Академический Документы

Профессиональный Документы

Культура Документы

Manufacturing Process-I 2009-5-6 0

Загружено:

ritendertИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Manufacturing Process-I 2009-5-6 0

Загружено:

ritendertАвторское право:

Доступные форматы

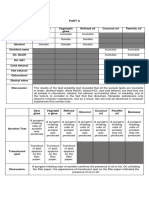

MANUFACTURING PROCESS - I

B.E. (MECHANICAL) 5TH SEM

[Time Allowed: 3 hrs] [Max Marks: 100] NOTE:- Attempt any five questions by selecting at least two from each section. Assume any missing data.

PART-A

Q1. a) What are distinguishing features between a casting and a pattern? b) Explain briefly:i) Draft Allowance ii) Shake allowance c) What is meant by core prints? Explain how they are to be provided. d) Describe the type of risers and their uses with suitable sketches. e) Design the ingate dimensions for pouring a 15 Kg casting in 10 seconds with runner having a cross section area of 625 mm2 and the two ingates of 25mm width each. Assume equal flow through gates. (4, 4, 4, 4, 4) Q2. a) Describe the operation of cupola furnace for melting cast iron with a neat sketch. b) Write short notes on:i) Centrifugal casting ii) Continuous casting c) Compare precision investment casting and shell moulding from standpoint of process, product and applications. (8, 6, 6)

Q3. a) Briefly explain the principle of rolling with a neat sketch.

b) Differentiate between hot working and cold working. c) Explain various rolling stand arrangements with neat sketches. d) Distinguish between open die and close die forging. e) List and briefly explain various forging defects. (3, 3, 4, 5, 5)

Q4. a) Distinguish between spinning and cup drawing with reference to processes and components produced. b) Differentiate between coining and embossing. c) Explain with neat sketches the difference between direct and indirect extrusion. d) Explain the following processes: i) Wire and Tube drawing ii) Swaging iii) Blanking iv) Bending (4, 4, 4, 8)

PART-B

Q5. a) Write in brief the basic steps of powder metallurgy process. b) State the advantages and disadvantages of powder metallurgy process. c) Discuss the various methods of powder manufacture. d) Explain briefly the manufacturing of self lubricated bearing with powder metallurgy process. (5, 5, 5, 5) Q6. a) What are the different types of welding joints? Explain with neat sketches.

b) Describe the types of flames obtained in oxy-acetylene gas welding process giving the applications. c) What are the advantages of AC equipment over DC equipment in arc welding? d) Briefly explain the coding method used for the electrodes used in shielding metal arc welding (SMAW). (5, 5, 5, 5) Q7. a) Explain the TIG and MIG systems of arc welding. Give the applications of each. b) Explain clearly the difference between upset welding and flash welding with neat sketches. c) Explain briefly thermit welding along with its advantages and applications. d) What are the defects that are generally found in welding? Describe their causes and remedies. (5, 5, 5, 5) Q8. Write short notes on the following:i) Briquetting and sintering ii) Hot Iso-elastic Processing iii) Resistance Seam Welding (RSEW) and Projection Welding (RPW) iv) Brazing and soldering (5, 5, 5, 5)

14/Oct/2011

Disclaimer: Well this looks a little stupid but we are not responsible if any portion of this paper is not relevant with todays syllabus. Due care has been taken to make this paper error free, but there always remains a chance of error so please ignore any typographical error if present..

http://www.myuiet.com

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 320 E Book3Документ225 страниц320 E Book3Krishnamoorthy VijayalakshmiОценок пока нет

- My Successful Intraday Trading Setup: Tools UsedДокумент4 страницыMy Successful Intraday Trading Setup: Tools UsedritendertОценок пока нет

- Welcome To Sparrow PDFДокумент1 страницаWelcome To Sparrow PDFritendertОценок пока нет

- NG Ee Hwa - How To Draw Trendlines 2007Документ2 страницыNG Ee Hwa - How To Draw Trendlines 2007ansar99Оценок пока нет

- Officer Reported UponДокумент7 страницOfficer Reported UponritendertОценок пока нет

- Why We Do Sanskrit in This SchoolДокумент3 страницыWhy We Do Sanskrit in This SchoolritendertОценок пока нет

- FAQ and User Manual GSTR4Документ48 страницFAQ and User Manual GSTR4ritendertОценок пока нет

- Welcome LetterДокумент1 страницаWelcome LetterritendertОценок пока нет

- Nios Accountancy Full BookДокумент300 страницNios Accountancy Full BookVivek Ratan100% (1)

- Annexure-VII-General Renewal Trade Licence Fees-1Документ8 страницAnnexure-VII-General Renewal Trade Licence Fees-1ritendertОценок пока нет

- Annexure-VI-General Renewal Trade Licence ChecklistДокумент22 страницыAnnexure-VI-General Renewal Trade Licence ChecklistritendertОценок пока нет

- Annexure XiiДокумент2 страницыAnnexure XiiritendertОценок пока нет

- Nios Accountancy Full BookДокумент300 страницNios Accountancy Full BookVivek Ratan100% (1)

- Annexure - A Declaration of Food Bill Expenditure: Calculation On Lumpsum BasisДокумент1 страницаAnnexure - A Declaration of Food Bill Expenditure: Calculation On Lumpsum BasisritendertОценок пока нет

- ReportДокумент3 страницыReportritendertОценок пока нет

- Student's Leave FormДокумент1 страницаStudent's Leave FormritendertОценок пока нет

- Circle Officers - AssamДокумент5 страницCircle Officers - Assammail2shanuОценок пока нет

- Covering LetterДокумент1 страницаCovering LetterritendertОценок пока нет

- Workshop On: Effective Maintenance of CNC Machines For Productivity ImprovementДокумент1 страницаWorkshop On: Effective Maintenance of CNC Machines For Productivity ImprovementritendertОценок пока нет

- Total Quality ManagementДокумент3 страницыTotal Quality ManagementritendertОценок пока нет

- Fess 1 PsДокумент2 страницыFess 1 PsRaffi SkОценок пока нет

- 286 287 288 289 2012Документ4 страницы286 287 288 289 2012ritendertОценок пока нет

- Annexure IIIДокумент2 страницыAnnexure IIIritendertОценок пока нет

- Invitation To Guest ArchitectsДокумент1 страницаInvitation To Guest ArchitectsritendertОценок пока нет

- Project Proposal BuestДокумент2 страницыProject Proposal BuestritendertОценок пока нет

- Quality Control (QC) Process Quality ControlДокумент2 страницыQuality Control (QC) Process Quality ControlritendertОценок пока нет

- Annexure IIIДокумент2 страницыAnnexure IIIritendertОценок пока нет

- Spare Parts ManagementДокумент11 страницSpare Parts Managementritendert100% (3)

- Introduction To MAINTENANCEДокумент28 страницIntroduction To MAINTENANCEritendertОценок пока нет

- Introduction To MAINTENANCEДокумент28 страницIntroduction To MAINTENANCEritendertОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- 49CFR Chemical Table Revisions 01012013Документ8 страниц49CFR Chemical Table Revisions 01012013nct_nctОценок пока нет

- Stellungnahme ANDRITZ GMBH - EnglischДокумент13 страницStellungnahme ANDRITZ GMBH - EnglischAnonymous 7jBNyvNMОценок пока нет

- Nylon (Textiles Industry) Organic Chemistry Assignment SlideДокумент21 страницаNylon (Textiles Industry) Organic Chemistry Assignment SlideEitrah Tasnim Mohamat KasimОценок пока нет

- Chapter 1 and 2 Pre OralДокумент36 страницChapter 1 and 2 Pre OralSherwin CruzОценок пока нет

- SKF BearingДокумент75 страницSKF Bearingli xianОценок пока нет

- Answers To Problems Introduction To Spectroscopy, 4th Edition Pavia, Lampman, Kriz, VyvyanДокумент2 страницыAnswers To Problems Introduction To Spectroscopy, 4th Edition Pavia, Lampman, Kriz, Vyvyanسیاہ پوش100% (1)

- Applications of Critical Solution TemperatureДокумент5 страницApplications of Critical Solution TemperatureParveen88% (8)

- Sodium Hydroxide BookletДокумент24 страницыSodium Hydroxide BookletbbmokshОценок пока нет

- Acid Gas Dew PointДокумент8 страницAcid Gas Dew Pointzubair195Оценок пока нет

- 2014 AFPM Cat Cracker Seminar - Evaluating Equilibrium Catalyst (Ecat) DataДокумент43 страницы2014 AFPM Cat Cracker Seminar - Evaluating Equilibrium Catalyst (Ecat) Datasaleh4060Оценок пока нет

- RefractoryДокумент38 страницRefractoryDucОценок пока нет

- Module 8 - BIOCHEM LABДокумент5 страницModule 8 - BIOCHEM LABStarrrОценок пока нет

- Laporan PJ Kefarmasian 2023 (Maret)Документ8 страницLaporan PJ Kefarmasian 2023 (Maret)kevinvngzОценок пока нет

- Hydrometallurgy in Codelco Norte: Division Production KT Copper Net Cost US$/lbДокумент12 страницHydrometallurgy in Codelco Norte: Division Production KT Copper Net Cost US$/lbLuis Paulo Medina ArévaloОценок пока нет

- CW December 2012Документ68 страницCW December 2012Clint FosterОценок пока нет

- 2017 EnvironmentalTechnologyДокумент16 страниц2017 EnvironmentalTechnologyThong NguyenОценок пока нет

- Las 7-W3Документ4 страницыLas 7-W3Zeyya Nikka Cordova PingadОценок пока нет

- Chemistry: Pearson Edexcel International GCSE (9-1)Документ24 страницыChemistry: Pearson Edexcel International GCSE (9-1)gyogi1989Оценок пока нет

- Bab 7 Diagram Alir ProsesДокумент2 страницыBab 7 Diagram Alir ProsesWisnu Center'zОценок пока нет

- Easicult Application Brochure - Jet FuelДокумент2 страницыEasicult Application Brochure - Jet Fuelviktor_gligorovОценок пока нет

- Chemistry Pre Test - Before Starting Yr 12Документ8 страницChemistry Pre Test - Before Starting Yr 12Nhi HinОценок пока нет

- Kulka 2018Документ4 страницыKulka 2018Cherif AbbasОценок пока нет

- Acids, Bases and Salts PDFДокумент2 страницыAcids, Bases and Salts PDFHakim Abbas Ali PhalasiyaОценок пока нет

- Activity 1 Calc 1 and 2 PDFДокумент7 страницActivity 1 Calc 1 and 2 PDFonyxОценок пока нет

- ET411 Synthetic Polymer 0 COVER PAGEДокумент1 страницаET411 Synthetic Polymer 0 COVER PAGERonald NgueleОценок пока нет

- Draw LewisДокумент3 страницыDraw LewisclrgeekОценок пока нет

- Deepak 2017 IOP Conf. Ser.: Mater. Sci. Eng. 197 012067 PDFДокумент9 страницDeepak 2017 IOP Conf. Ser.: Mater. Sci. Eng. 197 012067 PDFMakeshОценок пока нет

- ICSE Class 10 Chemistry Previous Year Question Paper 2012Документ8 страницICSE Class 10 Chemistry Previous Year Question Paper 2012megha rohillaОценок пока нет

- G11 Chem PRACTICE EXAMДокумент17 страницG11 Chem PRACTICE EXAMCullan Ln100% (1)