Академический Документы

Профессиональный Документы

Культура Документы

Crystal Structure and Transformation Behavior of Ni-Mn-Ga Martensites

Загружено:

Emma LoydИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Crystal Structure and Transformation Behavior of Ni-Mn-Ga Martensites

Загружено:

Emma LoydАвторское право:

Доступные форматы

Scripta Materialia 54 (2006) 17971801 www.actamat-journals.

com

Crystal structure and transformation behavior of NiMnGa martensites

M. Richard *, J. Feuchtwanger, D. Schlagel, T. Lograsso, S.M. Allen, R.C. OHandley

Massachusetts Institute of Technology, Department of Materials Science and Engineering, MIT 13-5130, 77 Massachusetts Avenue, Cambridge, MA 02139, United States Received 10 January 2006; received in revised form 20 January 2006; accepted 22 January 2006 Available online 21 February 2006

Abstract The crystal structure of the martensitic phase NiMnGa ferromagnetic shape memory alloys has been found to be extremely sensitive to composition. A systematic exploration of the compositionstructure relationship has been performed using X-ray diraction on several single crystals having large composition gradients. Also, temperature-dependent magnetic measurements show the martensitic transition to orthorhombic martensite is broader than to tetragonal martensite. This distinct character can be understood by considering the relative importance of strain energy eects in the two martensite phases. 2006 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Keywords: Crystal structure; X-ray diraction (XRD); Martensitic phase transformation

1. Introduction The Heusler alloy NiMnGa has been shown to give large magnitude magnetic eld-induced strains that are achieved through eld-induced twin boundary motion. The maximum strain of ferromagnetic shape-memory alloys (FSMAs) is limited by the crystal structure of the material which is known to be composition dependent [1]. NiMnGa compositions exhibiting tetragonal martensite have shown up to 6% strain [24] and orthorhombic martensites show up to 10% [5,6]. The present work examines the dependence of crystal structure on composition in alloys whose martensitic transformation temperatures are at or above room temperature. These alloys are of potential technical interest because they have shown eld-induced strain at useful operation temperatures. There has been little previous work investigating a large number of compositions within this particular range.

Also, the transformation of the orthorhombic and tetragonal phases are examined here using temperature-dependent magnetization measurements and are found to show marked dierences in transformation character. 2. Experimental The NiMnGa crystals used in this study were grown by the Bridgman technique at the Ames Laboratory [7]. High-purity nickel, manganese and gallium were arc melted into buttons and then drop cast into a chilled copper mould. The as-cast ingots were placed in an alumina crucible and heated up to 1350 C for 1 h and allowed to homogenize. The crucible was then withdrawn from the hot zone at a rate of 5.0 mm/h. In order to minimize evaporation of manganese during crystal growth, the furnace was back-lled to a positive pressure of 6.8 105 Pa with puried argon gas after the chamber had been outgassed at 1350 C under vacuum. Composition gradients were present in most of the early crystals due to the crystal growth procedure. Because of this gradient, many samples, each of a dierent composition, can be obtained from one large single crystal. A

Corresponding author. Tel.: +1 6172536922. E-mail address: mrichard@mit.edu (M. Richard).

1359-6462/$ - see front matter 2006 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved. doi:10.1016/j.scriptamat.2006.01.033

1798

M. Richard et al. / Scripta Materialia 54 (2006) 17971801

longitudinal piece was cut from each crystal and then heattreated for 24 h at 900 C under a puried argon atmosphere. Individual samples of approximately 23 mm in length were cut from this piece and crushed into powders. The composition of each piece was then determined using a JEOL JXA-733 electron probe microanalyzer. Powders were annealed at 700 C for 3 h to relieve stresses imparted during crushing. Compositions of the powders were measured again after annealing and are displayed in Table 1, identied as coming from crystals TL2, TL3, TL5, and TL8. Powders were analyzed for crystal structure using a Rigaku rotating-anode X-ray diractometer with copper target operated at 60 kV and a current of 300 mA. A monochromator isolated the Cu-Ka radiation. Temperature dependent structure information was collected using a sample holder outtted with a resistive heating element and controlled by an external temperature controller. Martensitic transformation and Curie temperatures were determined by measuring low-eld magnetization as a function of temperature.

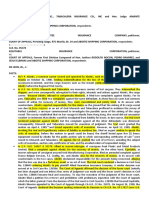

3. Results A representative set of X-ray diraction patterns used to determine crystal structure is shown in Fig. 1. Intensities have been scaled by a fraction of the maximum observed intensity and the range limited to 50100 in 2h to draw attention to the peak splitting that occurs on the tetragonal to orthorhombic transition. Peak indexing is done with reference to the parent cubic phase and unlabeled peaks are those associated with the superstructure, also called the modulated structure [8]. Diraction patterns for samples TL2-7 through TL2-11 were identical and only two patterns of that set are shown. Those on the higher manganese end of the crystal displayed the orthorhombic (14M) structure, while the compositions closer to 50 at.% Ni showed the tetragonal (5M) phase. Lattice parameters for each of the samples studied were calculated from the room temperature X-ray data using the Cohen analytical method [9] based on all observed peaks (20100 in 2h). The resulting parameters are shown in Table 1 and plotted in Fig. 2. The crystallographic conven-

Table 1 Compositions of powders after stress-relief treatment (in at.%), transformation temperatures (C), room temperature structures, and relevant lattice constants (A) for all samples Sample TL2-1 TL2-2 TL2-3 TL2-4 TL2-5 TL2-6 TL2-7 TL2-8 TL2-9 TL2-11 TL3-1 TL3-2 TL3-3 TL3-4 TL3-5 TL3-6 TL3-6 TL3-7 TL3-8 TL3-9 TL3-10 TL3-11 TL3-12 TL3-13 TL5-1 TL5-3 TL5-5 TL5-7 TL5-11 TL8-1 TL8-5 TL8-7 TL8-11 Ni 48 49.1 49.3 49.2 49.6 49.5 50.1 50.1 50 50 50.1 49.9 49.8 49.7 50 49.5 49.5 49.2 49.2 49.3 48.6 48.3 47.2 45.7 47.3 48.2 48.9 48.7 49 50.5 50.3 50.1 50.4 Mn 31.9 30.5 30.3 30.1 29.9 29.5 28.9 28.6 28.3 28.9 29.1 29 29.3 29.2 29 29.7 29.7 30.2 31 30.5 31.3 32.7 34 36.6 33.1 31.7 30.5 21.1 30.6 27.9 28.2 28.4 28.1 Ga 20.1 20.3 20.4 20.7 20.5 21 21.1 21.3 21.7 21.1 20.8 21.1 20.9 21.1 21.0 20.8 20.8 20.6 19.8 20.2 20.1 19 18.8 17.7 18.6 20.1 20.6 20.2 20.4 21.6 21.5 21.5 21.5 Ts m 50 46 38 37 36 35 34 34 33 34 32 32 36 39 44 49 49 Structure 14M 14M 14M Mixed Mixed 5M 5M 5M 5M 5M 5M 5M 5M 5M 5M Mixed-5M Mixed-14M 14M 14M 14M 14M 14M 14M 14M 14M 14M 14M 14M 14M 5M 5M 5M 5M a 5.8158 5.8432 5.8384 5.8470 5.8551 5.9832 5.9425 5.9400 5.9413 5.9419 5.9353 5.9403 5.9462 5.9453 5.9443 5.9472 5.8404 5.8393 5.8260 5.8333 5.8230 5.8124 5.8274 5.8472 5.8466 5.8333 5.8507 5.8375 5.8450 5.9414 5.9315 5.9294 5.9325 b 6.1530 6.0968 6.1068 6.0875 6.0860 6.0794 6.0920 6.1020 6.1201 6.1236 6.1435 6.2120 6.2125 6.1432 6.1466 6.1035 6.1153 6.0951 c 5.5203 5.5559 5.5502 5.5627 5.5668 5.6295 5.5997 5.6075 5.6133 5.6034 5.5977 5.6001 5.5869 5.5973 5.599 5.5701 5.5658 5.5501 5.5384 5.5433 5.5337 5.4908 5.4934 5.4828 5.5391 5.5478 5.5651 5.5498 5.5602 5.6184 5.6057 5.5862 5.6055 c/a 0.95 0.95 0.95 0.95 0.95 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.95 0.95 0.95 0.95 0.95 0.94 0.94 0.94 0.95 0.95 0.95 0.95 0.95 0.95 0.95 0.94 0.94 c/b 0.90 0.91 0.91 0.91 0.91 0.92 0.91 0.91 0.91 0.90 0.89 0.88 0.88 0.90 0.90 0.91 0.91 0.91

52 52 46 46 43 50 45 42 40 37 30 29 32 28

5M indicates tetragonal, 14M is orthorhombic, and mixed indicates both phases were present. A typical austenite lattice constant is 5.8472 A.

M. Richard et al. / Scripta Materialia 54 (2006) 17971801

Sample #

1

1799

23.0 22.5

22.0 21.5

Ga (at%)

21.0

Tetragonal

20.5

Mixed

20.0 19.5

Orthorhombic

280K

11

(040) (400) 60

(004)

(242) (422) 80

(224)

(440) 90

(044) (404) 100

19.0

370

70

300K

33 34 35

50

18.5 25 26 27 28 29 30 31 32

2-Theta

Mn (at%)

Fig. 1. X-ray diraction patterns taken from samples of crystal TL2. There is a shift from tetragonal at one end (Sample 11Mn poor, Ni rich) to orthorhombic at the other (Sample 1Mn rich, Ni poor).

6.2

Fig. 3. Composition of all samples plotted along with property data assembled by Jin et al. [10]. Solid lines indicate martensite transformation temperatures and dashed line indicates compositions with 50% Ni. Compositions noted with s have tetragonal structures at room temperature, n are mixed orthorhombic and tetragonal, and h are orthorhombic. Tetragonal samples with Mn content between 28 and 30% have been shown to be active at room temperature.

b

6.1

Lattice constant (A)

6.0

0.09

a' (for mixed samples) a

MS(T)

AF(T)

MS(O)

AF(O)

0.08 0.07

5.9

Tetragonal

5.8

Magnetization (emu)

0.06 0.05 0.04 0.03 0.02

5.7

Orthorhombic

5.6

MF(O) AS(O) MF(T) AS(T)

5.5 0 1 2 3 4 5 6 7 8 9 10 11 12

Sample position

0.01 0 20 25 30 35 40 45 50 55 60 65 70

Fig. 2. Calculated lattice constant for samples from crystals TL2 (dashed), which showed tetragonal and orthorhombic martensites, and TL5 (solid), which was entirely orthorhombic. The parameter a 0 indicates the tetragonal lattice parameter in the mixed samples.

Temperature (C)

tion of b > a > c for orthorhombic structures was used. The transition from a tetragonal to orthorhombic martensitic structure can be seen in sample TL2 with a range of compositions containing a mixture of the two phases. This is in contrast to sample TL5, which had a higher Mn content and showed the orthorhombic structure throughout the entire crystal boule with small changes in the lattice parameters. In order to understand the compositional dependence of the crystal structure, all the structure data were plotted on the phase/property diagram (Fig. 3) presented by Jin et al. [10]. The transformation temperatures measured here agree with those plotted in the diagram. The orthorhombic and tetragonal crystals fall into two well dened regions separated by the mixed phase compositions. Magnetic eld induced actuation at room temperature has been observed in tetragonal samples in the composition range of 2830%

Fig. 4. Representative magnetization versus temperature measurements performed at 500 Oe. The orthorhombic samples show a broad martensitic transformation (MS(O) MF(O)) while the tetragonal samples transform over a narrow temperature range (MS(T) MF(T)).

Mn cut from these three crystals. No eld-induced twinboundary motion was observed in the orthorhombic samples, but no additional processing was done to attempt to make them active. The transformation behavior of compositions with tetragonal structure was markedly dierent from that of those with orthorhombic structures (Fig. 4). It was determined that the alloys that are in the tetragonal (5M) phase at room temperature displayed a much sharper transition (510 C) than those that are in the orthorhombic (14M) phase (2030 C). In this case, the terms sharper and broader refer specically to the temperature dierence between the start and the nish of the transition, both for the forward and the reverse transformation, i.e.,

1800

M. Richard et al. / Scripta Materialia 54 (2006) 17971801

Fig. 5. Plot showing the forward and reverse transformation widths in C and the dierence between the two for (a) orthorhombic (14M) and (b) tetragonal (5M) samples. Each set of bars represents data from a separate sample.

T s T f and T s T f , where T s is the martensitic transform m a a m mation start temperature, T f is the martensite nish temm perature, T s is the austenite start, and T f is the austenite a a nish temperature. This dierence in transformation width was observed in both powder samples and single-crystals. In the materials that transform into orthorhombic martensite the hysteresis observed upon one cooling and heating cycle was similar to the tetragonal behavior, but the slope of the forward and reverse transition dier, as seen in Fig. 4. When the magnetization versus temperature data from all samples, as seen in Fig. 4, are tabulated, as shown in Fig. 5, it is clear that the dierence in transformation behavior is connected to the martensite crystal structure rather than the chemical composition. The change from the sharper to the broader transition is abrupt and does not change smoothly with sample composition. The orthorhombic transitions consistently exhibit transformations which are 1015 C wider than those observed in the tetragonal martensite. 4. Discussion

martensitic transformations in dierent alloy compositions [1115]. In some compositions, the tetragonal 5M martensite transformed to the 14M orthorhombic structure at lower temperatures, and when further cooled transformed into the non-modulated structure. However, temperaturedependent X-ray measurements do not indicate the presence of an intermediate phase in the present study. The transitions are from the parent cubic phase directly to the tetragonal or orthorhombic martensite in these samples. Another possible source of the dierence in transformation behavior could be the presence of structural defects such as dislocations due to a large degree of lattice incompatibility between the parent austenite and the martensite phases. James and Hane [16] present two criteria on the martensitic transformation matrix (U), also known as the lattice deformation or the Bain strain, that indicate the degree of lattice compatibility between the two phases. This approach has been used in the search for low hysteresis shape-memory alloys [17], but also could be related to the width of the forward and the reverse transition. The rst criterion for austenitemartensite lattice compatibility is 1 TraceU 1, which signies no change in 3 volume on transformation from austenite to martensite. The second criterion is that the middle eigenvalue of U (that is the one of intermediate magnitude of the three) should be as close to unity as possible. When this term is equal to one, an undistorted plane exists between the austenite and the martensite, which is what Wayman refers to as condition A on the transformation geometry [18]. If this condition is met exactly, there is no need for an additional shear, known as the lattice invariant shear, to ensure an invariant plane and only rotation is needed. Using lattice parameters measured in the austenite and the martensite phases of the present alloys, the transformation matrices calculated for two particular samples, one tetragonal and one orthorhombic are: 0 1 1:0184 0 0 B C U TL28 @ 0 1:0184 0 A 1 1:0506 0 B @ 0 0:9999 0 0 0 0 0 0:9614 0 0 0:9473 1 C A 2

U TL51 One possible cause of the broader transitions in the orthorhombic samples could be inhomogeneities in the sample composition. If each sample had portions that begin to transform at dierent temperatures, the expected bulk transition would be broader. However, each small sample was cut from the larger single-crystal boules and was determined to be homogenous; composition variation in each sample was less than 0.15%. Neither the orthorhombic nor the tetragonal samples showed any measurable change in composition due to heat treatment. Another possible cause for the breadth of the transition observed in the orthorhombic martensites could be intermartensitic transformations occurring at relatively close temperatures. Several studies have revealed many inter-

with the corresponding traces calculated to be 0.9994 for the TL2-8 (tetragonal) and 0.9993 for TL5-1 (orthorhombic). These trace values are both almost equal to one (DV/V % 67 104, much less than the transformation strain), indicating there is a minimal volume dierence between the parent and the martensite phase in both structures. The orthorhombic phase does have one eigenvalue close to 1 indicating a possible coherent martensite/austenite interface without the additional lattice invariant shear. The middle eigenvalue cannot be unity in a tetragonal transformation if 1 TraceU 1. The tetragonal martens3 itic transition requires a lattice invariant shear to achieve

M. Richard et al. / Scripta Materialia 54 (2006) 17971801

1801

an invariant plane upon transformation. Thus, the orthorhombic martensite more closely matches the two conditions than the tetragonal martensite. The lattice compatibility criteria therefore fail to account for the broader martensitic transition in orthorhombic NiMnGa. Considering all terms of the transformation matrix, the orthorhombic phase has a larger transformation strain (56%) compared to a maximum of 4% for the tetragonal. Following the work of Patel and Cohen [19] a thermodynamic explanation of the dierences in transformation character can be constructed. In the absence of any other energy eects, once the chemical driving force reaches the critical value for nucleation, the transformation begins and continues in a very sharp manner. However, other energy terms exist which may play a role in the width of the martensitic transition. Most importantly, strain energy can broaden the transformation on a temperature scale because it is a function of the volume transformed. As more material transforms to martensite, incompatibilities between transformation regions and large transformation strains may reduce the driving force. Therefore, further undercooling would be necessary in order to continue the transformation process. This approach explains why thermoelastic martensitic transformations generally do not occur as a spontaneous avalanche once the critical undercooling is reached, except in the so-called autocatalytic or burst transition seen in FeNi and other alloys [20,21]. The transformation will occur gradually over a range of temperatures due to the accumulation of elastic energy that raises the energy of the martensite. Using this approach, the contrasting transformation behaviors seen in NiMnGa can be attributed to the larger magnitude of the strain energy contribution in the orthorhombic martensites. The orthorhombic phase exhibits a much larger transformation strain of 56% compared to a maximum of 4% in the tetragonal structure. This larger strain could result in interfaces that would be more dicult to move due to the larger elastic energy. Further, in the orthorhombic martensite, there is an additional set of twin planes due to the unique b-axis which could lead to more stress being relieved through twinning. However, this could also lead to the intersection of incompatible twin variants, thus locking up the twins and preventing further relief of the transformation strain. The resulting transition in the orthorhombic phase would have to be much broader due to the larger strain energy eects requiring additional undercooling. 5. Conclusions The systematic relationship between the composition and the structure of a variety of NiMnGa alloys has been

documented. Alloys from this composition range have exhibited magnetic eld-induced strain and thus their martensitic structure and transition behavior are of great importance. The martensitic transformation of the orthorhombic phase has been observed to be much broader than that of the tetragonal phase. This is consistent with a thermodynamic argument involving the increased role of strain energy as the orthorhombic material transforms. This difference in transformation behavior may be linked to the diculty in magnetic eld induced actuation of alloys with this structure through an increase in defect population resulting from the larger transformation strains. Acknowledgement This work has been supported by ONR under MURI Grant No. N00014-01-10758. References

[1] Pons J, Chernenko VA, Santamarta R, Cesari E. Acta Mater 2000;48:302738. [2] Murray SJ, Marioni MA, Allen SM, OHandley RC, Lograsso TA. Appl Phys Lett 2000;77:886. [3] Murry SJ, Marioni MA, Tello PG, Allen SM, OHandley RC. J Mag Mat 2001;226:945. [4] Heczko O, Sozinov A, Ullakko K. IEEE Trans Mag 2000;36:3266. [5] Sozinov A, Likhachev AA, Lanska N, Ullakko K. Appl Phys Lett 2002;80:1746. [6] Sozinov A, Likhachev AA, Lanska N, Ullakko K, Lindroos VK. J Phys IV 2003;112:955. [7] Schlagel DL, Wu YL, Zhang W, Lograsso TA. J Alloys Comp 2000;312:77. [8] Ge Y, Soderberg O, Lanska N, Sozinov A, Ullakko K, Lindroos VK. J Phys IV 2003;112:921. [9] Lipson H, Steeple H. Interpretation of X-ray powder diraction patterns. NY: MacMillan and Co; 1970. [10] Jin X, Marioni M, Bono D, Allen SM, OHandley RC, Hsu TY. J Appl Phys 2002;91:8222. [11] Chernenko VA, Pons J, Segu C, Cesari E. Acta Mater 2002;50:5360. [12] Segu C, Chernenko VA, Pons J, Cesari E. J Magn Magn Mater 2005;290:8115. [13] Chernenko VA, Cesari E, Khovailo VV, Pons J, Segu C, Tagaki T. J Magn Magn Mater 2005;290:8713. [14] Segu C, Chernenko VA, Pons J, Cesari E. J de Phys IV 2003;112:9036. [15] Liu ZH, Wu GH, Wang WH, Chen JL, Ao L, Chin TS. Acta Phys Sin 2002;51(3):6404. [16] James RD, Hane KF. Acta Mater 2000;48:197222. [17] Cui J, Chu Y, Ludwig A, Famodu OO, Hattrick-Simpers J, Furuya Y, et al. [submitted for publication]. [18] Wayman CM. Introduction to the crystallography of martensites. New York: The Macmillan Company; 1964. [19] Patel JR, Cohen M. Acta Met 1953;1:5318. [20] Machlin ES, Cohen M. Trans Amer Inst Min (Metall) Engrs 1951;191:746. [21] Christian JW. The theory of transformations in metals and alloys. 2nd ed. Oxford: Pergamon Press; 1975.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- MHS Week 3. Quality Culture-KWOДокумент37 страницMHS Week 3. Quality Culture-KWOKevin SinagaОценок пока нет

- Broukal Milada What A World 3 Amazing Stories From Around TH PDFДокумент180 страницBroukal Milada What A World 3 Amazing Stories From Around TH PDFSorina DanОценок пока нет

- Department of Education: School-Based Action Research ACTION PLAN FOR S.Y. 2021-2022Документ4 страницыDepartment of Education: School-Based Action Research ACTION PLAN FOR S.Y. 2021-2022roela badiangОценок пока нет

- The Impact of Dementia On The ClinicalДокумент8 страницThe Impact of Dementia On The ClinicalihsansabridrОценок пока нет

- Past Simple PDFДокумент4 страницыPast Simple PDFderlinОценок пока нет

- Kase Handout On StopsДокумент10 страницKase Handout On StopsCynthia Ann KaseОценок пока нет

- Prose: Jooprencess E. PonoДокумент11 страницProse: Jooprencess E. Ponoaye plazaОценок пока нет

- Account StatementДокумент12 страницAccount StatementGladson JsОценок пока нет

- 6C33C-B OTL Amplifier - Background and OTL CircuitsДокумент14 страниц6C33C-B OTL Amplifier - Background and OTL CircuitsettorreitОценок пока нет

- Introductory Econometrics A Modern Approach Solutions Manual PDFДокумент9 страницIntroductory Econometrics A Modern Approach Solutions Manual PDFAnonymous bzcYj42Ain0% (2)

- Factors Influencing The PerceptionДокумент1 страницаFactors Influencing The PerceptionTinesh Kumar100% (1)

- Rocketology ProjectДокумент6 страницRocketology ProjectJosue Grana0% (1)

- Journal of The Neurological Sciences: SciencedirectДокумент12 страницJournal of The Neurological Sciences: SciencedirectBotez MartaОценок пока нет

- Evaluation of UNHCR's Leadership of The Global Protection Cluster and Field Protection Clusters, 2017Документ101 страницаEvaluation of UNHCR's Leadership of The Global Protection Cluster and Field Protection Clusters, 2017andyfeatherstoneОценок пока нет

- 1st-Year ObliconДокумент10 страниц1st-Year ObliconIts SaoirseОценок пока нет

- 4067 XLS EngДокумент11 страниц4067 XLS EngMILIND SHEKHARОценок пока нет

- DPP-Control and Coordination (Prashant Kirad)Документ9 страницDPP-Control and Coordination (Prashant Kirad)ABHI TECH 983Оценок пока нет

- Azeem English Magazine Vol. 22 Issue 01Документ68 страницAzeem English Magazine Vol. 22 Issue 01Raheel Asghar100% (1)

- The Importance of Instructional MaterialДокумент3 страницыThe Importance of Instructional MaterialJheramae SegoviaОценок пока нет

- Behavioral Pattern - FinalДокумент6 страницBehavioral Pattern - FinalSaileneGuemoDellosaОценок пока нет

- Calle Zorro - Penis Size ParanoiaДокумент0 страницCalle Zorro - Penis Size ParanoiaAquarius Sharp BladeОценок пока нет

- DLL Gen Math Ems AnnuitiesДокумент13 страницDLL Gen Math Ems AnnuitiesFreyy Agad Maligot0% (1)

- What Is Black Box Testing?: Black Box Testing Is Done Without The Knowledge of The Internals of The System Under TestДокумент127 страницWhat Is Black Box Testing?: Black Box Testing Is Done Without The Knowledge of The Internals of The System Under TestusitggsipuОценок пока нет

- Business Statistics For Contemporary Decision Making 9th Edition Black Solutions ManualДокумент25 страницBusiness Statistics For Contemporary Decision Making 9th Edition Black Solutions ManualKevinSandovalitreОценок пока нет

- G.R. No. 92735 Monarch V CA - DigestДокумент2 страницыG.R. No. 92735 Monarch V CA - DigestOjie Santillan100% (1)

- Ecdis-24 01Документ4 страницыEcdis-24 01Leandro PintoОценок пока нет

- 330A 2018docДокумент20 страниц330A 2018docDavid MendozaОценок пока нет

- CHAPTER 1 Final OkДокумент43 страницыCHAPTER 1 Final Okroneldayo62Оценок пока нет

- Mosaic TRD4 Tests EOY 1Документ4 страницыMosaic TRD4 Tests EOY 1MarcoCesОценок пока нет

- Career Indecision and Career Anxiety in High SchooolДокумент19 страницCareer Indecision and Career Anxiety in High SchooolP.CОценок пока нет