price of $1,700 per ton.The maximum demand for AA101 is 400 tons & for AA102 is 100 tons. The annual plant capacity of 2,400 hrs is fully utilized at present to manufacture 600 tons of AA100. The marketing manager proposed that Aramis sell 300 tons of AA100,100 tons of AA101 & 75 tons of AA102in the next year.It requires 4 hrs of capacity to make 1 ton of AA100, 2 hrs for refine of AA100 further into AA101, and 4 hrs to refine 1 ton of AA100 into AA102 instead.The plant accountant made this following sheet.

Cost Item

Dir. Material - Chemical & Fragrance Dir. Material - AA 100 Direct labor Variable manufacturing support (Variable) Fixed Total manufacturing cost Total selling support (Variable) Fixed Total Cost Proposed sales Level Max Demand

AA100

$560 60 60 120 $800 20 10 830 300 ton 600 ton

AA101

$400 800 30 30 60 $1,320 30 10 1,360 100 ton 400 ton

AA102

$470 800 60 60 120 $1,510 30 10 1,550 75 ton 100 ton

(a) Conribution margin for each product? (b) Determine the production lvl for three product under the present constraints on plant capacity that maximize total contribution? (c) Suppose a customer, Cosmos Cosmetics Company, is very interested in the new product AA101. It has offered to sign a long-term contract for 400 tons of AA101. It is also willing to pay a higher price if the plant capacity is dedicated to the production of AA101. What is the minimum price for AA101 at which it becomes worthwhile for Aramis to dedicate its entire capacity to the production of AA101?

(d) Suppose, instead, that the price of AA101 is $1,500 per ton and that the capacity can be increased temporarily by 600 hours if the plant is operated overtime. Overtime premium payments to workers and supervisors will increase direct labor and variable manufacturing support cost by 50% for all products. All other cost will remain unchanged. It is worthwhile operating the plant overtime? If the plant is operated overtime for 600 hours, what are the optimal production levels for the three products?

Presented By: Group IV

Udai Kr. Jayant Das : Mukul Mehra : Saurabh Tyagi : Sanjay Gupta : 033 Vipin Kr Singh : 047 Gaurav Bhargava : 012

(A.)

Unit cost

Dir. Material - Chemical & Fragrance Dir. Material - AA 100 Direct labor Variable manufacturing support Total variable manufacturing cost Total selling support Total variable cost Sales price Contribution margin per ton MH per ton Contribution margin per MH

AA100

$560 60 60 $680 20 $700 940 $240 4 hrs $60

AA101

$400 800 30 30 $1,260 30 $1,290 1,500 $210 6 hrs $35

AA102

$470 800 60 60 $1,390 30 $1,420 1,700 $280 8 hrs $35

(B.) AA100 has a higher contribution margin per MH than AA101 and A102.

Aramis Aromatics should produce AA100 up to 600 tons. Since the production of 600 tons of AA100 requires = 600x4= 2400MH Which is equals available capacity, no other products will be manufactured. Therefore, the optimal production levels are: AA100 = 600 tons AA101 = 0 tons AA102 = 0 tons

(C.) Opportunity cost is $60 per MH (the contribution margin per MH for AA100 production

that must be sacrificed) and each ton of AA101 requires 6 MH. Required contribution margin per ton = $60x6 = $360 Variable cost per ton = 1,290 Required minimum sales per ton =$1,650

(D.) It is worthwhile operating the plant overtime.

The optimal production level is AA100 = 600 tons AA101 = 100 tons AA102 = 0 tons Because regular capacity of plant is 2,400 MH (before overtime) to produce 600 tons of AA100.In this case demand for AA100 has been filled fully now we are concentrating on AA101 & AA102. Under overtime: Dir. Material - Chemical & Fragrance Dir. Material - AA 100 Direct labor Variable manufacturing support Total variable manufacturing cost Total selling support Total variable cost Sales price Contribution margin per ton MH per ton Contribution margin per MH AA100 $560 90 90 $740 20 $760 940 $180 4 $45 AA101 $400 800 45 45 $1,290 30 $1,320 1,500 $180 6 $30 AA102 $470 800 90 90 $1,450 30 $1,480 1,700 $220 8 $27.5

Since, contribution margin per MH for AA101 & AA102 is positive, So it is worthwhile to opertate the plant overtime.

Вам также может понравиться

- Group - 9 - Sec - B - IQDM - Merton - Truck - CompanyДокумент8 страницGroup - 9 - Sec - B - IQDM - Merton - Truck - CompanyMANVENDRA SINGH PGP 2019-21 BatchОценок пока нет

- PanchtantraДокумент4 страницыPanchtantraJD_04100% (5)

- Merton Trucks Case Note: I I M A IIMA/QM-xxxДокумент8 страницMerton Trucks Case Note: I I M A IIMA/QM-xxxAyush GuptaОценок пока нет

- Week 8Документ3 страницыWeek 8yogeshgharpureОценок пока нет

- Planning The Product Mix at Panchtantra CorporationДокумент14 страницPlanning The Product Mix at Panchtantra CorporationNRLDCОценок пока нет

- Indian Electricals Limited (Complete) 1Документ8 страницIndian Electricals Limited (Complete) 1Prashant BarsingОценок пока нет

- Indian Electricals Cost SheetДокумент1 страницаIndian Electricals Cost SheetPratul BatraОценок пока нет

- DHL Global Forwarding Consolidation Program - Group Assignment Case AnalysisДокумент13 страницDHL Global Forwarding Consolidation Program - Group Assignment Case AnalysisNitin Shankar100% (1)

- Davey & Classic Pen CA - Abhishek - .2022B2PGPMX001docxДокумент4 страницыDavey & Classic Pen CA - Abhishek - .2022B2PGPMX001docxabhishek pattanayakОценок пока нет

- CVPДокумент3 страницыCVPRajShekarReddyОценок пока нет

- Case Problem 1 - Product MixДокумент7 страницCase Problem 1 - Product Mixgorgory_30% (1)

- Lecture 19Документ32 страницыLecture 19Riaz Baloch NotezaiОценок пока нет

- Vayutel Case StudyДокумент10 страницVayutel Case StudyRenault RoorkeeОценок пока нет

- Sources/ $/ton Mile Tons Coordinates Markets: Buffalo Memphis St. Louis Atlanta Boston Jacksonville Philadelphia New YorkДокумент2 страницыSources/ $/ton Mile Tons Coordinates Markets: Buffalo Memphis St. Louis Atlanta Boston Jacksonville Philadelphia New YorkNithya RathnaОценок пока нет

- Problem SetДокумент6 страницProblem SetKunal KumarОценок пока нет

- Daud Engine Parts CompanyДокумент3 страницыDaud Engine Parts CompanyJawadОценок пока нет

- Abhishek 2 - Asset Id 1945007Документ3 страницыAbhishek 2 - Asset Id 1945007Abhishek SinghОценок пока нет

- Rougir Cosmetics International Did Not Have Internal Capacity To Meet DemandДокумент3 страницыRougir Cosmetics International Did Not Have Internal Capacity To Meet DemandSameed Zaheer Khan100% (1)

- Solved The Dijon Company S Total Variable Cost Function Is TVC 50qДокумент1 страницаSolved The Dijon Company S Total Variable Cost Function Is TVC 50qM Bilal SaleemОценок пока нет

- JHT Case ExcelДокумент4 страницыJHT Case Excelanup akasheОценок пока нет

- SectionA Group 3 RAOBDA ReportДокумент7 страницSectionA Group 3 RAOBDA ReportIsha ChaudharyОценок пока нет

- Merton Truck Company PDFДокумент8 страницMerton Truck Company PDFSrinivas NandikantiОценок пока нет

- Problem Sheet II - Confidence Interval, Sample SizeДокумент4 страницыProblem Sheet II - Confidence Interval, Sample SizeShamil MОценок пока нет

- Assignment PDFДокумент3 страницыAssignment PDFshruthinОценок пока нет

- 11 7Документ2 страницы11 7Mesut SarıtemurОценок пока нет

- Problem Set 1 PDFДокумент3 страницыProblem Set 1 PDFrenjith0% (2)

- Chapter 11Документ11 страницChapter 11PeterGomesОценок пока нет

- Answer To VMD Medical Imaging CenterДокумент2 страницыAnswer To VMD Medical Imaging CenterPragathi SundarОценок пока нет

- MAC Davey Brothers - AkshatДокумент4 страницыMAC Davey Brothers - AkshatPRIKSHIT SAINI IPM 2019-24 BatchОценок пока нет

- Nptel Course Financial Management Assignment Ii: Liabilities Rs. (Million) Asset Rs. (Million)Документ3 страницыNptel Course Financial Management Assignment Ii: Liabilities Rs. (Million) Asset Rs. (Million)yogeshgharpureОценок пока нет

- QM QuestionsДокумент16 страницQM QuestionsPriyanshu KumarОценок пока нет

- Modern Pharma SolnДокумент3 страницыModern Pharma SolnSakshiОценок пока нет

- Assembly LineДокумент8 страницAssembly LineAnshik YadavОценок пока нет

- ARS Waltham Case TransactionsДокумент2 страницыARS Waltham Case TransactionsRajnikaanth SteamОценок пока нет

- FC - 1 - Master Budgeting CS - Stylistic 2021 - With SolutionДокумент18 страницFC - 1 - Master Budgeting CS - Stylistic 2021 - With SolutionQuang NhựtОценок пока нет

- CMA Individual Assignment Manu M EPGPKC06054Документ6 страницCMA Individual Assignment Manu M EPGPKC06054CH NAIRОценок пока нет

- Case Study: Dreamworld Amusement Park Dreamworld: Initial Years of OperationДокумент3 страницыCase Study: Dreamworld Amusement Park Dreamworld: Initial Years of OperationArnav MittalОценок пока нет

- Chapter 5Документ11 страницChapter 5L LОценок пока нет

- Chapter 5Документ30 страницChapter 5فاطمه حسينОценок пока нет

- Standard Costing I SolutionДокумент7 страницStandard Costing I SolutionDheeraj DoliyaОценок пока нет

- Thumbs UpДокумент4 страницыThumbs Upwasif ahmedОценок пока нет

- Megacard CorporationДокумент16 страницMegacard CorporationAntariksh ShahwalОценок пока нет

- Case - Breeden (B) - Recomputation of CostsДокумент6 страницCase - Breeden (B) - Recomputation of CostsRaviteja VeluvoluОценок пока нет

- EA19034 - Assignment 3 - Merton Truck Case Study Problem - PAOSEA19Документ29 страницEA19034 - Assignment 3 - Merton Truck Case Study Problem - PAOSEA19ishfaqОценок пока нет

- Case1 Nett Colorscope SaddamrobertobinuДокумент10 страницCase1 Nett Colorscope SaddamrobertobinucicishintyaОценок пока нет

- OR Case Study Analysis: - by Aditya Karam (04), Gurjinder Singh (10), Deepti Sana (40), Kaushik Mandal (41), Pankaj BajajДокумент15 страницOR Case Study Analysis: - by Aditya Karam (04), Gurjinder Singh (10), Deepti Sana (40), Kaushik Mandal (41), Pankaj BajajMaria MercadoОценок пока нет

- Case-1 - MM1 - Vora and Company - Anirban Kar - EPGP-12A-022Документ6 страницCase-1 - MM1 - Vora and Company - Anirban Kar - EPGP-12A-022Anirban KarОценок пока нет

- CAN Submission-Unilever in India: Hindustan Lever's Project Shakti - Marketing FMCG To The Rural ConsumerДокумент3 страницыCAN Submission-Unilever in India: Hindustan Lever's Project Shakti - Marketing FMCG To The Rural ConsumerRitik MaheshwariОценок пока нет

- Autumn 2011 - Midterm Assessment (25089)Документ8 страницAutumn 2011 - Midterm Assessment (25089)Marwa Nabil Shouman0% (1)

- Hospital Supply Inc.Документ4 страницыHospital Supply Inc.alomelo100% (2)

- This Study Resource Was: InstructionsДокумент3 страницыThis Study Resource Was: InstructionsRama fauziОценок пока нет

- PGP I 2021 Fra Quiz 1Документ3 страницыPGP I 2021 Fra Quiz 1Pulkit SethiaОценок пока нет

- Service CostingДокумент6 страницService Costingbinu100% (1)

- Hamilton - Case A - 5 PDFДокумент2 страницыHamilton - Case A - 5 PDFJayash Kaushal0% (1)

- Manvi Motors - Linear ProgrammingДокумент2 страницыManvi Motors - Linear ProgrammingKaranki DineshОценок пока нет

- Managerial Accounting - Classic Pen Company Case: GMITE7-Group 7Документ21 страницаManagerial Accounting - Classic Pen Company Case: GMITE7-Group 7bharathtgОценок пока нет

- Management ScienceДокумент3 страницыManagement ScienceErikaNicoleDumoranGumilinОценок пока нет

- Activity Based CostingДокумент2 страницыActivity Based CostingVivek KheparОценок пока нет

- 202E10Документ33 страницы202E10Ashish BhallaОценок пока нет

- Eco10004: Economic Principles - Week 2: Tutorial QuestionsДокумент3 страницыEco10004: Economic Principles - Week 2: Tutorial QuestionsPark ChannieОценок пока нет