Академический Документы

Профессиональный Документы

Культура Документы

Purchasing Agent or Purchasing Manager

Загружено:

api-121447506Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Purchasing Agent or Purchasing Manager

Загружено:

api-121447506Авторское право:

Доступные форматы

John Marshall JOHN MARSHALL [925] 281-3964 [ALT 925-461-0206] jm139ceee@westpost.

net POSITION SOUGHT: Senior Buyer, Purchasing/ Materials Manager SUMMARY * Procurement Professional with charted success in cost reduction, time to market product development, design for manufacturability and Lean Manufacturing. * Experience in Manufacturing Techniques and Processes as well as Supply Chain Management. Earned Tool & Die Journeyman papers 1970. * Outstanding team building and problem resolution skills. * Developed, initiated and managed programs that significantly reduced inventory levels. (i.e., $6M net within 6 months of program start.) * Procurement team coordinator for implementation of SAP and ERP launch while maintaining daily operations. Completed implementation on time and under budget. * Commodity Manager of MRO and Capital Equipment for facility relocation project. * Procurement Program Manager for Co-Gen facility construction completed two weeks ahead of schedule and under budget._ _ PROFESSIONAL EXPERIENCE SYSTRON DONNER, CONCORD, CA 3/2004-7/2010 COMPANY PROFILE: Develops and manufactures micro electro mechanical systems, inertial navigation units and quartz rate sensors for aerospace applications. SENIOR PURCHASING CONTRACTS ADMINISTRATOR

Managed and controlled inventory of fabricated components and assemblies for guidance systems and motion sensing devices valued at over $20M annually. * Reduced supplier base in manufacture components by 18% through review of supplier capabilities allowing savings of over $2M by consolidation of procurement. * Developed sourcing and managed materials acquisitions for R&D and new products under development, worked closely with Engineering to select supplier with highest level of performance to contract, pricing and quality for all programs. Contract types: CPFF, FFP. CRAF * Initiated and tracked RFP documents for complex manufacturing and test equipment, building services, office telephone, copy equipment and computer equipment, consulting services, negotiated final contracts & tracked progress. * Generated and provided total cost evaluations for management with specific recommendations. Upon receipt of authorization developed, negotiated and initiated the contracts and non-disclosure documentation with suppliers. * Regulations management under ITAR, EAR, FAR, DOD & DFAR & UCC * Coordinated and negotiated complete facility relocation (twice) for the company. Achieved significant cost reductions which permitted completion $10K under budget. KEY COMMODITIES: * subcontract machined components * stampings, castings and forgings * Ceramic and Quartz components * Hermetic assemblies * Application Specific Integrated circuits

SIEMENS ONCOLOGY SYSTEMS, CONCORD, CA 8/1998-3/2004 COMPANY PROFILE: Siemens Healthcare is one of the first companies to bring together medical imaging and therapy, laboratory diagnostics, and healthcare IT solutions across the continuum of care. LOGISTICS PURCHASING ADMINISTRATOR Planned and purchased all major system components and fabrications for large medical treatment equipment valued at $10-15MM annually. * Generated cost savings in excess of $250,000 annually thru negotiation of national supply contracts, and strategic procurement of business critical items. * Reduced supplier base 15% in first 6 months through supplier consolidation efforts. * Contract types: CPFF, FFP. CRAF & T&M * Regulations management under GMP, FDA & MBP & UCC * Served as purchasing coordinator for implementation of SAP software and ERP program. Completed implementation on time and $7.5K under budget. KEY COMMODITIES: * complex drive system components * electromechanical subassemblies * large welded & fabricated and machined sub-assemblies * cast and forged copper and tungsten components * standard and custom components and MRO supplies POWIS PARKER, INC, BERKELEY, CA 3/1995-7/1998 COMPANY PROFILE: Powis Parker is the inventor of Fastback revolutionary tabletop binding machines that produce strong, tape binding, and bookstore-quality binding and hard covers.

PURCHASING MANAGER Planned and developed the purchasing department. * Worked closely with Engineering on development of new equipment and source selection for cost control management and time to market production. Project completed on time and below proposed budget. * Developed Policies & Procedures Manual for department. * Hired & trained a staff of buyers and Shipping /Receiving Department clerk. * Procured tooling and production for 2 new products which reduced overall pricing for products by ~10%. Purchased equipment & tooling for 2 production lines. * Negotiated long term supply contracts for production supplies. * Provided design assistance for plastic molded components. * Contracted for the design, development and manufacture of printed circuit assemblies achieving savings of 10-15% over in-house manufacture. SYSTRON DONNER, CONCORD, CA 10/1988-3/1995 COMPANY PROFILE: Develops and manufactures micro electro mechanical systems, inertial navigation units and quartz rate sensors for aerospace applications. MANAGER, FABRICATED PARTS Responsible for the procurement of all components for electro-mechanical motion sensing systems and navigation system components valued at approximately $ 9M annually for both automotive and aerospace applications. * Reduced automotive product cost by 15% by improved sourcing techniques. * Improved automotive time to market by 15%.

* Improved on-time delivery of production requirements from suppliers (avg = 98.8%) and coordinated the implementation of FAR regulations for procurement. * Supervised planner and expeditor. * Purchased critical fabricated components and assemblies to Scope of Work documents. * Converted Machined parts to Laser Welded, Extruded or cast components eliminating Machining. * Initiated Preferred Supplier Program for Printed Circuit assemblies & established first company Partnering Agreement. * Negotiated & purchased complex equipment, tooling & consultant sservices for development of Quartz Rate Sensor technology. * Managed and controlled precious metal inventories by tracking London Metal Market Forecast trends in metals for management. * Contract types: CPFF, FFP. CRAF. Regulations management under EAR, FAR, DOD, DFAR & UCC EDUCATION BA Psychology & Business Oakland University a" Rochester, MI PROFESSIONAL DEVELOPMENT Certificate in Purchasing - U C Berkeley AFFILIATIONS APICS - Membership 26 years APICS - V.P. Membership - Solano Chapter 1994 to 1998 APICS - V.P. Membership - Golden Gate Chapter 1990 to 1998 NAPM - Member 35 years

ADDITIONAL SKILLS & TRAINING Trained in ASPR, FAR, DFAR, EAR, ITAR, TQM, ISO 9000, 9001 & AS9100, ANSY 14.2 design specs & Mechanical Drafting & Design Six-Sigma green belt- Packaging Design & Recycling Proficient in: MS Office Suite, SAP ERP, PowerCerv MRP, J D Powers ERP and Mapics DB. John Marshall Resume 4 jm139ceee@westpost.net

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Courses at School of Electrical Engineering, Electronics Engineering, and Computer Engineering (EECE)Документ43 страницыCourses at School of Electrical Engineering, Electronics Engineering, and Computer Engineering (EECE)Nồi NguyễnОценок пока нет

- Reference Letter Example For Student Applying For Master Programme in Computer ScienceДокумент2 страницыReference Letter Example For Student Applying For Master Programme in Computer ScienceAyman AbbasОценок пока нет

- Ipd Workflow AutodeskДокумент1 страницаIpd Workflow AutodeskPuneet AroraОценок пока нет

- STS Chapter 1 ReviewerДокумент4 страницыSTS Chapter 1 ReviewerEunice AdagioОценок пока нет

- CRITERION - 3: Course Outcomes and Program Outcomes 3. Course Outcomes and Program OutcomesДокумент2 страницыCRITERION - 3: Course Outcomes and Program Outcomes 3. Course Outcomes and Program OutcomesUdaysingh PatilОценок пока нет

- Mid Year Examination 50 Mathematics: SM Sains Banting Jalan Sultan Suleiman Shah 42700 BANTING SelangorДокумент2 страницыMid Year Examination 50 Mathematics: SM Sains Banting Jalan Sultan Suleiman Shah 42700 BANTING Selangorhana balqisОценок пока нет

- Thomson Reuters Master Journal List JOURNAL LIST - Biomedical 21112014Документ6 страницThomson Reuters Master Journal List JOURNAL LIST - Biomedical 21112014vsalaiselvamОценок пока нет

- Library Register Recorded Books-FinalДокумент985 страницLibrary Register Recorded Books-Finalrao159951Оценок пока нет

- MSC Telecommunications BCUДокумент2 страницыMSC Telecommunications BCUHannah CresseyОценок пока нет

- Jami CV 2Документ2 страницыJami CV 2Sabbir AhmedОценок пока нет

- RoboticsДокумент15 страницRoboticsMilan Pitroda0% (1)

- Ethics of Biotechnology PDFДокумент2 страницыEthics of Biotechnology PDFKeithОценок пока нет

- Robotic Arm LabДокумент5 страницRobotic Arm LabBryan Owen Salcedo SantosОценок пока нет

- Delhi Public School, Raipur: Result Summary of AISSCE-2021Документ3 страницыDelhi Public School, Raipur: Result Summary of AISSCE-2021abcdОценок пока нет

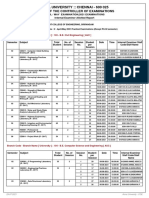

- Anna University:: Chennai - 600 025: Office of The Controller of ExaminationsДокумент4 страницыAnna University:: Chennai - 600 025: Office of The Controller of ExaminationsAarthi JОценок пока нет

- Why The Future Doesn't Need UsДокумент2 страницыWhy The Future Doesn't Need UsOne Dozen50% (2)

- Letter of IntentДокумент1 страницаLetter of IntentReigneth VillenaОценок пока нет

- Task Committee On Sti-Ength: Minimum Design Loads For Buildings and Other StructuresДокумент1 страницаTask Committee On Sti-Ength: Minimum Design Loads For Buildings and Other StructuresDhina karanОценок пока нет

- 4mca7 - Dbms Lab: List of PracticalsДокумент3 страницы4mca7 - Dbms Lab: List of PracticalsPallav KumarОценок пока нет

- Raju Govindharajan 2Документ6 страницRaju Govindharajan 2Onggo Firstha NichitaОценок пока нет

- Operation AnalysisДокумент16 страницOperation AnalysisLyne LerinОценок пока нет

- 2nd Batch Admission ListДокумент69 страниц2nd Batch Admission ListDauda BabaОценок пока нет

- AICTE STTP Civil Cold Form Steel (Series II) 1Документ2 страницыAICTE STTP Civil Cold Form Steel (Series II) 1Ujwal KarkiОценок пока нет

- Hafiz Muhammad Amir Sultan: Manufacturers of Polyethylene, Normal Alpha Olefin 1-Hexene, SulfurДокумент1 страницаHafiz Muhammad Amir Sultan: Manufacturers of Polyethylene, Normal Alpha Olefin 1-Hexene, SulfurShafi LuckyОценок пока нет

- Cover LetterДокумент1 страницаCover Lettersweet notОценок пока нет

- Visvesvaraya Technological University: Belagavi Karnataka, 590 018Документ4 страницыVisvesvaraya Technological University: Belagavi Karnataka, 590 018Sueja MalligwadОценок пока нет

- SHS SchoolsДокумент2 страницыSHS SchoolsRAIZA CANILLASОценок пока нет

- TM500Документ3 страницыTM500Raja KalyanОценок пока нет

- Courses On Offer Aug To Dec 2020 6-10-2020Документ6 страницCourses On Offer Aug To Dec 2020 6-10-2020BlessingОценок пока нет

- Vit Sjam2009Документ40 страницVit Sjam2009Deepak Kumar Vasudevan100% (2)