Академический Документы

Профессиональный Документы

Культура Документы

APR11 Bearing Software Brochure

Загружено:

Dagim GirmaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

APR11 Bearing Software Brochure

Загружено:

Dagim GirmaАвторское право:

Доступные форматы

Total system approach to advanced bearing technology for manufacturers and end users

Quickly and accurately assess bearing performance

Bearing durability is a key factor for reliability in all driveline applications ranging from automotive transmissions to wind turbine gearboxes. The Romax Software Suite offers a system analysis tool for the whole transmission to quickly and accurately assess bearing performance under the influence of shaft and housing deflection. Bearing selection for a specific gearbox design can easily be carried out and assessed without the need for extensive prototyping and testing.

Identify and optimise problems early in the design process

With the Romax Software Suite, you can define bearing internal geometry for the majority of bearing types and adjust it according to the loading conditions. The interactions between individual components such as deformation and misalignment of the shafts and housings can be used to accurately predict loading within the bearing. Possible problems can be identified and optimisation carried out to refine performance at an early stage in the design process.

Solutions for all your bearing needs

As well as providing software, Romax Technology offers consultancy for any area of bearing technology. Such activities range from strategic consulting and technical due diligence, technology transfer on design and manufacturing, bearing selection for new gearbox designs, optimisation of internal raceway profiles, analysis of bearing failures and support on developing new or complex design arrangements.

Automotive

Accurately predict bearing life under detailed duty cycles in the design

concept phase Improve bearing choice by unique and accurate prediction of bearing behaviour Analyse and compare bearing arrangements for new transmission concepts Investigate influences of internal geometry, lubrication and housing design on bearing durability Benchmark and compare gearbox designs Reduce the risk of selecting alternate bearing suppliers for second source and cost down exercises Automate the design and analysis of integrated wheel hub bearing arrangements

Off-highway

Bearing selection for heavy duty hydrostatic and powershift transmission Predict system and bearing behaviour under misuse conditions Compare the effects of different lubrication conditions on bearing life

Industrial equipment

Design for improved bearing reliability in process machinery,

material handling, power take offs, speed reducers and production line equipment Reduce failures in bearings due to precise prediction of misalignments Analyse influence on durability of bearings and shafts from vibration Design of casings to minimise influence on bearing life

Wind turbine

Software tool for advanced analysis of bearing behaviour to identify

undesired load conditions Improve bearing choice by accurate life prediction including flexible housings, carriers and shafts Design, analysis and manufacturing solutions for pitch, yaw, main shaft and gearbox bearings Gearbox bearing selection review and analysis Consultancy for obtaining wind turbine bearing certification Technical due diligence on component suppliers, such as bearings, gearboxes and mechanical systems Detailed investigation of wind turbine drivetrain failures, especially on gearboxes and bearings

Consumer and office appliance

Select bearing types and design for power tools, food processors,

washing machines, printers and photocopiers

Simulation of complex shaft, gear and bearing arrangements to assess

complete system durability

Railway

Assessment of bearing performance and selection for transmission

and final drive configurations

Investigation and analysis of axle box bearings for new or

in-service railway bogies

Aerospace

Predict bearing behaviour under extreme load and climate conditions Analyse high speed dynamic effects for gears and bearings Identify root causes for bearing failures during test or service User defined micro-geometry input for special bearing design Technical service for complex stress analysis on large size bearings and their mounting arrangements

Romax Software Suite Overview

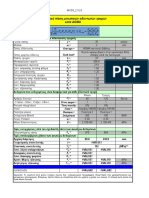

Whether you are calculating the expected life of a bearing in a wind turbine or optimising roller raceway profiles, with our bearing software you are provided with all the necessary tools which give you confidence that the bearings are suitable for testing and in-service. Realistic modelling and simulation provide you with the capabilities to assess bearing selection and internal geometry in much more detail than traditional analytical tools. One key feature of the software not accounted for in most bearing software tools is the inclusion of the housing deflection influence. Complex components can be imported into the model from FE pre-processors for the housing design. The stiffness characteristics from this, combined with the bearing and shaft positions allow a complete analysis of the system deflection. The consideration of the housing deflection and shaft misalignments in this way show the significant influence these factors can have on bearing durability. As well as a database of existing bearing catalogues, Romax Advanced Bearings modules allow the user to fully define any custom bearing, including internal and external geometry, roller and raceway profiles and load ratings. Should the exact bearing details not be known, the software will accurately estimate the internal details meaning conceptual designs can be quickly and easily modelled without the need for specialist information which is often hard to obtain. When selecting a bearing, it is essential that the bearing life meets the requirements in relation to the operating conditions. A variety of mounting conditions and the radial internal clearance can be specified to account for assembly conditions, ensuring a truly accurate representation of real world performance. A simple yet comprehensive bearing report is provided after each durability analysis is conducted and raw data for graphs can be exported for further investigation. Romax offers four methods for predicting bearing life: ISO 281 the basic bearing life calculation method based on approximate formulae Romax Adjusted extends the ISO 281 calculation to include affects of misalignment Romax Advanced uses an even more accurate model for contact stress than the previous two methods New ISO 281 Specification follows on from the original ISO method, but also makes use of the advanced contact stress analysis and adds the affects of lubrication, temperature and contamination. This is the only method that makes allowance for extended life when operating below the material fatigue limit Romax is undertaking continual research to develop the software for even more accurate life prediction, such as consideration of raceway surface roughness or cage dynamics.

Bearing duty damage calculated by four life methods Romax model incorporating housing and shaft deflections

Catalogue and custom bearing geometry definition

Gears

Gear forces translated to shaft & bearings Macro- & micro-geometry definition

Bearings

Catalogue or custom geometry Contact stress analysis Advanced life calculation Element/raceway loads Misalignment affect Lubrication film thickness

Integrated Transmission Model

Full transmission system analysis for bearing durability & performance

Housings

Imported FE housing stiffness characteristics Influence on bearing misalignment

Shafts

Shaft relative displacement

Synchronisers

Full definition of duty cycle for all gear selections on automotive transmissions

Advanced Ball Bearing

The Advanced Ball Bearing module allows complex analysis of the internal geometry within the bearing. You can assess the effect of internal clearance through calculating the load distribution within the shaft/bearing model. Contact patch analysis allows you to calculate contact ellipses which you can compare against the raceway geometry. In the case of bearings under high axial loading it is possible to assess if the element contact extends over the edge of the raceway which would result in a truncated contact patch and induce extremely high stresses. If ellipse truncation occurs then the bearing damage will instantly increase and the bearing is highly likely to fail before its intended life has been reached. Centrifugal effects at high rotational speeds can have a large influence on element loading and contact angles and this factor can also be analysed within the software.

Contact footprint of balls on raceway considering overhang of shoulder

Capabilities

Full definition of bearing internal geometry Element load distribution and contact stress analysis Contact patch analysis High speed centrifugal effects Advanced life calculation including misalignment and lubricant film thickness influences

Benefits

Accurately predict bearing durability with full integration of system components Understand bearing performance under complex loading and deflections Carry out analysis of factors affecting life not typically considered in standard calculations Enables flexibility and quick calculation results

Load distribution for elements within a ball bearing design

Advanced Roller Analysis

Advanced modules for roller bearing design allow you to optimise the roller and raceway profile for a specific driveline application. This process can be carried out for a given loading condition or duty cycle involving both radial load and misalignment. A number of options are available for profile modification such as semi-crowned, fully-crowned or a logarithmic profile; in addition, empirical measured data can also be entered. The software allows contact stress to be calculated for each individual roller bearing and by refining the profile, maximum stress can be considerably reduced to give an increase in bearing life. In addition to the raceway loading, rib loading on tapered or some cylindrical bearings can also be analysed within the software. You can study the relationship between axial load, radial load and rib loads to ensure no detrimental effect exists from the roller to rib contact for a particular bearing design.

Influence of misalignment and load on contact stress

Capabilities

Full definition of roller and raceway internal profile Contact stress analysis along roller length considering misalignment influence Calculation of rib and roller interface under radial and axial loading Advanced life calculation including lubrication film thickness analysis

Benefits

Improve bearing life through optimisation of raceway and roller internal geometry under given load conditions Accurately assess load and stress conditions on the raceway, rib and rollers for any applied loading Diagnose and solve problems in existing designs on test or in the application

Typical results for inner contact stress for each roller in a bearing

Romax Engineering Services

Romax has a large number of experienced engineers in the field of bearing design, analysis and manufacture so is able to offer a wide range of engineering services to bearing manufacturers and end users. Romax engineering services are unique in offering a range of consulting and technology transfer programmes, working with both bearing suppliers and gearbox manufacturers across a variety of industry sectors.

Yaw bearing design and system model

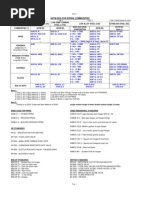

Capabilities

Consultancy services that can be provided are listed in the following areas:

Bearing design

Slewing bearing design, including wind turbine yaw and pitch bearings Large size bearing design for cylindrical and taper types Specialist bearing design for specific applications, including wheel hubs

Bearing analysis

Bearing damage and endurance prediction for gearbox applications Analysis and improvement of raceway roller profile Finite element static analysis of raceway to rolling element contact Roller skew and misalignment assessment Lubrication and film thickness calculations Bespoke software development for analysis and design

Surface roughness affect on film thickness and subsurface stress distribution

Bearing manufacturing support

Audit on manufacturing facilities to assess suitability of existing production Selection and specification of production machines and equipment Material and heat treatment specification definition Support set up of new or improved bearing manufacturing plants

Raceway defect identified from grinding damage

Failure investigation

Investigation of failure causes in various applications Failure countermeasures and DFMEA considerations

Technical due diligence

Review of existing bearing designs for performance and manufacture Risk assessment and approval of new bearing suppliers for lower cost Test specification definition and specification setting

Feasibility study

Market research on bearing supply for various business sectors Benchmarking of competitor products Sales and marketing support for bearing suppliers Technology road map for product development

Example of technology roadmap for bearing development

Training

Theoretical aspects of bearing design and analysis Types of failure modes and bearing inspection methods Overview of bearing manufacturing processes and quality procedures Information on materials and heat treatment used for bearings RomaxDesigner use in relation to bearings and application based case studies

Benefits

Reduce risk on introducing new bearing designs or suppliers and minimise failures Improve capability to develop new products and achieve cost down targets Shorter development time with lower requirement for testing and reduced design iterative steps Optimise bearing design, manufacturing and quality processes Partner with a transmission and bearing technology expert with over 20 years experience

Bearing training session held at Romax

Bearing Finite Element Analysis

Use of Finite Element (FE) analysis allows for the flexible structural analysis of bearing components. However, there are many disadvantages of conventional large FE models where small contact zones require large mesh sizes and extensive operator input to create them. Romax contact elements and plug-ins for ANSYS allow roller or ball contacts to be modelled in unrefined structural meshes providing accurate stiffness calculations.

3D FE model of wind turbine

Capabilities

Perform full 3D FE static analysis for bearing assembly Consider axial, radial and bending loads Vary contact angles with load around bearing circumference Take into account flexible structures Include the effects of pre-load and internal clearance The results from bearing FE analysis include: rolling element load sharing bearing contact angle, contact stress and contact dimensions bearing life prediction

Benefits

Quickly and easily build complex 3D models Efficiently solve huge non-linear models using standard hardware Avoid convergence problems in complex contact models Accurately and efficiently calculate contact stiffness

Case Study: Wind Turbine Bearing Analysis for Certification

The issue

Wind turbine gearbox applications have to be designed and tested according to strict standards to ensure the long reliability requirements are maintained. Germanischer Lloyd Wind Energy (GL Wind) is an internationally operating certification body for wind turbines which assesses the suitability of gearbox designs before they can be used in-service. Design and selection of the bearings is of prime importance in wind turbine gearboxes, Romax was asked to provide durability calculations for a bearing manufacturer against a specified duty cycle and extreme load cases in order to pass the required certification.

The solution

Romax provided the facility to produce reports with durability results needed to satisfy guidelines produced by GL, with analysis for wind turbine gearboxes easily carried out in RomaxDesigner. This allowed modelling of the detailed shaft geometry, complex planetary gear systems, spline connections, FE housing models and internal bearing details.

Model of a three stage planetary and helical wind turbine gearbox design

The result

Reports for bearing performance provided by Romax for GL Wind certification have allowed the supplier to successfully use their products in wind turbine applications. With extensive experience in this area, Romax now offers this type of service to gearbox and bearing manufacturers along with providing consultancy for the detailed design issues involved with these large size bearings.

Analysis process

Evaluate and select bearings using Load Duration Distributions (LDD) and extreme loads Calculate rating life according to ISO 281 and DIN ISO 281 Supplement 4 Investigate and optimise pre-load, clearances, misalignment, bearing internal geometry and lubrication conditions Use detailed results such as static safety factors, bearing raceway stress contours and rolling element load sharing to validate bearing selection

Bearing load and life results for high speed shaft in wind turbine gearbox

Case Study: Low Cost Bearing Supplier Selection

The issue

Romax was asked to undertake a review for a medium duty truck transmission, to assess the use of bearings from low cost suppliers to ensure sufficient load capacity and good manufacturing quality were present to maintain reliability. The gearbox manufacturer requested, using RomaxDesigners total system approach, detailed analysis of the bearing types along with Romax expertise during the manufacturing audit of the potential bearing manufacturer.

The solution

Analysis results were reviewed in terms of durability, raceway surface profiles, stiffness and contact stress. Advanced life calculations were carried out for each of the bearing positions considering the vehicle duty cycle and the affects of lubrication, contamination and temperature. Romax manufacturing specialists spent time at the bearing production facility to investigate quality against the required design intent.

Cross section of the model for a heavy duty truck transmission showing bearing positions

The result

The use of the analysis results allowed a number of different bearing designs to be assessed, with the internal geometry being entered directly into the model. Risk assessment could then be performed on the suppliers bearing designs and optimisation of the raceway profiles carried out to ensure sufficient performance was obtained for the required reliability. The capability of the supplier to manufacture and achieve the required design drawings tolerances was verified.

Bearing evaluation

Bearing selection and optimisation based on analysis of the complete system gearbox within the model Assessment of all factors affecting bearing performance such as pre-load, misalignment, lubrication and production variability to identify key influences on bearing performance Significant time and costs were saved by modelling and manufacturing auditing to verify the suitability of all components without the need for extensive and expensive testing

Maximum contact stress results for bearings within the gearbox under duty cycle loading

Multi-shaft Analysis

Recently, transmission engineers have been considering some unusual shaft/bearing arrangements for a new generation of gearboxes. The new arrangements present such a challenge to the traditional analysis methods and tools that Romax Technology has been asked by major bearing manufacturers to help. Using our softwares unique analysis capabilities, such an arrangement can be modelled and analysed in a short amount of time. A study we carried out considered two concentric shafts connected via one thrust and two radial needle roller bearings. The analysis had to take into account the elastic deflections of all the components, the radial internal clearance of the two radial needle roller bearings and the pre-load of the tapered roller bearings that support the shafts. Changing the preload/end-play of the tapered roller bearings had a dramatic effect on the life of the thrust needle roller bearing.

Example of multi-shaft arrangement and model in a new gearbox design

Capabilities

Analysis of multi-shaft arrangements not usually possible by conventional tools Consideration of bending of the complex shaft arrangement and the interaction between different bearing deflections Consideration for the affects of bearing pre-load and internal clearance Consultancy on any unusual or complex shaft bearing arrangement requiring analysis

Benefits

Fast and cost effective development process for complex arrangements Understand the influence on performance from factors such as bearing position and shaft design Improve concept designs at an early stage with accurate prediction of bearing life and stiffness for various load conditions Enhance ability to assess mounting condition of all bearings within the assembly in terms of pre-load and clearance

Influence on thrust bearing life from needle radial internal clearance and taper bearing pre-load

UK Head Office Rutherford House Nottingham Science & Technology Park Nottingham NG7 2PZ +44 (0) 115 951 8800 sales@romaxtech.com Romax Bearing Design & Analysis Carlo Bianco Rutherford House Nottingham Science & Technology Park Nottingham NG7 2PZ +44 (0) 115 951 8800 sales@romaxtech.com China - Hangzhou Romax Technology (Hangzhou) Ltd 10-05 Building 1 Huarui Centre 66 Jianshe Yi Road Xiaoshan Hangzhou 311215 +86 (0) 571 8378 6230 romaxchina@romaxtech.com China - Beijing 806 Air China Plaza No. 36 Xiao Yun Road Chao Yang District Beijing 100027 +86 (0) 10 8447 5055 romaxchina@romaxtech.com China - Chongqing 17-4 Room Future International Mansion Guanyin Qiao Plaza Jiang Bei District Chongqing 400013 +86 (0) 23 6773 4181 romaxchina@romaxtech.com

India 302, Third Floor Sai Capital Senapati Bapat Road Pune 411016 +91 (0) 20 6720 1800 sales_in@romaxtech.com France 13 rue Louis Gibert 13004 Marseille +33 (0) 6 80 91 82 80 sales_eu@romaxtech.com Japan Romax Technology Tokyo Business Center 2F Taikai Building 3-23-13 Minami-Ooi Shinagawa-ku Tokyo 140-0013 +81 (0) 3 5767 9400 South Korea 2F Jae-yoon Building 75-3 Yangjae-dong Seocho-gu Seoul 137-889 +82 (0) 70 7580 6210 sales_kr@romaxtech.com North America Romax Technology Inc Suite 380 Columbia Center I 201 West Big Beaver Road Troy Michigan 48084 +1 (0) 248 250 7691 sales_us@romaxtech.com

RomaxDesigner is the complete simulation environment for transmission and driveline engineering. The software suite encompasses a variety of configurations focused on industries and applications, including: noise, vibration and harshness transmission design and durability design automation and optimisation advanced bearing simulation wind turbine solutions

About Romax Technology

Romax Technology offers integrated solutions for noise, vibration, harshness [NVH] and bearings analysis through software tools, process, training and engineering services to major OEM and Tier 1 suppliers in the automotive, aerospace, wind energy, industrial equipment, rail and marine industries around the world. Romax Technologys pioneering full-system flexibility and integrated software package encompasses 20 years of development and benchmarking in partnership with major OEMs and extensive research in conjunction with top academic establishments. Romaxs customised and off-the-shelf software provides customers with the tools for right-first-time transmissions and driveline design and analysis. Romax Technologys engineering teams are integrated with its advanced transmission software development which encompasses 20 years of expertise and benchmarking. Service offerings include benchmarking, concepts generation, issue investigation and resolution, analysis and detail design through to production. Romax offers agile issue resolution with a flexible team approach dedicated to individual projects with execution available remotely in the UK or locally with the customer. Local co-ordination of engineering programs is undertaken through offices in USA, Korea, Japan, China, India, Germany and the UK.

At NTN, there is no doubt that RomaxDesigner has greatly improved and accelerated preliminary development. However, much shorter development times are just one of many advantages of the program. The simulation contributes greatly to a much better understanding of the effects that occur in the system as a whole and also within the bearing itself. This means that any necessary action can then be taken, whilst making the whole process transparent to the customer.

NTN Bearings

April 11

Вам также может понравиться

- Kisssoft Tut 009 E GearsizingДокумент20 страницKisssoft Tut 009 E GearsizingDejan DrumacОценок пока нет

- Product Catalogue-300M Series Modular Planetary Gearboxes IE2-IE3 - ENG - R02 - 0Документ598 страницProduct Catalogue-300M Series Modular Planetary Gearboxes IE2-IE3 - ENG - R02 - 0Dispatch TranstechgearsОценок пока нет

- ANL TruckДокумент162 страницыANL Truckmail_krkОценок пока нет

- Gears - Engineering InformationДокумент138 страницGears - Engineering InformationGiang T LeОценок пока нет

- AGMA gear standard reference guideДокумент10 страницAGMA gear standard reference guideponnivalavans_994423Оценок пока нет

- Optimizing Gear Geometry For Minimum Transmission Error, Mesh Friction Losses and Scuffing Risk Through Computer - Aided EngineeringДокумент10 страницOptimizing Gear Geometry For Minimum Transmission Error, Mesh Friction Losses and Scuffing Risk Through Computer - Aided EngineeringGoffardОценок пока нет

- ANSI Replaces AGMA Gear Accuracy StandardsДокумент5 страницANSI Replaces AGMA Gear Accuracy StandardsCarlosQuelartОценок пока нет

- Gearbox Design and Analysis - ProgramДокумент4 страницыGearbox Design and Analysis - Programمحمد نتعيОценок пока нет

- Kisssoft Tut 010 E GearlifetimeДокумент16 страницKisssoft Tut 010 E GearlifetimeBùi Văn HợpОценок пока нет

- GT 0916Документ84 страницыGT 0916Davide MaranoОценок пока нет

- GB/T 10095.2-2008 Cylindrical Gears Accuracy StandardДокумент5 страницGB/T 10095.2-2008 Cylindrical Gears Accuracy StandardtaghdirimОценок пока нет

- Rating of Asymmetric Tooth Gears: Alex L. Kapelevich and Yuriy V. ShekhtmanДокумент6 страницRating of Asymmetric Tooth Gears: Alex L. Kapelevich and Yuriy V. ShekhtmanDavide MaranoОценок пока нет

- PDFДокумент112 страницPDFstefan.vince536Оценок пока нет

- Kisssoft Tut 015 E BevelgearДокумент22 страницыKisssoft Tut 015 E BevelgearJorge Ronald Cabrera ÑaupaОценок пока нет

- Gear DesignДокумент83 страницыGear DesignmuhammadaminjamalmutОценок пока нет

- Effect of Transmission Design On Electric Vehicle (EV) PerformanceДокумент6 страницEffect of Transmission Design On Electric Vehicle (EV) PerformanceSwati NikamОценок пока нет

- A Crowning Achievement For Automotive ApplicationsДокумент10 страницA Crowning Achievement For Automotive ApplicationsCan CemreОценок пока нет

- Hob Seminar (English)Документ26 страницHob Seminar (English)RizwanAliОценок пока нет

- The Application of Bevel GearsДокумент6 страницThe Application of Bevel GearsPrasanth ThiagarajanОценок пока нет

- A Kinematic Analysis of Meshing Polymer Gear TeethДокумент16 страницA Kinematic Analysis of Meshing Polymer Gear TeethsandeepОценок пока нет

- Kisssoft Tut 010 E GearlifetimeДокумент23 страницыKisssoft Tut 010 E GearlifetimeLuis TestaОценок пока нет

- Design and Analysis Procedures For Shafts and Splines: Paul E. BurkeДокумент21 страницаDesign and Analysis Procedures For Shafts and Splines: Paul E. BurkeBalasrinivasan Murugan100% (3)

- ECOmove Powertrain SpecificationsДокумент6 страницECOmove Powertrain SpecificationsjavierОценок пока нет

- KISSsoft Tutorial - Cylindrical Gear Fine SizingДокумент20 страницKISSsoft Tutorial - Cylindrical Gear Fine SizingLuis TestaОценок пока нет

- Steering Universal JointsДокумент11 страницSteering Universal JointsAman JainОценок пока нет

- Load Sharing Methods of Backstops 2004 01Документ10 страницLoad Sharing Methods of Backstops 2004 01Ruben SalgadoОценок пока нет

- Iso 13282013Документ15 страницIso 13282013Kailas KatharОценок пока нет

- Bev Gear Design PDFДокумент5 страницBev Gear Design PDFMawan BentzОценок пока нет

- Cycloid Drive - Replaced by Planocentric Involute Gearing PDFДокумент6 страницCycloid Drive - Replaced by Planocentric Involute Gearing PDFMax GrandeОценок пока нет

- Worm gear calculation softwareДокумент22 страницыWorm gear calculation softwarekismugan0% (1)

- Kisssoft Tut 007 E BearingsДокумент12 страницKisssoft Tut 007 E BearingsIkshit JainОценок пока нет

- Tseng 2004 Mechanism and Machine TheoryДокумент15 страницTseng 2004 Mechanism and Machine TheoryKhanh VqОценок пока нет

- Gleason LTCA ExampleДокумент8 страницGleason LTCA ExamplereddykvsОценок пока нет

- Profile & Longitudinal Corrections On Involute GearsДокумент25 страницProfile & Longitudinal Corrections On Involute GearsRezende Julio100% (1)

- Agma 914 b04Документ45 страницAgma 914 b04Nursena SEVİNÇОценок пока нет

- Losses in Gear Box ModellingДокумент10 страницLosses in Gear Box ModellingSiva ReddyОценок пока нет

- Gear Grinding: SoftwareДокумент68 страницGear Grinding: SoftwareTungОценок пока нет

- The Importance of Profile Shift, Root Angle Correction and Cutter Head TiltДокумент4 страницыThe Importance of Profile Shift, Root Angle Correction and Cutter Head TiltvijaykumarnОценок пока нет

- CAD-based Simulation of The Hobbing ProcessДокумент11 страницCAD-based Simulation of The Hobbing ProcessGabriel MariusОценок пока нет

- Agma 2002 b88Документ48 страницAgma 2002 b88Nursena SEVİNÇОценок пока нет

- Parametric Design On Internal Gear of Cycloid Gear Pump With NX10.0Документ6 страницParametric Design On Internal Gear of Cycloid Gear Pump With NX10.0PanagiotisОценок пока нет

- Approximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingДокумент11 страницApproximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingCan CemreОценок пока нет

- An Investigation of The Fatigue and Fretting PerformanceДокумент19 страницAn Investigation of The Fatigue and Fretting PerformanceKrishna PrasadОценок пока нет

- Standards Development: Enclosed Drives: Agma VoicesДокумент2 страницыStandards Development: Enclosed Drives: Agma VoicesRittik ChakrabortyОценок пока нет

- Ansi Agma 2000 A88Документ4 страницыAnsi Agma 2000 A88MickloSoberanОценок пока нет

- Σχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAДокумент1 страницаΣχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAkstayroskОценок пока нет

- Design and Assembly Analysis of A Worm-Assembly in A Gear BoxДокумент11 страницDesign and Assembly Analysis of A Worm-Assembly in A Gear BoxGourav SharmaОценок пока нет

- Isis DriveДокумент18 страницIsis DriveTms ArnОценок пока нет

- Module IV: Gears and Gear TrainsДокумент38 страницModule IV: Gears and Gear TrainsSuraj VinayОценок пока нет

- 4319B - Flank Modifications in Bevel Gears Using A UMCДокумент22 страницы4319B - Flank Modifications in Bevel Gears Using A UMCRaul PerezОценок пока нет

- A Method to Optimize Brass Synchronizer RingДокумент6 страницA Method to Optimize Brass Synchronizer RingaravindhОценок пока нет

- Measurements & Metrology (English)Документ29 страницMeasurements & Metrology (English)Kumar SubramanianОценок пока нет

- SEW Eurodrive Industrial Gear UnitsДокумент15 страницSEW Eurodrive Industrial Gear UnitsSteve IpОценок пока нет

- Kisssoft Tut 003 E KeyДокумент11 страницKisssoft Tut 003 E KeyJorge Ronald Cabrera ÑaupaОценок пока нет

- Cycloid Drive - Replaced by Planocentric Involute GearingДокумент6 страницCycloid Drive - Replaced by Planocentric Involute GearingMax GrandeОценок пока нет

- Asymmetric Cylindrical GearsДокумент6 страницAsymmetric Cylindrical Gearsकृष्णकुमार दत्तात्रेय जोशीОценок пока нет

- Design - Ring Gear MaterialsДокумент4 страницыDesign - Ring Gear Materialstushar11singhОценок пока нет

- POWERTRAINДокумент10 страницPOWERTRAINarpitaОценок пока нет

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987От EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonОценок пока нет

- Small Volume Prover Manual 005 To 025Документ136 страницSmall Volume Prover Manual 005 To 025anafadoОценок пока нет

- Ame101 F17 PS2Документ2 страницыAme101 F17 PS2nuncafalhaОценок пока нет

- Laporan Harian WS 34 Dan 15 2021Документ2 страницыLaporan Harian WS 34 Dan 15 2021tyok sajaОценок пока нет

- Solarizer Spring Data SheetДокумент1 страницаSolarizer Spring Data SheetEmmvee SolarОценок пока нет

- Instrumentation Training for Engineers and TechniciansДокумент9 страницInstrumentation Training for Engineers and TechniciansshareyhouОценок пока нет

- KawasakiTools Vol50Документ25 страницKawasakiTools Vol50ata03003993360Оценок пока нет

- PE Handbook Errata SheetДокумент8 страницPE Handbook Errata SheetFrancis ReyesОценок пока нет

- F.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentДокумент13 страницF.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentIksan Adityo Mulyo100% (1)

- 2-Convective Mass-Transfer-E7240 PDFДокумент49 страниц2-Convective Mass-Transfer-E7240 PDFHasieb Alam KhanОценок пока нет

- 6 Pile GroupДокумент29 страниц6 Pile GroupAnonymous nwByj9LОценок пока нет

- 00 en Drilling 05-2022 No Mark Ups 01Документ4 страницы00 en Drilling 05-2022 No Mark Ups 01ihydraulicsОценок пока нет

- Rs46 Series Technical Guide: WWW - Til-Hyster - inДокумент8 страницRs46 Series Technical Guide: WWW - Til-Hyster - indeepakgkdОценок пока нет

- Retrofitting of Columns of An Existing Building byДокумент8 страницRetrofitting of Columns of An Existing Building bysp thipathiОценок пока нет

- EngMech - Lecture 1.1Документ18 страницEngMech - Lecture 1.1omay12Оценок пока нет

- Year 11 Physics Dynamics Notes Part 1 1 PDFДокумент5 страницYear 11 Physics Dynamics Notes Part 1 1 PDFMark Quach100% (2)

- FH100 FH120 FH135 FH160: EU Stage 4 EngineДокумент16 страницFH100 FH120 FH135 FH160: EU Stage 4 EngineSabah100% (1)

- Siemens SPPA P3000Документ2 страницыSiemens SPPA P3000shahin_bОценок пока нет

- Hdpe Pipe Price List 2017Документ2 страницыHdpe Pipe Price List 2017sukiraj100% (2)

- M0066206-02 (En-Us) - 00-ALLCD - 001Документ1 039 страницM0066206-02 (En-Us) - 00-ALLCD - 001Edilberto zegarra camposОценок пока нет

- System ConfigurationДокумент64 страницыSystem ConfigurationMuhamad Sayid Akil MhsAkilОценок пока нет

- Keep 316Документ68 страницKeep 316AdityaОценок пока нет

- GKR GKS GSS Gearboxes With MD MH AC Motors - v1-0 - ENДокумент84 страницыGKR GKS GSS Gearboxes With MD MH AC Motors - v1-0 - ENm.chagaevОценок пока нет

- IP Ratings Chart V3 PDFДокумент1 страницаIP Ratings Chart V3 PDFsuprakashpaul93Оценок пока нет

- Astm Nos For PipingДокумент6 страницAstm Nos For PipingJessica HerringОценок пока нет

- Catalogo Motores Hidraulicos DanfossДокумент40 страницCatalogo Motores Hidraulicos DanfossTiago RezendeОценок пока нет

- Heat Load-KitchenДокумент1 страницаHeat Load-Kitchenrinko447459Оценок пока нет

- SR Rivet sr02 PDFДокумент2 страницыSR Rivet sr02 PDFdeepakjothivelОценок пока нет

- Aircraft Major Structural Stresses Copy of DiscussionДокумент34 страницыAircraft Major Structural Stresses Copy of DiscussionangeloОценок пока нет

- Rock Stress AnalysisДокумент30 страницRock Stress Analysissamwel juliusОценок пока нет

- The Laws and Velocity of Planetary Motion: Section - 10 FДокумент3 страницыThe Laws and Velocity of Planetary Motion: Section - 10 FFiyory TassewОценок пока нет