Академический Документы

Профессиональный Документы

Культура Документы

Kristof T. J. Loones Et Al - Microwave-Assisted Organic Synthesis: Scale-Up of Palladium-Catalyzed Aminations Using Single-Mode and Multi-Mode Microwave Equipment

Загружено:

Nstm3Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Kristof T. J. Loones Et Al - Microwave-Assisted Organic Synthesis: Scale-Up of Palladium-Catalyzed Aminations Using Single-Mode and Multi-Mode Microwave Equipment

Загружено:

Nstm3Авторское право:

Доступные форматы

Tetrahedron 61 (2005) 1033810348

Microwave-assisted organic synthesis: scale-up of palladium-catalyzed aminations using single-mode and multi-mode microwave equipment

Kristof T. J. Loones,a Bert U. W. Maes,a,* Geert Rombouts,a Steven Hostyna and Gaston Dielsb

b

Organic Synthesis, Department of Chemistry, University of Antwerp, Groenenborgerlaan 171, B-2020 Antwerp, Belgium Janssen Pharmaceutica, Johnson and Johnson Pharmaceutical Research & Development, Turnhoutseweg 30, B-2340 Beerse, Belgium

Received 23 May 2005; revised 25 July 2005; accepted 27 July 2005 Available online 8 September 2005 Dedicated to the memory of Nancy Verhaert

AbstractBatch wise scale-up of BuchwaldHartwig aminations under microwave irradiation has been investigated for the rst time. Multi-mode (microSYNTH and MARS) (several vessels irradiated in parallel per batch) as well as single-mode (Discover) (one vessel irradiated per batch) platforms can be successfully used for this purpose with triuoromethylbenzene (benzotriuoride: BTF) as amination solvent. The obtained yields indicate a direct scalability in BTF for all the studied aminations. The Voyager equipment (based on a Discover platform) is the most convenient system since it allows an automatic continuous batch wise production without the necessity to manually load and unload reaction vessels. q 2005 Elsevier Ltd. All rights reserved.

1. Introduction Microwave-assisted organic synthesis (MAOS) is a rapidly growing subeld within the area of organic chemistry.1 Since the rst reports in the literature on MAOS in the mid eighties the number of annually published articles using microwave heating has increased continuously.2 In the early days domestic microwaves were used, often giving only a poor reproducibility. Moreover, accidents were common due to the lack of control. This lack of control and reproducibility is partly responsible for the initial slow take up of microwave heating in organic syntheses. The introduction of dedicated equipment by Prolabo (closed down already), CEM, Milestone, Biotage (formerly Personal Chemistry), Plazmatronika and more recently by Anton Paar allowing the on-line monitoring of temperature, power and pressure had a large impact on the further development of this relatively young research eld.3 The latest trend is to use only microwave equipment designed for organic synthesis and to abandon scientic results for publication obtained using domestic microwaves. The organisation of annual workshops and conferences focusing

Keywords: Palladium; Homogeneous catalysis; BuchwaldHartwig amination; Aryl chlorides; Multi-mode cavity; Single-mode cavity; Microwave irradiation. * Corresponding author. Tel.: C32 3 265 32 05; fax: C32 3 265 32 33; e-mail: bert.maes@ua.ac.be 00404020/$ - see front matter q 2005 Elsevier Ltd. All rights reserved. doi:10.1016/j.tet.2005.07.105

on MAOS such as the MAOS meeting in Graz and the International Microwaves in Chemistry Conference in Orlando clearly support that microwave-assisted organic synthesis has now reached a mature scientic level. The growing interest, both from industry and academia, for such events indicates that the real impact of microwaves on the eld of organic syntheses still has to come! Most of the chemistry hitherto performed in a dedicated microwave system has been executed on a small scale only. Singlemode microwaves are standardly used for this purpose, typically allowing the production of several hundred milligram quantities per run. One of the major current issues is the question whether microwave heating could be used to scale-up these reactions to gram and kilogram scale, preferentially without the requirement to reoptimize reaction parameters tuned for the small scale runs. For the scale-up purpose historically two different approaches, batch4 and continuous-ow,5 have been followed taking into account the physical limitations inherent to microwave equipment construction.1h Large batch reactors have been developed for a multi-mode or single-mode microwave platform. For these the most important drawback is the limited penetration depth of microwave irradiation. Alternatively, multi-mode equipment supplied with a rotor with several smaller vessels has been launched, which allows the use of a large total volume in one microwave run without the penetration depth issue. Besides batch approaches

K. T. J. Loones et al. / Tetrahedron 61 (2005) 1033810348

10339

continuous-ow systems based on single-mode and multimode cavities have been used as well. The major limitation of these continuous microwave reactors is that they are unsuitable for heterogeneous mixtures and viscous liquids. Interestingly, reports on scale-up using dedicated microwave equipment in peer reviewed journals is hitherto rather limited. In particular more complex chemistry, such as transition metal catalyzed reactions, is hardly studied.6 Based on the limited availability of more complex examples and the background of our research group, we decided to investigate the scale-up of BuchwaldHartwig aminations under microwave irradiation using dedicated multi-mode (MicroSYNTH, MARS) and single-mode (Voyager) batch reactors.7,8

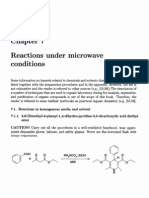

2. Description of microwave equipment used 2.1. Voyager3 The Voyager system (stop/ow system) of CEM is based on the Discover single-mode platform equipped with an 80 mL glass vessel (borosilicate), a peristaltic pump and two valves (Fig. 1). The system has a continuous unpulsed microwave output ranging from 0 to 300 W. The temperature in the vessel is controlled internally by a ber optic probe. On-line pressure monitoring is also provided. The Voyager microwave is designed to automatically ll the 80 mL vessel with reagents (two stock solutions), seal the vessel, perform a microwave experiment, release the vessel, remove the reaction mixture from the vessel and subsequently clean it with solvent (even under microwave irradiation if desired) (Fig. 2). The liquid of the cleaning step can be collected separately via a waste line or can be added to the product if desired. We always chose the latter. The contents of the closed vessel can be released after a microwave experiment at a pre-programmed temperature and pressure (in our experiments we used 95 8C and 10 psi as vessel release parameters), which allows a serious increase of the throughput (number of cycles in a given timeframe) of the system. Cooling to the set temperature value is done using a propelled air ow. When the Voyager platform is based on an older type of Discover microwave an enhanced stirring device is standardly used. This device ts in the small cavity located at the bottom of the microwave cavity (on top of the IR sensor). It consists of a magnet at both ends of the bar, which couples with the magnetic stirring plate located at the bottom of the Discover

Figure 2. Add step (1), remove step (2) and clean vessel step (3) ((3a) ll with solvent, (3b) remove solvent to waste).

Figure 1. Voyager platform (1) and 80 mL glass vessel (2).

10340

K. T. J. Loones et al. / Tetrahedron 61 (2005) 1033810348

unit. Two more centrally located magnets couple with the stirring bar in the reaction vessel. The enhanced stirring device gives access to a microwave unit with a more powerful stirring capacity. All our experiments were done using this special device. Recent Discover units are equipped with electromagnetic stirring plates that deliver more stirring power in comparison with the older type of Discover unit. Therefore the enhanced stirring device is not used anymore in this newer unit. 2.2. MicroSYNTH3 The MicroSYNTH system of Milestone is a multi-mode platform equipped with a magnetic stirring plate and a rotor that allows parallel processing of several vessels per batch (Fig. 3). We used the high-pressure vessel assembly type based on a rotor with 10 vessel positions (teon (TFM) inserts) (vessel volume 100 mL, max pressure 1450 psi, max temperature 300 8C). The system has two magnetrons that together deliver a maximum power output of 1000 W. The power supply of the magnetron is pulsed. Temperature is controlled internally by ber optic probe in one control reference vessel. On-line pressure monitoring of the reference vessel is also provided. All rotor segments are protected by a reclosing (vent and reseal) relief valve mechanism. Additionally, the system is equipped with a solvent sensor detector safety feature. Cooling down of the rotor segments to room temperature is done by an air ow provided by the exhaust fan. 2.3. MARS3

positions rotor. The system delivers a continuous power output between 0 and 1200 W. Temperature is controlled internally by ber optic probe in one control reference vessel. On-line pressure monitoring of the reference vessel is also provided. All rotor segments are protected by a vent nut that contains a rupture membrane. Additionally, the system is equipped with a solvent sensor detector safety feature. Cooling down of the rotor segments to room temperature is done by an air ow provided by the exhaust fan. 3. Results Recently our laboratory reported the rapid palladiumcatalyzed amination of aryl chlorides under temperature controlled microwave heating using a CEM Discover single-mode microwave unit.7c,7l In a reaction time of only 10 min using a relatively low catalyst loading (1 mol%) complete conversion of starting material and a good yield could be achieved for the coupling of both electron rich and electron neutral aryl chlorides with all types of amines (anilines, primary and secondary aliphatic amines). For the coupling of anilines and secondary cyclic aliphatic amines palladium precatalyst based on Pd(OAc)2 and 2-(dicyclohexylphosphanyl)biphenyl9 (DCPB) ligand worked smoothly while for the amination reactions using acyclic secondary and primary aliphatic amines Pd(OAc)2 in combination with 2-(di-t-butylphospanyl)biphenyl 9 (DTPB) ligand was found to be optimal. All the reported examples were performed on a 1 mmol scale of aryl chloride allowing the production of hundred milligram quantities of N-substituted anilines. First we investigated the direct scalability going from a 10 mL vessel to an 80 mL vessel in a Discover apparatus. We selected the coupling of electron rich 4-chloroanisole with morpholine, which we previously performed on a 1 mmol scale as a test case.7l Unfortunately, running this reaction on a 20-fold scale (20 mmol 4-chloroanisole, 24 mmol morpholine, 28 mmol NaOtBu, 20 mL toluene) using the same microwave program (initial set power 300 W, 150 8C, 10 min (total reaction time including ramp time to set temperature)) as for the small scale reaction was unsuccessful. The reaction mixture heated up relatively slowly and the obtained nal temperature after 10 min of microwave irradiation was only 128 8C, which is substantially lower than the desired set temperature of 150 8C. Consequently, an incomplete conversion of starting material and an isolated yield of 4-(4-methoxyphenyl)morpholine of only 38% was obtained (Table 1). In contrast,

Figure 3. MicroSYNTH platform (1), control vessel rotor segment (2), high-pressure sleeve, insert and cap of a standard vessel assembly (3).

The MARS system of CEM is a multi-mode platform equipped with a magnetic stirring plate and a rotor that allows the parallel processing of several vessels per batch (Fig. 4). We used the HP-500 (teon (TFA) insert) (vessel volume 80 mL, max pressure 350 psi, max temperature 210 8C) and Greenchem (glass (borosilicate) insert) (vessel volume 80 mL, max pressure 200 psi, max temperature 200 8C) vessel assembly types both based on a fourteen

Figure 4. MARS platform (1), control vessel rotor segment (2), Greenchem insert, cap and sleeve of a standard vessel assembly (3) and HP-500 insert, cap and sleeve of a standard vessel assembly (4).

K. T. J. Loones et al. / Tetrahedron 61 (2005) 1033810348 Table 1. Scale-up of the Pd-catalyzed amination of 4-chloroanisole with morpholine

10341

Microwave

4-Chloroanisole (mmol) Volume (mL) 1 20 20 1 20 3!20 6!20 6!20 10 80 80 10 80 80 100 80

Vessel Type Glass Glass Greenchem Glass Glass Glass High-Pressure Greenchem

Initial set power (W) 300 300 1200 300 300 300 600 600

Solvent

Yield (%)a

Discover Discover Mars Discover Discover Voyager microSYNTH Mars

a b c

Toluene Toluene Toluene BTF BTF BTF BTF BTF

76 38b 78 78 85 78c 77c 80c

4-Chloroanisole (y mmol), morpholine (1.2y mmol), NaOt-Bu (1.4y mmol), toluene or BTF (y mL). 150 8C could not be reached in 10 min. Average yield.

for the 1 mmol scale experiment in a 10 mL vessel the set temperature was reached in 2 min allowing a full conversion of starting material in 10 min.7l Although polar reagents are present in the reaction mixture we realized the poor coupling characteristic of the solvent (tan d tolueneZ 0.04) is responsible for the failure of the scale-up experiment.10 Due to this failure we became interested to investigate

whether there is a substantial difference between single and multi-mode microwaves when solvents with low tan d are used. Therefore, we performed power/time experiments (temperature is slave of the power) using 20 mL of pure toluene at full power in several commercial available microwave platforms (Discover, max power 300 W)11 (MARS, max power 1200 W) 11 (microSYNTH, max power 1000 W)11 (Fig. 5). The vessels used were either from glass (borosilicate) or teon (PTFE or TFM). In all

Figure 5. Heating prole of 20 mL of toluene in several commercial available microwave systems, irradiated in a power/time experiment at a constant maximum power output for 10 min.

10342

K. T. J. Loones et al. / Tetrahedron 61 (2005) 1033810348

Figure 6. Heating prole of 20 mL of toluene in several commercial available microwave systems, irradiated in a power/time experiment at a constant power of 300 W for 10 min.

cases, the temperature was measured internally using a ber optic probe. Interestingly, 20 mL of toluene could be heated to 156 8C in 10 min in a Greenchem vessel in the MARS

platform. In contrast, 20 mL of toluene could only be heated to 61 8C in a similar 80 mL glass vessel in the Discover system. Important to mention is that even if the same

Figure 7. Heating prole of 20 mL of tetrachloromethane in several commercial available microwave systems, irradiated in a power/time experiment at a constant power of 300 W for 10 min.

K. T. J. Loones et al. / Tetrahedron 61 (2005) 1033810348

10343

constant power output is used in all microwave systems the nal temperature of toluene is not the same (Fig. 6).11 Heating the same volume of solvent in the three selected microwaves allows a direct comparison of the heating efciency of these machines for that specic volume by simply comparing the obtained nal temperatures of the heated solvent.11 However, one should be very careful since the differences observed are also related to the specic material used for the vessel construction. This can be clearly deduced from a comparison of the heating proles of toluene in the Greenchem and HP-500 vessel in the MARS at the same constant power (Fig. 6).11 A simple heating experiment with 20 mL of microwave transparent tetrachloromethane clearly showed that the vessel material itself (sleeve and/or insert) is not completely microwave transparent and is at least partially responsible for the heating up of the irradiated solvent via conduction (Fig. 7).12 This process becomes more and more important the more microwave transparent the irradiated solvent is. Remarkably, toluene and tetrachloromethane can not be heated in the high-pressure vessel of the microSYNTH at a constant power of 300 W since the system shuts down after a few minutes. The heating proles of pure toluene conrm that our failure with the scale-up of the amination of 4-chloroanisole with morpholine is related to the use of toluene as solvent in that specic microwave platform. Importantly, the heating proles also indicate that in the Greenchem vessel of the MARS multi-mode microwave, scale-up of the desired amination might be possible. Indeed, performing the amination on a 20 mmol scale of substrate at 150 8C using an initial set power of 1200 W and for a total reaction time of 10 min gave a complete conversion of

starting material and an isolate yield of 4-(4-methoxyphenyl)morpholine of 78% (Table 1). This is similar to the result obtained on a 1 mmol scale in the 10 mL glass vessel of the Discover (76%). Although we were able to successfully perform scale-up in one glass vessel we realized that the further scale-up making use of the possibility to process multiple Greenchem vessels (rotor) in one microwave run would be problematic using toluene as solvent. Indeed, Figure 8 clearly shows that the nal temperature of toluene in power/time experiments performed at 1200 W for 10 min drops each time a rotor segment that contains a glass vessel with 20 mL of toluene is added. This is obvious since the total volume to be heated increases each time a rotor segment is added. Therefore we looked for an alternative solvent for palladium-catalyzed aminations to allow scale-up in single-mode as well as multi-mode platforms. Possible candidates were screened by performing power/time experiments with 20 mL of solvent at 300 W for 10 min in each microwave system. 300 W was chosen as set power since it is the maximum power output of the Discover. First we looked at tetrahydrofurane (tan dZ0.047),10 which has already been used frequently as solvent in BuchwaldHartwig aminations (Fig. 9).8f,8j In comparison with toluene at the same power (Fig. 6), tetrahydrofurane signicantly increased the obtained nal temperatures in all microwave platforms (Fig. 9) although the tan d is only slightly higher than that of toluene. Even though the heating prole of tetrahydrofurane is certainly a lot better, the solvent reaches a nal temperature of only 94 8C upon heating at maximum power output for 10 min in the Discover. Therefore we looked for other alternatives. Inspired by a lecture where

Figure 8. Heating prole of 1, 3, 4 and 6 Greenchem vessels, each lled with 20 mL of toluene, irradiated in the MARS system for 10 min in a power/time experiment at a constant power of 1200 W.

10344

K. T. J. Loones et al. / Tetrahedron 61 (2005) 1033810348

Figure 9. Heating prole of 20 mL of tetrahydrofurane in several commercial available microwave systems, irradiated in a power/time experiment at a constant power of 300 W for 10 min.

Figure 10. Heating prole of 20 mL of triuoromethylbenzene (BTF) in several commercial available microwave systems, irradiated in a power/time experiment at a constant power of 300 W for 10 min.

K. T. J. Loones et al. / Tetrahedron 61 (2005) 1033810348

10345

Figure 11. Experimental setup for the scale-up of Pd-catalyzed aminations using the Voyager platform.

Claisen rearrangements were executed using triuoromethylbenzene (benzotriuoride: BTF) as the solvent and a review stating the stability of this solvent under strongly basic conditions at high temperature we investigated the heating prole of 20 mL of this solvent at a constant power of 300 W.13,14 Interestingly, we found that BTF heats up very rapidly, including in the Discover system at maximum power output, since all vessel-microwave combinations gave a nal solvent temperature equal or higher than 148 8C (Fig. 10). Since in the real experiments our vessel contains in addition to solvent also polar reagents that will couple with microwaves we can expect that the required 150 8C will certainly be reached in one to two minutes as desired. Therefore we considered BTF as a good solvent candidate for scale-up of BuchwaldHartwig aminations in singlemode as well as multi-mode platforms. Since BTF has hitherto never been used in palladium-catalyzed reactions we checked its potential as an amination solvent. Rewardingly, when we coupled 4-chloroanisole with morpholine at small scale in a 10 mL glass vessel in the Discover we found that in the same reaction time at the same nal temperature a similar isolated yield was obtained using this solvent as a toluene substitute (Table 1).

For the scale-up experiments we rst evaluated the Discover single-mode microwave of CEM. An attempt to scale-up our test case amination of 4-chloroanisole with morpholine with a factor 20 (20 mmol 4-chloroanisole, 24 mmol morpholine, 28 mmol NaOt-Bu, 20 mL BTF) in an 80 mL vessel proceeded smoothly since a complete conversion of starting material and an isolated yield of 85% of 4-(4methoxyphenyl)morpholine could be achieved in the same reaction time (10 min) as when 1 mmol of the aryl chloride was used in BTF (Table 1).15 Next we looked at the possibility to perform this experiment in a completely automized batch wise process. For this purpose we used the Voyager (stop/ow system) system of CEM. For our automized scale-up experiment we made a stock solution of catalyst (Pd(OAc)2/2 DCPB) in BTF and a second solution containing 4-chloroanisole, morpholine and NaOtBu in BTF. The latter is a heterogeneous mixture due to the low solubility of NaOtBu in BTF. Therefore this stock solution was put on a magnetic stirring plate, which prevented precipitation of the base at the bottom of the bottle and, which allowed the creation of a more or less homogeneous suspension. The whole setup can be seen in Figure 11. When we programmed the Voyager for three cycles of 20 mmol aryl chloride the average yield was similar as the one obtained in the previously mentioned one batch experiment (Table 1). Even when we performed 12 cycles the yield did not drop signicantly since an average yield of 76% for batches 1012 was obtained. When one takes into account that a complete cycle takes only 16 min, the stop/ow system gives the opportunity to make 1.35 mol (around 261 g) of 4-(4-methoxyphenyl)morpholine in one day. Next we attempted to scale-up the most challenging coupling we previously published namely the amination of 4-chloroanisole with N,N-dibutylamine using DTPB as ligand for the palladium catalyst. Performing the experiment on a 20 mmol scale of 4-chloroanisole in an 80 mL glass vessel in the Discover gave the same yield as on a 1 mmol scale in a 10 mL glass vessel in toluene (Table 2). Further scale-up in the Voyager gave an average yield of 44% over three cycles and clearly illustrates the power of the Voyager system. Finally, we also tried to use a heteroaromatic substrate namely 3-chloropyridine. Pdcatalyzed amination of 3-chloropyridine (20 mmol) with benzylamine (30 mmol) using DTPB as ligand gave a 85% isolated yield in a one batch experiment in the 80 mL vessel

Table 2. Scale-up of the Pd-catalyzed amination of 4-chloroanisole with N,N-dibutylamine

Microwave

4-Chloroanisole (mmol) Volume (mL) 1 20 3!20 10 80 80

Vessel Type Glass Glass Glass

Initial set power (W) 300 300 300

Solvent

Yield (%)a

Discover Discover Voyager

a b

Toluene BTF BTF

50 45 44b

4-Chloroanisole (y mmol), N,N-dibutylamine (1.2y mmol), NaOtBu (1.4y mmol), toluene or BTF (y mL). Average yield.

10346

K. T. J. Loones et al. / Tetrahedron 61 (2005) 1033810348

Table 3. Scale-up of the Pd-catalyzed amination of 3-chloropyridine with benzylamine

Microwave

3-Chloropyridine (mmol) Volume (mL) 1 20 3!20 10 80 80

Vessel Type Glass Glass Glass

Initial Set Power (W) 300 300 300

Solvent

Yield (%)a

Discover Discover Voyager

a b

Toluene BTF BTF

87 85 81b

3-Chloropyridine (y mmol), benzylamine (1.5y mmol), NaOt-Bu (1.4y mmol), toluene or BTF (y mL). Average yield.

in the Discover, which is essentially the same as the result obtained on a 1 mmol scale in toluene (Table 3). Running three cycles in the Voyager also gave a similar result (average yield of 81%) (Table 3). Secondly, we looked at the scale-up possibilities (6! 20 mmol) of the MARS (Greenchem vessels) and microSYNTH (high-pressure vessels) multi-mode microwaves of the companies CEM and Milestone, respectively. To get an idea about the set power required to heat up multiple vessels we performed power/time experiments with 6 vessels each containing 20 mL of BTF. We decided to execute these power/time experiments in the microSYNTH (high-pressure vessels) since we already found that heating one Greenchem vessel with 20 mL of BTF at a constant power of 300 W for 10 min in the MARS system gives a higher nal temperature than when a similar experiment is performed in a highpressure vessel in the microSYNTH (Fig. 10). Heating 6 high-pressure vessels with 20 mL of BTF at a constant power of 300 W gave a nal solvent temperature of 127 8C, which is 21 degrees lower than when one vessel is heated at the same constant power in the same time (Fig. 10). Increasing the power to 600 W increased the nal temperature of the solvent for the 6 high-pressure vessels to a similar value as with one high-pressure vessel at 300 W and therefore 600 W was selected as the set power for the large scale amination experiments. Irradiating a rotor with 6 high-pressure vessels each containing 20 mmol 4-chloroanisole, 24 mmol morpholine, 28 mmol NaOtBu and 1 mol% Pd(OAc)2/2 mol% DCPB catalyst in 20 mL BTF to 150 8C using an initial set power of 600 W gave a complete conversion of starting material in 10 min and an average isolated yield of 77% of 4-(4-methoxyphenyl)morpholine (Table 1). A similar experiment with 6 Greenchem vessels in the MARS using the same microwave parameters gave 80% reaction product (Table 1). Both large scale (6!20 mmol) experiments performed in a microSYNTH and MARS multi-mode system gave a similar yield as the small scale (1 mmol) experiment in a 10 mL glass vessel in the Discover (Table 1).

microwave irradiation can be easily scaled-up without yield decrease if triuoromethylbenzene (BTF) is used as solvent. Single-mode as well as multi-mode platforms can be used for this purpose. Although similar yields could be obtained in the Voyager, microSYNTH and MARS equipment, we prefer the Voyager since it is a completely automized unit that allows the continuous production of reaction product without the necessity to manually load and unload reaction vessels. Moreover, the Voyager allows pumping of heterogeneous mixtures, which is problematic in continuous-ow units.

5. Experimental 5.1. General For column chromatography Kieselgel 60 (ROCC, 0.040 0.063 mm) was used. Pd(OAc)2 (Acros), DCPB (Strem Chemicals or Acros), DTPB (Strem Chemicals or Acros), BTF (Acros) as well as all the amines and (hetero)aryl chlorides were obtained from commercial sources and used as such. The characterization data of 4-(4-methoxyphenyl) morpholine, N,N-dibutyl-4-methoxyaniline and N-benzylpyridin-3-amine were identical with those previously reported in the literature.7l,16 For the microwave-assisted amination experiments in toluene extra dry (!30 ppm water) toluene of Acros was used. The toluene (Acros) used to determine the heating proles was p.a. quality. 5.2. Scale-up of palladium-catalyzed aminations of (hetero)aryl chlorides using the Voyager platform 5.2.1. Preparation of the stock solutions. Stock solution one. A 250 mL bottle (Schott) was charged with (hetero)aryl chloride (70 mmol), amine (morpholine or N,N-dibutylamine: 84 mmol) (N-benzylamine: 105 mmol) and NaOt Bu (9.42 g, 98 mmol) and BTF (35 mL) in air. Subsequently, the bottle was ushed with Ar for a few minutes under magnetic stirring. The stock solution of reagents (including base) is heterogeneous. Therefore it was placed on a magnetic stirring plate, which prevented precipitation of the base at the bottom of the bottle. This allowed the creation of a more or less homogeneous suspension.

4. Conclusion Rapid Pd-catalyzed amination of aryl chlorides under

K. T. J. Loones et al. / Tetrahedron 61 (2005) 1033810348

10347

Stock solution two. A 250 mL bottle (Schott) was charged with Pd(OAc)2 (0.157 g, 0.70 mmol), 2-(dicyclohexylphosphanyl)biphenyl (DCPB) or 2-(di-t-butylphospanyl) biphenyl (DTPB) (1.4 mmol) and BTF (35 mL) in air. Subsequently, the bottle was ushed with Ar for 10 min under magnetic stirring. When DTPB was used as ligand for the catalyst the stock solution was stirred for 16 h before using it.17 5.3. Remarks

Acknowledgements B. M. acknowledges the nancial support by the Fund for Scientic Research-Flanders (FWO-Vlaanderen) (research grant 1.5.088.04), the European Union and the University of Antwerp (RAFO-RUCA). The authors wish to thank the technical staff (ing. J. Aerts, J. Schrooten, W. Van Lierde and ing. J. Verreydt) and Gitte Van Baelen of the research group for their assistance. S. H. thanks the IWT-Vlaanderen (Instituut voor de Aanmoediging van Innovatie door Wetenschap en Technologie in Vlaanderen) for a scholarship.

* The viscosity of the stock solutions inuences the actual volume that will be pumped out of the stock solutions in the reaction vessel of the Voyager system in a certain timeframe. Therefore one needs to calibrate the system rst by determining the pumping time necessary to pump in the desired volume (#mmol of reagents and base, catalyst). * We coupled the Voyager platform to a nitrogen cylinder (Fig. 11). In this way ushing of the tubing during loading, unloading and cleaning of the reaction vessel is performed with N2 gas instead of air. * The set power for all amination experiments using the Voyager or Discover system was 300 W, the set temperature 150 8C. The total irradiation time (including the ramp time to the set temperature) was 10 min. Crude reaction mixture was ltered over Celite and rinsed well with dichloromethane. The ltrate was subsequently evaporated under reduced pressure and the residue puried by ash column chromatography on silica gel.

References and notes

1. For recent reviews and books on microwave-assisted organic synthesis: (a) Lidstrom, P.; Tierney, J.; Wathey, B.; Westman, J. Tetrahedron 2001, 57, 92259283. (b) Larhed, M.; Hallberg, A. Drug Discovery Today 2001, 6, 406416. (c) Kappe, C. O. Am. Lab. 2001, 33, 1319. (d) Larhed, M.; Moberg, C.; Hallberg, A. Acc. Chem. Res. 2002, 35, 717727. (e) Lew, A.; Krutzik, P. O.; Hart, M. E.; Chamberlin, A. R. J. Comb. Chem. 2002, 4, 95105. (f) Kappe, C. O. Curr. Opin. Chem. Biol. 2002, 6, 314320. (g) Hayes, B. L. Microwave Synthesis: Chemistry at the Speed of Light; CEM: Matthews, 2002. (h) Microwaves in Organic Synthesis; Loupy, A., Ed.; Wiley-VCH: Weinheim, 2002. (i) Hayes, B. L. Aldrichim. Acta 2004, 37, 6677. (j) Microwave-Assisted Organic Synthesis; Lindstrom, P., Tierney, J. P., Eds.; Blackwell: Oxford, 2004. (k) Kappe, C. O. Angew. Chem., Int. Ed. 2004, 43, 62506284. 2. (a) Gedye, R.; Smith, F.; Westaway, K.; Ali, H.; Baldisera, L.; Laberge, L.; Rousell, J. Tetrahedron Lett. 1986, 27, 279282. (b) Giguere, R. J.; Bray, T. L.; Duncan, S. M.; Majetich, G. Tetrahedron Lett. 1986, 27, 49454958. 3. http://www.cem.com/; http://www.milestonesrl.com/; http:// www.biotage.com/; http://www.plazmatronika.pl/eng/index. html; http://www.anton-paar.com/. 4. (a) Raner, K. D.; Strauss, C. R.; Trainor, R. W.; Thorn, J. S. J. Org. Chem. 1995, 60, 24562460. (b) Perio, B.; Dozias, M.-J.; Hamelin, J. Org. Process Res. Dev. 1998, 2, 428430. (c) Cleophax, J.; Liagre, M.; Loupy, A.; Petit, A. Org. Process Res. Dev. 2000, 4, 498504. 5. (a) Cablewski, T.; Faux, A. F.; Strauss, C. R. J. Org. Chem. 1994, 59, 34083412. (b) Kazba, K.; Chapados, B. R.; Gestwicki, J. E.; McGrath, J. L. J. Org. Chem. 2000, 65, 12101214. (c) Khadilkar, B. M.; Madyar, V. R. Org. Process Res. Dev. 2001, 5, 452455. (d) Esveld, E.; Chemat, F.; van Haveren, J. Chem. Eng. Technol. 2000, 23, 279283. (e) Esveld, E.; Chemat, F.; van Haveren, J. Chem. Eng. Technol. 2000, 23, 429435. (f) Shieh, W.-C.; Dell, S.; Repi, O. Tetrahedron Lett. 2002, 43, 56075609. 6. For the scale-up of Heck and Negishi reactions in a prototype multi-mode microwave of Anton Paar GmbH see: Stadler, A.; Youse, B. H.; Dallinger, D.; Walla, P.; Van der Eycken, E.; Kaval, N.; Kappe, C. O. Org. Process Res. Dev. 2003, 7, 707716. For the scale-up of Suzuki reactions in a single-mode microwave of CEM (Discover) using a 50 mL round-bottomed ask see: Leadbetter, N. E.; Marco, M. J. Org. Chem. 2003, 68, 888892.

5.4. Scale-up of the palladium-catalyzed amination of 4-chloranisole with morpholine using the MARS and microSYNTH platform A Greenchem or high-pressure vessel was charged with 4-chloranisole (20 mmol), morpholine (24 mmol) and NaOtBu (2.69 g, 28 mmol) in air. Subsequently the vial was ushed with Ar for one minute. Then, 20 mL of a stock solution of catalyst was added via a syringe and the resulting mixture stirred and ushed with Ar for a few minutes. Next, the Greenchem or high-pressure vessel was sealed. 6 Greenchem or high-pressure vessels lled in this way were then heated to 150 8C in a MARS or microSYNTH platform, respectively. The set power was 600 W. The total irradiation time (including the ramp time to the set temperature) was 10 min. After the rotor was cooled down to room temperature the vessels were opened, the contents of the 6 vessels combined, ltered over Celite and rinsed well with dichloromethane. The ltrate was subsequently evaporated under reduced pressure and the residue puried by ash column chromatography on silica gel.

Stock solution of catalyst, A 250 mL bottle (Schott) was charged with Pd(OAc)2 (0.314 g, 1.40 mmol), 2-(dicyclohexylphosphanyl)biphenyl (DCPB) (0.981 g, 2.8 mmol) and BTF (70 mL) in air. Subsequently, the bottle was ushed with Ar for 10 min under magnetic stirring.

10348

K. T. J. Loones et al. / Tetrahedron 61 (2005) 1033810348

7. For small scale microwave-assisted Pd-catalyzed amination of aryl halides see: (a) Shari, A.; Hosseinzadeh, R.; Mirzaei, M. Monatsh. Chem. 2002, 133, 329332. (b) Wan, Y.; Alterman, M.; Hallberg, A. Synthesis 2002, 15971600. (c) Maes, ` B. U. W.; Loones, K. T. J.; Lemiere, G. L. F.; Dommisse, R. A. Synlett 2003, 18221824. (d) Wang, T.; Magnin, D. R.; Hamann, L. G. Org. Lett. 2003, 5, 897900. (e) Antane, S. Synth. Commun. 2003, 33, 21452149. (f) Burton, G.; Cao, P.; Li, G.; Rivero, R. Org. Lett. 2003, 5, 43734376. (g) Weigand, K.; Pelka, S. Mol. Divers. 2003, 7, 181184. (h) McCarroll, A. J.; Sandham, D. A.; Titcomb, L. R.; de K. Lewis, A. K.; Cloke, F. G. N.; Davies, B. P.; de Santana, A. P.; Hiller, W.; Caddick, S. Mol. Divers. 2003, 7, 115123. (i) Brain, C. T.; Steer, J. T. J. Org. Chem. 2003, 68, 68146816. (j) Jensen, T. A.; Liang, X. F.; Tanner, D.; Skjaerbaek, N. J. Org. Chem. 2004, 69, 49364947. (k) Harmata, M.; Hong, X.; Ghosh, S. K. Tetrahedron Lett. 2004, 45, 52335236. (l) Maes, B. U. W.; Loones, K. T. J.; Hostyn, S.; Diels, G.; Rombouts, G. Tetrahedron 2004, 60, 1155911564. (m) Poondra, R. R.; Turner, N. J. Org. Lett. 2005, 7, 863866. 8. For reviews on palladium-catalyzed amination see: (a) Baranano, D.; Mann, G.; Hartwig, J. F. Curr. Org. Chem. 1997, 1, 287305. (b) Frost, C. G.; Mendonca, P. J. Chem. Soc., Perkin Trans. 1 1998, 26152623. (c) Hartwig, J. F. Angew. Chem., Int. Ed. 1998, 37, 20472067. (d) Yang, B. H.; Buchwald, S. L. J. Organomet. Chem. 1999, 576, 125146. (e) Hartwig, J. F. In Modern Amination Methods; Ricci, A., Ed.; Wiley-VCH: Weinheim, 2000; pp 195262. (f) Muci, A. R.; Buchwald, S. L. Top. Curr. Chem. 2002, 219, 131209. For reviews containing a part on recent progress made in palladium-catalyzed amination see: (g) Littke, A. F.; Fu, G. C. Angew. Chem., Int. Ed. 2002, 41, 41764211. (h) Prim, D.; Campagne, J.-M.; Joseph, D.; Andrioletti, B. Tetrahedron 2002, 58, 20412075. (i) Wolfe, J. P.; Thomas, J. S. Curr. Org. Chem. 2005, 9, 625655. For a review dealing with palladium-catalyzed aminations seen from an industrial point of view see: (j) Schlummer, B.; Scholz, U. Adv. Synth. Catal. 2004, 346, 15991626. 9. For pioneering literature on Buchwalds monodentate phosphine ligands based on a biphenyl backbone see: (a) Old, D. W.; Wolfe, J. P.; Buchwald, S. L. J. Am. Chem. Soc. 1998, 120, 97229723. (b) Wolfe, J. P.; Buchwald, S. L. Angew. Chem., Int. Ed. 1999, 38, 24132416. (c) Wolfe, J. P.; Tomori, H.; Sadighi, J. P.; Yin, J.; Buchwald, S. L. J. Org. Chem. 2000, 65, 11581174. 10. Gabriel, C.; Gabriel, S.; Grant, E. H.; Halstead, B. S. J.; Mingos, D. M. P. Chem. Soc. Rev. 1998, 27, 213223. 11. The maximum power measurement method the manufacturers (CEM, Milestone) use to determine the power output of their multi-mode system (MARS, microSYNTH) is different. If the IEC method is used for the MARS platform it delivers a maximum power output of 1500 W instead of 1200 W. The microSYNTH platform delivers a maximum power output of 1000 W following the IEC method. This means one should take into account that the compared heating proles, resulting from power/time experiments performed at the same constant power output in the MARS and microSYNTH platform, give only a rough indication of the difference in performance of both multi-modes. Working at the same set constant power output in both multi-mode platforms is in reality actually not

12.

13.

14.

15.

16.

17.

working at the same power. The maximum power measurement method used to determine the power output of the singlemode Discover unit (CEM) is also different so comparing heating proles, resulting from power/time experiments performed at the same constant power output in a multimode or single-mode platform, gives also only a rough indication of the difference in performance of the microwave systems. Working at the same set constant power output in both platforms is in reality actually not working at the same power. In addition, for all commercial microwaves (singlemode and multi-mode) there is a nominal power. Not all units of a certain type produce exactly the same power so even comparison between two units can be tricky (MARS G15%, microSYNTH G10%, Discover G10%). Microwave power measurement: (1) MARS (1200 W): heat 1 L of water (Tinitial: 1822 8C) in a beaker for 2 min at the maximum power of the microwave and determine the temperature difference of the water; power in WattsZ35 (TnalKTinitial); (2) microSYNTH (1000 W): heat 1 L of water (Tinitial: around 10 8C) for 1 min in a beaker at the maximum power of the microwave and determine the temperature difference of the water; power in WattsZ70 (TnalKTinitial); (3) Discover (300 W): heat 50 mL of water (Tinitial: 1822 8C) for 30 s in a 100 mL roundbottomed ask at the maximum power of the microwave and determine the temperature difference of the water; Power in WattsZ7 (TnalKTinitial). For the heating proles (IR) of quartz and glass vessels lled with microwave transparent CCl4 measured in a Smith Synthesizer (Personal Chemistry) see: Garbacia, S.; Desai, B.; Lavastre, O.; Kappe, C. O. J. Org. Chem. 2003, 68, 91369139. Lecture of N. Moorcroft presented at the 2nd International Microwaves in Chemistry Conference, Orlando (USA), 4/3 7/3 2004. Use of BTF as solvent in organic synthesis: Maul, J. J.; Ostrowski, P. J.; Ublacker, G. A.; Linclau, B.; Curran, D. P. Top. Curr. Chem. 1999, 206, 79105. For the amination of 4-chloroanisole with morpholine we also attempted to scale-up with a factor 36 (36 mmol 4-chloroanisole, 43.2 mmol morpholine, 50.4 mmol NaOt-Bu, 36 mL BTF) in the 80 mL vessel of the Discover apparatus. In the same reaction time as for the 1 mmol and 20 mmol experiments (10 min) an isolated yield of 73% of 4-(4methoxyphenyl)morpholine could be obtained. This is similar to the yield obtained on a 1 mmol scale (78%) but lower than the isolated yield of the 20 mmol experiment (85%). (a) Trifonov, L. S.; Orahovats, A. S. Helv. Chim. Acta 1987, 70, 17321736. (b) OConnor, S. J.; Barr, K. J.; Wang, Le.; Sorensen, B. K.; Tasker, A. S.; Sham, H.; Ng, S.-C.; Cohen, J.; Devine, E.; Cherian, S.; Saeed, B.; Zhang, H.; Lee, J. Y.; Warner, R.; Tahir, S.; Kovar, P.; Ewing, P.; Alder, J.; Mitten, M.; Leal, J.; Marsh, K.; Bauch, J.; Hoffman, D. J.; Sebti, S. M.; Rosenberg, S. H. J. Med. Chem. 1999, 42, 37013710. Recently, Buchwald and co-workers reported that by stirring a mixture of Pd(OAc)2 and DTPB in toluene for 16 h at room temperature a palladacycle is formed. In consequence of this report, we always stirred our stock solution of Pd(OAc)2 and DTPB for at least 16 h before using it: Zim, D.; Buchwald, S. L. Org. Lett. 2003, 5, 24132415.

Вам также может понравиться

- Antonio de La Hoz, Angel Diaz-Ortiz and Andres Moreno - Microwaves in Organic Synthesis. Thermal and Non-Thermal Microwave EffectsДокумент15 страницAntonio de La Hoz, Angel Diaz-Ortiz and Andres Moreno - Microwaves in Organic Synthesis. Thermal and Non-Thermal Microwave EffectsNstm3Оценок пока нет

- Danielle L. Jacobs - Microwave Assisted Organic SynthesisДокумент28 страницDanielle L. Jacobs - Microwave Assisted Organic SynthesisNstm3Оценок пока нет

- Anic Chemistry ReviewДокумент59 страницAnic Chemistry ReviewEnrica GaОценок пока нет

- C. Oliver Kappe - Microwave-Enhanced Chemistry - Enabling Technology Revolutionising Organic Synthesis and Drug DiscoveryДокумент5 страницC. Oliver Kappe - Microwave-Enhanced Chemistry - Enabling Technology Revolutionising Organic Synthesis and Drug DiscoveryNstm3Оценок пока нет

- Jonathan M. Collins and Nicholas E. Leadbeater - Microwave Energy: A Versatile Tool For The BiosciencesДокумент10 страницJonathan M. Collins and Nicholas E. Leadbeater - Microwave Energy: A Versatile Tool For The BiosciencesNstm3Оценок пока нет

- C. Oliver Kappe and Doris Dallinger - The Impact of Microwave Synthesis On Drug DiscoveryДокумент14 страницC. Oliver Kappe and Doris Dallinger - The Impact of Microwave Synthesis On Drug DiscoveryNstm3Оценок пока нет

- Bernadett Bacsa Et Al - Rapid Solid-Phase Peptide Synthesis Using Thermal and Controlled Microwave IrradiationДокумент6 страницBernadett Bacsa Et Al - Rapid Solid-Phase Peptide Synthesis Using Thermal and Controlled Microwave IrradiationNstm3Оценок пока нет

- Peakdale Molecular - Microwave Chemistry ServicesДокумент2 страницыPeakdale Molecular - Microwave Chemistry ServicesNstm3Оценок пока нет

- R. R. Gupta - Topics in Heterocyclic Chemistry: Microwave-Assisted Synthesis of HeterocyclesДокумент14 страницR. R. Gupta - Topics in Heterocyclic Chemistry: Microwave-Assisted Synthesis of HeterocyclesNstm30% (1)

- Jonathan D. Moseley - Microwave Synthesis in Process Chemistry: Method, Scale and ScopeДокумент4 страницыJonathan D. Moseley - Microwave Synthesis in Process Chemistry: Method, Scale and ScopeNstm3Оценок пока нет

- Gheorghiţă N. Zbancioc Et Al - Microwave-Assisted Synthesis of Aromatic Bis-Esters in Liquid PhaseДокумент6 страницGheorghiţă N. Zbancioc Et Al - Microwave-Assisted Synthesis of Aromatic Bis-Esters in Liquid PhaseNstm3Оценок пока нет

- Naser M. Alandis - Evidence of Formation of Hydrogen Peroxide by Radical Reaction Induced by Microwave Irradiation of Sodium HydroxideДокумент3 страницыNaser M. Alandis - Evidence of Formation of Hydrogen Peroxide by Radical Reaction Induced by Microwave Irradiation of Sodium HydroxideNstm3Оценок пока нет

- Bernadett Bacsa Et Al - Rapid Solid-Phase Synthesis of A Calmodulin-Binding Nonapeptide Using Thermal and Controlled Microwave IrradiationДокумент1 страницаBernadett Bacsa Et Al - Rapid Solid-Phase Synthesis of A Calmodulin-Binding Nonapeptide Using Thermal and Controlled Microwave IrradiationNstm3Оценок пока нет

- Marian Risca Et Al - Microwave Assisted Reactions of Imidazole Derivatives of Potential Practical ApplicationsДокумент3 страницыMarian Risca Et Al - Microwave Assisted Reactions of Imidazole Derivatives of Potential Practical ApplicationsNstm3Оценок пока нет

- Zoubida Chemat-Djenni Et Al - Atmospheric Pressure Microwave Assisted Heterogeneous Catalytic ReactionsДокумент11 страницZoubida Chemat-Djenni Et Al - Atmospheric Pressure Microwave Assisted Heterogeneous Catalytic ReactionsNstm3Оценок пока нет

- C. Oliver Kappe - Microwaves in Organic Chemistry: From Laboratory Curiosity To Standard Practice in 25 YearsДокумент2 страницыC. Oliver Kappe - Microwaves in Organic Chemistry: From Laboratory Curiosity To Standard Practice in 25 YearsNstm3Оценок пока нет

- AppendixДокумент3 страницыAppendixNstm3Оценок пока нет

- Chapter 6 - Safety Precautions On The Application of Microwaves in LaboratoryДокумент4 страницыChapter 6 - Safety Precautions On The Application of Microwaves in LaboratoryNstm3Оценок пока нет

- Jianming Dai - Microwave-Assisted Extraction and Synthesis Studies and The Scale-Up Study With The Aid of FDTF SimulationДокумент281 страницаJianming Dai - Microwave-Assisted Extraction and Synthesis Studies and The Scale-Up Study With The Aid of FDTF SimulationNstm3Оценок пока нет

- Process Intensification: Oxidation of Benzyl Alcohol Using A Continuous Isothermal Reactor Under Microwave IrradiationДокумент5 страницProcess Intensification: Oxidation of Benzyl Alcohol Using A Continuous Isothermal Reactor Under Microwave IrradiationNstm3Оценок пока нет

- Chapter 3 - Microwave EquipmentДокумент10 страницChapter 3 - Microwave EquipmentNstm3Оценок пока нет

- Argonaut Technologies - Literature Review: An Overview of Microwave-Assisted Organic Synthesis Using Polymer-Supported Reagents and Scavengers: Part 1Документ4 страницыArgonaut Technologies - Literature Review: An Overview of Microwave-Assisted Organic Synthesis Using Polymer-Supported Reagents and Scavengers: Part 1Nstm3Оценок пока нет

- ReferencesДокумент4 страницыReferencesNstm3Оценок пока нет

- Dariusz Bogdal and Aleksander Prociak - Microwave Synthesis of Polymeric Materials: Scale Up and Commercial AspectsДокумент3 страницыDariusz Bogdal and Aleksander Prociak - Microwave Synthesis of Polymeric Materials: Scale Up and Commercial AspectsNstm3Оценок пока нет

- Use of Alternative Energy Sources For The Initiation and Execution of Chemical Reactions and ProcessesДокумент21 страницаUse of Alternative Energy Sources For The Initiation and Execution of Chemical Reactions and ProcessesNstm3Оценок пока нет

- IndexДокумент4 страницыIndexNstm3Оценок пока нет

- Chapter 4 - Reaction Vessels and GlasswareДокумент5 страницChapter 4 - Reaction Vessels and GlasswareNstm3Оценок пока нет

- Chapter 5 - Techniques For Conducting Chemical Reactions Under Microwave Irradiation.Документ4 страницыChapter 5 - Techniques For Conducting Chemical Reactions Under Microwave Irradiation.Nstm3Оценок пока нет

- Chapter 7 - Reactions Conditions Under MicrowaveДокумент144 страницыChapter 7 - Reactions Conditions Under MicrowaveNstm3Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- PH Eur 1433 Herbal DrugsДокумент2 страницыPH Eur 1433 Herbal DrugsLuisSanabriaSaavedra0% (1)

- 2002 Guizard - Potentiality of Organic Solvents Filtration With Ceramic MembranesДокумент6 страниц2002 Guizard - Potentiality of Organic Solvents Filtration With Ceramic MembranesericconchamunozОценок пока нет

- HS5671 GDRBRXДокумент916 страницHS5671 GDRBRXDeepakОценок пока нет

- MT201 Lab - 1 - Lab Safety, PH, and BuffersДокумент4 страницыMT201 Lab - 1 - Lab Safety, PH, and BuffersTob MoradosОценок пока нет

- Absorption SumaДокумент6 страницAbsorption SumaLulav BarwaryОценок пока нет

- Organic Chemistry Practical ReportДокумент17 страницOrganic Chemistry Practical ReportSteffi YapОценок пока нет

- The Puraq Seawater Desalination Process - An UpdateДокумент16 страницThe Puraq Seawater Desalination Process - An UpdateMD Omar FarukОценок пока нет

- Lab 8 Solubility-1Документ4 страницыLab 8 Solubility-1FNSA Region 5Оценок пока нет

- Myriophyllum SibiricumДокумент15 страницMyriophyllum SibiricumEric GozzerОценок пока нет

- Lichtenthal Er 1987Документ33 страницыLichtenthal Er 1987Gabriel EspinozaОценок пока нет

- Contreras Et Al. - 2008 - Propensity of Lignin To Associate Light Scattering Photometry Study With Native Lignins Propensity of Lignin PDFДокумент9 страницContreras Et Al. - 2008 - Propensity of Lignin To Associate Light Scattering Photometry Study With Native Lignins Propensity of Lignin PDFThiago YukiОценок пока нет

- Topic 3Документ22 страницыTopic 3Salna Susan AbrahamОценок пока нет

- PT - Science 6 - Q1Документ8 страницPT - Science 6 - Q1ROWENA PANDACОценок пока нет

- Supercritical Fluid ExtractionДокумент37 страницSupercritical Fluid ExtractionNASUKHA RIFAI RIFAIОценок пока нет

- EN NA Tyvek (R) Graphics Printing&Technical Guide 2018Документ40 страницEN NA Tyvek (R) Graphics Printing&Technical Guide 2018amitleckОценок пока нет

- World's Largest Refinery Starts UpДокумент5 страницWorld's Largest Refinery Starts UpSteve WanОценок пока нет

- Chapter 4 Cheat Sheet on Solutions, Ionic Compounds, Acid-Base ReactionsДокумент4 страницыChapter 4 Cheat Sheet on Solutions, Ionic Compounds, Acid-Base ReactionsArianne FosterОценок пока нет

- Especificaciones SSPC y Definiciones SP1-SPX PDFДокумент32 страницыEspecificaciones SSPC y Definiciones SP1-SPX PDFjorgelunaОценок пока нет

- Producing Highly Purified Acrylic AcidДокумент13 страницProducing Highly Purified Acrylic AcidArdian SyahОценок пока нет

- 03 1 TD3100 Manual TraningДокумент38 страниц03 1 TD3100 Manual TraningPhit Nguyen Viet100% (1)

- Pro Duk IndustriДокумент40 страницPro Duk IndustriJamilah EdwardОценок пока нет

- B - Kelompok 2 - GAS, VAPORS & SOLVENTДокумент19 страницB - Kelompok 2 - GAS, VAPORS & SOLVENTAlya RosaliОценок пока нет

- A Review On Proniosomes Drug Delivery: An Innovative ApproachДокумент13 страницA Review On Proniosomes Drug Delivery: An Innovative ApproachGaurav ShuklaОценок пока нет

- Liquid-Liquid Extraction Using The UNIQUAC ModelДокумент9 страницLiquid-Liquid Extraction Using The UNIQUAC Modelpardise4000Оценок пока нет

- Quick Exam Notes NA Science Chemistry PDFДокумент88 страницQuick Exam Notes NA Science Chemistry PDFMaverickОценок пока нет

- Aerosol Spray Paint SDSДокумент14 страницAerosol Spray Paint SDSSPG MAN MAGОценок пока нет

- Basic Protocol: Silanizing GlasswareДокумент2 страницыBasic Protocol: Silanizing GlasswareJenncardОценок пока нет

- D 5001 - 90a R95 Ball-on-Cylinder Lubricity EvaluatorДокумент6 страницD 5001 - 90a R95 Ball-on-Cylinder Lubricity Evaluatoreduardoperez.uniОценок пока нет

- 005 Primo Collection 1Документ28 страниц005 Primo Collection 1vihar aslaliyaОценок пока нет

- 95 843 Xiameter Ofx 0531 FluidДокумент5 страниц95 843 Xiameter Ofx 0531 FluidMau RoОценок пока нет