Академический Документы

Профессиональный Документы

Культура Документы

DTC P1345 Crankshaft Position (CKP) - Camshaft Position (CMP) Correlation

Загружено:

Gregorio Pedro CervantesИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DTC P1345 Crankshaft Position (CKP) - Camshaft Position (CMP) Correlation

Загружено:

Gregorio Pedro CervantesАвторское право:

Доступные форматы

Document ID: 188693

Page 1 of 5

1998 Chevrolet Chevy K Pickup - 4WD

Chevy Pickup, GMC Pickup, Suburban, Tahoe, Yukon (VIN C/K) Service Manual

Document ID: 188693

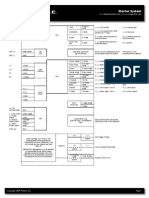

DTC P1345 Crankshaft Position (CKP)-Camshaft Position (CMP) Correlation

Circuit Description

This diagnostic trouble code (DTC) monitors the crankshaft position (CKP) and the camshaft position (CMP) signals to determine if they are synchronized. If both signals are not observed by the control module within a narrow time window, the vehicle control module (VCM) will determine that an error has occurred.

Conditions for Running the DTC

The engine is running

Conditions for Setting the DTC

When the engine is running, the cam sensor reference pulse is not detected at the correct position relative to the crankshaft position sensor pulse.

Action Taken When the DTC Sets

2009 General Motors Corporation. All rights reserved.

http://gsi.xw.gm.com/si/showDoc.do?docSyskey=188693&deliveryEffectiveDate=Jul+1%... 7/17/2009

Document ID: 188693

Page 2 of 5

The control module illuminates the malfunction indicator lamp (MIL) the first time the diagnostic runs and fails. The control module will set the DTC and records the operating conditions at the time the diagnostic fails. The control module stores the failure information in the scan tools Freeze Frame/Failure Records.

Conditions for Clearing the MIL or DTC

The control module turns OFF the MIL after 3 consecutive drive trips when the test has run and passed. A history DTC will clear if no fault conditions have been detected for 40 warm-up cycles. A warm-up cycle occurs when the coolant temperature has risen 22C (40F) from the startup coolant temperature and the engine coolant reaches a temperature that is more than 70 C (158F) during the same ignition cycle. Use a scan tool in order to clear the DTCs.

Diagnostic Aids

Check the following items: A loose CMP sensor causing a variance in the sensor signal Excessive free play in the timing chain and gear assembly Incorrectly installed distributor - 1 tooth off in either advance or retard positions A loose distributor rotor on the distributor shaft A loose or missing distributor hold down bolt An intermittent may be caused by any of the following conditions: A poor connection Rubbed through wire insulation A broken wire inside the insulation Thoroughly check any circuitry that is suspected of causing the intermittent complaint. Refer to Intermittents and Poor Connections Diagnosis in Wiring Systems. If a repair is necessary, refer to Wiring Repairs or Connector Repairs in Wiring Systems.

Test Description

The numbers below refer to the step numbers on the table. 4. This test will determine if this DTC is intermittent. 5. When the engine speed is raised to 2000 RPM the camshaft retard offset should not vary more than 2 degrees. 6. If excessive pressure is used when performing this test unintentional damage to the

http://gsi.xw.gm.com/si/showDoc.do?docSyskey=188693&deliveryEffectiveDate=Jul+1%... 7/17/2009

Document ID: 188693

Page 3 of 5

distributor shaft could result. 7. If the distributor is one tooth off in either the advanced or retard positions the vehicle may run but 0 degrees camshaft retard offset will not be obtained. 8. If 0 degrees cannot be obtained during this procedure refer to Diagnostic Aids. Step Action Important: Before clearing the DTCs, use the scan tool Capture Info to save the Freeze Frame and Failure Records for reference. The control module's data is deleted once the Clear Info function is used. Did you perform the Powertrain On-Board Diagnostic (OBD) System Check? 1. Install the scan tool. 2. Start the engine. 3. Use the scan tool in order to monitor the engine speed. Does the engine speed fluctuate (up to twice the desired RPM)? Replace the Crankshaft Position Sensor. Refer to Crankshaft Position Sensor Replacement . Is the action complete? Perform the Camshaft Retard Offset test procedure as follows: 1. Install the scan tool. 2. Start the engine. Important: The camshaft retard reading will not be accurate below 1000 RPM. 3. Raise the engine speed to the first specified value. 4. Monitor the camshaft retard with the scan tool. Is the camshaft retard reading within the second specified value? 1. Note the camshaft retard reading from the previous step. 2. Raise the engine speed to the first specified value. Does the camshaft retard reading change more than the second specified value? Go to Step 5 Value(s) Yes No

-Go to Step 2

Go to Powertrain On Board Diagnostic (OBD) System Check

-Go to Step 3

Go to Step 4

--

Go to Step 10

--

1000 RPM -2 to 2

Go to Step 6

2000 RPM 2 Go to Step 6 Go to Diagnostic Aids

http://gsi.xw.gm.com/si/showDoc.do?docSyskey=188693&deliveryEffectiveDate=Jul+1%... 7/17/2009

Document ID: 188693

Page 4 of 5

With the engine at operating temperature and the engine OFF, perform the following procedure: 6 1. Remove the distributor cap. 2. Grasp the distributor rotor and gently attempt to rotate the rotor. Does the rotor turn on the distributor shaft? Check for proper installation of the distributor. Repair as necessary. Refer to Distributor Installation in Engine Mechanical. Did you find a problem? Perform the Camshaft Retard Offset adjustment procedure as follows: 1. With the engine OFF slightly loosen the distributor hold down bolt. 2. Start the engine and raise the engine speed to 1000 RPM. 3. Using the scan tool monitor the camshaft retard offset. 4. Rotate the distributor as follows: To compensate for a negative reading rotate the distributor in the counterclockwise direction. To compensate for a positive reading rotate the distributor in the clockwise direction. 5. Repeat step 4 until 0 degrees offset is obtained. 6. When 0 degrees has been obtained turn OFF the ignition and tighten the distributor hold down bolt. Did you obtain 0 degrees camshaft retard? Replace the distributor. Refer to Distributor Replacement in Engine Electrical. Is the action complete? 1. Using the scan tool, clear the DTCs. 2. Start the engine. 3. Allow the engine to idle until the engine reaches normal operating temperature. 4. Select DTC and the Specific DTC function. 5. Enter the DTC number which was set. 6. Operate the vehicle, with the Conditions for Setting this DTC, until the scan tool indicates the diagnostic Ran. Go to Step 10 Go to Diagnostic Aids --

Go to Step 9

Go to Step 7

-Go to Step 10 Go to Step 8

--

--

Go to Step 10

--

10

--

http://gsi.xw.gm.com/si/showDoc.do?docSyskey=188693&deliveryEffectiveDate=Jul+1%... 7/17/2009

Document ID: 188693

Page 5 of 5

Does the scan tool indicate the diagnostic Passed? 11 Does the scan tool display any additional undiagnosed DTCs? --

Go to Step 11 Go to the applicable DTC table

Go to Step 2

System OK

http://gsi.xw.gm.com/si/showDoc.do?docSyskey=188693&deliveryEffectiveDate=Jul+1%... 7/17/2009

Вам также может понравиться

- SsangYong Actyon Service Manual PDFДокумент2 172 страницыSsangYong Actyon Service Manual PDFVictor Abel Ovalle Retamal94% (35)

- DEUTZ TBD 616, WH, enДокумент322 страницыDEUTZ TBD 616, WH, enZu Pi89% (9)

- Engine Cat c16 PDFДокумент4 страницыEngine Cat c16 PDFSagar Magar100% (1)

- Schematic and Routing Diagrams: 2006 Cadillac CTS 2006 Cadillac CTSДокумент104 страницыSchematic and Routing Diagrams: 2006 Cadillac CTS 2006 Cadillac CTSMon DiОценок пока нет

- Isuzu 6WG1Документ14 страницIsuzu 6WG1Agus Yulfizar0% (1)

- 608Документ690 страниц608ccbulgariaОценок пока нет

- Car Seats R CodeДокумент5 страницCar Seats R Codenvnkmr9999Оценок пока нет

- DTC B2575: Headlamp Low Beam Relay Control CircuitДокумент3 страницыDTC B2575: Headlamp Low Beam Relay Control CircuitMaria Elisabeth RamirezОценок пока нет

- Kohler Courage SV710-SV740 & Courage Pro SV810-SV840 Service ManualДокумент76 страницKohler Courage SV710-SV740 & Courage Pro SV810-SV840 Service ManualEric OlsonОценок пока нет

- Test Nav Install Troubleshoot Rev6Документ34 страницыTest Nav Install Troubleshoot Rev6Maria Elena Beltran PuricaОценок пока нет

- 1977 TiogaДокумент28 страниц1977 TiogaJon JeysОценок пока нет

- 04-13-012 Engine Controls Emissions - OBDII Drive Cycle ReviДокумент29 страниц04-13-012 Engine Controls Emissions - OBDII Drive Cycle Reviapi-3855859100% (2)

- Bimotion 2-Stroke Case StudyДокумент11 страницBimotion 2-Stroke Case Studytfour200080% (5)

- Diesel Power PlantДокумент17 страницDiesel Power PlantMuhammed ThaslimОценок пока нет

- Engine - Data - Sheet - (FR-6675) PDFДокумент4 страницыEngine - Data - Sheet - (FR-6675) PDFBidonsBidonsОценок пока нет

- DTC P1345 Crankshaft Position (CKP) - Camshaft Position (CMP) CorrelationДокумент5 страницDTC P1345 Crankshaft Position (CKP) - Camshaft Position (CMP) CorrelationChino PlagaОценок пока нет

- Ford FaultcodesДокумент5 страницFord FaultcodesJuan PabloОценок пока нет

- Installation Guide: IndexДокумент15 страницInstallation Guide: IndexunknownipОценок пока нет

- Trouble Codes OBDIIДокумент55 страницTrouble Codes OBDIIFrancisco Cordova SandovalОценок пока нет

- Z TT Plus ManualДокумент44 страницыZ TT Plus ManualHerbert Frota CuradoОценок пока нет

- C5 Corvette Computer CodesДокумент8 страницC5 Corvette Computer CodesScott KramerОценок пока нет

- 05 Fuel SystemДокумент60 страниц05 Fuel Systemfrancisco fernandezОценок пока нет

- DTC P0017 Codigo AvengerДокумент6 страницDTC P0017 Codigo Avengerflash_24014910Оценок пока нет

- SQ416V-SQ420V-SQ420W-SQ625W-SQ416Q-SQ420Q - Wiring Manual PDFДокумент153 страницыSQ416V-SQ420V-SQ420W-SQ625W-SQ416Q-SQ420Q - Wiring Manual PDFDaniel BarrientosОценок пока нет

- OMZ104746 - 7250, 7350, 7450, 7550, 7750 and 7850 Self-Propelled Forage Harvesters, Block File - ZX09263 - 0002ACA - 19 - 22JUL08.htm PDFДокумент5 страницOMZ104746 - 7250, 7350, 7450, 7550, 7750 and 7850 Self-Propelled Forage Harvesters, Block File - ZX09263 - 0002ACA - 19 - 22JUL08.htm PDFmuftah76Оценок пока нет

- Ford Key ProgrammingДокумент2 страницыFord Key ProgrammingKandy KnОценок пока нет

- Ford Rep Matrix 7-5-06Документ41 страницаFord Rep Matrix 7-5-06rodrigo michelОценок пока нет

- Altenator PDFДокумент26 страницAltenator PDFluisОценок пока нет

- The Immobilizer SystemДокумент22 страницыThe Immobilizer SystemОстап ФеренсовичОценок пока нет

- GM OBDII Manufacturer Specific Trouble Codes For GMДокумент30 страницGM OBDII Manufacturer Specific Trouble Codes For GMheartofdixie100% (1)

- Useful Info For Acura Legend 1993Документ3 страницыUseful Info For Acura Legend 1993jcalaqОценок пока нет

- ZG Chime/Buzzer Warning Systems 8U - 1Документ4 страницыZG Chime/Buzzer Warning Systems 8U - 1ensmartisОценок пока нет

- Powertrain Control SoftwareДокумент6 страницPowertrain Control SoftwareJosé AntonioОценок пока нет

- Installation Guide DS3+ / DS4+: 2015 Chevrolet Equinox. 933.GM10 4.27.195.3Документ24 страницыInstallation Guide DS3+ / DS4+: 2015 Chevrolet Equinox. 933.GM10 4.27.195.3patОценок пока нет

- PATS Key Type: All Keys Are 8-Cut Unless Otherwise NotedДокумент2 страницыPATS Key Type: All Keys Are 8-Cut Unless Otherwise NotedAlbertОценок пока нет

- Engine Mechanical: SectionДокумент204 страницыEngine Mechanical: SectionIRAKLI DVALADZEОценок пока нет

- FMP User GuideДокумент24 страницыFMP User Guidekamaleon doradoОценок пока нет

- 086 - ImmobilizerДокумент62 страницы086 - ImmobilizerGedas GvildysОценок пока нет

- 2009 Mercedes C300 Fuse Location and NumberДокумент3 страницы2009 Mercedes C300 Fuse Location and NumbercplОценок пока нет

- 2007 GMC Yukon 5.3L Eng VIN 0 Base U1814 00Документ2 страницы2007 GMC Yukon 5.3L Eng VIN 0 Base U1814 00AlainbravopaezОценок пока нет

- 2007 Ford 500 Owners ManualДокумент288 страниц2007 Ford 500 Owners ManualSlava Bouttchenko100% (1)

- Mazda Protege 5 Control SystemДокумент14 страницMazda Protege 5 Control SystemJGAR2009Оценок пока нет

- Comestereo VekslerДокумент105 страницComestereo VekslerZoffi Pedersen100% (1)

- Hitec X1+AC LiPo Charger ManualДокумент36 страницHitec X1+AC LiPo Charger Manualhossrod100% (1)

- HDS7 ManualДокумент132 страницыHDS7 ManualTed G.Оценок пока нет

- Diesel PowertrainДокумент284 страницыDiesel PowertrainCOSTIN NESTIANОценок пока нет

- Intermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047Документ6 страницIntermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047peter064Оценок пока нет

- 2001 Ford Ranger Owners ManualДокумент272 страницы2001 Ford Ranger Owners ManualAaron Monk100% (1)

- Dodge Trouble Codes PDFДокумент12 страницDodge Trouble Codes PDFbelchiorОценок пока нет

- E P1 KH2 EJAZai CCVZ G1 KW1600900047Документ35 страницE P1 KH2 EJAZai CCVZ G1 KW1600900047RosОценок пока нет

- CompuStar CM5200Документ7 страницCompuStar CM5200JamesParadisoОценок пока нет

- Bulldog Security SystemДокумент14 страницBulldog Security SystemphilipisaiaОценок пока нет

- Errores JeepДокумент17 страницErrores JeepsolokikeОценок пока нет

- 2008-08-09 105818 Alarm 96 Jeep CherokeeДокумент9 страниц2008-08-09 105818 Alarm 96 Jeep CherokeeAxel FernandezОценок пока нет

- 2011 Fusion Hybrid MKZДокумент12 страниц2011 Fusion Hybrid MKZTung NguyenОценок пока нет

- Ford CrownVic 1998 ManualДокумент160 страницFord CrownVic 1998 ManualNasir AyubОценок пока нет

- 2006 F 350 Remote Start WiringДокумент6 страниц2006 F 350 Remote Start WiringcrystalgeekОценок пока нет

- 2004 Maxima in Failsafe:: No Transmission Codes StoredДокумент8 страниц2004 Maxima in Failsafe:: No Transmission Codes StoredRaul GonzalesОценок пока нет

- Ford-F-150 2003 EN-US US E182b16aadДокумент280 страницFord-F-150 2003 EN-US US E182b16aadmiguelОценок пока нет

- Model Indentifiction For Cars TestsДокумент454 страницыModel Indentifiction For Cars TestsRichard Thodé JrОценок пока нет

- PATS Diagnostic Flowchart TSBДокумент31 страницаPATS Diagnostic Flowchart TSBMiguel CarrilloОценок пока нет

- 2010 Uconnect User Manual 2ndДокумент108 страниц2010 Uconnect User Manual 2nduncleangusОценок пока нет

- Genesis 3.8L Section 9Документ52 страницыGenesis 3.8L Section 9Nacho MowjiОценок пока нет

- Codigo P0722 Chevrolet Captiva 2010Документ5 страницCodigo P0722 Chevrolet Captiva 2010Jose Luis Velasquez RomeroОценок пока нет

- Petrol Injection Motronic Me 7.4.6Документ99 страницPetrol Injection Motronic Me 7.4.6Alejandro Lingua100% (1)

- DTC p1351 Ignition Coil Control Circuit High VoltajeДокумент5 страницDTC p1351 Ignition Coil Control Circuit High VoltajeBenito LopezОценок пока нет

- 1nr-Fe, 2nr-Fe - 01-02Документ7 страниц1nr-Fe, 2nr-Fe - 01-02Jimmy Quise LlamoccaОценок пока нет

- Electronic Engine Logbook: Engine Number:-Engine Type: - Constructor: - Date of ConstructionДокумент53 страницыElectronic Engine Logbook: Engine Number:-Engine Type: - Constructor: - Date of ConstructionArabyAbdel Hamed SadekОценок пока нет

- SB388CДокумент13 страницSB388CBenjamin LeedsОценок пока нет

- Aircraft Design: Lecture 2: G. Dimitriadis and O. LéonardДокумент53 страницыAircraft Design: Lecture 2: G. Dimitriadis and O. LéonardJosue Eleazar Guerrero Duran100% (1)

- Piaggio Beverly Cruiser 500 I.E. (EN)Документ364 страницыPiaggio Beverly Cruiser 500 I.E. (EN)ManuallesОценок пока нет

- TafeДокумент14 страницTafeHALO MC NOBLE ACTUALОценок пока нет

- Diagrama Hilux 2012 Engine Control (2KD-FTV VN Turbocharger o DPF)Документ13 страницDiagrama Hilux 2012 Engine Control (2KD-FTV VN Turbocharger o DPF)Rafael Olave100% (2)

- Series: Single Stage Reciprocating CompressorДокумент8 страницSeries: Single Stage Reciprocating CompressorrobertОценок пока нет

- Hydraulic Cylinder Unit (Jan2015)Документ29 страницHydraulic Cylinder Unit (Jan2015)A.i. StergianosОценок пока нет

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342Документ10 страницPratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342EstebanОценок пока нет

- Evaluation of Engine Oils in Diesel Four-Stroke Cycle Supercharged 1M-PC Single Cylinder Oil Test EngineДокумент55 страницEvaluation of Engine Oils in Diesel Four-Stroke Cycle Supercharged 1M-PC Single Cylinder Oil Test Enginemohammed karasnehОценок пока нет

- Manual Allis Chalmers tl14Документ7 страницManual Allis Chalmers tl14Johan QuesadaОценок пока нет

- AlpinaB5 PartsДокумент48 страницAlpinaB5 PartsLaci100% (1)

- IcenginesДокумент27 страницIcenginessaravanan l mechОценок пока нет

- Service: 4-Cylinder Direct-Injection Engine (1.4 L, EA 111, Turbocharger, Supercharger)Документ441 страницаService: 4-Cylinder Direct-Injection Engine (1.4 L, EA 111, Turbocharger, Supercharger)nicola mentiОценок пока нет

- Lista de Peças Novas PT2 C PreçoДокумент3 страницыLista de Peças Novas PT2 C PreçovitrinetecnicaОценок пока нет

- Comprehensive Component Monitor (CCM)Документ2 страницыComprehensive Component Monitor (CCM)rodrigo alexis aravena ponceОценок пока нет

- Modeling of A Large Marine Two-Stroke Diesel Engine With Cylinder Bypass Valve and EGR SystemДокумент6 страницModeling of A Large Marine Two-Stroke Diesel Engine With Cylinder Bypass Valve and EGR SystemhelenОценок пока нет

- Empilhadeira Hyster 1698731 - (J006) - H-PM-US-EN - (10-2021)Документ826 страницEmpilhadeira Hyster 1698731 - (J006) - H-PM-US-EN - (10-2021)Antonio100% (1)

- TechДокумент1 страницаTechvasanthanvijy200Оценок пока нет

- Motores BG Gas - 4103877Документ6 страницMotores BG Gas - 4103877Elio Custodio HuachacaОценок пока нет

- 096500-0180 Plano TesteДокумент4 страницы096500-0180 Plano TesteJunior IungОценок пока нет

- Microsquirt Ignition Coil LS2 WS REVAДокумент1 страницаMicrosquirt Ignition Coil LS2 WS REVARafael MendozaОценок пока нет