Академический Документы

Профессиональный Документы

Культура Документы

Time Waveform Analysis

Загружено:

Surika Martalina100%(1)100% нашли этот документ полезным (1 голос)

1K просмотров26 страницTime domain analysis is a graphic description of the overall physical behavior of a vibration structure as a function of time. Each defect type has a characteristic waveform, which subsequently translates to the frequency domain. A number of different displays "averaging modes" use the time domain.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документTime domain analysis is a graphic description of the overall physical behavior of a vibration structure as a function of time. Each defect type has a characteristic waveform, which subsequently translates to the frequency domain. A number of different displays "averaging modes" use the time domain.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

1K просмотров26 страницTime Waveform Analysis

Загружено:

Surika MartalinaTime domain analysis is a graphic description of the overall physical behavior of a vibration structure as a function of time. Each defect type has a characteristic waveform, which subsequently translates to the frequency domain. A number of different displays "averaging modes" use the time domain.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 26

1

TIME AND FREQUENCY ANALYSIS

Machinery vibration analysis techniques

Time domain analysis

Frequency analysis

Demodulation

TIME DOMAIN ANALYSIS

Use of time domain analysis

Signal processing and presentation

Phase measurement

Instrument setup

Time waveform shape analysis

Synchronous vs nonsynchronous data

Random noise and vibration

Conclusions

USE OF TIME DOMAIN ANALYSIS

A graphic description of the overall physical behavior of a

vibration structure as a function of time

Clarification of FFT processed data

The position of the measurement point at each instant of

time relative to the position at rest

Overall peak amplitude

Phase and amplitude relationships of different

frequencies and different positions

The nature of amplitude modulation or frequency content

USE OF TIME DOMAIN ANALYSIS

(cont.)

The symmetry of a signal; this relates to the

linearity of the vibrating system, the nature of the

forcing function, and the severity of the vibration

A measure of damping in the system

Direction of the initial exciting force

SIGNAL PROCESSING and

PRESENTATION

Instrumentation

Presentation

Presentation setup

Differential time

Waveform Characteristics

Objectives

Describe five waveform characteristics.

Identify waveform symmetry using APD.

Discuss waveform modulation and how it translates

to the FFT.

12-1

2

Waveform Characteristics

12-1

A number of different displays "averaging modes" use the time

domain. Displays such as synchronous time averaged data is

averaged in the time domain.

APD (Amplitude Problability Distribution) this is a function of

Wavepak, displays the symmetry and skewness of the waveform

signal.

Each defect type has a characteristic waveform, which

subsequently translates to the frequency domain.

There are characteristics and specific events that do not

translate to the frequency domain as discrete peaks. In order to

truly understand this limitation, the analyst must first understand

how the time domain data is gathered and transformed into a

spectrum through the Fast Fourier Transform (FFT) process.

Waveform Characteristics

12-2

Time domain data, raw transducer output, signal voltage and

many other terms refer to waveforms.

Waveform or time domain data is comprised of amplitude with

respect to time. Signals with an amplitude, whether vibration,

current, voltage changes, or other signal types, change with time.

Waveform Characteristics

12-2

There are certain things to look for when conducting waveform

analysis, the waveform provides specific characteristics for

defects of a single or multiple nature.

BAL - C-20 FLOAT ROLL FAN

C-20 FLOAT-FIH FAN BEARING INBOARD HORIZONTAL

WaveformDisplay

25-APR-96 09:36

RMS = 1.28

LOAD = 100.0

RPM = 3550.

RPS = 59.17

PK(+) = 6.94

PK(-) = 5.84

CRESTF= 5.40

0 20 40 60 80 100 120 140

-8

-6

-4

-2

0

2

4

6

8

Time in mSecs

A

c

c

e

le

ra

tio

n

in

G

-s

Time:

Ampl:

135.09

.00000

Waveform Characteristics

12-3

Note: The waveform is only as good as its definition. If the

resolution of your waveform lacks definition, the data can be

worthless, or poor at best.

Once the characteristics have been properly identified, the

analyst can rule out certain fault types.

For example:

If a waveform is periodic (sinusoidal)

looseness

cracks

resonance

antifriction bearings

Could probably be ruled out. You may not know what the problem

is, but you know what it is not.

Waveform Characteristics

12-3

Listed below are waveform characteristics an analyst should look

for when analyzing the waveform:

Amplitude

Asymmetry

Electrical vs Mechanical

Distortions

Periodic

Spikes/Impacts

Non-Periodic

Modulation

Complexity

Discontinuities

Low Frequency Events

Truncation/Restrictions

to Motion

Amplitude

12-4

When diagnosing machinery faults using the time

waveform, similar to spectral data, we are concerned with

the amplitude of the waveform.

When we are discussing bearing and gear waveforms,

we use the peak to peak amplitude of the waveform. This is

often referred to as g swing.

The g swing is the sum of the absolute value of the

maximum positive and negative amplitude in that period.

MasterTrend calculates this value and gives us the ability

to trend and alarm based on this and other waveform

values.

3

Amplitude

C-20 - C-20 FLOAT ROLL FAN

C-20 FLOAT-FIH FANBEARINGINBOARDHORIZONTAL

WaveformDisplay

25-APR-96 09:36

RMS = 1.28

LOAD= 100.0

RPM= 3550.

RPS = 59.17

PK(+) = 6.94

PK(-) = 5.84

CRESTF= 5.40

0 20 40 60 80 100 120 140

-8

-6

-4

-2

0

2

4

6

8

Time in mSecs

A

c

c

e

le

r

a

t

io

n

in

G

-

s

ALERT

ALERT

FAULT

FAULT

Time:

Ampl:

76.72

-.109

12-4

Periodic

12-5

Sometimes referred to as a deterministic simple

signal, this is an ideal signal which repeats itself

exactly after a fixed period.

This is not possible in the real world. However,

there are some machinery faults which have this

characteristic.

A single plane balance problem will have a very

periodic waveform due to the mass rotational center

and the rotor shaft of other component center line

differences.

Periodic

12-5

BAL - ZONE 6 EXHAUST

C-30 Z6X -FOH FANBEARINGOUTBOARDHORIZONTAL

WaveformDisplay

13-JUN-95 14:52

RMS = .1390

LOAD= 100.0

RPM= 1000.

RPS = 16.67

PK(+) = .3672

PK(-) = .4322

CRESTF= 3.11

0 100 200 300 400 500

-0.6

-0.4

-0.2

-0.0

0.2

0.4

0.6

Time in mSecs

A

c

c

e

le

r

a

t

io

n

in

G

-

s

Complexity

12-6

To determine the complexity of the waveform,

establish whether the signal is:

periodic in nature

estimate the harmonic content

determine if the signal is synchronous

non-synchronous

identify whether the waveform correlates

directly to the spectral data.

Complexity

12-6

C-20 - C-20 FLOAT ROLL FAN

C-20 FLOAT-FOH FANBEARINGOUTBOARDHORIZONTAL

Label: LOOSE, OUT OF BALANCE

WaveformDisplay

25-APR-96 09:37

RMS = 1.59

LOAD= 100.0

RPM= 3508.

RPS = 58.47

PK(+) = 4.88

PK(-) = 5.25

CRESTF= 3.30

0 20 40 60 80 100 120 140

-6

-4

-2

0

2

4

6

Time in mSecs

A

c

c

e

le

r

a

t

io

n

in

G

-

s

Impacts/Spikes

12-7

Impacts or Spikes may or may not be repetitive in nature.

The non repetitive spikes generate white noise.

Repetitive impacts or spikes, such as those produced by rolling

element bearing defects or broken gear teeth, may excite discrete

frequencies and therefore show up well in the spectrum.

This characteristic is best detected by defining a waveform

amplitude type in acceleration. Acceleration data is proportional

to force.

The crest factor, which is equal to the maximum peak (positive

or negative) divided by the RMS of the waveform, is a good

indicator of the impacting. This value can be setup as an analysis

parameter and trended in MasterTrend.

4

Impacts/Spikes

12-7

Repetitive Spikes

Discontinuities

12-8

This characteristic is usually associated with faulty

equipment due to the discontinuous nature of the

data.

Data with this characteristic has breaks in the data

where there appears to be a loss of input signal or a

significant increase/decrease in amplitude.

This is not a uniform change such as resonance,

load changes, or even sudden component failures.

Discontinuous data is typically unpredictable, and

very distinct.

If you see this type of waveform pattern

( YOU HAVE A PROBLEM )

Discontinuities

12-8

Asymmetry

12-9

Asymmetry refers to the relationship between the

positive and negative energy.

A waveform is asymmetric when there is more energy in

the positive plane than the negative or vice versa.

Asymmetry refers to the direction of movement relative to

the transducer mounting with a positive signal

representing energy into ( towards ) the accelerometer and

a negative signal representing away.

A tool which is designed to check this type of

characteristic is the APD, Amplitude Probability

Distribution.

Asymmetry

12-9

MISC- #1 H2OBOOSTER

4661 -MIV MOTORINBOARDVERTICAL

Label: LOOSE BASE

WaveformDisplay

16-NOV-95 10:18

RMS = .5155

LOAD= 100.0

RPM= 1789.

RPS = 29.82

PK(+) = 2.24

PK(-) = 1.43

CRESTF= 4.35

0 60 120 180 240 300

-2.0

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

2.5

Time in mSecs

A

c

c

e

le

r

a

t

io

n

in

G

-

s

Asymmetry

12-10

Select the Analyze Data feature in Diagnostics Plotting when in

Waveform Analysis.

5

APD

12-10

APD

12-11

Amplitude Probability Distribution

An APD or Amplitude Probability Distribution is similar to a

Hystorgram.

The signal is broken down into amplitude percentages, and then

the amplitude is plotted.

The X-Axis is the amplitude and the Y-Axis is the percentage of

the signal that falls into that amplitude range.

The APD is typically used for acoustical analysis.

It can also be used for machine vibration analysis to find the

balance of the signal (asymmetries), the direction, and possibly

the location of a specific defect especially those that may not

stand out in the waveform or the spectrum.

Sinewaves

Sinewaves are very symmetrical, which means

there is a balance of energy in the positive and

negative planes.

If most of the vibration signal is evenly distributed

and sinusoidal, there is a strong possibility it is due to

a synchronous component such as imbalance,

misalignment, gears, blades, etc.

The waveform and APD show the shape of a

sinewave and the probability related to this type of

signal.

12-11

Sinewaves

12-11

Notice that the APD at the bottom of the above display shows a

set of peaks at the maximum and minimum amplitude locations.

This could also be called a Hysteresis display. The probability of

the signal being in the 10 volt location is much more probable

that the signal being at the zero location of the display.

Triangle Wave

12-13

With a triangle wave, we see the relationship of the

waveform and a different type of APD display.

Note that the data is skewed to the negative plane.

Again, this provides the analyst with the direction of

motion.

The following illustration displays the direct relationship

between the waveform and the APD. Bear in mind that

the APD provides another tool to determine location,

direction, and asymmetry.

Triangle Wave

12-13

6

Squarewave

12-14

The squarewave on the next slide provides some insight

into the use of the APD for checking asymmetries.

Remember that symmetry refers to the balance of energy.

Therefore, with a slightly more complex signal, this becomes

more important especially when performing Root Cause

Failure Analysis(RCFA).

In the next illustration, the signal is asymmetric, and there

is more energy in the positive plane than the negative.

The energy in the positive plane shows movement toward

the transducer, and the negative plane is obviously the

opposite.

Squarewave

12-14

Truncation/Restrictions to Motion

12-15

Truncation means to abruptly shorten, or to appear to

terminate.

In waveform analysis, this characteristic indicates restrictive

motion.

Modulation

12-15

All the waveform characteristics up to this point have

dealt with signals of a constant amplitude.

A varying signal will cause the waveform to become

modulated. The type of modulation occurring

determines its classification. Commonly referred to as

Beat frequencies, these may be broken into three

specific categories.

Amplitude

Beating

Frequency

Amplitude

12-16

The spectrum will have a peak at the signal's

frequency with one peak on each side spaced at the

frequency of the amplitude change. These peaks are

referred to as sidebands.

Amplitude modulation is common when analyzing

inner race bearing defects. This occurs when the

defective bearing component passes in and out of the

bearing load zone. The middle of the load zone is

typically where the highest amplitudes in the

waveform show up.

Amplitude

12-16

The spectrum and waveform show slot pass frequency from an

AC induction motor. The primary signal at 34xTS is marked with

a vertical line. The sideband cursors mark the amplitude change

at 120 Hz.

7

Beating

12-17

A beat is comprised of two unrelated single

frequency signals, closely spaced in frequency.

Beating is often found in two pole induction AC

motors. The close proximity of two times line

frequency and the second harmonic of turning speed

cause this beat.

An example of beating is shown next. The 2x RPM

and 2x line frequency are separated by less than .5

Hz. The waveform shows the amplitude modulation

associated with beating.

Beating

12-17

WAVEFORMDISPLAY

06-DEC-94 10:15

RMS = .0678

PK(+) = .1300

PK(-) = .1790

CRESTF= 2.64

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

-0.20

-0.15

-0.10

-0.05

-0.00

0.05

0.10

Time in Seconds

A

c

c

e

le

r

a

t

io

n

in

G

-

s

AMGL - CENTAC3 STAGE COMPRESSOR

#1 CENTAC-1BA MOTOROUTBDAXIAL TO200 Hz

REFERENCE SPECTRUM

06-DEC-94 10:15

OVRALL= .0581 V-DG

PK = .0380

LOAD= 100.0

RPM= 3575.

RPS = 59.58

60 80 100 120 140 160 180

0

0.01

0.02

0.03

0.04

Frequency in Hz

P

K

V

e

l in

In

/S

e

c

Freq:

Ordr:

Spec:

Dfrq:

119.00

1.997

.02520

1.000

Frequency

12-18

Rarely seen in a routine environment, this is a change in

frequency without a change in the signal amplitude.

Frequency modulation typically occurs in gearmeshing

vibration, due to the small speed fluctuations caused by

tooth spacing errors and faults as they develop. A very wide

spread of sidebands in the spectrum is usually an indication

that significant frequency modulation is present.

On our example shown next. The vertical line in the

spectrum marks gearmesh frequency at 24xTS. The

sideband cursors mark the output shaft speed with labels

identifying sidebands spaced at input shaft speed. The

waveform has been expanded to show the frequency

modulation occurring. A good illustration is shown between

170 and 180 msecs.

Frequency

12-18

Frequency modulation

Low Frequency Events

12-19

When performing detailed analysis, you need to be

able to collect and analyze data in excess of one

minute for low frequency problems. This is extremely

important when the machine in question has an

operational speed below 200 RPM. The challenge in

identifying low frequency defects is having sufficient

time in the waveform. A low frequency event may only

appear once in the collected time domain. As

discussed earlier, this event will not be transformed

into the spectrum.

Low Frequency Events

12-20

8

Electrical vs. Mechanical

12-20

Determining if the source of energy is mechanical

or electrical is sometimes difficult.

Appropriately set up waveforms can be a great

help. Setting up for a long enough time to capture

the operational conditions and the machine shutoff

point can identify the source.

The advantage of using the time domain as

opposed to the frequency domain is there is no need

to worry about the screen update time or sampling

rate.

Electrical vs. Mechanical

12-20

Waveform and Spectrum

Relationships

12-21

Each spectrum has an associated waveform. The

spectrum is made of this waveform. As discussed earlier in

this section, some of the characteristics in the waveform do

not translate to the FFT due to the way the calculations are

made. The assumption is that there is a repetitive cycle of

events made up of sines and cosines. However, this is not

actually the case.

If an event happens only once, then this event has no

frequency; therefore, the spectral representation is a

continuous spectrum.

In the waveform shown next, there is no repetition in the

event; therefore, there is no frequency.

Waveform and Spectrum

Relationships

12-21

Modulated Waveforms

12-22

Finally, when modulation is involved, there is a direct

relationship between the waveform and the spectrum

depending on the differential time (t).

Knowledge of the modulation t helps determine the

resolution required for detailed spectral analysis. Also,

from our previous discussion on modulation, we know

there is a carrier frequency that the modulation must

follow.

Gears, bearings, and electrical defects each have

carrier frequencies. For gears the carrier is the

frequency where the gears mesh. However, a carrier

frequency for an electrical defect could be the line

frequency (F

L

) or 2 * F

L

.

Modulated Waveforms

12-22

9

Waveform Analysis As Confirmation

12-23

Every fault condition has a corresponding waveform

characteristic.

Unbalance, for example, has a sinusoidal pattern with

one major event per revolution.

Misalignment, which is primarily offset, typically has

harmonic activity with the waveform having the same

number of events per cycle as the spectral data has peaks.

A misalignment condition generating a second and possibly

a third order peak shows two or three sinewaves per

revolution.

Looseness will have a complex waveform with many

peaks within one revolution. This will confirm the spectral

characteristics of multiple harmonics of turning speed.

Vertical Turbine Pump

Unbalance Example

12-24

MOH

MIH

MOV

MIV

Vertical Turbine Pump

Unbalance Example

The multiple point spectrum plot below shows radial and axial

measurements taken from the top of the vertical motor.

FWEL - FRESHWATERBOOSTERPUMP 1

131-546-03 - PTS=MOHMOV MOA

P

K

V

e

lo

c

ity

in

In

/S

e

c

Frequency in Order

0 3 6 9 12 15 18 21 24 27

Max Amp

.65

Plot

Scale

0

0.7

09-FEB-96 09:22

131-546-03-MOH

09-FEB-96 09:22

131-546-03-MOV

09-FEB-96 09:22

131-546-03-MOA

12-25

M

u

l

t

i-

s

p

e

c

t

r

a

l

-

D

a

t

a

C

o

m

p

a

r

is

o

n

Vertical Turbine Pump

Unbalance Example

12-26

The sharpness of the peak indicates that it has been created

from a waveform dominated by a single frequency.

FWEL - FRESH WATER BOOSTER PUMP 1

131-546-03-MOV MOTOR OUTBOARD VERTICAL

Route Spectrum

09-FEB-96 09:22

OVRALL= .6466 V-DG

PK = .6464

LOAD = 100.0

RPM = 1776.

RPS = 29.60

0 5 10 15 20 25 30 35 40 45 50

0

0.2

0.4

0.6

0.8

1.0

Frequency in Order

Ordr:

Freq:

Spec:

1.000

1776.2

.646

S

i

n

g

l

e

S

p

e

c

t

r

u

m

-

A

m

p

l

it

u

d

e

R

e

l

a

t

io

n

s

Vertical Turbine Pump

Unbalance Example

12-27

Approximately 270 milliseconds of time (8 shaft revolutions)

shows the clear one per revolution signal generated by the

unbalance condition.

FWEL - FRESHWATERBOOSTERPUMP 1

131-546-03-MOV MOTOROUTBOARDVERTICAL

WaveformDisplay

09-FEB-96 09:22

RMS = .2679

LOAD= 100.0

RPM= 1776.

RPS = 29.60

PK(+) = .5932

PK(-) = .6215

CRESTF= 2.32

0 60 120 180 240 300

-0.8

-0.6

-0.4

-0.2

-0.0

0.2

0.4

0.6

0.8

Time in mSecs

A

c

c

e

le

r

a

tio

n

in

G

-s

T

im

e

W

a

v

e

f

o

r

m

-

S

in

u

s

o

i

d

a

l

Fan Bearing

Looseness Example

12-28

The fan bearing looseness data provides the initial spectral data

for diagnostics and the waveform data to confirm the looseness

fault diagnosis.

The fan ran in an out of balance condition for two years. The

bearings now have excess clearance, allowing the shaft to move

around.

Direct Driven Overhung Fan

10

Fan Bearing

Looseness Example

12-29

Note the small amounts of harmonic activity and axial data

amplitude.

C-20 - C-20 FLOAT ROLL FAN

C-20 FLOAT - PTS=FIH FIVFIA FOH FOVFOA

P

K

V

e

lo

c

ity

in

In

/S

e

c

Frequency in Order

0 2 4 6 8 10 12 14 16

Max Amp

.46

Plot

Scale

0

1.0

14-JUN-95 08:08

C-20 FLOAT-FIH

14-JUN-95 08:09

C-20 FLOAT-FIV

14-JUN-95 08:09

C-20 FLOAT-FIA

14-JUN-95 08:09

C-20 FLOAT-FOH

14-JUN-95 08:10

C-20 FLOAT-FOV

14-JUN-95 08:10

C-20 FLOAT-FOA

Ordr:

Freq:

Sp 1:

1.000

3499.0

.395

M

u

l

t

i-

s

p

e

c

t

r

a

l

-

D

a

t

a

C

o

m

p

a

r

is

o

n

Fan Bearing

Looseness Example

12-30

The spectral plot below shows vibration in the

horizontal direction on the fan outboard bearing.

C-20 - C-20 FLOAT ROLL FAN

C-20 FLOAT-FIH FAN BEARINGINBOARD HORIZONTAL

Label: HARMONICS-BALANCE/LOOSENESS

Route Spectrum

14-JUN-95 08:08

OVRALL= .5095 V-DG

PK = .5065

LOAD = 100.0

RPM= 3498.

RPS = 58.30

0 2 4 6 8 10 12 14 16

0

0.1

0.2

0.3

0.4

0.5

0.6

Frequency in Order

P

K

V

e

lo

c

ity

in

In

/S

e

c

Ordr:

Freq:

Spec:

1.000

3499.0

.395

S

i

n

g

l

e

S

p

e

c

t

r

u

m

-

A

m

p

l

it

u

d

e

R

e

l

a

t

io

n

s

Fan Bearing

Looseness Example

12-30

The cursor markers note the locations of harmonics

of running speed.

Virtually all the vibration energy in this spectrum is

caused by turning speed and harmonics. The sides, or

skirts, of this peak are also very narrow.

The number of harmonics tells us that the spectrum

is derived from a complex, repetitive time waveform.

Fan Bearing

Looseness Example

12-31

C-20 - C-20 FLOAT ROLL FAN

C-20 FLOAT-FIH FANBEARINGINBOARDHORIZONTAL

Label: HARMONICS-BALANCE/LOOSENESS

WaveformDisplay

14-JUN-95 08:08

RMS = 1.06

LOAD= 100.0

RPM= 3498.

RPS = 58.30

PK(+) = 3.08

PK(-) = 3.01

CRESTF= 2.88

0 30 60 90 120 150 180 210 240

-4

-3

-2

-1

0

1

2

3

4

Time in mSecs

A

c

c

e

le

r

a

t

io

n

in

G

-

s

T

im

e

W

a

v

e

f

o

r

m

-

S

in

u

s

o

i

d

a

l

C

h

a

r

a

c

t

e

r

Fan Bearing

Looseness Example

12-31

A clear and repeatable waveform occurs once per

shaft revolution, 1 x RPM.

There is also multiple peaks within one revolution

The waveform shows the acceleration created on the

bearing housing by the looseness.

The repeatability of the waveform in time with

respect to the shaft turning speed and amplitude

means that the vibration force is tied to the shaft

running speed.

Motor to Pump

Misalignment Example

12-32

The pump has had high vibration since installation and

numerous seal/packing and bearing failures. The maintenance

personnel stated that the alignment was difficult because the

base was drilled incorrectly at the manufacturers facility.

M1H

M1V

M1A

M2H

M2V

P1H

P1V

P2H

P2V

P2A

P1A

M2A

11

Motor to Pump

Misalignment Example

12-33

At first glance, the problem might appear to be unbalance. If

we take a closer look we see that 2X running speed peaks

are present in all directions. #1 - TIMBERLINEBOOSTER(PROSPECT

TIMBSTRPRO- PTS=MOHMOVMIHMIVMIA

P

K

V

e

lo

c

ity

in

In

/S

e

c

Frequency in Order

0 5 10 15 20 25 30 35 40 45 50 55

Max Amp

.43

Plot

Scale

0

0.5

21-JUN-95 16:11

TIMBSTRPRO-MOH

21-JUN-95 16:11

TIMBSTRPRO-MOV

21-JUN-95 16:11

TIMBSTRPRO-MIH

21-JUN-95 16:11

TIMBSTRPRO-MIV

21-JUN-95 16:12

TIMBSTRPRO-MIA

M

u

l

t

i-

S

p

e

c

t

r

a

l

-

A

m

p

l

it

u

d

e

C

o

m

p

a

r

i

s

o

n

Motor to Pump

Misalignment Example

12-34

Harmonics of running speed are denoted by the fault

frequency markers (dashed lines).

The first through sixth orders of running speed are visible

with the 2X T.S. predominant.

#1 - TIMBERLINE BOOSTER(PROSPECT

TIMBSTRPRO-MIV MOTORINBOARDVERTICAL

Reference Spectrum

21-JUN-95 16:11

OVRALL= .1780 V-DG

PK = .1771

LOAD= 100.0

RPM= 1768.

RPS = 29.47

0 3 6 9 12 15 18 21 24 27

0

0.03

0.06

0.09

0.12

0.15

0.18

0.21

0.24

Frequency in Order

P

K

V

e

lo

c

ity

in

In

/S

e

c

Ordr:

Freq:

Spec:

1.004

1774.9

.01562

A=MOTORHARMONIC

: 1.00

A A A A A

S

i

n

g

l

e

S

p

e

c

t

r

u

m

-

2

x

T

S

Motor to Pump

Misalignment Example

12-35

The waveform is repetitive for each revolution with two distinct

peaks for each period.

#1 - TIMBERLINE BOOSTER(PROSPECT

TIMBSTRPRO-MIV MOTORINBOARDVERTICAL

WaveformDisplay

21-JUN-95 16:11

RMS = .1784

LOAD= 100.0

RPM= 1768.

RPS = 29.47

PK(+) = .5682

PK(-) = .5457

CRESTF= 3.19

0 60 120 180 240 300

-0.8

-0.6

-0.4

-0.2

-0.0

0.2

0.4

0.6

0.8

Time in mSecs

A

c

c

e

le

r

a

tio

n

in

G

-s

1

2

T

im

e

W

a

v

e

f

o

r

m

-

T

w

ic

e

p

e

r

R

e

v

o

lu

t

i

o

n

Pump Bearing

Looseness Example

12-36

The diagram above shows a centerhung pump with bearing

housing dimensions worn oversize .

The worn housings makes the pump very loose .

Typical of many looseness problems, this has grown worse over

time. A small dimension problem has gradually made itself worse.

Speed 1775 RPM

H.p. 150

Pump Bearing

Looseness Example

12-37

Many harmonics of running speed are visible on all measurement

positions. Baseline or floor energy is also very visible.

CWTR- COOLINGWATERPUMP 1

341-545-01 - PTS=PIV PIHPOV POHPOA

P

K

V

e

lo

c

ity

in

In

/S

e

c

Frequency in Hz

0 400 800 1200 1600

Max Amp

.14

Plot

Scale

0

0.14

18-APR-96 08:46

341-545-01-PIV

18-APR-96 08:46

341-545-01-PIH

18-APR-96 08:46

341-545-01-POV

18-APR-96 08:47

341-545-01-POH

18-APR-96 08:47

341-545-01-POA

M

u

l

t

i-

s

p

e

c

t

r

a

l

-

B

r

o

a

d

b

a

n

d

Pump Bearing

Looseness Example

12-38

CWTR- COOLINGWATERPUMP 1

341-545-01-POA PUMP OUTBOARDAXIAL

Route Spectrum

18-APR-96 08:47

OVRALL= .3663 V-DG

PK = .3675

LOAD= 100.0

RPM= 1775.

RPS = 29.58

0 400 800 1200 1600

0

0.02

0.04

0.06

0.08

0.10

0.12

0.14

Frequency in Hz

P

K

V

e

lo

c

it

y

in

In

/S

e

c

Freq:

Ordr:

Spec:

29.58

1.000

.03901

S

i

n

g

l

e

S

p

e

c

t

r

a

l

-

9

-

1

5

x

T

S

a

n

d

B

r

o

a

d

b

a

n

d

12

Pump Bearing

Looseness Example

12-38

A cursor is positioned at 1x running speed and on the

harmonics of running speed.

The peaks are broad and have wide skirts.

Notice, no individual peak exceeds .1 in/sec, but the

overall energy is .3663 in/sec.

This is common with looseness. Broad humps of energy

show up in the 9X to 15x running speed range.

This indicates that the time waveform cannot be cleanly

transformed into a spectrum. Therefore, the waveform

must have random, non-periodic energy present.

Pump Bearing

Looseness Example

12-39

There is no similarity in its pattern from

revolution to revolution. Non-periodic, random

patterns do not convert well in the FFT process.

It is very difficult to assign specific frequencies

and amplitudes to patterns in waveforms like

the one on the next page.

This difficulty leads to the broadband energy

humps in the spectrum. Broader humps

indicate more random energy. Higher humps

indicate more impacting in the waveform.

Pump Bearing

Looseness Example

12-39

CWTR- COOLINGWATERPUMP 1

341-545-01-POA PUMP OUTBOARDAXIAL

WaveformDisplay

18-APR-96 08:47

RMS = 2.12

LOAD= 100.0

RPM= 1775.

RPS = 29.58

PK(+) = 7.68

PK(-) = 6.42

CRESTF= 3.63

0 60 120 180 240 300

-8

-6

-4

-2

0

2

4

6

8

10

Time in mSecs

A

c

c

e

le

r

a

t

io

n

in

G

-

s

T

im

e

W

a

v

e

f

o

r

m

-

R

a

n

d

o

m

E

n

e

r

g

y

Rolling Element Bearing Example

12-40

Maintenance personnel reported vibration from the back end

of the motor after only 200 hours operating time on a newly

installed drive.

The analyst investigated and found visible flakes of a bronze

colored material near the back end of the motor. The motor

manufacturer was contacted to determine if the 6330 bearings

had a bronze retainer and the reply given was no.

Ski Lift Motor

850 HP DC Motor Right Angle Gearbox

6330 Bearings

Rolling Element Bearing Example

12-41

All the levels appear very low in amplitude, but notice the location of the

dominant peaks.

There appears to be groups of many peaks closely spaced in the mid to

higher frequency range. These mounds of energy can indicate bearing

defects.

NSTR- BACKSIDE QUAD

BACKSIDEQD - PTS=MOV MOAMOH

P

K

V

e

lo

c

ity

in

In

/S

e

c

Frequency in Hz

0 400 800 1200 1600 2000

Max Amp

.19

Plot

Scale

0

0.20

05-JAN-96 08:46

BACKSIDEQD-MOV

05-JAN-96 08:57

BACKSIDEQD-MOA

05-JAN-96 08:56

BACKSIDEQD-MOH

M

u

l

t

i-

s

p

e

c

t

r

a

l

-

N

o

n

-

S

y

n

c

h

r

o

n

o

u

s

E

n

e

r

g

y

Rolling Element Bearing Example

12-42

The fault frequencies for the 6330 bearing ball pass frequency outer race

are marked. Notice the number of peaks surrounding the higher frequency

defect harmonics.

The large number of harmonics and sidebands will be created from a

complex waveform.

NSTR- BACKSIDE QUAD

BACKSIDEQD-MOH MOTOROUTBOARD HORIZONTAL

Label: OUTERRACE FREQUENCIES W/CAGE SB

Analyze Spectrum

05-JAN-96 08:56

PK = .3611

LOAD = 100.0

RPM = 1298.

RPS = 21.64

0 400 800 1200 1600 2000

0

0.06

0.12

0.18

0.24

0.30

Frequency in Hz

P

K

V

e

lo

c

ity

in

In

/S

e

c

Freq:

Ordr:

Spec:

77.50

3.582

.03297

>SKF 6330

C=BPFO : 77.64

C C C C C C C C C C

S

i

n

g

l

e

S

p

e

c

t

r

u

m

-

B

a

d

B

e

a

r

i

n

g

13

Rolling Element Bearing Example

12-43

NSTR- BACKSIDE QUAD

BACKSIDEQD-MOH MOTOROUTBOARDHORIZONTAL

Label: OUTERRACE FREQUENCIES W/CAGE SB

WaveformDisplay

05-JAN-96 08:56

RMS = 1.75

LOAD= 100.0

RPM= 1298.

RPS = 21.64

PK(+) = 5.81

PK(-) = 5.13

CRESTF= 3.32

0 40 80 120 160 200

-6

-4

-2

0

2

4

6

8

Time in mSecs

A

c

c

e

le

r

a

t

io

n

in

G

-

s

T

im

e

W

a

v

e

f

o

r

m

-

B

a

d

B

e

a

r

i

n

g

Rolling Element Bearing Example

12-43

The number and height of the spikes in the time

waveform confirm the presence of severe impacting.

The waveform shape is random and complex. This

shape cannot be transformed into a clean spectrum,

so the spectrum on the previous page with broad

humps of energy is created.

The bearing cage turned out to be bronze! It was

deteriorating and did not have much life left. The outer

race had major spalls from impacting balls. The

bearing was replaced.

12-44

This is an example of Unbalance.

12-44

This is an example of Unbalance.

The cursor on the previous slide is marking 1xTS

(1 Order) at 59.34 Hz in the Spectrum.

How does that frequency relate in the Waveform.

The discussions on waveform analysis are not

intended for the analyst to discard the Spectral

analysis.

The Spectrum is Amplitude vs. Frequency. The

Time Waveform is Amplitude vs. Time.

12-45

Now let us look at the Waveform in Time.

This is an example of Unbalance.

12-45

This is an example of Unbalance.

The cursors are marking the harmonics of

the turning speed frequency, harmonic

cursors was selected. The frequency at

59.34 Hz 0r 59.35 Hz. = (1 Order).

The time is 16.85 msec. 16.85 msec

divided by 1000 = .01685 sec, this is the Time

to complete 1 revolution.

Frequency = 1 divided by the Time

1 divided by .01685 = 59.347 Hz = turning

speed of the rotor.

14

This is an example of Unbalance.

12-46

Change the display to Revolutions of the shaft.

Notice the time is now 1.000 that is (1 Order).

Viewing the Waveform in Revolutions can often make

analyzing a little simpler.

Misalignment Example

12-47

Now look at a Misalignment example.

The cursors are marking harmonics of turning speed. The

peak at 2x turning speed is the highest amplitude. We have 3

or 4 peaks per revolution of the shaft in the Time Waveform.

Misalignment Example

12-48

Take a closer look at the misalignment waveform pattern.

Harmonic cursors are marking the harmonics of what frequency?

From this display you still do not really know! You only know

that these marked peaks are harmonic.

Misalignment Example

12-49

From this display the same frequency was marked and the

Set Mark enabled, and the Difference cursors was

selected.

Misalignment Example

Look at the time, it is 13.05 msec.

13.05 msec divided by 1000 = .01305 sec

1 divided by .01305 sec = 76.63 Hz

76.63 Hz x 60 = 4598 rpm

When we look at the freq: 76.65 in the display at

lower right hand corner we can see the frequency

has already been calculated for us. The

harmonics displayed are harmonics of 76.63 Hz.

This the frequency of 1xTS.

12-49

Misalignment Example

12-50

Change the display to Revolutions of the shaft.

Mark the same frequency, Set Mark select Difference

cursors.

15

Misalignment Example

12-51

We can control the cursor and look at the time.

The time is in Orders .999 orders.

We must remember it is very difficult marking exact

frequencies in the Time Waveform.

Misalignment Example

12-52

1x turnining speed is at 76.63 Hz. 76.63 Hz x 60 = 4598 rpm.

We can see two events occurring in 1 revolution of the shaft.

How often is the second event occurring in the Time Waveform

We will mark the 1

st

event, select Set Mark, select

Difference cursors

Misalignment Example

12-52

Move cursor to the peak representing the 2

nd

event in

one revolution.

Look at the time between these two frequencies. It is

6.523 msec. 6.523 divided by 1000 = .006523 sec.

1 divided by .006523 sec = 153.3 Hz

153.3 Hz x 60 = 9,196 rpm

The 1x TS was 4,598 rpm, 4,598 x 2 = 9,196 rpm

Now, it is easy now to see that this frequency is

occurring at 2 x TS of the rotor. It is repeated every

revolution of the shaft.

Bearing Problem

12-53

On the following slide the cursor is marking

1xTS, we have peaks at the bearing defect

frequencies.

Also displayed on the following slide is the

Spectrum with Fault Frequencies for the BPFI .

The Primary calculated defect frequency for the

BPFI is 5.91 orders. There are about 10

harmonics of 5.91 orders in the spectral data.

Bearing Problem

12-53

Bearing Problem

12-54

How do the bearing frequencies relate in the Time Waveform?

This display shows the Fault Frequencies for the BPFI displayed.

We must realize that the dotted lines do not automatically fall on

the defect frequency we may want to mark. Just any frequency

was selected. Notice where the fault lines are now.

16

Bearing Problem

12-55

In the plot displayed below the cursor was placed on a different

frequency before the fault lines where brought up. We can see

that the fault lines will fall where we place the cursor.

Bearing Problem

Our main concern is knowing the spacing of the defect

frequencies. This is what is displayed when we bring

up the fault frequencies in the Time Waveform, the

Spacing.

Let us examine the Waveform further:

The Primary calculated defect frequency for the

BPFI = 134.4 HZ, so the repetition rate of the

impacts would calculate to 134.4 Hz.

We still have to find the impacts that are occurring at

that spacing. This will take some time for the analyst

to develop this ability to spot the equal spacing.

12-55

Bearing Problem

12-56

When initially viewing the Waveform we look for events that are

repeated, we also look for events that are equally spaced. In this

plot there are several events that are repeated and equally

spaced.

Bearing Problem

12-56

We know from the Spectral display that we have an inner race

defect. Lets display the fault frequency for the BPFI, first without

a cursor marking any event.

Bearing Problem

12-57

All we are trying to do with this display at this point is to look for

impacts that may represent the BPFI. There could be BPFOs,

BSFs also. We will focus on the BPFIs.

Bearing Problem

12-57

After placing the cursor on a peak we suspect is an impact from

a BPFI, then displaying the fault frequency for the BPFI, we can

see we have several peaks that match up.

17

Bearing Problem

12-58

We can view an expanded plot to see this a little clearer.

Bearing Problem

12-58

Place the cursor on an impact that matches up with a fault

line. Select the Set Mark option. Select Difference

cursor. Move the cursor to the next fault line, now look at the

Freq: at lower right hand corner. This should be very close to

the Primary Calculated Freq. for the BPFI.

In this example it is very close.

Bearing Problem

12-59

Alarms can also be utilized in Waveform analysis.Select Set-Up

from Tool Bar and you can set the Alarms and display them in the

Waveform.

Bearing Problem

12-59

Bearing Problem

12-60

The value for the Crest-Factor has been set to Peak 1.5 for the

display seen below.

Bearing Problem

12-60

18

pumps, fans, steam flow, late life bearings random vibration and noise

nonsynchronous frequencies cause moving, non stationary waveform synchronous vs

nonsynchronous

truncation of signal by bearings, supports, foundations or couplings nonlinear behavior truncated beats

bearings, gears, rolls natural frequencies or forcing frequency modulated by low frequency that is generated by the

fault

modulated pulses

motor faults, gears, bearings a forcing frequency is modulated by a fault frequency modulated frequencies

bearings, recips, flat spots, gear teeth (broken) some functional; some fault based pulses

grinders, motor driven fans, pumps where two forcing frequencies are close beats

generators (slot passing), gears, vane pass, bearings, naturally generated harmonics superimposed on 1x multiple harmonics

heavy 1x behavior can excite order located natural frequencies order excited natural

frequencies

misalignment, looseness, generator faults orders

rubs, oil whirl, resonance, trapped fluid hysteresis, looseness subharmonics

gear mesh, blade pass, natural frequencies, nonlinear behavior truncated harmonics

excessive mass unbalance, thermal growth, bearing clearance problems, pedestal nonlinearity, rubs truncated 1x

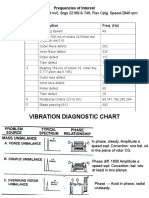

mass unbalance, resonance, eccentricity, misalignment, bow, blade/diffuser interaction harmonic

MECHANISM SHAPE

TABLE 4.5. TIME WAVEFORMSHAPE ANALYSIS

Part 1 - Summary

12-61

Waveform data may be used for much more than what

is typically seen in industry. The ability to check for

specific characteristics such as periodicity and

modulation, helps the analysis process.

Energy balance (asymmetry) may be checked for

direction of signal and for the predominant traits of the

signal.

Overall waveform is much more understandable and

useful than most would lead us to believe. However,

this section enhances your analysis abilities using the

time waveform.

DIGITIZED TIME DOMAIN

TRENDS

What is this spectrum Lines?

DIGITIZED TIME DOMAIN

DETAILS

What is this spectrum Lines?

PRESENTATION OF TIME

WAVEFORM

TIME (sec.) DISPLAY PURPOSE

T/100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - DETAILS OF

T/80 HIGHER FREQUENCY

T/20

T/10 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- -TRENDS OF

T/3 HIGHER FREQUENCY

T/2

T - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - BALANCING/PHASE

2T

3T

10 T- - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - PHASE TRENDS

20T

80T

100T - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - LONG TERM TIME TRENDS

Table 4.4. An Approach to the Presentation of a Standardized Time Waveform

4.1

TIME DOMAIN WAVEFORM TREND

4000 HP Induction Motor with 200T Display

19

TIME DOMAIN WAVEFORM SHORT

TERM

4000 HP Electric Motor with 20T Display

TIME DOMAIN WAVEFORM BALANCING

4000 HP Electric Motor with T Display

TIME DISPLAY SMALL MOTOR

400T

Small Motor with a 400T Display

SMALL MOTOR 100T

Small Motor with a 100T Display

GEARBOX 10T

Gearbox with 10T Display

GEARBOX 1T ON MESH

Gearbox with T Display Shows Gearmeshing Effects

20

PRESENTATION SETUP

Visual process

Setup to accommodate visual analysis

to evaluate

periodicity

to evaluate amplitude changes

Processing types

dual processing

expansion

STANDARD SETUP

Standard Time Waveform Display from an FFT Analyzer

DUAL PROCESSING

Dual Processing to Enhance the Time Waveform

SPECTRUM:

10x operating speed

f

max

= 250 Hz

TIME WAVEFORM:

Period = = 0.0421

Display = 8 cycles x 0.0421 0.336 sec

Use 0.4 sec then

DUAL PROCESSING

cycle

sec

75 . 23

1

cycle

sec

Hz 000 , 1

sec + . 0

lines +00

F

NAX

= =

Dual Processing means:the capability to produce each

Spectrum and Time waveform data independently

(spectrum Fmax not equal to waveform Fmax)

PHASE MEASUREMENT

Use of Cursor to Measure Period and Amplitude

TRUNCATED 1X

Single Frequency Due to Mass Unbalance with

Clipping Due to Excessive Amplitude

21

TRUNCATED HARMONIC

Clipped Vane Pass Signal from Hull of a Ship

SUBHARMONIC

Loose Bearing Housing Orders and Multiples

ORDERS

Nonlinear Generator Pedestal Response to Differing Vertical

Stiffness

FAR REMOVED ORDER

Slot Passing Frequency, 36X, Generated by Air Gap Variation (120

Hz)

BEATS

Beats Caused by Two Adjacent Cavitated Vacuum Pumps

PULSES

Pulses from a Bearing Defect

22

AMPLITUDE MODULATION

Sidebands Caused by Amplitude Modulation Broken Rotor Bar

PULSE INDUCED NATURAL

FREQUENCIES

Pulse Induced Natural Frequencies in Printing Roll

TRUNCATED BEATS

Truncated Beat Waveform from a Motor Driven Fan

SYNCHRONOUS ORDERS

Exciter to Generator Misalignment Causing 1x and 2x

RANDOM NOISE and VIBRATION RMS

AVERAGING

Excessive Flow Noise Caused by

Pump Operating Off the Curve-Recirculation

CONCLUSIONS

True physical behavior

Determine origin of frequencies

Determine severity

23

NONSYNCHRONOUS MULTIPLE

FREQUENCIES

Boiler Feed Pump Drive Nonsynchronous Second Order and

Multiples

SINUSOIDAL AMPLITUDE

MODULATION

Amplitude Modulation by a Single Frequency

NONSINUSOIDAL AMPLITUDE

MODULATION

Amplitude Modulation in a Gearbox Nonsinusoidal

MACHINE RESPONSE TO IMPACT

EXCITATION

Response of a Machine to Impulse Excitation

IMPACT INDUCED NATURAL

FREQUENCIES

Broken Gear Tooth Yielding Pulse Induced Natural Frequencies and

Abrupt Pulse Loading in Time Domain

LIGHT IMPACT

INDUCED ORDERS

Gradual Entering Pulse Caused by Misalignment, Eccentricity, or

Tooth Profile Wear in a Gearbox

24

FREQUENCY MODULATION

Torsional Vibration a Form of Frequency Modulation

DIFFERENCE FREQUENCIES

Two Lobed Blower Generated Difference Frequencies Pressure

Pulsations Generated by Lobes Passing Discharge Port

MECHANISMS FOR

ORDER GENERATION

Natural excitation

Nonlinear parameters

Signal truncation

BEAT MECHANISM

Figure 4.50. Beat Mechanism

TRUNCATED BEATS

Hypothetical Vibration Response Exhibiting Beat Frequency

SUM and DIFFERENCE

FREQUENCY TABLE

25

SUM and DIFFERENCE

FREQUENCY MECHANISMS

Rotating Machinery Fault Diagnosis Using Sum and Difference

Frequencies (Sidebands) (After Eshleman 4.2)

SUM and DIFFERENCE FREQUENCIES

PISTON PUMP/ENGINE

Pulsating Torque from an Engine-Pump Unit

SUM and DIFFERENCE

FREQUENCIES

TURBINE PIPING

Frequency Domain Record of Line Shaft

Turbine Piping Vibration

SPECTRUM SHAPE

Misalignment Induced Air Gap Vibration

DEMODULATION

Mechanism

Rolling element bearings

Techniques

MODULATION MECHANISM

High frequency vibration amplitude is altered due

to mechanical defects

Low frequency modulator points to problem area

Used extensively for gears and bearings

26

GEARBOX MODULATION

Amplitude Modulation in a Gearbox Nonsinusoidal

IMPACT INDUCED MODULATION

Pulse Induced Natural Frequencies in Printing Roll

DEMODULATION

Figure 4.58. Spectrum of a Demodulated Signal

BEARING DEFECT

Outer Race Defect on Rolling Element Bearing Pulsation Effect

BEARING DEFECT FREQUENCY

ZONES

Machine Vibration Response to Bearing Faults

DEMODULATION

OF A SIGNAL

Demodulation of a Signal

Copyright 2002 by Ronald L. Eshleman. All rights reserved. This figure may not be reproduced without permission of

Ronald L. Eshleman.

Вам также может понравиться

- Mechanical Vibrations and Condition MonitoringОт EverandMechanical Vibrations and Condition MonitoringРейтинг: 5 из 5 звезд5/5 (1)

- An Introduction To Time Waveform AnalysisДокумент21 страницаAn Introduction To Time Waveform AnalysisMohd Asiren Mohd Sharif100% (3)

- Section II - Basic Vibration TheoryДокумент85 страницSection II - Basic Vibration Theoryagiba100% (7)

- Timebase Plots ExplainedДокумент18 страницTimebase Plots ExplainedManuel L LombarderoОценок пока нет

- An Introduction To Time Waveform AnalysisДокумент17 страницAn Introduction To Time Waveform AnalysisBassemОценок пока нет

- Detection of Ski Slopes in Vibration SpectrumsДокумент7 страницDetection of Ski Slopes in Vibration SpectrumsjeyaselvanmОценок пока нет

- Detect Machinery Faults by Using Peak VueДокумент13 страницDetect Machinery Faults by Using Peak VueHarold Alconz100% (2)

- VibMatters Current IssueДокумент19 страницVibMatters Current IssueUsman JabbarОценок пока нет

- AMPLITUDE MODULATION Versus BEATSДокумент5 страницAMPLITUDE MODULATION Versus BEATSHaitham YoussefОценок пока нет

- SKF - Tech Associates of CharlotteДокумент57 страницSKF - Tech Associates of Charlotteiatorres100% (4)

- Introduction To PeakvueДокумент55 страницIntroduction To PeakvuesebastianОценок пока нет

- Vibration Diagnostic Chart1Документ16 страницVibration Diagnostic Chart1Anand KumarОценок пока нет

- Autocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookДокумент8 страницAutocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookLe Thanh Hai100% (2)

- VIBS Modal Overview 021703 MACLДокумент55 страницVIBS Modal Overview 021703 MACLBakkiya RajОценок пока нет

- Advanced Vibration Analysis TechniquesДокумент324 страницыAdvanced Vibration Analysis Techniquesharikrishnanpd3327Оценок пока нет

- CHAPTER 6 Resonance and Critical Speed TestingДокумент31 страницаCHAPTER 6 Resonance and Critical Speed TestingHosam Abd Elkhalek67% (3)

- PeakvueДокумент68 страницPeakvueChe Khairuddin100% (1)

- Phase MeasurementДокумент5 страницPhase Measurementuak107080Оценок пока нет

- 11 PeakVue OverviewДокумент38 страниц11 PeakVue OverviewAhmad Syahroni100% (1)

- Using Time Waveform Analysis To Distinguish Looseness From MisalignmentДокумент5 страницUsing Time Waveform Analysis To Distinguish Looseness From MisalignmentManel Montesinos100% (1)

- Analisis de Vibraciones Mecanicas SKFДокумент31 страницаAnalisis de Vibraciones Mecanicas SKFJhonathan GarciaОценок пока нет

- A Review of Enveloping and Demodulation TechniquesДокумент6 страницA Review of Enveloping and Demodulation TechniquesMohamed WahidОценок пока нет

- ORBIT AnalysisДокумент4 страницыORBIT AnalysisManoj PaneriОценок пока нет

- Analyzing Gearbox Degradation Using Time-Frequency Signature AnalysisДокумент13 страницAnalyzing Gearbox Degradation Using Time-Frequency Signature AnalysisMohd Asiren Mohd Sharif100% (1)

- Vibration Analysis Manual Rev0Документ143 страницыVibration Analysis Manual Rev0iradanke100% (5)

- Time Waveform Analysis Choosing Proper SettingsДокумент3 страницыTime Waveform Analysis Choosing Proper SettingssebastianОценок пока нет

- Time Waveform Analysis CourseДокумент4 страницыTime Waveform Analysis CourseDean LofallОценок пока нет

- Vibration Adv 0402Документ433 страницыVibration Adv 0402Sajid Rafique100% (7)

- ISO 18436 Category IVДокумент2 страницыISO 18436 Category IVzona amrullohОценок пока нет

- Diagnostic Techniques For Vibration Analysis of BearingsДокумент9 страницDiagnostic Techniques For Vibration Analysis of BearingsMohd Asiren Mohd Sharif100% (1)

- Advanced Vibration Analysis On Gear Box TrainДокумент25 страницAdvanced Vibration Analysis On Gear Box TrainmitrachintuОценок пока нет

- Vibration NotesДокумент95 страницVibration NotesHaitham Youssef100% (1)

- PeakVue TrainingДокумент98 страницPeakVue TrainingThyagaraju Palisetty100% (5)

- Vibration Chart CharloteДокумент25 страницVibration Chart Charloteantok09100% (1)

- Gearbox Vibration Analysis Case StudiesДокумент8 страницGearbox Vibration Analysis Case StudiesAndré Luiz Nogueira100% (5)

- Electric Motor Diagnostics Defect Frequencies and Data ColleДокумент51 страницаElectric Motor Diagnostics Defect Frequencies and Data ColleSubrata Dubey50% (2)

- Envelope BearingДокумент14 страницEnvelope BearingHussein Razaq100% (1)

- Introduction To Time Wave Form AnalysisДокумент19 страницIntroduction To Time Wave Form Analysissaidha4568483Оценок пока нет

- Vibration Measurements On Slow Speed MachineryДокумент9 страницVibration Measurements On Slow Speed MachineryMohd Asiren Mohd SharifОценок пока нет

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- Forsthoffer’s Component Condition MonitoringОт EverandForsthoffer’s Component Condition MonitoringРейтинг: 4 из 5 звезд4/5 (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentОт EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionОт EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionОценок пока нет

- Intelligent Fault Diagnosis and Remaining Useful Life Prediction of Rotating MachineryОт EverandIntelligent Fault Diagnosis and Remaining Useful Life Prediction of Rotating MachineryРейтинг: 5 из 5 звезд5/5 (2)

- Vibration AnalyzersДокумент16 страницVibration Analyzersyogacruise100% (1)

- Capgo - Vibration MonitoringДокумент3 страницыCapgo - Vibration MonitoringSufean SakinОценок пока нет

- Sonic Scanner GuideДокумент12 страницSonic Scanner Guidesdb158Оценок пока нет

- EECKT230 - Course Material 1Документ35 страницEECKT230 - Course Material 1reasjames0Оценок пока нет

- Oscillator Noise Analysis: Cyclostationary NoiseДокумент12 страницOscillator Noise Analysis: Cyclostationary Noisedeepakvaj25Оценок пока нет

- VibrationДокумент54 страницыVibrationmayureshrmahajan100% (3)

- United States Naval Academy: Division ofДокумент13 страницUnited States Naval Academy: Division ofdrdinglechengОценок пока нет

- Radar Signal Processing Graduate CourseДокумент70 страницRadar Signal Processing Graduate CourseWesley GeorgeОценок пока нет

- Introduction To Radar: - Information in This Presentation Can Be Found in A Number of Texts On RadarДокумент66 страницIntroduction To Radar: - Information in This Presentation Can Be Found in A Number of Texts On RadarParveen Verma100% (1)

- TC 503 Digital Communication Theory: Bandpass Modulation and DemodulationДокумент20 страницTC 503 Digital Communication Theory: Bandpass Modulation and Demodulationsyed02Оценок пока нет

- BTS3911B Product Description (V100R010C10 - 01) (PDF) - enДокумент34 страницыBTS3911B Product Description (V100R010C10 - 01) (PDF) - enmirs100% (1)

- ZTE UMTS Congestion Control Feature Guide - V1 10Документ47 страницZTE UMTS Congestion Control Feature Guide - V1 10GiftОценок пока нет

- Stud Finder Final v1Документ6 страницStud Finder Final v1api-323825539Оценок пока нет

- Introduction To Modulation: Baseband and Passband SignalsДокумент7 страницIntroduction To Modulation: Baseband and Passband Signalspraveen alwisОценок пока нет

- SK08A Addressable Loop-Powered Siren Installation Sheet (Multilingual) R2.0Документ12 страницSK08A Addressable Loop-Powered Siren Installation Sheet (Multilingual) R2.0123vb123Оценок пока нет

- Daily Top 10 Worst Cell Report - 2G & 3GДокумент8 страницDaily Top 10 Worst Cell Report - 2G & 3GBona RadiantoОценок пока нет

- Seminar Report On Wireless Local Area NetworkДокумент38 страницSeminar Report On Wireless Local Area Networknjpatel9100% (12)

- Saini 2015Документ6 страницSaini 2015SaduMunisekharОценок пока нет

- 2945A ManualДокумент249 страниц2945A Manualmakara5966Оценок пока нет

- 399 Open Amipv2Документ2 страницы399 Open Amipv2CanhCuaCàMuốiОценок пока нет

- Manual de Usuario SMCWEBT-GДокумент2 страницыManual de Usuario SMCWEBT-GxXHercules01XxОценок пока нет

- Computer Networks-2024Документ1 страницаComputer Networks-2024dreamdalesocietyОценок пока нет

- Airspan Mobile Wimax RF Planning Parameters PDFДокумент23 страницыAirspan Mobile Wimax RF Planning Parameters PDFrapsterxОценок пока нет

- Digital Subscriber Line (DSL)Документ6 страницDigital Subscriber Line (DSL)Archangel Gab100% (1)

- Jitter Wander SynchronisationДокумент58 страницJitter Wander Synchronisationaajayagarwal80Оценок пока нет

- Antenna RFI MonitoringДокумент71 страницаAntenna RFI MonitoringmoannaОценок пока нет

- FTTX GPONДокумент25 страницFTTX GPONAlirezaОценок пока нет

- ADC0808/ADC0809: General DescriptionДокумент7 страницADC0808/ADC0809: General DescriptionSebastin AshokОценок пока нет

- Nokia Wi-Fi Access Point AC400i 4x4 Standalone Indoor - Data Sheet v3.9Документ3 страницыNokia Wi-Fi Access Point AC400i 4x4 Standalone Indoor - Data Sheet v3.9zeb066100% (1)

- QSC Amp Spa2-60 PDFДокумент2 страницыQSC Amp Spa2-60 PDFAnthony Marin De FreitasОценок пока нет

- Crystal oscillation circuit diagrams for quartz crystal unitsДокумент3 страницыCrystal oscillation circuit diagrams for quartz crystal unitsRAVINDERОценок пока нет

- Adu4518r5 PDFДокумент2 страницыAdu4518r5 PDFНиколайИгоревичНасыбуллинОценок пока нет

- Local Area Networks GuideДокумент27 страницLocal Area Networks GuidePriyanka BhavsarОценок пока нет

- Signals and SystemsДокумент42 страницыSignals and Systemsjijo123408Оценок пока нет

- Ericsson Product Training: Rahul KansalДокумент83 страницыEricsson Product Training: Rahul KansalThinley Wangmo100% (1)

- 5GNOW D3.2 v1.3Документ100 страниц5GNOW D3.2 v1.3Edson SilvaОценок пока нет

- SCX2 W100BCДокумент2 страницыSCX2 W100BCpandavision76Оценок пока нет

- IARU Region 1 HF Band Plan: Effective 01 June 2016Документ4 страницыIARU Region 1 HF Band Plan: Effective 01 June 2016Andreas KakkavasОценок пока нет

- ZYTLДокумент9 страницZYTLqlxiaoОценок пока нет

- 1.LZU 1088614 R1A Microwave Transmission Technology - OverviewДокумент14 страниц1.LZU 1088614 R1A Microwave Transmission Technology - OverviewAmine MohamedОценок пока нет