Академический Документы

Профессиональный Документы

Культура Документы

Toolholder BT DV CAT HSK Shank Standard

Загружено:

SimonАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Toolholder BT DV CAT HSK Shank Standard

Загружено:

SimonАвторское право:

Доступные форматы

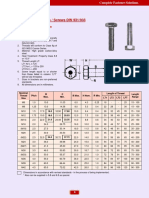

Standard Table dimensions

BT MAS 403

MAS 403 Japanese Standard

Taper A G L L1 L2 T

BT30 46.0 31.75 48.4 22.0 2.0 M12

BT35 53.0 38.10 56.5 22.0 2.0 M12

BT40 63.0 44.45 65.4 27.0 2.0 M16

BT50 100.0 69.85 101.8 38.0 3.0 M24

DV DIN 69871 A & B

DIN 69871 Form 'A'

Taper A B G L T

DV30 49.95 45.0 31.75 47.65 M12

DV40 63.50 50.0 44.45 68.25 M16

DV45 82.50 63.0 57.15 82.55 M20

DV50 97.45 80.0 69.85 101.60 M24

DIN 69871 Form'B'

Taper A B G L F T

DV40 63.50 50.0 44.45 68.25 27.0 M16

DV50 97.45 80.0 69.85 101.60 42.0 M24

Tel: +44(0) 24 7664 5999 A6 Email: info@coventrytoolholders.co.uk

CAT/ANSI B5.50

CAT/ANSI B5.50

Taper A B G L T

CV40 63.50 44.45 44.45 68.25 M16

CV50 96.38 69.85 69.85 101.60 M24

ISO TAPERS

ISO Tapers

QC30 & QC40 shanks have flanges to suit B.E. Quick Change spindles

Taper A G L L1 L2 T

QC30 46.0 31.75 68.33 8.74 1.96 M12

QC40 63.5 44.45 93.73 7.95 1.93 M16

IT401 64.0 44.45 93.73 8.15 1.83 5/8"UNC

DT50 97.2 69.85 126.8 12.0 3.2 M24

R8 TAPER

Tel: +44(0) 24 7664 5999 A7 Email: info@coventrytoolholders.co.uk

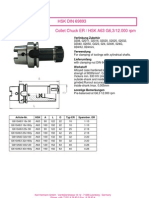

HSK DIN 69893 A

DIN 69893-1:1996-01- Form ‘A’ general purpose

Standard type for use on milling

machines and milling centres with

automatic tool change. Also suitable

for manual tool change.

Toolholder supplied less coolant tube

assembly which must be ordered

separately.

HSK DIN 69893 Form ‘A’

Taper A B C G D1 D2 L L1 L2 L3 L4 S1 T

HSK32A 32.0 26.0 21.0 24.0 9.0 7.0 16.0 35.0 8.92 20.0 3.2 13.0 M10x1.0

HSK40A 40.0 34.0 25.5 30.0 11.0 9.0 20.0 35.0 11.42 20.0 4.0 17.0 M12x1.0

HSK50A 50.0 42.0 32.0 38.0 14.0 12.0 25.0 42.0 14.13 26.0 5.0 21.0 M16x1.0

HSK63A 63.0 53.0 40.0 48.0 18.0 16.0 32.0 42.0 18.13 26.0 6.3 26.5 M18x1.0

HSK80A 80.0 67.0 50.0 60.0 20.0 18.0 40.0 42.0 22.85 26.0 8.0 34.0 M20x1.0

HSK100A 100.0 85.0 63.0 75.0 22.0 20.0 50.0 45.0 28.56 29.0 10.0 44.0 M24x1.0

HSK125A 125.0 105.0 80.0 95.0 28.0 25.0 63.0 45.0 36.27 29.0 12,5 55.5 M30x1.0

HSK160A 160.0 130.0 100.0 120.0 36.0 32.0 80.0 47.0 45.98 31.0 16.0 72.0 M35x1.0

HSK DIN 69893 C

DIN 69893-1:1996-01- Form ‘C’ manual shank

HSK DIN 69893 Form 'C'

Taper A C G L L2 L3 L4

HSK32C 32.0 21.0 24.0 16.0 8.92 10.0 3.2

HSK40C 40.0 25.5 30.0 20.0 11.42 10.0 4.0

HSK50C 50.0 32.0 38.0 25.0 14.13 12.5 5.0

HSK63C 63.0 40.0 48.0 32.0 18.13 12.5 6.3

HSK80C 80.0 50.0 60.0 40.0 22.85 16.0 8.0

Manual tool change type only

HSK100C 100.0 63.0 75.0 50.0 28.56 16.0 10.0 For use as a modular system

For special purpose machines

For transfer lines and lathes.

Coolant supply through the centre.

Tel: +44(0) 24 7664 5999 A8 Email: info@coventrytoolholders.co.uk

HSK DIN 69893 E

DIN 69893-1:1996-01- Form ‘E’ high speed applications

High speed applications for automatic tool change.

Option coolant fitting as form ‘A’

Note: No rear drive slots, no slots or notches in the

flange.

Toolholder supplied less coolant tube assembly

which must be ordered separately.

HSK DIN 69893 Form ‘E’

Taper A B C G L L1 L2 L3 L4 T

HSK25E 25.0 20.0 16.4 19.0 13.0 20.0 7.21 10.0 2.5 -

HSK32E 32.0 26.0 21.0 24.0 16.0 35.0 8.92 20.0 3.2 M10x1.0

HSK40E 40.0 34.0 25.5 30.0 20.0 35.0 11.42 20.0 4.0 M12x1.0

HSK50E 50.0 42.0 32.0 38.0 25.0 42.0 14.13 26.0 5.0 M16x1.0

HSK63E 63.0 53.0 40.0 48.0 32.0 42.0 18.13 26.0 6.3 M18x1.0

HSK DIN 69893 B

DIN 69893-1:1996-01- Form ‘B’ coolant through the flange with automatic tool change

Coolant supply through the flange

Enlarged flange diameter for rigidity

Drive slots are in the flange

For use on milling machines and lathes

Machining centres with automatic tool change

HSK DIN 69893 Form ‘B’

Taper A B C G D1 L L1 L2 L3 L4 S1

HSK40B 40.0 34.0 21.0 24.0 10.0 16.0 35.0 8.92 20.0 3.2 16.0

HSK50B 50.0 42.0 25.5 30.0 12.0 20.0 42.0 11.42 26.0 4.0 20.0

HSK63B 63.0 53.0 32.0 38.0 16.0 25.0 42.0 14.13 26.0 5.0 25.0

HSK80B 80.0 67.0 40.0 48.0 18.0 32.0 42.0 18.13 26.0 6.3 31.5

HSK100B 100.0 85.0 50.0 60.0 20.0 40.0 45.0 22.85 29.0 8.0 40.0

HSK125B 125.0 105.0 63.0 75.0 25.0 50.0 45.0 28.56 29.0 10.0 50.0

HSK160B 160.0 130.0 80.0 95.0 32.0 63.0 47.0 36.27 31.0 12.5 62.5

Tel: +44(0) 24 7664 5999 A9 Email: info@coventrytoolholders.co.uk

HSK DIN 69893 D

DIN 69893-1:1996-01- Form ‘D’ coolant through the flange

Manual change Coolant supply through the flange

Enlarged flange diameter for rigidity

Drive slots are in the flange

For use on milling machines, lathes

drilling and grinding machines, with

manual tool change

HSK DIN 69893 Form ‘D’

Taper A C G D1 L L1 L2 L4 S1

HSK40D 40.0 21.0 24.0 10.0 16.0 20.0 8.92 3.2 16.0

HSK50D 50.0 25.5 30.0 12.0 20.0 26.0 11.42 4.0 20.0

HSK63D 63.0 32.0 38.0 16.0 25.0 26.0 14.13 5.0 25.0

HSK80D 80.0 40.0 48.0 18.0 32.0 26.0 18.13 6.3 31.5

HSK100D 100.0 50.0 60.0 20.0 40.0 29.0 22.85 8.0 40.0

HSK DIN 69893 F

DIN 69893-1:1996-01- Form ‘F’ high speed applications

Automatic tool High speed applications

change Enlarged flange diameter for rigidity

No drive slots

Symmetrical design

For use on machines with automatic

tool change

HSK DIN 69893 Form ‘F’

Taper A B C G L L1 L2 L3 L4

HSK50F 50.0 42.0 25.5 30.0 20.0 42.0 11.42 26.0 4.0

HSK63F 63.0 53.0 32.0 38.0 25.0 42.0 14.13 26.0 5.0

Tel: +44(0) 24 7664 5999 A10 Email: info@coventrytoolholders.co.uk

Вам также может понравиться

- Surface Finish ChartsДокумент5 страницSurface Finish ChartsagssugaОценок пока нет

- Roll PinsДокумент8 страницRoll Pinshemanth337Оценок пока нет

- Diamond DA 42 Systems - V12 - 5clases 19 de JunioДокумент402 страницыDiamond DA 42 Systems - V12 - 5clases 19 de JunioLiu Antonio Tang100% (1)

- Analysis of The Yokeless and Segmented Armature MachineДокумент7 страницAnalysis of The Yokeless and Segmented Armature MachineSeksan KhamkaewОценок пока нет

- Asme Y1441Документ45 страницAsme Y1441Lucas SalasОценок пока нет

- 12 Machinery EbookДокумент135 страниц12 Machinery EbookPimen AjjahОценок пока нет

- Precision machining parametersДокумент1 страницаPrecision machining parametersjok1974Оценок пока нет

- Complete Fastener Solutions Hexagon BoltsДокумент2 страницыComplete Fastener Solutions Hexagon Boltscoolkaisy100% (2)

- Handbook Prototyp Threading UsДокумент124 страницыHandbook Prototyp Threading UsRobotОценок пока нет

- HSK DIN 69893 enДокумент29 страницHSK DIN 69893 enalphatoolsОценок пока нет

- Screw ThreadsДокумент37 страницScrew ThreadsOmkaar SinghОценок пока нет

- Ns-En 13001-3-6Документ64 страницыNs-En 13001-3-6WojciechОценок пока нет

- Spiral Wound GasketsДокумент7 страницSpiral Wound GasketsPrem NautiyalОценок пока нет

- Titanium DRILLINGДокумент50 страницTitanium DRILLINGDome StoiОценок пока нет

- Honing Machine Actuated by ServomotorДокумент45 страницHoning Machine Actuated by ServomotorNissan PatelОценок пока нет

- Tesi Poligono P3GДокумент172 страницыTesi Poligono P3Ger_sor_magaraОценок пока нет

- Helicoil Catalog - hc2000 Rev.5Документ36 страницHelicoil Catalog - hc2000 Rev.5Hugo CastroОценок пока нет

- Static Electricity and Charge AccumulationДокумент75 страницStatic Electricity and Charge AccumulationArjav DesaiОценок пока нет

- Calibration of stylus instruments for roughness measurementДокумент11 страницCalibration of stylus instruments for roughness measurementsandeepОценок пока нет

- Tapping ChucksДокумент14 страницTapping ChucksDHAMODHARANОценок пока нет

- Broaches - Basic CharacteristicДокумент5 страницBroaches - Basic CharacteristicDhan CОценок пока нет

- PRO E LibraryДокумент11 страницPRO E LibrarygokulahbОценок пока нет

- Hotpoint Service Manual Fridge FreezerДокумент36 страницHotpoint Service Manual Fridge FreezerMANUEL RODRIGUEZ HERRERA100% (1)

- Gears HoningДокумент7 страницGears Honingsav33Оценок пока нет

- ABRASIVES: Belts, Coils, Sheets, Burrs, Discs, Wheels & MoreДокумент192 страницыABRASIVES: Belts, Coils, Sheets, Burrs, Discs, Wheels & Moresfi_chennaiОценок пока нет

- Astm B187Документ9 страницAstm B187Plata Elpidio100% (3)

- Surface Roughness Parameters - EN - 2009 PDFДокумент2 страницыSurface Roughness Parameters - EN - 2009 PDFRakesh CОценок пока нет

- ICTM Standard ToolingДокумент12 страницICTM Standard ToolingAmshgautamОценок пока нет

- Synopsis of ISO Standards For AnodizingДокумент6 страницSynopsis of ISO Standards For AnodizingHoang TanОценок пока нет

- Tolerance Charting PDFДокумент7 страницTolerance Charting PDFSudeep Kumar SinghОценок пока нет

- Design and Development of An Octagonal Strain Ring Based Load Cell - 2Документ16 страницDesign and Development of An Octagonal Strain Ring Based Load Cell - 2Arunava ChoudhuryОценок пока нет

- Manufacturing Tolerance Chart GuideДокумент38 страницManufacturing Tolerance Chart GuideParthi ParthipanОценок пока нет

- Self Tapping Screw StandardsДокумент4 страницыSelf Tapping Screw StandardsVino KumarОценок пока нет

- Technology of Machine ToolsДокумент60 страницTechnology of Machine ToolsMayank SharmaОценок пока нет

- Drafting ThreadsДокумент15 страницDrafting Threadsm_stasys9939Оценок пока нет

- Catalog Strunguri Pentru Lemn - August 2013Документ11 страницCatalog Strunguri Pentru Lemn - August 2013Expert Masini UnelteОценок пока нет

- UNF ThreadДокумент4 страницыUNF ThreadMUUTHUKRISHNANОценок пока нет

- Bossard Taptite Self Tapping Screw CatalogueДокумент10 страницBossard Taptite Self Tapping Screw CataloguepmlmkpОценок пока нет

- Effect of Microstructure On Mechanical Properties of High Strength Steel Weld MetalsДокумент72 страницыEffect of Microstructure On Mechanical Properties of High Strength Steel Weld MetalsGökhan Altin100% (1)

- Cone Tolerance PDFДокумент21 страницаCone Tolerance PDFsosu_sorin3904Оценок пока нет

- Auto Collimator SДокумент7 страницAuto Collimator SRamanjooloo DeelanОценок пока нет

- SSAB Machining Strenx 2017Документ28 страницSSAB Machining Strenx 2017RogerОценок пока нет

- Limit Gauge PDFДокумент11 страницLimit Gauge PDFParamasivam VeerappanОценок пока нет

- Milling Machine OperationsДокумент7 страницMilling Machine OperationsSachinОценок пока нет

- Phu Tung YokeДокумент19 страницPhu Tung YokeAnh TranОценок пока нет

- Kinkelder StandardДокумент24 страницыKinkelder StandardJason StephensОценок пока нет

- Products GuideДокумент12 страницProducts GuideWK SinnОценок пока нет

- HeliCoil Insert Specs MetricДокумент1 страницаHeliCoil Insert Specs MetricAce Industrial SuppliesОценок пока нет

- Schallater Gaas80 Gaa100 DownloadДокумент4 страницыSchallater Gaas80 Gaa100 DownloadRakesh SrivastavaОценок пока нет

- ISO 8015-85 (Engelsk Ver.)Документ7 страницISO 8015-85 (Engelsk Ver.)Peter Bruun100% (1)

- Production - Technology Lab Manual 181903Документ29 страницProduction - Technology Lab Manual 181903jhpatelОценок пока нет

- 5.1 Chordal Tooth Thickness MeasurementДокумент20 страниц5.1 Chordal Tooth Thickness Measurementsharma RISHIОценок пока нет

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987От EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonОценок пока нет

- A Review For Cutting Forces and Stresses in Circular SawsДокумент5 страницA Review For Cutting Forces and Stresses in Circular SawsPaolo RossiОценок пока нет

- Stress-Strain GraphДокумент10 страницStress-Strain GraphEzy WaqaОценок пока нет

- SSAB - 912 en Bending of High Strength Steel PDFДокумент8 страницSSAB - 912 en Bending of High Strength Steel PDFchristos032Оценок пока нет

- Ansi Asme Asa B18 11 1961 R 2005 PDFДокумент11 страницAnsi Asme Asa B18 11 1961 R 2005 PDFSebastiánОценок пока нет

- HeliCoil Insert Specs ImperialДокумент1 страницаHeliCoil Insert Specs ImperialAce Industrial SuppliesОценок пока нет

- How To Determine The Arc Stability Marjan SubanДокумент7 страницHow To Determine The Arc Stability Marjan SubanMarjan Suban100% (1)

- Cutting Data Catalogue PDFДокумент138 страницCutting Data Catalogue PDFlyxuandatbkОценок пока нет

- Ventpro: Dimensional and Electrical DataДокумент15 страницVentpro: Dimensional and Electrical DataManuelОценок пока нет

- 05 - 03 - C - High Torque ChuckДокумент27 страниц05 - 03 - C - High Torque Chuckce.mirelessepulvedaОценок пока нет

- HVM Technical ManualДокумент18 страницHVM Technical ManualSindhu PandreОценок пока нет

- Glands File PDFДокумент30 страницGlands File PDFJyoti ShekharОценок пока нет

- The Existence of An External Redundancy ASM DiskgroupДокумент55 страницThe Existence of An External Redundancy ASM Diskgroupsidd_aish@yahoo.comОценок пока нет

- Spec Oem National 300qДокумент2 страницыSpec Oem National 300qJose Javier GamaОценок пока нет

- Pneumatic Actuator Eb-Syd, Double Acting Pneumatic Actuator Eb-Syd, Double ActingДокумент4 страницыPneumatic Actuator Eb-Syd, Double Acting Pneumatic Actuator Eb-Syd, Double ActingYi WUОценок пока нет

- Best Practices in PL/SQL: Karthikeyan MДокумент15 страницBest Practices in PL/SQL: Karthikeyan MranusofiОценок пока нет

- Nexans - MPRX (2002)Документ63 страницыNexans - MPRX (2002)Dan Ghimbasanu0% (1)

- Geotech Final ReportДокумент38 страницGeotech Final Reportapi-320590292Оценок пока нет

- Heat Exchangers: T T T TДокумент11 страницHeat Exchangers: T T T Tcjc0706Оценок пока нет

- Acoples Lovejoy (Rejilla - Grid, 8 Pág.)Документ8 страницAcoples Lovejoy (Rejilla - Grid, 8 Pág.)marcelo castilloОценок пока нет

- Bulb Flat Sizes, Dimensions and Weight - Steel Bulb Flats - Weight Table - Rushmore Enterprises IncДокумент3 страницыBulb Flat Sizes, Dimensions and Weight - Steel Bulb Flats - Weight Table - Rushmore Enterprises IncHerlambang Miracle YudhianОценок пока нет

- PHCbi Refrigerators MPRS163 MPRS313Документ2 страницыPHCbi Refrigerators MPRS163 MPRS313Eslam HassanОценок пока нет

- Commsys 2 2012 4Документ47 страницCommsys 2 2012 4AnuОценок пока нет

- Drum Unloading SystemДокумент2 страницыDrum Unloading SystemJas SumОценок пока нет

- Desmodure-Rfe-Tds CROSSLİNKİNG AGENTДокумент2 страницыDesmodure-Rfe-Tds CROSSLİNKİNG AGENTGİZEM DEMİRОценок пока нет

- Emergency Braking SystemДокумент4 страницыEmergency Braking Systemieee4mybusinessonlyОценок пока нет

- Portfolio Isaura SagredoДокумент22 страницыPortfolio Isaura SagredoIsauraОценок пока нет

- Basic Electronics PowerpointДокумент16 страницBasic Electronics PowerpointEarle Sean MendozaОценок пока нет

- High-Efficiency Controllers for Notebook ComputersДокумент28 страницHigh-Efficiency Controllers for Notebook ComputerscОценок пока нет

- LTODriveSCSI - 040809 (GA32-450-10)Документ346 страницLTODriveSCSI - 040809 (GA32-450-10)Eduardo Rodriguez NajarОценок пока нет

- Electrical Machine DesignДокумент2 страницыElectrical Machine DesignAnonymous 1abQZIОценок пока нет

- Price ListДокумент2 страницыPrice ListCHeng SOngco TAlosigОценок пока нет

- Damping FactorДокумент2 страницыDamping FactorAngel Morales MartínezОценок пока нет

- SAP Plant Maintenance User Acceptance TestДокумент7 страницSAP Plant Maintenance User Acceptance TestBagaz KarmawanОценок пока нет

- Review of Antenna Designs for India's Regional Navigation Satellite SystemДокумент9 страницReview of Antenna Designs for India's Regional Navigation Satellite SystemkhyatichavdaОценок пока нет

- Supports For Pipelines 1758uk 7-03-15 PDFДокумент46 страницSupports For Pipelines 1758uk 7-03-15 PDFAndor MolitoriszОценок пока нет

- RCP-15 Drilling Fluid Agitator Parts ListДокумент5 страницRCP-15 Drilling Fluid Agitator Parts ListwaleedОценок пока нет

- Romanian Power Grid Substation Refitting StrategyДокумент16 страницRomanian Power Grid Substation Refitting StrategyParmeshwar MbОценок пока нет