Академический Документы

Профессиональный Документы

Культура Документы

TDA7072 Datasheet

Загружено:

sergio_741Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TDA7072 Datasheet

Загружено:

sergio_741Авторское право:

Доступные форматы

INTEGRATED CIRCUITS

DATA SHEET

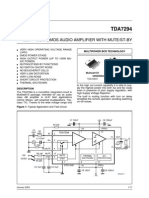

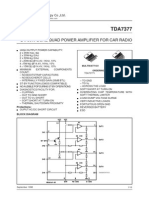

TDA7072A/AT Single BTL power driver

Objective specication File under Integrated circuits, IC01 July 1994

Philips Semiconductors

Objective specication

Single BTL power driver

FEATURES No external components Very high slew rate Single power supply Short-circuit proof High output current (0.6 A) Wide supply voltage range Low output offset voltage Suited for handling PWM signals up to 176 kHz ESD protected on all pins Missing Current Limiter (MCL) GENERAL DESCRIPTION

TDA7072A/AT

The TDA7072A/AT are single power driver circuits in a BTL configuration, intended for use as a power driver for servo systems with a single supply. They are specially designed for compact disc players and are capable of driving focus, tracking, sled functions and spindle motors.

A MCL protection circuit is built-in. The MCL circuit is activated when the difference in current between the output terminal of each amplifier exceeds 100 mA (typical 300 mA). This level of 100 mA allows for headphone applications (single-ended).

QUICK REFERENCE DATA SYMBOL VP Gv IP SR IO Ibias fco PARAMETER positive supply voltage range internal voltage gain total quiescent current slew rate output current input bias current cut-off frequency 3 dB VP = 5 V; RL = CONDITIONS MIN. 3.0 32.5 TYP. 5.0 33.5 4 12 100 1.5 MAX. 18 34.5 8 0.6 300 UNIT V dB mA V/s A nA MHz

ORDERING INFORMATION EXTENDED TYPE NUMBER TDA7072A TDA7072AT Notes 1. SOT97-1; 1996 September 10. 2. SOT96-1; 1996 September 10. 8 8 PACKAGE PINS DIL mini-pack PIN POSITION MATERIAL plastic plastic CODE SOT97(1) SOT96A(2)

July 1994

Philips Semiconductors

Objective specication

Single BTL power driver

TDA7072A/AT

VP

handbook, full pagewidth

TDA7072A TDA7072AT

I + i 5 positive output

positive input

2 SHORT - CIRCUIT AND THERMAL PROTECTION

negative input

I i

negative output

4 n.c.

7 n.c.

MCD377 - 1

ground

Fig.1 Block diagram.

PINNING SYMBOL VP IN+ IN n.c. OUT+ GND n.c. OUT 1 2 3 4 5 6 7 8 PIN DESCRIPTION positive supply voltage positive input negative input not connected positive output ground not connected negative output Fig.2 Pin configuration.

n.c. 4

MCD378

handbook, halfpage

VP IN + IN

1 2 3 TDA7072A TDA7072AT

8 7 6 5

OUT n.c. GND OUT +

July 1994

Philips Semiconductors

Objective specication

Single BTL power driver

FUNCTIONAL DESCRIPTION The TDA7072A/AT are single power driver circuits in a BTL configuration, intended for use as a power driver for servo systems with a single supply. They are particular designed for compact disc players and are capable of driving focus, tracking, sled functions and spindle motors. Because of the BTL configuration, the devices can supply a bi-directional DC current in the load, with only a single supply voltage. The voltage gain is fixed by internal

TDA7072A/AT

feedback at 33.5 dB and the devices operate in a wide supply voltage range (3 to 18 V). The devices can supply a maximum output current of 0.6 A. The outputs can be short-circuited over the load, to the supply and to ground at all input conditions. The differential inputs can handle common mode input voltages from ground level up to (VP 2.2 V). The devices have a very high slew rate. Due to the large bandwidth, they can handle PWM signals up to 176 kHz.

LIMITING VALUES In accordance with the Absolute Maximum System (IEC 134. SYMBOL VP IORM IOSM Ptot PARAMETER positive supply voltage range repetitive peak output current non repetitive peak output current total power dissipation TDA7072A TDA7072AT Tstg Tvj Tsc storage temperature range virtual junction temperature short-circuit time see note Tamb < 25 C 55 1.25 0.54 +150 +150 1 W W C C hr CONDITIONS MIN. MAX. 18 1 1.5 UNIT V A A

Note to the limiting values The outputs can be short-circuited over the load, to the supply and to ground at all input conditions. THERMAL RESISTANCE SYMBOL Rth j-a TDA7072A TDA7072AT Note to the thermal resistance TDA7072A: VP = 5 V; RL = 8 ; The typical voltage swing = 5.8 V and Vloss is 2.1 V therefore IO = 0.36 A and Ptot = 0.76 W; Tamb (max) = 150 0.76 100 = 74 C TDA7072AT: VP = 5 V; RL = 16 typical voltage swing = 5.8 V and Vloss is 2.1 V therefore IO = 0.18 A and Ptot = 0.38 W; Tamb (max) = 150 0.38 155 = 91 C PARAMETER from junction to ambient in free air 100 K/W 155 K/W THERMAL RESISTANCE

July 1994

Philips Semiconductors

Objective specication

Single BTL power driver

TDA7072A/AT

CHARACTERISTICS VP = 5 V; f = 1 kHz; Tamb = 25 C; unless otherwise specied (see Fig.3>). TDA7072A: RL = 8 ; TDA7072AT: RL = 16 . SYMBOL VP IORM IP VOUT THD PARAMETER positive supply voltage range repetitive peak output current total quiescent current output voltage swing total harmonic distortion TDA7072A TDA7072AT Gv Vno(rms) B SVRR |V5-8| VI(CM) CMRR ZI Ibias SR voltage gain noise output voltage (RMS value) bandwidth supply voltage ripple rejection DC output offset voltage DC common mode voltage range DC common mode rejection ratio input impedance input bias current slew rate note 4 RS = 500 note 5 note 6 note 3 RL = ; note 1 note 2 VOUT = 1 V (RMS) 32.5 40 0 0.3 0.1 33.5 75 55 100 100 100 12 34.5 150 1.5 100 2.8 300 % % dB V MHz dB mV V dB k nA V/s CONDITIONS MIN. 3.0 5.2 TYP. 5.0 4 5.8 MAX. 18 0.6 8 UNIT V A mA V

Notes to the characteristics 1. With a load connected to the outputs the quiescent current will increase, the maximum value of this increase being equal to the DC output offset voltage divided by RL. 2. The output voltage swing is typically limited to 2 x (VP 2.1 V) (see Fig.4). 3. The noise output voltage (RMS value), unweighted (20 Hz to 20 kHz) is measured with RS = 500 . 4. The ripple rejection is measured with RS = 0 and f = 100 Hz to 10 kHz. The ripple voltage of 200 mV (RMS value) is applied to the positive supply rail. 5. The DC common mode voltage range is limited to (VP 2.2 V). 6. The common mode rejection ratio is measured at Vref = 1.4 V, VI(CM) = 200 mV and f = 1 kHz.

July 1994

Philips Semiconductors

Objective specication

Single BTL power driver

APPLICATION INFORMATION

TDA7072A/AT

(1)

handbook, full pagewidth

VP = 5 V 100 nF 220 F

1 SERVO SYSTEM

TDA7072A TDA7072AT

I + i 5

driver signal Rs Vref 500

2 (2) RL 3 I i 8

4 n.c.

7 n.c.

MCD379

ground (1) This capacitor can be omitted if the 220 F electrolytic capacitor is connected close to pin 1. (1) RL can be: focus, tracking, sled function or spindle motor.

Fig.3 Test and application diagram.

+ (VP 2.1) V

0V

MCD380

(VP 2.1) V

Fig.4 Typical output voltage swing over RL.

July 1994

Philips Semiconductors

Objective specication

Single BTL power driver

PACKAGE OUTLINES DIP8: plastic dual in-line package; 8 leads (300 mil)

TDA7072A/AT

SOT97-1

D seating plane

ME

A2

A1

c Z e b1 w M (e 1) b2 5 MH

b 8

pin 1 index E

5 scale

10 mm

DIMENSIONS (inch dimensions are derived from the original mm dimensions) UNIT mm inches A max. 4.2 0.17 A1 min. 0.51 0.020 A2 max. 3.2 0.13 b 1.73 1.14 0.068 0.045 b1 0.53 0.38 0.021 0.015 b2 1.07 0.89 0.042 0.035 c 0.36 0.23 0.014 0.009 D (1) 9.8 9.2 0.39 0.36 E (1) 6.48 6.20 0.26 0.24 e 2.54 0.10 e1 7.62 0.30 L 3.60 3.05 0.14 0.12 ME 8.25 7.80 0.32 0.31 MH 10.0 8.3 0.39 0.33 w 0.254 0.01 Z (1) max. 1.15 0.045

Note 1. Plastic or metal protrusions of 0.25 mm maximum per side are not included. OUTLINE VERSION SOT97-1 REFERENCES IEC 050G01 JEDEC MO-001AN EIAJ EUROPEAN PROJECTION

ISSUE DATE 92-11-17 95-02-04

July 1994

Philips Semiconductors

Objective specication

Single BTL power driver

TDA7072A/AT

SO8: plastic small outline package; 8 leads; body width 3.9 mm

SOT96-1

A X

c y HE v M A

Z 8 5

Q A2 A1 pin 1 index Lp 1 e bp 4 w M L detail X (A 3) A

2.5 scale

5 mm

DIMENSIONS (inch dimensions are derived from the original mm dimensions) UNIT mm inches A max. 1.75 A1 0.25 0.10 A2 1.45 1.25 A3 0.25 0.01 bp 0.49 0.36 c 0.25 0.19 D (1) 5.0 4.8 0.20 0.19 E (2) 4.0 3.8 0.16 0.15 e 1.27 0.050 HE 6.2 5.8 0.24 0.23 L 1.05 Lp 1.0 0.4 Q 0.7 0.6 v 0.25 0.01 w 0.25 0.01 y 0.1 Z (1) 0.7 0.3

0.0098 0.057 0.069 0.0039 0.049

0.019 0.0098 0.014 0.0075

0.039 0.028 0.041 0.016 0.024

0.028 0.004 0.012

8 0o

Notes 1. Plastic or metal protrusions of 0.15 mm maximum per side are not included. 2. Plastic or metal protrusions of 0.25 mm maximum per side are not included. OUTLINE VERSION SOT96-1 REFERENCES IEC 076E03S JEDEC MS-012AA EIAJ EUROPEAN PROJECTION

ISSUE DATE 92-11-17 95-02-04

July 1994

Philips Semiconductors

Objective specication

Single BTL power driver

SOLDERING Introduction There is no soldering method that is ideal for all IC packages. Wave soldering is often preferred when through-hole and surface mounted components are mixed on one printed-circuit board. However, wave soldering is not always suitable for surface mounted ICs, or for printed-circuits with high population densities. In these situations reflow soldering is often used. This text gives a very brief insight to a complex technology. A more in-depth account of soldering ICs can be found in our IC Package Databook (order code 9398 652 90011). DIP SOLDERING BY DIPPING OR BY WAVE The maximum permissible temperature of the solder is 260 C; solder at this temperature must not be in contact with the joint for more than 5 seconds. The total contact time of successive solder waves must not exceed 5 seconds. The device may be mounted up to the seating plane, but the temperature of the plastic body must not exceed the specified maximum storage temperature (Tstg max). If the printed-circuit board has been pre-heated, forced cooling may be necessary immediately after soldering to keep the temperature within the permissible limit. REPAIRING SOLDERED JOINTS Apply a low voltage soldering iron (less than 24 V) to the lead(s) of the package, below the seating plane or not more than 2 mm above it. If the temperature of the soldering iron bit is less than 300 C it may remain in contact for up to 10 seconds. If the bit temperature is between 300 and 400 C, contact may be up to 5 seconds. SO REFLOW SOLDERING Reflow soldering techniques are suitable for all SO packages. Reflow soldering requires solder paste (a suspension of fine solder particles, flux and binding agent) to be applied to the printed-circuit board by screen printing, stencilling or pressure-syringe dispensing before package placement.

TDA7072A/AT

Several techniques exist for reflowing; for example, thermal conduction by heated belt. Dwell times vary between 50 and 300 seconds depending on heating method. Typical reflow temperatures range from 215 to 250 C. Preheating is necessary to dry the paste and evaporate the binding agent. Preheating duration: 45 minutes at 45 C. WAVE SOLDERING Wave soldering techniques can be used for all SO packages if the following conditions are observed: A double-wave (a turbulent wave with high upward pressure followed by a smooth laminar wave) soldering technique should be used. The longitudinal axis of the package footprint must be parallel to the solder flow. The package footprint must incorporate solder thieves at the downstream end. During placement and before soldering, the package must be fixed with a droplet of adhesive. The adhesive can be applied by screen printing, pin transfer or syringe dispensing. The package can be soldered after the adhesive is cured. Maximum permissible solder temperature is 260 C, and maximum duration of package immersion in solder is 10 seconds, if cooled to less than 150 C within 6 seconds. Typical dwell time is 4 seconds at 250 C. A mildly-activated flux will eliminate the need for removal of corrosive residues in most applications. REPAIRING SOLDERED JOINTS Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron (less than 24 V) applied to the flat part of the lead. Contact time must be limited to 10 seconds at up to 300 C. When using a dedicated tool, all other leads can be soldered in one operation within 2 to 5 seconds between 270 and 320 C.

July 1994

Philips Semiconductors

Objective specication

Single BTL power driver

DEFINITIONS Data sheet status Objective specication Preliminary specication Product specication Limiting values

TDA7072A/AT

This data sheet contains target or goal specications for product development. This data sheet contains preliminary data; supplementary data may be published later. This data sheet contains nal product specications.

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation of the device at these or at any other conditions above those given in the Characteristics sections of the specication is not implied. Exposure to limiting values for extended periods may affect device reliability. Application information Where application information is given, it is advisory and does not form part of the specication. LIFE SUPPORT APPLICATIONS These products are not designed for use in life support appliances, devices, or systems where malfunction of these products can reasonably be expected to result in personal injury. Philips customers using or selling these products for use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such improper use or sale.

July 1994

10

This datasheet has been download from: www.datasheetcatalog.com Datasheets for electronics components.

Вам также может понравиться

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Ax2012 Enus Devi 01Документ26 страницAx2012 Enus Devi 01Tunde ObaОценок пока нет

- Modbus RTU Quick GuideДокумент8 страницModbus RTU Quick Guidehernangyc100% (1)

- Altec - Loudspeaker Enclosure - Their Design and Use (Circa 1975) PDFДокумент31 страницаAltec - Loudspeaker Enclosure - Their Design and Use (Circa 1975) PDFRaju100% (1)

- DGS 700 ManualДокумент28 страницDGS 700 Manualcarla monic dialinoОценок пока нет

- TDA7073A DatasheetДокумент17 страницTDA7073A Datasheetsergio_741Оценок пока нет

- Tda 1552 QДокумент10 страницTda 1552 QAnderson PotrikusОценок пока нет

- Data Sheet: 1 W BTL Mono Audio AmplifierДокумент9 страницData Sheet: 1 W BTL Mono Audio AmplifierJuan Cruz PalmaОценок пока нет

- Tda 1517Документ11 страницTda 1517minhchatnguyenОценок пока нет

- Tda 7052Документ8 страницTda 7052kunambersahajaОценок пока нет

- TDA1554Q 44W Audio AmplifierДокумент11 страницTDA1554Q 44W Audio Amplifiersava7698Оценок пока нет

- Data Sheet: Low Voltage Mono/stereo Power AmplifierДокумент9 страницData Sheet: Low Voltage Mono/stereo Power AmplifiergusguicorОценок пока нет

- Data Sheet: 2 X 6 W Stereo Car Radio Power AmplifierДокумент10 страницData Sheet: 2 X 6 W Stereo Car Radio Power Amplifierazzeddine_a7601Оценок пока нет

- Tda 7053Документ13 страницTda 7053Fer TgОценок пока нет

- VERTICAL DEFLECTION CIRCUIT DATA SHEETДокумент12 страницVERTICAL DEFLECTION CIRCUIT DATA SHEETd_richard_dОценок пока нет

- TDA1557QДокумент11 страницTDA1557QLuiz FernandoОценок пока нет

- TDA1552QДокумент11 страницTDA1552QMaja i Aleksandar JovanovićОценок пока нет

- Tda8920 2x50w Rms Class D AmplifierДокумент16 страницTda8920 2x50w Rms Class D AmplifierMarcisio Souza0% (1)

- Data Sheet: TDA1510AQДокумент12 страницData Sheet: TDA1510AQGerardo PonceОценок пока нет

- Tda 7293Документ16 страницTda 7293Gerson FelipeОценок пока нет

- Tda 1517Документ14 страницTda 1517Cris VMОценок пока нет

- TDA7262Документ9 страницTDA7262Nelson PereiraОценок пока нет

- 60528Документ23 страницы60528Andres CaminoОценок пока нет

- TDA7267AДокумент7 страницTDA7267AshareatorОценок пока нет

- ZVP4525GДокумент8 страницZVP4525GAlexander AnotherSituation MartinsonОценок пока нет

- Tda 7384Документ10 страницTda 7384totovasiОценок пока нет

- 5V Powered Multi-Channel RS-232 Drivers and Receivers: Feature SummaryДокумент19 страниц5V Powered Multi-Channel RS-232 Drivers and Receivers: Feature SummaryJosé PerezОценок пока нет

- Bt169 Series 3Документ7 страницBt169 Series 3Maneesh BakaleОценок пока нет

- Tda 7052Документ8 страницTda 7052Srinath NettemОценок пока нет

- Guide to 1W BTL Mono Audio Amplifier with DC Volume ControlДокумент12 страницGuide to 1W BTL Mono Audio Amplifier with DC Volume ControlMateus Soares Da SilvaОценок пока нет

- Tda 2613 QДокумент11 страницTda 2613 Qpaulmx13Оценок пока нет

- TDA8920C: 1. General DescriptionДокумент40 страницTDA8920C: 1. General DescriptionDaniel QuishpeОценок пока нет

- BT1306-400D/600D: 1. Product ProfileДокумент12 страницBT1306-400D/600D: 1. Product Profilesvhanu4010Оценок пока нет

- Tda 4662Документ12 страницTda 4662Miguel TorresОценок пока нет

- TDA7000Документ10 страницTDA7000Sreesha AmjuriОценок пока нет

- TDA7233 TDA7233D: 1W Audio Amplifier With MuteДокумент7 страницTDA7233 TDA7233D: 1W Audio Amplifier With MutepempushekОценок пока нет

- TDA2008Документ10 страницTDA2008miusayОценок пока нет

- TDA8941P: 1. General DescriptionДокумент21 страницаTDA8941P: 1. General DescriptionJosé Nicolás Auciello IОценок пока нет

- Tea2025b, D ST PDFДокумент10 страницTea2025b, D ST PDFblueword66Оценок пока нет

- Ta7280p, Ta7281pДокумент15 страницTa7280p, Ta7281pivirgilОценок пока нет

- Tda 7294Документ17 страницTda 7294Abubakar SidikОценок пока нет

- Hcmos Compatible, High CMR, 10 MBD OptocouplersДокумент16 страницHcmos Compatible, High CMR, 10 MBD Optocouplersnithinmundackal3623Оценок пока нет

- 3 Video Ampop - Tda6107qДокумент16 страниц3 Video Ampop - Tda6107qAnderson LuizОценок пока нет

- BLF244Документ16 страницBLF244Luis AlfredoОценок пока нет

- TDA1555QДокумент11 страницTDA1555QНикифор СтанојоскиОценок пока нет

- Ca 3083Документ4 страницыCa 3083tabassam7801Оценок пока нет

- 89v51Rd2 Microcontroller: Appendix 1Документ10 страниц89v51Rd2 Microcontroller: Appendix 1AmrutanarkhedeОценок пока нет

- Auo t370hw02 v1 Lcdpanel DatasheetДокумент28 страницAuo t370hw02 v1 Lcdpanel DatasheetIonescu CristinaОценок пока нет

- D D D D D D D D: DescriptionДокумент10 страницD D D D D D D D: DescriptionVíctor LópezОценок пока нет

- Tda 8947Документ24 страницыTda 8947lilithenigelОценок пока нет

- Tda8950 PDFДокумент39 страницTda8950 PDFElcura EdgarОценок пока нет

- Data Sheet: SAB6456 SAB6456TДокумент11 страницData Sheet: SAB6456 SAB6456Tbanduat83Оценок пока нет

- TDA1514AДокумент10 страницTDA1514AMuammar RiskiОценок пока нет

- 1915 LMM 40km WDMДокумент5 страниц1915 LMM 40km WDMwattanayimpearОценок пока нет

- TDA7294Документ18 страницTDA7294frank121212Оценок пока нет

- Tda 8920 CJДокумент40 страницTda 8920 CJhawarnetОценок пока нет

- Tda 7268Документ6 страницTda 7268suckysuckОценок пока нет

- 110 Waveform Generator Projects for the Home ConstructorОт Everand110 Waveform Generator Projects for the Home ConstructorРейтинг: 4 из 5 звезд4/5 (1)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsОт EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsОценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1От EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Рейтинг: 4.5 из 5 звезд4.5/5 (3)

- AutoCAD 2015 2018 Geolocation Online Map HotfixДокумент2 страницыAutoCAD 2015 2018 Geolocation Online Map HotfixkovaryОценок пока нет

- Ax2012 Enus Devi 04Документ20 страницAx2012 Enus Devi 04sergio_741Оценок пока нет

- SSRS 2008 TutorialДокумент23 страницыSSRS 2008 TutorialajelenaОценок пока нет

- SQL Queries ExamplesДокумент13 страницSQL Queries ExamplesSrinadh MulpuriОценок пока нет

- Ax2012 Enus Devi 02Документ32 страницыAx2012 Enus Devi 02sergio_741Оценок пока нет

- GIS For Web DevelopersДокумент258 страницGIS For Web DevelopersHardik KalasuaОценок пока нет

- Ax2012 Enus Dev 2Документ162 страницыAx2012 Enus Dev 2sergio_741Оценок пока нет

- Ax2012 Enus Dev 3Документ210 страницAx2012 Enus Dev 3sergio_741Оценок пока нет

- 7816v2.0 (G52-78161X4) (Z87-G43 GAMING - H87-G43 GAMING - B85-G43 GAMING)Документ110 страниц7816v2.0 (G52-78161X4) (Z87-G43 GAMING - H87-G43 GAMING - B85-G43 GAMING)sergio_741Оценок пока нет

- Ax2012 Enus Dev 1Документ110 страницAx2012 Enus Dev 1sergio_741Оценок пока нет

- Ax2012 Enus Dev 2Документ162 страницыAx2012 Enus Dev 2sergio_741Оценок пока нет

- ZPL Vol2Документ164 страницыZPL Vol2obanja1Оценок пока нет

- Ax2012 Enus Devi TocДокумент2 страницыAx2012 Enus Devi Tocsergio_741Оценок пока нет

- Ax2012 Enus Devi DisclДокумент2 страницыAx2012 Enus Devi Disclsergio_741Оценок пока нет

- 4 X 40W Quad Bridge Car Radio Amplifier: Protections: DescriptionДокумент10 страниц4 X 40W Quad Bridge Car Radio Amplifier: Protections: DescriptionAngel QuiñonesОценок пока нет

- Autodesk Storm Sanitary Analysis 2011Документ520 страницAutodesk Storm Sanitary Analysis 2011driettiОценок пока нет

- TL 072Документ47 страницTL 072serocktuxОценок пока нет

- 2 X 3 W Dual/Quad Power Amplifier For Car Radio: ProtectionsДокумент10 страниц2 X 3 W Dual/Quad Power Amplifier For Car Radio: ProtectionsJosé VidalОценок пока нет

- AX2012 User Interfaces 03Документ24 страницыAX2012 User Interfaces 03indusaОценок пока нет

- TL074 Datasheet Op - AmpДокумент15 страницTL074 Datasheet Op - Ampsergio_741Оценок пока нет

- Exelente Amplificador de 100w TDA7294Документ17 страницExelente Amplificador de 100w TDA7294Everson CorreaОценок пока нет

- Tda 2052Документ15 страницTda 2052Mocanu Vicentiu-AdrianОценок пока нет

- 32W Hi-Fi Audio Power Amplifier: DescriptionДокумент13 страниц32W Hi-Fi Audio Power Amplifier: DescriptionIrfan JomblizОценок пока нет

- IC TDA 1562Q DatsheetДокумент20 страницIC TDA 1562Q Datsheetnaupas007Оценок пока нет

- Can Ana and Ted be friendsДокумент14 страницCan Ana and Ted be friendssergio_741Оценок пока нет

- Info Pasa BajosДокумент18 страницInfo Pasa Bajossergio_741Оценок пока нет

- Detectors and Focal Plane Assembly: Christine Allen Naresh Das Mike AmatoДокумент72 страницыDetectors and Focal Plane Assembly: Christine Allen Naresh Das Mike Amatobjsimard100% (1)

- DENSO Diagnostic TipsДокумент1 страницаDENSO Diagnostic TipsVerona MamaiaОценок пока нет

- How To Design Multi KW Converters For Electric Vehicles Part 1 Ev System OverviewДокумент8 страницHow To Design Multi KW Converters For Electric Vehicles Part 1 Ev System OverviewSROTRIYA TRIPATHIОценок пока нет

- Vehicle Tracking System Using GpsДокумент3 страницыVehicle Tracking System Using GpsDhruv PatelОценок пока нет

- Samsung LCD Le40b530Документ336 страницSamsung LCD Le40b530Carlos SeguraОценок пока нет

- Tugas Jawab TN-F 1-100 Hal 1225-1249Документ25 страницTugas Jawab TN-F 1-100 Hal 1225-1249Anonymous jyWpsYОценок пока нет

- MX23C6410MC 10Документ9 страницMX23C6410MC 10tangbunna8696Оценок пока нет

- Bosch PAViRO Controller SpecsДокумент3 страницыBosch PAViRO Controller SpecsMihai ConstantinescuОценок пока нет

- PWMДокумент30 страницPWMMelissa MillerОценок пока нет

- 1 Oy034sДокумент4 страницы1 Oy034sPhuc HoangОценок пока нет

- Simplex 4100-0005Документ4 страницыSimplex 4100-0005vlaya1984100% (1)

- HT-MC100 DS en 02.2013 V3.2Документ3 страницыHT-MC100 DS en 02.2013 V3.2Muhammad UmarОценок пока нет

- Wire Lengths For 4 and 9-1 UnunsДокумент4 страницыWire Lengths For 4 and 9-1 UnunsPatrickBelaireОценок пока нет

- CH - 1 Digital SystemsДокумент44 страницыCH - 1 Digital SystemsRaquel BarretoОценок пока нет

- Microprocessor and Programming 4TH SEM CM-IfДокумент174 страницыMicroprocessor and Programming 4TH SEM CM-IfAbha SinghОценок пока нет

- BGY888 Philips PDFДокумент12 страницBGY888 Philips PDFPoso TvОценок пока нет

- Discrete 1Документ14 страницDiscrete 1Narmatha RamasamyОценок пока нет

- A Simple TestДокумент3 страницыA Simple Testkipkoech_rotichОценок пока нет

- Programming FundamentalsДокумент35 страницProgramming FundamentalsAli SarmadОценок пока нет

- 01 Lineas de AudiomaДокумент43 страницы01 Lineas de AudiomaAleex IsLassОценок пока нет

- MRA1 - Trip Circuit Supervision: Manual MRA1 (Revision A)Документ20 страницMRA1 - Trip Circuit Supervision: Manual MRA1 (Revision A)Andrea MaurillaОценок пока нет

- Lecture16 PDFДокумент32 страницыLecture16 PDFBaphelele MnisiОценок пока нет

- Quanta BLBD R1a 20101122 SchematicsДокумент43 страницыQuanta BLBD R1a 20101122 SchematicskasimkaОценок пока нет

- Digilent Synchronous Parallel Interface (DSTM)Документ10 страницDigilent Synchronous Parallel Interface (DSTM)Raul Gil BayardoОценок пока нет

- Automatic Power Factor Detection and CorДокумент53 страницыAutomatic Power Factor Detection and CorAshritaОценок пока нет

- SMX Range: Operating InstructionsДокумент28 страницSMX Range: Operating InstructionsIanRendallОценок пока нет

- Assignment 1 Comp314Документ6 страницAssignment 1 Comp314Lam DerekОценок пока нет