Академический Документы

Профессиональный Документы

Культура Документы

A-320 - Fire Proofing of Steel Structure

Загружено:

Poorvi BhaveИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A-320 - Fire Proofing of Steel Structure

Загружено:

Poorvi BhaveАвторское право:

Доступные форматы

< Security Level 2 > Sheet 1 of 11

ENGINEERING SPECIFICATION FIRE PROOFING OF STEEL STRUCTURES

FOR CIVIL WORKS FOR HINDUSTAN PETROLEUM CORPORATION LTD. VISAKH REFINERY

DHT PROJECT

TEIL JOB NO. : 6261 DOCUMENT NO. : A-320

01.06.09

For Bid Enquiry

UCM

PRK

SSV

Rev. no.

Issue Date

Description

Prepared by Checked by Approved by

TOYO ENGINEERING INDIA LIMITED

MUMBAI INDIA

< Security Level 2 > Sheet 2 of 11

Revision History Rev. A Date 01.06.09 Description For Bid Enquiry

< Security Level 2 >

FIRE PROOFING OF STEEL STRUCTURE

HPCL, Visakh ISSUED : 29.12.2008 DOC.No: A-320

TOYO ENGINEERING INDIA LTD.

JOB NO. : 6261 DHT PROJECT

Sheet 3 of 11

CONTENTS

SR. NO. 1.0 2.0 3.0 4.0 4.1 4.2 5.0 5.1 5.2 6.0 7.0 8.0 9.0 10.0 11.0 SKETCH-1 SKETCH-2 SKETCH-3 SCOPE

DESCRIPTION

PAGE NO. 4 4 4 4 4 4 5 5 5 5 5 6 6 7 8 9 10 11

APPLICABLE CODES PRIORITY OF REQUIREMENTS GENERAL Purpose Fire Resistance Rating CRITERIA OF FIRE PROOFING Pipe Racks Equipment Supporting Structures SURFACE PREPARATION FIRE PROOFING BY GUNITING FIRE PROOFING BY IN-SITU CONCRETE (ENCASING) VERMICULITE CEMENTITIOUS COATING APPLICATION SKETCHES FOR FIRE-PROOFING DETAILS CONCRETE FIRE-PROOFING TO BEAMS & BRACINGS CONCRETE FIRE-PROOFING TO COLUMNS MISCELLENEOUS DETAILS

< Security Level 2 >

FIRE PROOFING OF STEEL STRUCTURE

HPCL, Visakh ISSUED : 29.12.2008 DOC.No: A-320

TOYO ENGINEERING INDIA LTD.

JOB NO. : 6261 DHT PROJECT

Sheet 4 of 11

1.0

SCOPE This specification covers materials and methods of application for fireproofing of steel structures and equipment supports.

2.0

APPLICABLE CODES Note: - Wherever reference is made to IS Codes, on any page of this Technical Specification (including annexures), applicable year of publication of IS Code is as stated below. The Indian Standard Codes applicable to this section shall include but not limited to the following: IS 1566 - 1982 IS 6433 - 1972 IS 9012 - 1978 : Hard drawn steel wire fabric for concrete reinforcement. : Specification for guniting equipment. : Recommended practice for shotcreting.

3.0

PRIORITY OF REQUIREMENT In case of any variation and discrepancy in condition between the special conditions, this specification and codes, order of priority shall be as under:(1) (2) (3) Special conditions This specification Codes

4.0 4.1

GENERAL Purpose Fire proofing is aimed at providing resistance to all the load bearing steel structures and equipment supports that would collapse under fire conditions and contribute to the intensity of the fire. This fire resistance would allow the people to be evacuated and fire to be suppressed. Therefore, the supports of all potential fire sources shall be fireproofed. The support of non-potential fire hazards shall also be fireproofed, if their collapse is likely to endanger other hazardous equipments.

< Security Level 2 >

FIRE PROOFING OF STEEL STRUCTURE

HPCL, Visakh ISSUED : 29.12.2008 DOC.No: A-320

TOYO ENGINEERING INDIA LTD.

JOB NO. : 6261 DHT PROJECT

Sheet 5 of 11

4.2

Fire Resistance Rating A minimum of 2 hours fire resistance , shall be applied, unless specified otherwise.

5.0 5.1

CRITERIA OF FIRE PROOFING Pipe Racks

5.1.1 Pipe rack main members such as columns, girder, beams and vertical bracings withstanding long term loads shall be fireproofed upto the first pipe support level, in the fire hazardous area, unless specified otherwise. 5.1.2 Where equipments such as Air Fin coolers are supported on the pipe rack, fire proofing for columns shall be extended upto the equipment support level and the structural members transmitting the equipment loads shall be fire proofed. 5.1.3 The top flanges of beams supporting the pipes shall not be fire proofed. 5.1.4 Pipe racks outside the fire hazardous area shall not be fire proofed. 5.2 Equipment Supporting Structures

5.2.1 Where structure supports the equipments classified to the potential fire hazard, columns shall be fire proofed from the base plates to the equipment support level. The beams and bracings transmitting the equipment loads to the columns shall be fire proofed. 5.2.2 Platforms, stairways and their supports shall not be fireproofed. 6.0 6.1 SURFACE PREPARATION Steel surfaces to be fire proofed, shall not be painted and shall be cleared of all loose dirt, rust, mill scale, soot and concrete by mechanical wire brushing or shot blasting. Oil and grease deposits shall be removed with detergents and steel surface made clean and dry. Pipes and equipment in the vicinity shall be covered by tarpaulins to prevent them from spatter. Rebound and spatter which may enter open ends of pipe lines in the vicinity shall be protected by wood plugs or other suitable shields. FIREPROOFING BY GUNITING Materials, equipment and method of application shall be in accordance with IS 9012 and IS 6433. Placement shall be done only by skilled operators as approved by Engineer-In-Charge

6.2

7.0 7.1

< Security Level 2 >

FIRE PROOFING OF STEEL STRUCTURE

HPCL, Visakh ISSUED : 29.12.2008 DOC.No: A-320

TOYO ENGINEERING INDIA LTD.

JOB NO. : 6261 DHT PROJECT

Sheet 6 of 11

7.2

Hard drawn steel wire fabric of 2.5mm dia, 50 x 50mm mesh conforming to IS 1566 shall be used as reinforcement. The fabric shall be secured by 18 SWG galvanized tie wire to studs or spacers. Spacers shall be 5mm thick. Steel wire fabric reinforcement shall be placed, to maintain a clearance of not less than 20mm from the face of the member. Adjacent sheets shall be lapped at least 75mm and securely tied together. Shooting strips shall be used to obtain proper thickness and true lines over flanges, angles and re-entrant corners. Strips shall be designed to permit escape of rebound. The finish shall be wooden float or sponge trowelled sufficient to obtain a uniform appearance without attracting excessive laitance to the surface. Immediately after final finishing, surfaces shall be given a one spray coat of an approved curing compound. Brand name, name of manufacturer and test results shall be submitted to and got approved from the Engineer-In-Charge prior to procurement and use of curing compound.

7.3

7.4 7.5

7.6

Shotcrete thus applied shall develop not less than 24 N/mm compressive strength in 28 days. All outside edges of fire proofing shall be chamfered / rounded off by 20mm. The fixing of the reinforcing fabric shall be robust and in sufficient quantity to secure the fabric in the required position at all stages of the fire proofing application. The junction between fireproofing and bare steel shall be sealed against ingress of water, with minimum 10 mm thick mastic flashing. When not otherwise shielded. Bags of cement shall be kept dry until ready for use, stored off the ground, under cover and away from wet or damp surfaces or areas of high humidity. The mixing shall be made in concrete paddle blade mixers in accordance with the manufacturers instructions. The water added shall be of potable quality. Unless specified otherwise, the thickness tolerance shall be 2/+3mm. Each face shall be checked for thickness every 4m and at least once per member. FIRE PROOFING BY IN-SITU CONCRETE (ENCASING) Concrete for fire proofing shall be M20 grade. Mixing and placing shall be done as per TEIL specification no. A-318. Minimum thickness of concrete coating over the steel shall be 50 mm.

7.7 7.8

7.9

7.10 7.11 7.12 8.0 8.1

8.2

< Security Level 2 >

FIRE PROOFING OF STEEL STRUCTURE

HPCL, Visakh ISSUED : 29.12.2008 DOC.No: A-320

TOYO ENGINEERING INDIA LTD.

JOB NO. : 6261 DHT PROJECT

Sheet 7 of 11

8.3

Concrete shall be poured into forms properly oiled and made to correct dimensions. Concrete shall be vibrated as necessary to ensure smooth surface, free from voids and irregularities. Any defects, honey comb etc. shall be rectified by LSTK contractor at his own cost. VERMICULITE CEMENTITIOUS COATING Design Specifications :

9.0 9.1

9.1.1 Vermiculite cementitious coating shall restrict the temperature of a vessel / structure below 427o C for vessel supports & skirts and 550o C for structural steel members, for a minimum time of 2 hours. The material shall not fail till the end of specified time period.

9.1.2

The coating shall be strong enough to withstand thermal shock and impingement of water from fire hoses and / or monitors. The coating shall be asbestos free and shall be non corrosive to steel members and shall not be affected by environmental conditions, or from local leakages, spillage or pollution. The coating material shall be easily repairable and shall be durable. Application procedure of the coating shall be non hazardous, shall not interfere with the working of adjoining areas and shall be easy. The LSTK contractor shall submit calculation for the thickness of coating for all structures to be fireproofed for approval from the Engineer-In-Charge for the particular branded product he is going to use, but in no case the coating shall be less than 40 mm. APPLICATION

9.1.3

9.1.4 9.1.5

9.1.6

10.

Vermiculite cementitious coating shall be mixed with water in a suitable mixer or on clean platform as per manufacturers specifications. Water cement ratio shall be adjusted so that vermiculite cementitious coating adheres properly to steel surface and does not sag or slide after applying. Application of primer suitable with vermiculite cement coating as specified by manufacturer shall be applied over the steel surface after cleaning the shop primer, it required as per the manufacturers specifications. Generally spray gun shall be used for the application of the mixed vermiculite cementitious coating, except for small or inaccessible locations, where application with hand tools shall be permitted. Mixed vermiculite shall be used within the pot life specified by manufacturer. Under no circumstances rebound material shall be used.

< Security Level 2 >

FIRE PROOFING OF STEEL STRUCTURE

HPCL, Visakh ISSUED : 29.12.2008 DOC.No: A-320

TOYO ENGINEERING INDIA LTD.

JOB NO. : 6261 DHT PROJECT

Sheet 8 of 11

The full specified thickness shall be developed in three successive coats. Initial Coat Intermediate Coat : : Thickness between 8 mm to 12 mm. Thickness between 18 mm to 22 mm to give total thickness of 30 mm upto Intermediate coat. Not less than 8 mm thick.

Final Coat

Each successive layer shall only be applied after the previous layer has developed its initial set and is also properly scratched with steel brush to roughen the surface to develop proper bond. If the application is interrupted and does not satisfy successive layers criteria, the coating shall be cut back to the steel surface proceeding layer with a trowel at an inclined angle. Exposed surface of this coating shall be thoroughly wetted before resuming the work.

o Application of mixed vermiculite shall not be carried out if the air temperature is 4 C or less. Provision shall be made for adequate ventilation during and after application, until the coating is dry.

2 coats of micro-porous exterior top coat, compatible to cement surfaces, of approved make & colour conforming to IS specifications, should be applied, over the fire proof coating. Sealing with minimum 10 mm thick bitumen mastic flashing, shall be carried out at all exposed joints between fire proofing material coating & steel.

11.

SKETCHES SHOWING FIRE-ROOFING DETAILS Fire proofing work shall be carried out as per the sketches shown below.

< Security Level 2 >

FIRE PROOFING OF STEEL STRUCTURE

HPCL, Visakh ISSUED : 29.12.2008 DOC.No: A-320

TOYO ENGINEERING INDIA LTD.

JOB NO. : 6261 DHT PROJECT

Sheet 9 of 11

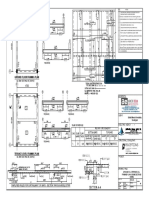

SKETCH-1

< Security Level 2 >

FIRE PROOFING OF STEEL STRUCTURE

HPCL, Visakh ISSUED : 29.12.2008 DOC.No: A-320

TOYO ENGINEERING INDIA LTD.

JOB NO. : 6261 DHT PROJECT

Sheet 10 of 11

SKETCH-2

< Security Level 2 >

FIRE PROOFING OF STEEL STRUCTURE

HPCL, Visakh ISSUED : 29.12.2008 DOC.No: A-320

TOYO ENGINEERING INDIA LTD.

JOB NO. : 6261 DHT PROJECT

Sheet 11 of 11

SKETCH-3 MISCELLENEOUS DETAILS

Вам также может понравиться

- 6-68-0033 Rev 7 PDFДокумент16 страниц6-68-0033 Rev 7 PDFRaj Sri100% (1)

- Fireproofing SpecificationДокумент48 страницFireproofing SpecificationEsteban Castellano100% (12)

- 9500-WGEL-G000-ISGP-G00000-CX-7880 - Specification For Structural Fire ProofingДокумент15 страниц9500-WGEL-G000-ISGP-G00000-CX-7880 - Specification For Structural Fire ProofingArshad IqbalОценок пока нет

- AVKOTE 650 Typ. Method StatementДокумент4 страницыAVKOTE 650 Typ. Method StatementNizarHamrouniОценок пока нет

- Geodesic Aluminum Dome & Cover Roof Specification API 650 Appendix GДокумент6 страницGeodesic Aluminum Dome & Cover Roof Specification API 650 Appendix GpassionОценок пока нет

- Fireproofing Ms PDFДокумент84 страницыFireproofing Ms PDFOlavilam Prakash100% (3)

- Fireproofing For Hydrocarbon ExposuresДокумент7 страницFireproofing For Hydrocarbon ExposuresN P SrinivasaraoОценок пока нет

- Fireproofing For Petrochemical FacilityДокумент12 страницFireproofing For Petrochemical FacilityJames Murray100% (4)

- Cover Sheet: Zapsib-2 ProjectДокумент12 страницCover Sheet: Zapsib-2 ProjectAkhtar AnsariОценок пока нет

- Fireproofing STD - ARAMCOДокумент1 страницаFireproofing STD - ARAMCOzampacaanasОценок пока нет

- Fire Profing SpecificationДокумент3 страницыFire Profing SpecificationMustafa Al-YasseriОценок пока нет

- AC-036915-001 Fireproofing For Column and Vessel SkirtsДокумент1 страницаAC-036915-001 Fireproofing For Column and Vessel Skirtsnarutothunderjet216100% (1)

- SECTION 07 8123 Intumescent Fireproofing Part 1 General 1.01 Section IncludesДокумент4 страницыSECTION 07 8123 Intumescent Fireproofing Part 1 General 1.01 Section IncludesStephen KokoОценок пока нет

- Fire Proofing of Steel StructuresДокумент28 страницFire Proofing of Steel Structuresdebjit2001100% (4)

- AA-036911-001 Insulation Details For Hot Piping PDFДокумент1 страницаAA-036911-001 Insulation Details For Hot Piping PDFzampacaanas100% (2)

- FireproofingДокумент15 страницFireproofingDubey Deepak100% (1)

- Industrial Fire ProofingДокумент20 страницIndustrial Fire Proofingkenoly123100% (3)

- Chartek 7 8+1709 Application Manual Rev0 010507Документ200 страницChartek 7 8+1709 Application Manual Rev0 010507Florin Balan100% (5)

- Method Statement Installation Os Static Equipment and InternalsДокумент24 страницыMethod Statement Installation Os Static Equipment and InternalsAjin SОценок пока нет

- Petroleum Development Oman Gathering Station - On Plot (No. 47), Ghaba North Pdo Contract No .Документ10 страницPetroleum Development Oman Gathering Station - On Plot (No. 47), Ghaba North Pdo Contract No .Burning TrainОценок пока нет

- BYBU - XR711 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq AVI 2020 PDFДокумент3 страницыBYBU - XR711 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq AVI 2020 PDFCIAKОценок пока нет

- Painting Procedures AДокумент7 страницPainting Procedures AMaged Lotfy Abdel-aal100% (1)

- Method Statement Application of Intumescent Paint Fire Proofing PDFДокумент20 страницMethod Statement Application of Intumescent Paint Fire Proofing PDFbryan67% (3)

- GP 52-20 - Passive Fire Protection Fireproofing - 0900a866801074adДокумент26 страницGP 52-20 - Passive Fire Protection Fireproofing - 0900a866801074adMichael Moore67% (3)

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesДокумент2 страницыDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarОценок пока нет

- Non Conformance Report: Refer Attached PhotographsДокумент8 страницNon Conformance Report: Refer Attached PhotographsJitender Tanwar100% (1)

- FPM-DC-5091 - Fireproofing Spec (Chevron)Документ20 страницFPM-DC-5091 - Fireproofing Spec (Chevron)theunknown076100% (1)

- Chartek 1709 SDSДокумент2 страницыChartek 1709 SDSJOHN100% (1)

- Mandolite 550 DSДокумент4 страницыMandolite 550 DSnrd9771Оценок пока нет

- Fireproofing From 2020chevron PDFДокумент25 страницFireproofing From 2020chevron PDFArmin MnОценок пока нет

- Monokote Mk6 - Hy TdsДокумент2 страницыMonokote Mk6 - Hy TdsEngTamerОценок пока нет

- Dfy - Coating Quality Key PointsДокумент1 страницаDfy - Coating Quality Key PointsMohammed SadiqОценок пока нет

- J718Документ4 страницыJ718Gatot KeceОценок пока нет

- Interzinc 52: Epoxy Zinc-RichДокумент4 страницыInterzinc 52: Epoxy Zinc-RichKrishna VachaОценок пока нет

- Passive Fire Protection Testing & CertificationДокумент9 страницPassive Fire Protection Testing & CertificationVikas Kumar Pathak100% (1)

- 187 NanoGrout EGДокумент2 страницы187 NanoGrout EGTristan Irvin Asi100% (3)

- SSPC Paint System RecommendationsДокумент3 страницыSSPC Paint System RecommendationsJayesh2281Оценок пока нет

- Blasting Coating Procedure For Fabricated Steel StructureДокумент8 страницBlasting Coating Procedure For Fabricated Steel StructureSalman Alfarisi100% (1)

- FireProofing SpecificationДокумент10 страницFireProofing SpecificationSalman ShaikhОценок пока нет

- APCS-22A HempelДокумент3 страницыAPCS-22A Hempelarjunmohanan50% (2)

- Painting Over Hot Dip Galvanized SteelДокумент6 страницPainting Over Hot Dip Galvanized SteelRico Tong100% (1)

- BTE Dome Brochure Jun 10Документ2 страницыBTE Dome Brochure Jun 10م.ذكى فضل ذكىОценок пока нет

- WMS or Procedure For FireproofingДокумент13 страницWMS or Procedure For FireproofingRodelio RemoОценок пока нет

- Dewpoint: Coating & Painting InspectionДокумент6 страницDewpoint: Coating & Painting InspectionMeet Patel100% (1)

- Chartek Application TrainingДокумент43 страницыChartek Application TrainingSerkan Akça100% (5)

- PROJECT-TGP Package 14 Sulfur Handling Facilities: Procedure For Coating of Concrete FoundationsДокумент9 страницPROJECT-TGP Package 14 Sulfur Handling Facilities: Procedure For Coating of Concrete FoundationsMohamed Reda Hussein Sengar100% (2)

- 13.0 Ms For Structural Steel Fab. Ofmisc. Structure, Embedded ItemsДокумент9 страниц13.0 Ms For Structural Steel Fab. Ofmisc. Structure, Embedded ItemsilliasuddinОценок пока нет

- Technical Submittal BunaДокумент17 страницTechnical Submittal Bunazaid khanОценок пока нет

- HSS (Heat-Shrinkable Sleeve) Installation ProcedureДокумент60 страницHSS (Heat-Shrinkable Sleeve) Installation ProcedureIntegrity EngineerОценок пока нет

- Ms - Removal of Damaged Anchor BoltsДокумент5 страницMs - Removal of Damaged Anchor Boltsmoytabura96Оценок пока нет

- GRP Lining of Water TanksДокумент7 страницGRP Lining of Water Tanksben100% (1)

- Y710Документ2 страницыY710RimОценок пока нет

- Tape WrappingДокумент8 страницTape WrappingwalitedisonОценок пока нет

- Standard Colour List PDFДокумент1 страницаStandard Colour List PDFKumarОценок пока нет

- WBSEDCL - Specification of Insulator As FebruaryДокумент15 страницWBSEDCL - Specification of Insulator As FebruaryshahpinkalОценок пока нет

- Specification of Insulator As On January 2013Документ11 страницSpecification of Insulator As On January 2013chums_23Оценок пока нет

- Material Submittal For Glass and MirrorДокумент104 страницыMaterial Submittal For Glass and MirrorChris EnyinnayaОценок пока нет

- Corten Steel Data SheetДокумент3 страницыCorten Steel Data SheetNur Hasanudin0% (1)

- 2Документ10 страниц2VivekChaudharyОценок пока нет

- Annexure D Spec PDFДокумент19 страницAnnexure D Spec PDFTanmay GorОценок пока нет

- BCE 323 Plate 1Документ2 страницыBCE 323 Plate 1Niccolo FloresОценок пока нет

- Pudur BillДокумент165 страницPudur BillsethuОценок пока нет

- Perhitungan CorbelДокумент2 страницыPerhitungan CorbelRonny WОценок пока нет

- 1103-Sun Construction of Pipe Roof and Support System in Proposed Outlet Drain Under Crossing North Buona Vista Road, SingaporeДокумент8 страниц1103-Sun Construction of Pipe Roof and Support System in Proposed Outlet Drain Under Crossing North Buona Vista Road, SingaporeCheng KimHuaОценок пока нет

- BT Road Estimate ModelДокумент10 страницBT Road Estimate Modelepe civil1Оценок пока нет

- ORISSA SCHOOL (STR-ARCH) - Model - pdf71Документ1 страницаORISSA SCHOOL (STR-ARCH) - Model - pdf71NISHIKANTA MONDALОценок пока нет

- MasterSpec 034900 GFRC 2012Документ12 страницMasterSpec 034900 GFRC 2012Taurai ChiwanzaОценок пока нет

- ETV-3A WDR-110 From 31st Dec To 06 Jan 23Документ46 страницETV-3A WDR-110 From 31st Dec To 06 Jan 23Bapan Deb SarkarОценок пока нет

- C3-Concrete Mix DesignДокумент9 страницC3-Concrete Mix DesignMuhammad khairinОценок пока нет

- Ground Floor PlanДокумент1 страницаGround Floor PlanNORTSEN ALBERTОценок пока нет

- System Seletion Chart PDFДокумент4 страницыSystem Seletion Chart PDFBakhtawar SabaОценок пока нет

- Form CIDB IBS Score M1 2018Документ12 страницForm CIDB IBS Score M1 2018nurfirdausfadzilОценок пока нет

- Basic Inputs Into Building ConstructionДокумент7 страницBasic Inputs Into Building ConstructionAnonymous 3hPIuGABОценок пока нет

- Voided SlabsДокумент8 страницVoided SlabsAnonymous dxsNnL6S8hОценок пока нет

- Working Breakdown Structure - WBS - Updated 12.02.12Документ1 страницаWorking Breakdown Structure - WBS - Updated 12.02.12Sohail Khan100% (1)

- ACI 318 Stiffness ModifierДокумент1 страницаACI 318 Stiffness ModifierEspn SachinОценок пока нет

- B4 - Tinh toán kiểm tra cấu kiện theo AISC (LLFD or ASD) PDFДокумент25 страницB4 - Tinh toán kiểm tra cấu kiện theo AISC (LLFD or ASD) PDFTam PhanОценок пока нет

- Column Design - As Per BS CodeДокумент16 страницColumn Design - As Per BS Codelasitha chandima jayasingheОценок пока нет

- CVE 601 Struct 1Документ8 страницCVE 601 Struct 1Peter UkwuejiОценок пока нет

- MR Denis Materials ScheduleДокумент18 страницMR Denis Materials ScheduleMuhangi ChristopherОценок пока нет

- Ultra High Performance Concrete BridgesДокумент199 страницUltra High Performance Concrete BridgesMiguel Perez100% (1)

- Beam and Beam Deflection Singularity MethodДокумент43 страницыBeam and Beam Deflection Singularity Methodjundi qowiОценок пока нет

- PHC Pile Model2Документ1 страницаPHC Pile Model2Chan ThornОценок пока нет

- Building Cost (Rumah Pam)Документ6 страницBuilding Cost (Rumah Pam)ezuan ESVОценок пока нет

- Concrete Reservoir ConstructionДокумент16 страницConcrete Reservoir ConstructionLovemore MalakiОценок пока нет

- Job Information: Engineer Checked ApprovedДокумент20 страницJob Information: Engineer Checked ApprovedNurmuliana Abdul WahabОценок пока нет

- ESTIMATE For HospitalДокумент2 страницыESTIMATE For HospitalAsantewaa AmoОценок пока нет

- Internship Program - I IP-I (IP201) Final PresentationДокумент27 страницInternship Program - I IP-I (IP201) Final PresentationSaurav ChoudhuryОценок пока нет

- Split-Beam Tee Connections-Prying ActionДокумент27 страницSplit-Beam Tee Connections-Prying ActionKaren JoyОценок пока нет

- Pile Integrity Test Report - Approval - 15!06!22Документ13 страницPile Integrity Test Report - Approval - 15!06!22Gayathry SanthoshОценок пока нет