Академический Документы

Профессиональный Документы

Культура Документы

Coating Surface Treatments Aerospace Conversion Coatings Pg24 25

Загружено:

Radulović RaduleИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Coating Surface Treatments Aerospace Conversion Coatings Pg24 25

Загружено:

Radulović RaduleАвторское право:

Доступные форматы

Conversion Coatings

24

Aircraft Depaint & Repaint

SURFACE TREATMENTS

25

See Technical Data Sheet Mix Ratio (product:water) Composite Applications Metal Processing Lines Aircraft Parts Cleaning

Aircraft Appearance

Jet Engine Cleaning

Aircraft Protection

Maintenance & Production Aides

Composite Materials

Stainless Steel

How to Apply

Temperature

Non-Ferrous

Consistency

Magnesium

Chemistry

Aluminum

Coolants

Titanium

Ferrous

Form

Product

CONVERSION COATINGS

Applications

Characteristics

Substrate

Operation

Time

Description

CONVERSION COATINGS

CONVERSION COATINGS

Alodine 120 Brush Kit

Liquid

Ready-to-Use Two-Part Kit

Kit

Use as Received

C hromate

Ambient

Until Dry

Alodine 120 Brush Kit contains products formulated for treating aluminum to conform to MIL-C -5541C , Class 1A. This kit contains sufficient chemicals for cleaning and coating approximately 100 square feet of aluminum surface when used under normal conditions and in accordance with the directions. Alodine 600 is a powdered chemical used to produce a chromate conversion coating on aluminum and its alloys, which ranges in color from light, iridescent gold to tan. Alodine 600 can be applied by immersion or spray method, does not contain complex cyanides, and is particularly recommended where a low dielectric resistance coating is desired. Approved under MIL-DTL-81706B for use by Application Methods A and C , classes 1A and 3. Listing on Q PL 81706 indicates its acceptance under the MIL-C -5541 document of current issue. Alodine 600 RTU is a ready-to-use, liquid product which produces a chromate conversion coating on aluminum and its alloys. The coating produced provides excellent protection for unpainted aluminum and bonds paint well.

Alodine 600

Powder

C oncentrated

Immersion or Spray

12.5 lbs per 100 gals Water

C hromate No C yanide

70F-100F 21 C -38 C

1-5 minutes

Alodine 600 RTU

Liquid

Ready-to-Use

Immersion or Spray

Use as Received

C hromate No C yanide

70F-100F 21 C -38 C

Immersion: 2-5 minutes Spray: 15-30 seconds

Alodine 1000 RTU

Liquid

Ready-to-Use

Brush or Spray

Use as Received

C hromate

Ambient

1-3 minutes

Alodine 1000 RTU is a ready-to-use, aqueous solution for producing a protective coating on aluminum and its alloys. The coating provides excellent protection for painted and unpainted aluminum and bonds paint well. It is specifically designed for touching-up abraded or damaged areas on work previously treated with Alodine coating chemicals.

Alodine 1200S

Powder

C oncentrated

Immersion

6.3 lbs per 100 gals Water

70F-100F 21 C -38 C

15 seconds 3 minutes

Alodine 1200S is a powdered chemical used to produce a protective coating on aluminum to minimize corrosion and provide an improved bond for paint. Alodine 1200S coating is chemically listed on Qualified Product List Q PL-81706, and is an approved material to produce Class 1A and Class 3 coatings, bare or painted, in accordance with Military Specifications MIL C -5541C .

Alodine 1201

Liquid

Brush: Ready-to-Use

Brush or Immersion

Immersion: 33 parts - Alodine 1201 67 parts - Water

C hromicAcid-Based

Ambient to 100F / 38C

2-5 minutes

Alodine 1201 is a nonflammable, chromic-acid-based, coating chemical that will produce a chrome conversion coating on aluminum and its alloys.

Alodine 1500

Liquid

C oncentrated

Immersion or Spray

1 gal per 100 gals Water 0.65 gals - Alodine 1600 1.3-2.0 gals Alodine 1660 per 100 gals Water 1.5-7.5 gals per 100 gals Water

70F-160F 21 C -71 C

IMMERSIO N: 2-5 minutes SPRAY: 15-30 seconds

Alodine 1500 is a liquid chemical used to produce a protective coating on aluminum or aluminum alloys. The coating provides protection for aluminum and is an excellent bond for clear organic coatings. Alodine 1500 should be used when the characteristic aluminum appearance must be retained. Listed on the register for Q PL-MIL-C -81706 and is approved to be used by Methods A and C (spray and immersion processing) to produce class 3 coatings in accordance with Military Specification MIL-C -5541 (current issue). May also be used to process aluminum under Specification MIL-S-5002. Alodine 1600 is a concentrated liquid, two-package chemical used to produce a chromate conversion coating on aluminum and all its alloys. The color ranges from light iridescent gold to tan. Alodine 1600 does not contain complex cyanides. Approved for use under Mil-DTL-81706B, formally Mil-C -81706, Classes 1A and 3, Form, I, Method C and Boeing BA C -5719.

Alodine 1600 Alodine 1600 Additive

Liquid

C oncentrated, Two Packages

Immersion or Spray

C hromate

60F-130F 16 C -54 C

1-5 minutes

Alodine 5200

Liquid

C oncentrated

Immersion or Spray

OrganoMetallic

70F-120F 21 C -49 C

1-5 minutes

Alodine 5200 treatment is a chromium-free product specifically formulated for treating non-ferrous alloys. Spray or immersion applications may be used. This process provides an excellent base for bonding of adhesives and organic finishes.

Alodine 5700

Liquid

Ready-to-Use

Spray

Use as Received

OrganoMetallic

Ambient to 100F/38C

2-5 minutes

Alodine 5700 is a chromium-free conversion coating specifically formulated for treating aluminum and its alloys. This product is formulated as a ready-to-use material for spray applications. The process provides an excellent base for organic finishes.

Alodine Magnesium Treatment Kit

Liquid

Ready-to-Use Two-Part Kit

Kit

Use as Received

C hromate

Ambient

Until Dry

The Alodine Magnesium Treatment Kit contains products formulated for treating magnesium alloys to produce a chromate conversion coating conforming to SAE AMS-M-3171, Type VI. The application method conforms to requirements in NAVAIR 01-1A-509 and is meant primarily for touch-up, corrosion repair processes of magnesium alloys. Alodine T 5900 treatment is a complex, trivalent chromium conversion coating formulated for treating aluminum and its alloys, metals coated with IVD aluminum, magnesium, titanium and zinc surfaces. The process provides bare ASTM-B117 salt spray resistance and it serves as an excellent base for bonding of paint and adhesives. Neither the product itself, nor the conversion coating developed by the process, contain hexavalent chromium. Alodine T 5900 can be used in immersion or pressure spray washers. Alodine T 5900 is approved to MIL-DTL-81706B. Alodine T 5900 RTU treatment is a complex, trivalent chromium conversion coating formulated for treating aluminum and its alloys, metals coated with IVD aluminum, magnesium, titanium and zinc surfaces. This Henkel product is formulated as a ready-to-use material for manual spray applications. The process provides bare ASTM-B-117 salt spray resistance and it also serves as an excellent base for organic finishes and adhesives. Alodine T 5900 RTU is approved to MIL-DTL-81706B. Alodine 871 Touch-N-Prep C oating is a non-hexavalent, chromium, dry-in-place conversion coating designed for use on aluminum and its alloys. The applicator used to deliver this product provides an easy and safe method of repairing bare areas of aluminum surfaces. Alodine 871 Touch-N-Prep C oating is formulated for both bare corrosion protection, such as ASTM 921-02, and bonding applications when combined with organic coatings or structural adhesives.

Alodine T 5900

Liquid

C oncentrated

Spray, Brush or Immersion

Alodine T 5900 5.0 gals per 100 gals Alodine T 5900 Toner 1.0 gals per 100 gals

Tri-C hrome

70F-90F 21 C -32 C

7-10 minutes

Alodine T 5900 RTU

Liquid

Ready-to-Use

Spray, Brush or Immersion

Use as Received

Tri-C hrome

70F-90F 21 C -32 C

7-10 minutes

Alodine 871 Touch-N-Prep Coating Alodine 1132 Touch-N-Prep Coating

Liquid

Ready-to-Use

Pen

Use as Received

Tri-C hrome

Ambient

Until Dry

Liquid

Ready-to-Use

Pen

Use as Received

C hromate

Ambient

Until Dry

Alodine 1132 Touch-N-Prep C oating is a felt-tipped marker that provides a chromate conversion coating on aluminum surfaces prior to painting. Meets MIL-DTL-81706B, Class 1A & 3, Form VI, Method D. Ideal for coating repair work.

Вам также может понравиться

- Solvalitt Alu: Technical Data Sheet Application GuideДокумент9 страницSolvalitt Alu: Technical Data Sheet Application GuideEngTamerОценок пока нет

- Technical Sheet ALOCROM 1200: PropertiesДокумент2 страницыTechnical Sheet ALOCROM 1200: Propertiesvijay yadavОценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Application Guide - Jotun Solvalitt AluДокумент9 страницApplication Guide - Jotun Solvalitt AluPolem IskandarОценок пока нет

- CoatedДокумент3 страницыCoatedmatteo2009Оценок пока нет

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965От EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Оценок пока нет

- Penguard HB: Technical Data Sheet Application GuideДокумент10 страницPenguard HB: Technical Data Sheet Application GuideAbrar HussainОценок пока нет

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityОт EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityРейтинг: 3 из 5 звезд3/5 (4)

- PPG CatalogДокумент332 страницыPPG Catalogdancas01100% (1)

- Most Frequently Used PaintsДокумент12 страницMost Frequently Used PaintssmartcharlinОценок пока нет

- Penguard HB AGДокумент10 страницPenguard HB AGSindh ScrapОценок пока нет

- ISO 9001:2015 Certified CompanyДокумент33 страницыISO 9001:2015 Certified CompanyMythri Metallizing Pvt Ltd ProjectsОценок пока нет

- Barrier 77: Technical Data Sheet Application GuideДокумент8 страницBarrier 77: Technical Data Sheet Application GuideNurmalinda SihombingОценок пока нет

- Dow MetalworkingДокумент6 страницDow MetalworkingBen Karthiben NathanОценок пока нет

- FTI 151 Englisch 06-2008aДокумент15 страницFTI 151 Englisch 06-2008ainsult2injuryОценок пока нет

- Barrier - 80 - Product - Description - Technicad HL PDFДокумент8 страницBarrier - 80 - Product - Description - Technicad HL PDFDimas BatamОценок пока нет

- Jotamastic 80 Aluminium: Technical Data Sheet Application GuideДокумент10 страницJotamastic 80 Aluminium: Technical Data Sheet Application GuideRohit KambleОценок пока нет

- En Copper and WireДокумент6 страницEn Copper and WireKasinathan JeevaОценок пока нет

- Alkydprimer AGДокумент8 страницAlkydprimer AGangelito bernalОценок пока нет

- Ceran FGДокумент2 страницыCeran FGUtkarshОценок пока нет

- Eni Grease AC 2 PDFДокумент1 страницаEni Grease AC 2 PDFranjanguptОценок пока нет

- Statoil LoadWay EP 100Документ2 страницыStatoil LoadWay EP 100mstan11Оценок пока нет

- Cal Guard Anti Spatter SprayДокумент2 страницыCal Guard Anti Spatter SprayMarhadi AdiОценок пока нет

- Penguard Special Application GuideДокумент10 страницPenguard Special Application GuideRaju KCОценок пока нет

- Barrier 65: Technical Data Sheet Application GuideДокумент8 страницBarrier 65: Technical Data Sheet Application Guidesabari ramasamyОценок пока нет

- AG 345 Aluminium Paint H.R. Euk GBДокумент7 страницAG 345 Aluminium Paint H.R. Euk GBSardar AmedОценок пока нет

- Synthetic AdditivesДокумент5 страницSynthetic AdditivesJako MishyОценок пока нет

- Barrier: Technical Data Sheet Application GuideДокумент8 страницBarrier: Technical Data Sheet Application GuideNurmalinda SihombingОценок пока нет

- Weicon Zinc Spray - Bright Grade TDSДокумент2 страницыWeicon Zinc Spray - Bright Grade TDSshoaib1985Оценок пока нет

- AluДокумент5 страницAluMekhmanОценок пока нет

- 2102 Shell Alvania RL PDFДокумент1 страница2102 Shell Alvania RL PDFthawatchai11222512Оценок пока нет

- Mobilgrease MPДокумент2 страницыMobilgrease MPjerrypoaОценок пока нет

- Especificaciones PAM RevisadaДокумент66 страницEspecificaciones PAM RevisadaToapanta FredyОценок пока нет

- Faircrete SB (L)Документ2 страницыFaircrete SB (L)Aniket ShahОценок пока нет

- Lithium No. 2 Grease 602 05Документ2 страницыLithium No. 2 Grease 602 05Amal ChinthakaОценок пока нет

- Application Jotamastic 90 AlДокумент13 страницApplication Jotamastic 90 Aladitya kristantoОценок пока нет

- Boeing Paint Catalog 2022Документ42 страницыBoeing Paint Catalog 2022jefferson velonzaОценок пока нет

- Jotamastic 90: Technical Data Sheet Application GuideДокумент13 страницJotamastic 90: Technical Data Sheet Application GuideAditya NugrahaОценок пока нет

- Penguard Express Application GuideДокумент10 страницPenguard Express Application GuidenizamuddinОценок пока нет

- Jotaprime Mastic 80 AGДокумент8 страницJotaprime Mastic 80 AGMuthu Sivarama Krishnan Nallaiah100% (2)

- THE Tri-Con SeriesДокумент6 страницTHE Tri-Con Seriespablopasqualini18Оценок пока нет

- Penguard Mio Application GuideДокумент9 страницPenguard Mio Application Guidenachi100Оценок пока нет

- 28.3. Mobil Permazone Ready To UseДокумент2 страницы28.3. Mobil Permazone Ready To UseJeefОценок пока нет

- Agip Gear Oil Pamphlet PDFДокумент4 страницыAgip Gear Oil Pamphlet PDFranjanguptОценок пока нет

- Marathon 500 AGДокумент10 страницMarathon 500 AGAbdul KharisОценок пока нет

- AG 720 Solvalitt Euk GBДокумент9 страницAG 720 Solvalitt Euk GBMoch. ArdiansyahОценок пока нет

- GLXXMobilgrease XHP 220 SeriesДокумент3 страницыGLXXMobilgrease XHP 220 SeriesJavier Cayampi PomallihuaОценок пока нет

- Leaflet Cabinet & Casing ProtectionДокумент4 страницыLeaflet Cabinet & Casing ProtectionMuhammad Javed BhattiОценок пока нет

- Technical Bulletin 6-13 BrigДокумент11 страницTechnical Bulletin 6-13 Brigjulianpellegrini860Оценок пока нет

- Jotamastic 80 AG NewДокумент10 страницJotamastic 80 AG NewMuthu Sivarama Krishnan NallaiahОценок пока нет

- Barrier: Technical Data Sheet Application GuideДокумент8 страницBarrier: Technical Data Sheet Application GuideANIBALLOPEZVEGAОценок пока нет

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 6Документ6 страницRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 6anony8103Оценок пока нет

- Renolin CLP - PIДокумент6 страницRenolin CLP - PIDương LêОценок пока нет

- SRB Grease DetailsДокумент2 страницыSRB Grease DetailsSofian AmaraОценок пока нет

- Valvoline Heavy Duty TDL PRO 75W-90-PI SheetДокумент2 страницыValvoline Heavy Duty TDL PRO 75W-90-PI SheetJUAN BAUTISTAОценок пока нет

- Pedestrian Stacker Truck HWE100 HWE100SДокумент4 страницыPedestrian Stacker Truck HWE100 HWE100SRadulović RaduleОценок пока нет

- 2013-02-23 500 L Phone Compatibility VP2-Uconnect (ITA)Документ5 страниц2013-02-23 500 L Phone Compatibility VP2-Uconnect (ITA)Radulović RaduleОценок пока нет

- Intertek RoHS 2 Services BrochureДокумент2 страницыIntertek RoHS 2 Services BrochureXiang LiuОценок пока нет

- Lean Integration Afe - John SchmidtДокумент12 страницLean Integration Afe - John SchmidtRadulović RaduleОценок пока нет

- 5 Whys TechniqueДокумент2 страницы5 Whys TechniqueprasetyohseОценок пока нет

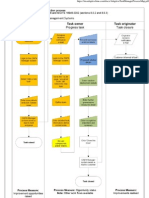

- Adaptive Task Manager User GuideДокумент17 страницAdaptive Task Manager User GuideRadulović RaduleОценок пока нет

- Adaptive Task Manager Process MapДокумент1 страницаAdaptive Task Manager Process MapRadulović RaduleОценок пока нет

- Metallic Coated SteelДокумент56 страницMetallic Coated SteelRadulović RaduleОценок пока нет

- Roush Paint Appearance Standard As-100-1Документ6 страницRoush Paint Appearance Standard As-100-1Radulović RaduleОценок пока нет

- Fasteners Exporter Manufacturer-Repute Steel INDIA BOLTSДокумент4 страницыFasteners Exporter Manufacturer-Repute Steel INDIA BOLTSPRAVINОценок пока нет

- Ansi-Aws A5.3-M-A5.3-1999Документ26 страницAnsi-Aws A5.3-M-A5.3-1999ALP69Оценок пока нет

- C1 To C5 Environment Application MatrixДокумент1 страницаC1 To C5 Environment Application MatrixakmlogaОценок пока нет

- 58 61Документ4 страницы58 61mscoleodinamicaОценок пока нет

- Steel Grade Equivalency TableДокумент2 страницыSteel Grade Equivalency TableBudy GedhaBlackОценок пока нет

- Cast Aluminium and Its Alloys - Ingots and Castings For General Engineering Purposes - SpecificationДокумент15 страницCast Aluminium and Its Alloys - Ingots and Castings For General Engineering Purposes - Specificationarunava001Оценок пока нет

- Temper Embrittlement - J and X FactorДокумент2 страницыTemper Embrittlement - J and X Factorgovimano100% (2)

- Reference List Ikio Boors (Version 1)Документ5 страницReference List Ikio Boors (Version 1)dhawal gargОценок пока нет

- Astm F436M.-11Документ5 страницAstm F436M.-11abhishek yadav100% (1)

- Laboratory Manual MEC 225: Material Science AND Metallurgy LaboratoryДокумент21 страницаLaboratory Manual MEC 225: Material Science AND Metallurgy LaboratoryUNITED2014Оценок пока нет

- Carbon Alloy Steel Stainless SteelДокумент4 страницыCarbon Alloy Steel Stainless Steelaswar_mhОценок пока нет

- Study of Constituents of An AlloyДокумент5 страницStudy of Constituents of An Alloymadicin0% (1)

- Find The Symbols of The Following Metals in The Periodic TableДокумент38 страницFind The Symbols of The Following Metals in The Periodic Tablemenaga ilangkovanОценок пока нет

- Author: Ferrous Alloys: Printed: December FДокумент20 страницAuthor: Ferrous Alloys: Printed: December FsunsirОценок пока нет

- B26B26MДокумент14 страницB26B26MAbraham MallisaОценок пока нет

- 117 Weldox 420 Uk DatasheetДокумент2 страницы117 Weldox 420 Uk DatasheetAndrewFranciscoОценок пока нет

- Welding 'Документ515 страницWelding 'Gopu Pushpangadhan67% (3)

- Gold Refining Handbook Vol 2-6-24 09Документ71 страницаGold Refining Handbook Vol 2-6-24 09Ronnie Smith100% (1)

- 55% Aluminum-Zinc Alloy Coated Steel Grade Data SheetДокумент3 страницы55% Aluminum-Zinc Alloy Coated Steel Grade Data SheetWahyu Ginanjar ArgianОценок пока нет

- Böhler CM 5-Ig: TIG Rod, High-Alloyed, Creep ResistantДокумент1 страницаBöhler CM 5-Ig: TIG Rod, High-Alloyed, Creep Resistantwesley59Оценок пока нет

- Health and Safety in Welding: WTIA Technical Note No. 7Документ148 страницHealth and Safety in Welding: WTIA Technical Note No. 7Tee Klong RungОценок пока нет

- Fig. 4 Fig. 4 Fig. 3 Fig. 4: 3.2.2. Analysis of Microscopic Appearance of Fatigue FractureДокумент7 страницFig. 4 Fig. 4 Fig. 3 Fig. 4: 3.2.2. Analysis of Microscopic Appearance of Fatigue FractureLuis HiguerasОценок пока нет

- MT Powder MetallurgyДокумент74 страницыMT Powder MetallurgyAhad RazzОценок пока нет

- Shrinkage in Ductile IronДокумент5 страницShrinkage in Ductile Ironkarthikkanda100% (1)

- RFQ of C45 SteelДокумент3 страницыRFQ of C45 Steelnhirpara1Оценок пока нет

- Copper GlycerolДокумент7 страницCopper Glycerolerem90Оценок пока нет

- Nova Perforated Metals Brochure NO BLEED 15th October 2010 PDFДокумент28 страницNova Perforated Metals Brochure NO BLEED 15th October 2010 PDFPriyagoenk Harda RukmonoОценок пока нет

- Materials I: Lecture Course 5 Phase Diagrams. Fe-C Diagram. Crystallisation of Alloys in Fe - Fe C SystemДокумент24 страницыMaterials I: Lecture Course 5 Phase Diagrams. Fe-C Diagram. Crystallisation of Alloys in Fe - Fe C SystemTiger ClaudiuОценок пока нет

- IEEMA Circular Aug 2020Документ2 страницыIEEMA Circular Aug 2020AMARENDRA SIОценок пока нет

- ACE Battery Knives ENДокумент4 страницыACE Battery Knives ENr0ll3rОценок пока нет