Академический Документы

Профессиональный Документы

Культура Документы

143 Xu

Загружено:

boyz535261Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

143 Xu

Загружено:

boyz535261Авторское право:

Доступные форматы

Figures 143 143

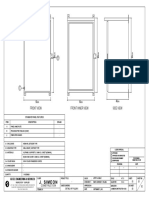

Cast Steel Globe Valves

Class 150 Outside Screw & Yoke Bolted Bonnet

Figure 143

Flanged

Material of Construction

Description Body Bonnet Seat Rings Disc Stem Packing Bonnet Gasket Back Seat Disc Stem Nut Disc Washer Gland Gland Flange Eye Bolt Eye Bolt Nuts Pins Bonnet Studs Bonnet Nuts Handwheel Handwheel Nut I.D. Tags I.D. Pins Material WCB WCB Hardfaced 13% CR Overlay 410 SS Graphite SS Tanged Ref. Flex. Graphite 410 SS 410 SS Carbon Steel 410 SS WCB Steel A563 Gr. A or O A193 Gr. B7 A194 Gr. 2H WCB A194 Gr. 2H SS SS

Figure 143

Butt Weld Size Range: 2 through 14 inches Pressure Temperature Rating Carbon Steel ASTM A216 Grade WCB 285 psi @ -20F to 100F

Industry Standards

Steel Valves Face-to-Face/End-to-End Flange Dimensions Weld End Testing Acceptance ASME B16.34 ASME B16.10 ASME B16.5 ASME B.16.25 API 598 API RP591

Dimensions and Weights

Valve Size 2 2 3 4 5 6 8 10 12 14 Weight (pounds) 143 143 53 43 70 60 90 73 143 112 199 165 246 195 392 330 605 480 900 820 1000 880 Dimensions (inches) A B 143 & 143 Valve Open 8.00 15.00 8.50 17.12 9.50 18.50 11.50 21.00 14.00 23.00 16.00 25.50 19.50 30.00 24.50 34.00 27.50 39.50 31.00 41.38 C 8.00 8.00 10.00 12.00 12.00 16.00 16.00 20.00 20.00 24.00

-14-

Cast Steel Valves

Materials of Construction

Steel bolted bonnet valves described in this catalog are typically manufactured of carbon steel. When specified, the valves are available in the alloys shown below which are suitable for steam, water, oil, oil vapor, gas and general services. Please contact factory or customer service for availability and material breakdowns.

Body and Bonnet or Cap Materials

Part No. Suffix

None 6 9 5 12 2

ASTM Classification

A216 WCB A217 WC6 A217 WC9 A217 C5 A217 C12 A351 LCC

Material Classification

Carbon Steel 1 CR, Mo 2 CR, 1 Mo 5% CR, Mo 9% CR, 1 Mo Low Carbon Steel

Service Conditions

For service up to 1000 F where corrosion and oxidation are not a factor. (1) (4) (5) For service up to 1000 F. (3) (4) (5) For service up to 1100 F where good creep strength is required. (3) (4) (5) For service up to 1200 F. Best corrosion and oxidation resistance plus high creep strength are required. For service up to 1200 F. Best corrosion and oxidation resistance than other grades. For service from 50 F to 650 F. This material must be quenched and tempered to obtain tensile and impact properties needed at subzero temperatures.

(4) Product used within the jurisdiction of Section 1 Power Boilers of the ASME Boiler and Pressure Vessel code is subject to the same temperature limitations as specified in that document. (5) Product used within the jurisdiction of Power Piping, ASME Code for Pressure Piping B31.1, is subject to the same maximum temperature limitations placed upon the material in paragraph 124.2.

(1) Upon prolonged exposure to temperatures above 800 F, the carbide phase of carbon steel may be converted to graphite. Permissible, but not recommended for prolonged usage above 800F. (2) Valve regularly rated to 1000 F. (3) Considerations should be given to the possibility of excessive oxidation (scaling) when used above 1050 F.

Trim Material

Part No. Suffix

X UF* A L XUF* AUF* LUF*

API Trim Number

1 5 9 10 8 11 12

Nominal Trim

F6 / F6 (1) HF / HF (2) Monel / Monel (4) 316 / 316 (3) F6 / HF (1) (2) Monel / HF (4) (2) 316 / HF (3) (2)

Seating Surfaces

13 Cr ASTM A217 (CA15) Stellite 6 Monel 316 SS 13 Cr ASTM A217 (CA 215) Stellite 6 Monel Stellite 6 316 SS Stellite 6

Stem Material

13 Cr (410) 13 Cr (410) Monel 316 SS 13 Cr (410) Monel 316 SS

Temperature

1100 F 1200 F 450 F 850 F 1100 F 450 F 850 F

(1) 13% Chromium AISI Type 410 Stainless Steel. (2) Hard Facing is weld deposited Cobalt base alloy. *F denotes Flex Wedge (only applies to Gate Valves).

(3) Austenitic Stainless Steel is a Ni-Cr-Mo stainless steel in the AISI Type 316 category. (4) Ni-Cu Alloy.

Valve Modification Suffix Identification

S.I. Description

TD BP PG Drain, Drill, and Tap Bypass Special Packing and/or Gasket

S.I. Description

ST BW RJ Special Trim Special Butt-Weld End Prep Ring Joint

S.I. Description

SP LD LR Special Paint Locking Device Lantern Ring

S.I. Description

OV (1) Gear (3) Electric (4) Pneumatic (6) Other (2) Chainwheel (5) Hydraulic

-4-

Cast Steel Globe Valves

Typical Globe Valve Features

Crane globe valves are highly efficient for services requiring frequent operation and throttling when pressure drop across the valve is about 20% of inlet pressure. Closer throttling, creating higher pressure drops may cause cavitation or excessive velocities which could cause high noise levels, vibration and possible damage to the valve or adjacent piping. Globe valves can be equipped with optional operators and are available with a variety of trims to match service requirements.

1. Body: Body is cast with heavy sections reinforced at points subjected to the greatest stress. Valves are available in both flanged and butt welding ends. All conform to ASME specifications. 2. Bonnet 3. Seat Ring 4. Disc 5. Disc Stem Nut: Disc Stem Ring connects the disc to the stem, permitting the disc to swivel and aid in securing tight seating for trouble-free service. 6. Disc Washer 7. Stem: Stem has long engagement with yoke bushing for accurate seating. 8. Bonnet Bushing 9. Yoke Bushing 10. Wheel Nut 11. Packing 12. Gland: Gland is a two-piece, ball-type which exerts even pressure on the packing without binding the stem. 13. Gland Flange 14. Gland Eye Bolts: Eye bolts are securely fastened to the bonnet yet swing away to permit easy access to the stuffing box. 15. Bonnet Gasket: Bonnet gasket provides a positive seal against leakage. Class 150 and 300 valves have a male/female bonnet joint. A ring-type gasket is employed in Class 600. 16. Bonnet Studs 17. Bonnet Nuts 18. Pin 19. Handwheel

-13-

Вам также может понравиться

- Silfab SIL 330 BL 20200910 FinalДокумент2 страницыSilfab SIL 330 BL 20200910 Finalboyz535261Оценок пока нет

- SIL-320 NL: High Efficiency Premium Mono-Perc PV ModuleДокумент2 страницыSIL-320 NL: High Efficiency Premium Mono-Perc PV Moduleboyz535261Оценок пока нет

- Silfab SIL 320 BL 20200910 FinalДокумент2 страницыSilfab SIL 320 BL 20200910 Finalboyz535261Оценок пока нет

- GECO Director Nomination Form 2015Документ1 страницаGECO Director Nomination Form 2015boyz535261Оценок пока нет

- 2014 FIT Price ScheduleДокумент1 страница2014 FIT Price Scheduleboyz535261Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Angle Grinder Gws 7 100 06013880f0Документ128 страницAngle Grinder Gws 7 100 06013880f0Kartik ParmeshwaranОценок пока нет

- Major Architecture Forms From Arunachal PradeshДокумент7 страницMajor Architecture Forms From Arunachal PradeshCharchil Saini100% (1)

- 21 UK Catalogo Primaled GBДокумент12 страниц21 UK Catalogo Primaled GBluc1902Оценок пока нет

- Startup ShutdownДокумент4 страницыStartup ShutdownPit_mkluОценок пока нет

- Introbook v4 enДокумент145 страницIntrobook v4 enGiuliano PertileОценок пока нет

- Data Sheet - Item Number: 249-117 Screwless End Stop 10 MM Wide For DIN-rail 35 X 15 and 35 X 7.5 GrayДокумент8 страницData Sheet - Item Number: 249-117 Screwless End Stop 10 MM Wide For DIN-rail 35 X 15 and 35 X 7.5 GrayJosé CarlosОценок пока нет

- Asentria Public - 48VDC - or - 24VDC - Power - Card - Wiring - InstructionsДокумент4 страницыAsentria Public - 48VDC - or - 24VDC - Power - Card - Wiring - Instructionsaelmai70Оценок пока нет

- BEL Papers Previous YearsДокумент121 страницаBEL Papers Previous YearsjayacharanОценок пока нет

- Application - Form Sirt PDFДокумент5 страницApplication - Form Sirt PDFAnonymous PnzDBWPUОценок пока нет

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Документ12 страницCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoОценок пока нет

- Pullbox Nema 3r Rv.0Документ1 страницаPullbox Nema 3r Rv.0Jholo SicabaloОценок пока нет

- Camino Frances GuideДокумент162 страницыCamino Frances GuidegregdedmanОценок пока нет

- LG P503 SVC Eng 101008Документ199 страницLG P503 SVC Eng 101008MaxAllgeruОценок пока нет

- Polyurathane FoamДокумент10 страницPolyurathane FoamltcminboxОценок пока нет

- Dowsil 51 AdditiveДокумент5 страницDowsil 51 AdditiveYến HoàngОценок пока нет

- CQ BalancingДокумент4 страницыCQ Balancingapi-218999959Оценок пока нет

- Materials Engineer Test Reviewer-1Документ47 страницMaterials Engineer Test Reviewer-1Rodrigo Castillo Cacho93% (27)

- Samsung Ar09 12hssfawkneu HasznalatiДокумент114 страницSamsung Ar09 12hssfawkneu HasznalatiEdison EspinalОценок пока нет

- Engineering Software Research Center SANSPRO V.5.20Документ4 страницыEngineering Software Research Center SANSPRO V.5.20Nathan M7Оценок пока нет

- 13bentonit SlurryДокумент24 страницы13bentonit SlurrykesharinareshОценок пока нет

- An Ultra-Low Voltage High Gain Operational Transconductance Amplifier For Biomedical ApplicationsДокумент4 страницыAn Ultra-Low Voltage High Gain Operational Transconductance Amplifier For Biomedical Applications90413027Оценок пока нет

- Tension Wheel Assemblies: Sicat 8WL5070 / 8WL5078 For Overhead Contact Line SystemsДокумент4 страницыTension Wheel Assemblies: Sicat 8WL5070 / 8WL5078 For Overhead Contact Line SystemsVictor Manuel BonettoОценок пока нет

- #Omega DPG409Документ3 страницы#Omega DPG409Cyrix.OneОценок пока нет

- GoedhartVCI P 2012 en Version1 IДокумент24 страницыGoedhartVCI P 2012 en Version1 IRodrigo GonçalvesОценок пока нет

- Soalan Fizik Chapter 9Документ10 страницSoalan Fizik Chapter 9Yusfalina Mohd YusoffОценок пока нет

- Deck Machinery PartsДокумент3 страницыDeck Machinery Partsmihat jasneyОценок пока нет

- APIs and Business Functions GuideДокумент104 страницыAPIs and Business Functions GuideSindhu RamОценок пока нет

- 16N60 Fairchild SemiconductorДокумент10 страниц16N60 Fairchild SemiconductorPop-Coman SimionОценок пока нет

- L14 15 ABCD and S ParametersДокумент15 страницL14 15 ABCD and S ParametersAmeya KadamОценок пока нет

- Industrial SecurityДокумент71 страницаIndustrial Securityharrison rojas64% (11)