Академический Документы

Профессиональный Документы

Культура Документы

Load Share Gateway WOODWARD PCC3100 PARALLEL

Загружено:

TTIBCCAОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Load Share Gateway WOODWARD PCC3100 PARALLEL

Загружено:

TTIBCCAАвторское право:

Доступные форматы

37442

Load Share Gateway (LSG)

Manual

Software Version 1.xxxx

Manual 37442

Manual 37442

LSG - Load Share Gateway

WARNING

Read this entire manual and all other publications pertaining to the work to be performed before installing, operating, or servicing this equipment. Practice all plant and safety instructions and precautions.

Failure to follow instructions can cause personal injury and/or property damage.

The engine, turbine, or other type of prime mover should be equipped with an overspeed (overtemperature, or overpressure, where applicable) shutdown device(s), that operates totally independently of the

prime mover control device(s) to protect against runaway or damage to the engine, turbine, or other

type of prime mover with possible personal injury or loss of life should the mechanical-hydraulic governor(s) or electric control(s), the actuator(s), fuel control(s), the driving mechanism(s), the linkage(s),

or the controlled device(s) fail.

Any unauthorized modifications to or use of this equipment outside its specified mechanical, electrical,

or other operating limits may cause personal injury and/or property damage, including damage to the

equipment. Any such unauthorized modifications: (i) constitute "misuse" and/or "negligence" within

the meaning of the product warranty thereby excluding warranty coverage for any resulting damage,

and (ii) invalidate product certifications or listings.

CAUTION

To prevent damage to a control system that uses an alternator or battery-charging device, make sure

the charging device is turned off before disconnecting the battery from the system.

Electronic controls contain static-sensitive parts. Observe the following precautions to prevent damage to these parts.

Discharge body static before handling the control (with power to the control turned off, contact a

grounded surface and maintain contact while handling the control).

Avoid all plastic, vinyl, and Styrofoam (except antistatic versions) around printed circuit boards.

Do not touch the components or conductors on a printed circuit board with your hands or with

conductive devices.

OUT-OF-DATE PUBLICATION

This publication may have been revised or updated since this copy was produced. To verify that you

have the latest revision, be sure to check the Woodward website:

http://www.woodward.com/pubs/current.pdf

The revision level is shown at the bottom of the front cover after the publication number. The latest

version of most publications is available at:

http://www.woodward.com/publications

If your publication is not there, please contact your customer service representative to get the latest

copy.

Important definitions

WARNING

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, could result in damage to equipment.

NOTE

Provides other helpful information that does not fall under the warning or caution categories.

Woodward reserves the right to update any portion of this publication at any time. Information provided by Woodward is believed to be

correct and reliable. However, Woodward assumes no responsibility unless otherwise expressly undertaken.

Woodward

All Rights Reserved.

Page 2/29

Woodward

Manual 37442

LSG - Load Share Gateway

Revision History

Rev. Date

NEW 08-07-17

Editor

TE

Changes

Release

Content

CHAPTER 1. GENERAL INFORMATION ....................................................................................... 5

Related Documents .................................................................................................................................. 5

Overview .................................................................................................................................................. 6

CHAPTER 2. INSTALLATION ...................................................................................................... 7

Safety Precautions ................................................................................................................................... 7

Regulatory Notes ..................................................................................................................................... 7

Electrostatic Discharge Awareness ......................................................................................................... 8

Mounting and Removal ............................................................................................................................ 8

Application Overview................................................................................................................................ 9

easYgen connected to EGCP-2 (CAN/RS-485) ............................................................................ 9

easYgen connected to legacy device (CAN/Analog) ................................................................... 10

CHAPTER 3. HOUSING ........................................................................................................... 13

Terminal and Interface Overview ........................................................................................................... 13

Dimensions............................................................................................................................................. 13

CHAPTER 4. CONNECTION ..................................................................................................... 15

Power Supply ......................................................................................................................................... 15

Analog Load Share ................................................................................................................................ 16

Interfaces................................................................................................................................................ 17

RS-485 Serial Interfaces .............................................................................................................. 17

CAN Bus Interface ....................................................................................................................... 19

Bus Shielding ............................................................................................................................... 21

CHAPTER 5. CONFIGURATION ................................................................................................ 22

LSG Configuration .................................................................................................................................. 22

easYgen Configuration........................................................................................................................... 22

easYgen LSG Display Information ...................................................................................................... 22

EGCP-2 Configuration ........................................................................................................................... 23

CHAPTER 6. OPERATION........................................................................................................ 24

Status LEDs ........................................................................................................................................... 24

Functional Test ....................................................................................................................................... 25

Testing the CAN Bus Communication ......................................................................................... 25

Testing the EGCP-2 Network Communication ............................................................................ 25

CHAPTER 7. TECHNICAL DATA ............................................................................................... 26

CHAPTER 8. ENVIRONMENTAL DATA ...................................................................................... 28

Woodward

Page 3/29

Manual 37442

LSG - Load Share Gateway

Figures and Tables

Figures

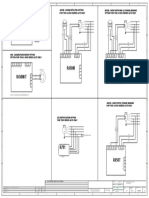

Figure 2-1: Application EGCP-2 ............................................................................................................................................. 9

Figure 2-2: Application analog active power ......................................................................................................................... 10

Figure 2-3: Application analog active and reactive power ..................................................................................................... 11

Figure 2-4: Application analog active power ......................................................................................................................... 12

Figure 2-5: Application analog active and reactive power ..................................................................................................... 12

Figure 3-1: Terminal and interface overview ............................................................................................................................ 13

Figure 3-2: Housing LSG dimensions.................................................................................................................................... 14

Figure 4-1: Power supply .......................................................................................................................................................... 16

Figure 4-2: RS-485 interface - overview................................................................................................................................... 17

Figure 4-3: RS-485 Connection EGCP-2 - LSG ....................................................................................................................... 17

Figure 4-4: RS-485 - connection for half-duplex operation ...................................................................................................... 18

Figure 4-5: CAN bus - overview............................................................................................................................................... 19

Figure 4-6: Interfaces - CAN bus - termination ........................................................................................................................ 20

Figure 4-7: Interfaces - shielding .............................................................................................................................................. 21

Figure 6-1: Status LEDs............................................................................................................................................................ 24

Tables

Table 1-1: Manual - overview ..................................................................................................................................................... 5

Table 4-1: Conversion chart - wire size .................................................................................................................................... 15

Table 4-2: Power supply - terminal assignment ........................................................................................................................ 15

Table 4-3: Analog load share - terminal assignment ................................................................................................................. 16

Table 4-4: RS-485 interface - pin assignment ........................................................................................................................... 17

Table 4-5: CAN bus - pin assignment ....................................................................................................................................... 19

Table 4-6: Maximum CAN bus length...................................................................................................................................... 20

Table 5-1: easYgen configuration ............................................................................................................................................. 22

Table 6-1: Outlines the indicator condition and the corresponding status after the baud rate is found. .................................... 24

Page 4/29

Woodward

Manual 37442

LSG - Load Share Gateway

Chapter 1.

General Information

TECHNICAL REQUIREMENTS

The Load Share Gateway (LSG) works only in combination with the easYgen-3000 Series (PackageP2)

and the entire easYgen-2000 Series.

State: 17 July 2009

Related Documents

Type

English

German

37442

easYgen-3000 Series (Package P2)

easYgen-3000 - Installation

easYgen-3000 - Configuration

easYgen-3000 - Operation

easYgen-3000 - Application

easYgen-3000 - Interfaces

easYgen-3000 - Parameter List

easYgen-3200 - Brief Operation Information

easYgen-3100 - Brief Operation Information

37414

37415

37416

37417

37418

37420

37399

37419

GR37414

GR37415

GR37416

GR37420

GR37399

-

easYgen-2000 Series

easYgen-2000 - Installation

easYgen-2000 - Configuration

easYgen-2000 - Operation

easYgen-2000 - Application

easYgen-2000 - Interfaces

easYgen-2000 - Parameter List

easYgen-2000 - Brief Operation Information

37426

37427

37428

37429

37430

37431

37432

DE37426

DE37427

DE37428

DE37431

DE37432

26076 / 26174

26086 / 26175

26099 / 26181

Load Share Gateway (LSG)

Load Share Gateway - Manual

EGCP-2 Series

EGCP-2 - Installation and Operation

EGCP-2 - Application

EGCP-2 - Communications

This Manual

Table 1-1: Manual - overview

Intended Use The unit must only be operated in the manner described by this manual. The prerequisite for a

proper and safe operation of the product is correct transportation, storage, and installation as well as careful operation and maintenance.

Woodward

Page 5/29

Manual 37442

LSG - Load Share Gateway

Overview

The Load Share Gateway (LSG) is a next generation communication converter specifically designed to operate

the easYgen-2000 / easYgen-3000 Series and legacy devices ( RS-485 Bus or analog load share line coupled ) in

one single load share network.

Page 6/29

Woodward

Manual 37442

LSG - Load Share Gateway

Chapter 2.

Installation

Safety Precautions

WARNING

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Only qualified workers should install this equipment. Such work should be performed only after reading this entire set of instructions.

NEVER work alone.

Before performing visual inspections, tests, or maintenance on this equipment, disconnect all

sources of electric power. Assume that all circuits are live until they have been completely deenergized, tested, and tagged. Pay particular attention to the design of the power system. Consider all

sources of power, including the possibility of backfeeding.

Apply appropriate personal protective equipment and follow safe electrical practices.

Turn off all power supplying the equipment in which the LSG is to be installed before installing and

wiring the LSG.

Always use a properly rated voltage sensing device to confirm that power is off.

Beware of potential hazards, wear personal protective equipment, and carefully inspect the work area

for tools and objects that may have been left inside the equipment.

The successful operation of this equipment depends upon proper handling, installation, and operation. Neglecting fundamental installation requirements may lead to personal injury as well as damage

to electrical equipment or other property.

Failure to follow these instructions will result in death or serious injury!

WARNING

No dead bus closure interlock between easYgen and legacy products is provided by the LSG. A closure of the easYgen or legacy product onto a dead busbar simultaneously with other controls must be

prevented by external means!

The unit does not provide any protection and in addition renders the built-in protection of the easYgen

dysfunctional!

Regulatory Notes

The LSG is suitable for use in non-hazardous locations only.

The LSG is not authorized for use in life support devices or systems.

Wiring and installation must be in accordance with applicable electrical codes in accordance with the authority having jurisdiction.

The LSG is designed for installation into an electrical switchboard or cubical as part of a fixed installation.

Woodward

Page 7/29

Manual 37442

LSG - Load Share Gateway

Electrostatic Discharge Awareness

All electronic equipment is static-sensitive, some components more than others. To protect these components

from static damage, you must take special precautions to minimize or eliminate electrostatic discharges.

Follow these precautions when working with or near the control.

1.

Before doing maintenance on the electronic control, discharge the static electricity on your body to ground

by touching and holding a grounded metal object (pipes, cabinets, equipment, etc.).

2.

Avoid the build-up of static electricity on your body by not wearing clothing made of synthetic materials.

Wear cotton or cotton-blend materials as much as possible because these do not store static electric

charges as much as synthetics.

3.

Keep plastic, vinyl, and Styrofoam materials (such as plastic or Styrofoam cups, cup holders, cigarette

packages, cellophane wrappers, vinyl books or folders, plastic bottles, and plastic ash trays) away from the

control, the modules, and the work area as much as possible.

4.

Opening the Control unit will void the warranty!

Do not remove the printed circuit board (PCB) from the control cabinet unless absolutely necessary. If you

must remove the PCB from the control cabinet, follow these precautions:

Make sure that the unit is completely de-energized (all connectors have to be pulled off).

Do not touch any part of the PCB except the edges.

Do not touch the electrical conductors, connectors, or components with conductive devices or with

bare hands.

When replacing a PCB, keep the new PCB in the plastic antistatic protective bag it comes in until you

are ready to install it. Immediately after removing the old PCB from the control unit, place it in the antistatic protective bag.

WARNING

To prevent damage to electronic components caused by improper handling, read and observe the precautions in Woodward manual 82715, Guide for Handling and Protection of Electronic Controls, Printed

Circuit Boards, and Modules.

Mounting and Removal

The enclosure provides protection against solid objects according to IP 20 classification and NEMA Type 1 rating. When mounting the enclosure observe the following rules:

Avoid splash water and water drops

Avoid aggressive gas, steam or liquids

Avoid dusty environments

Make sure there is sufficient air ventilation and clearance to other devices mounted next to the module

Do not exceed the specified operational temperatures.

Mount inside a sealed electrical switchboard or cubicle

Observe applicable local regulations like EN60204 / VDE0113

Page 8/29

Woodward

Manual 37442

LSG - Load Share Gateway

Application Overview

The LSG is available in two different types:

Active power load share (P)

Reactive power load share (Q)

The following figures show application examples for both LSG types (marked with P or Q).

easYgen connected to EGCP-2 (CAN/RS-485)

The easYgen devices communicate via CAN bus among each other and therefore cant communicate directly to

EGCP-2 devices which have no CAN bus interface. The LSG is able to connect EGCP-2 and easYgen devices in

a single load share network.

easYgen (CAN)

The LSG is fixed to work as generator with address 15 and 16. For this reason it is not allowed, to set any other

easYgen device to address 15 or 16. (For further information please refer to the easYgen manuals)

EGCP-2 (RS-485)

The LSG is fixed to work as generator with address 8. For this reason it is not allowed, to set any EGCP-2 to address 8. (For further information please refer to the EGCP-2 manuals)

CAN, RS-485 interface and power supply are isolated galvanically, so there is no need for any additional galvanic isolation.

easYgen Device

easYgen Device

easYgen Device

......

2nd Generator

1th Gtor

max. 30 Generators

CAN

LSG (P)

RS-485

EGCP-2

#1

EGCP-2

#2

......

EGCP-2

max. #7

Figure 2-1: Application EGCP-2

WARNING

Please arrange additional precautions for the dead bus closure interlock. The LSG connection doesnt

guarantee a dead bus closure interlock.

NOTE

All easYgen devices which are allowed to perform a dead bus closure, independent of the EGCP-2,

must have a generator number <15.

Woodward

Page 9/29

Manual 37442

LSG - Load Share Gateway

easYgen connected to legacy device (CAN/Analog)

The easYgen devices communicate via CAN bus among each other and therefore cant communicate directly to

analog legacy devices which have no CAN bus interface. The LSG is able to connect analog legacy devices and

easYgen devices in a single load share network.

NOTE

Find further informations on supported legacy devices in Chapter 5 - Configuration.

WARNING

Please arrange additional precautions for the dead bus closure interlock. The LSG connection doesnt

guarantee a dead bus closure interlock.

There are two application scenarios possible:

Examples A shows the applications with one LSG for all easYgen devices.

Examples B shows the applications with one LSG for each easYgen devices.

To decide which setup is to prefer in the application, different aspects for operation and safety should be regarded.

CAN, Analog Line and power supply are isolated galvanically, so there is no need for any additional galvanic

isolation.

Examples A:

Active power loadshare:

On CAN (easYgen) the LSG is fixed to work as generator with address (15) / 16. For this reason it is not allowed,

to set any easYgen to address (15) / 16.

easYgen Device

easYgen Device

1th Generator

2nd Generator

easYgen Device

......

max. 30 Generators

CAN

LSG (P)

analog line active power

Analog

Legacy

Device

Analog

Legacy

Device

Figure 2-2: Application analog active power

NOTE

The easYgen device reserves the address 15 and 16 by default. Address 15 is in this case not used.

Page 10/29

Woodward

Manual 37442

LSG - Load Share Gateway

Active and reactive power loadshare:

On CAN (easYgen) the LSG for active power loadsharing is fixed to work as generator with address 16 the LSG

for reactive power loadsharing to work as generator with address 15. For this reason it is not allowed, to set any

easYgen to address 15 or 16.

easYgen Device

Analog

Legacy

Device

easYgen Device

Analog

Legacy

Device

CAN

LSG

(Q)

LSG

(P)

analog line active power

analog line reactive power

Figure 2-3: Application analog active and reactive power

Woodward

Page 11/29

Manual 37442

LSG - Load Share Gateway

Examples B:

Active power loadshare:

On CAN (easYgen) the LSGs are fixed to work as generator with addresses 15 and 16. For this reason it is not allowed, to set any easYgen devices to address 15 and 16.

In this application the easYgen must not connected via CAN

easYgen Device

Analog

Legacy

Device

easYgen Device

CAN

CAN

LSG (P)

LSG (P)

Analog

Legacy

Device

analog line active power

Figure 2-4: Application analog active power

Active and reactive power loadshare:

On CAN (easYgen) the LSGs for active power loadsharing are fixed to work as generator with address 16 the

LSGs for reactive power loadsharing to work as generator with address 15. For this reason it is not allowed, to set

any easYgen device to address 15 or 16.

LSG

Analog

Legacy

Device

CAN

CAN

(Q)

Analog

Legacy

Device

easYgen Device

easYgen Device

LSG

(P)

LSG

(Q)

LSG

(P)

analog line active power

analog line reactive power

Figure 2-5: Application analog active and reactive power

Page 12/29

Woodward

Manual 37442

LSG - Load Share Gateway

Chapter 3.

Housing

Terminal and Interface Overview

7

6

RS485

CAN

CAN

RS485/Analog

Failure

V+

VShield

Ground

0V

24V

1.

Power terminal block socket

2.

RS-485 connector

3.

CAN connector

4.

Analog terminal block socket

5.

Error indication LED

6.

RS-485 / Analog Status Indicator

7.

easYgen (CAN) Communication Status LED

Figure 3-1: Terminal and interface overview

Dimensions

CAN

RS485

CAN

RS485/Analog

Failure

Ground

0V

24V

V+

VShield

79,38 mm 98,43 mm

9,53 mm

128,27 mm

140,97 mm

Hole Size 4x3,12 mm.375

Woodward

Page 13/29

Manual 37442

LSG - Load Share Gateway

21,00 mm

Figure 3-2: Housing LSG dimensions

Page 14/29

Woodward

Manual 37442

LSG - Load Share Gateway

Chapter 4.

Connection

WARNING

All technical data and ratings indicated in this chapter are not definite! Only the values indicated in

Chapter 7: Technical Data on page 26 are valid!

The following chart may be used to convert square millimeters [mm] to AWG and vice versa:

AWG

30

28

26

24

22

mm

0.05

0.08

0.14

0.25

0.34

AWG

21

20

18

17

16

mm

0.38

0.5

0.75

1.0

1.5

AWG

14

12

10

8

6

mm

2.5

4

6

10

16

AWG

4

2

1

1/0

2/0

mm

25

35

50

55

70

AWG

3/0

4/0

300MCM

350MCM

500MCM

mm

95

120

150

185

240

AWG

600MCM

750MCM

1000MCM

mm

300

400

500

Table 4-1: Conversion chart - wire size

Power Supply

RS485

CAN

RS485/Analog

CAN

Ground

0V

24V

V+

VShield

Failure

Terminal

3

2

1

Description

Earth Ground

12/24Vdc

0 Vdc

Amax

2.5 mm

2.5 mm

2.5 mm

Table 4-2: Power supply - terminal assignment

NOTE

Earth Ground Terminal #3 is galvanically connected to aluminum housing. If the housing is assembled

on a grounded metal plate possible ground current loops via terminal #3 are to be considered!

Woodward

Page 15/29

Manual 37442

LSG - Load Share Gateway

Analog Load Share

CAN

RS485

CAN

RS485/Analog

Ground

0V

24V

V+

VShield

Failure

Figure 4-1: Power supply

Terminal

6

5

4

Description

Analog Load Share V+

Analog Load Share VShield

Amax

2.5 mm

2.5 mm

2.5 mm

Table 4-3: Analog load share - terminal assignment

Page 16/29

Woodward

Manual 37442

LSG - Load Share Gateway

Interfaces

RS-485 Serial Interfaces

CAN

RS485

CAN

RS485/Analog

Ground

0V

24V

V+

VShield

Failure

Figure 4-2: RS-485 interface - overview

Terminal

1

2

3

4

5

6

7

8

9

Description

not connected

RS-485 (-)

not connected

not connected

GND

not connected

RS-485 (+)

not connected

not connected

Amax

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Table 4-4: RS-485 interface - pin assignment

EGCP-2

RS-485 Interface

Pin 77 (-)

Pin 76 (+)

Pin 2

Pin 7

LSG

RS-485 Interface

Figure 4-3: RS-485 Connection EGCP-2 - LSG

Woodward

Page 17/29

Manual 37442

LSG - Load Share Gateway

Half-Duplex on RS-485

LSG

A (-)

B (+)

120

120

EGCP-2

Figure 4-4: RS-485 - connection for half-duplex operation

NOTE

Please refer to EGCP-2 manual 26076 / 26174 Installation and Operation Chapter 3. Electrical Installation and Specifications.

This manual describes how the bus needs to be terminated. Is the LSG at the end of the RS-485 bus, a

terminating resistor of 120 ohm needs to be connected to the Sub-D connector.

The EGCP-2 must be configured via DIP switches according to the manual.

Page 18/29

Woodward

Manual 37442

LSG - Load Share Gateway

CAN Bus Interface

The CAN Baud rate is detected automatically. For the supported Baud rates please refer to Maximum CAN Bus

Length, Page 20.

RS485

CAN

RS485/Analog

CAN

Ground

0V

24V

V+

VShield

Failure

Figure 4-5: CAN bus - overview

Terminal

1

2

3

4

5

6

7

8

9

Description

not connected

CAN-L

GND

not connected

CAN Shield

GND

CAN-H

not connected

CAN-VCC

Amax

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Table 4-5: CAN bus - pin assignment

Woodward

Page 19/29

Manual 37442

LSG - Load Share Gateway

CAN Bus Topology

NOTE

Please note that the CAN bus must be terminated with a resistor, which corresponds to the impedance

of the cable (e.g. 120 Ohms, 1/4 W) at both ends. The termination resistor is connected between CAN-H

and CAN-L.

Figure 4-6: Interfaces - CAN bus - termination

Troubleshooting Possible CAN Bus Problems

If data is not transmitting on the CAN bus, check the following for common CAN bus communication problems:

A T-structure bus is utilized

CAN-L and CAN-H are interchanged

Not all devices on the bus are using identical Baud rates

Terminating resistor(s) are missing

The configured baud rate is too high for wiring length

The CAN bus cable is routed in close proximity with power cables

Woodward recommends the use of shielded, twisted-pair cables for the CAN bus (i.e.: Lappkabel Unitronic

LIYCY (TP) 220.25, UNITRONIC-Bus LD 220.22).

Maximum CAN Bus Length

The maximum length of the communication bus wiring is dependent on the configured Baud rate. Refer to Table

4-6 for the maximum bus length (Source: CANopen; Holger Zeltwanger (Hrsg.); 2001 VDE VERLAG GMBH,

Berlin und Offenbach; ISBN 3-8007-2448-0).

Baud rate

1000 kbit/s

800 kbit/s

500 kbit/s

125 kbit/s

50 kbit/s

20 kbit/s

Max. length

25 m

50 m

100 m

250 m

1000 m

2500 m

Table 4-6: Maximum CAN bus length

The maximum specified length for the communication bus wiring might not be achieved if poor quality wire is

utilized, there is high contact resistance, or other conditions exist. Reducing the baud rate may overcome these issues.

Page 20/29

Woodward

Manual 37442

LSG - Load Share Gateway

Bus Shielding

All bus connections of the LSG are internally grounded via an RC element. Therefore, they may either be

grounded directly (recommended) or also via an RC element on the opposite bus connection.

CAN / RS-485 / Analog Share Load

LSG

1 MOhm

2.7 nF

2000 V

PE

Terminal #3

Figure 4-7: Interfaces - shielding

Woodward

Page 21/29

Manual 37442

LSG - Load Share Gateway

Chapter 5.

Configuration

LSG Configuration

The LSG does not need to be configured.

The LSG is receiving his operation mode via CAN from the easYgen with the lowest address.

The CAN baud rate will be detected automatically.

The RS-485 parameters are fixed.

The LSG transmits always segmentnumber 1.

easYgen Configuration

The operation mode of the LSG must be configured by the parameter 5568 of the easYgen.

Operation Modes

No.

0

1

2

3

4

5

6

7

8

9 to 15

Device

Off

Woodward EGCP-2

Woodward SPM-D

MFR 15

Woodward 2301 A

Caterpillar LSM

Cummins (prepared)

POW-R-CON (prepared)

Prepared

Prepared

Not defined

Internal Resistance | Voltage Range

RS-485

R = 4.99k | P: 0 4V (0 to 100%) | Q: 0 5V (-85% to +85%)

R = 4.99k | P: 0 4V (0 to 100%)

R = 54.90k | P: 0 3V (0 to 100%)

R = 25.00k | P: 0 3V (0 to 100%)

R = 5.00k | P: 0 2.5V (-14.1 to 121.9%) | Q: 0 2.5V (-16.7% to +125.3%)

R = 20.67k | P: 0 5V (0 to 100%) *1

R = 25.00k | P: -5 +5V (0 to 100%) *1

R = 25.00k | P: 0 7V (0 to 100%) *1

Table 5-1: easYgen configuration

*1

If this setting is reactive power mode, the voltage is representing a Q range: -100% to +100%

If the operation mode is not 0, the device numbers 15/ 16 are reserved for the LSG, the easYgen device

numbers must not be configured as 15 and16.

The Loadshare Can ID must be set to 5xx (=default Value).

easYgen LSG Display Information

If the LSG mode is set to 1 (EGCP-2) the icon LSG at the LDSS screen (easYgen) is twinkling if the CAN

connection between easYgen and LSG is ok. This icon is permanent, if an EGCP-2 in automatic mode is detected

on the RS-485 bus.

The GCB icon shows closed if one or more EGCP-2 has a closed GCB.

In analog mode LSG at the LDSS screen is permanent if the CAN connection between easYgen and LSG is ok.

The GCB icon shows closed if at least one easYgen device, which is connected via CAN to the LSG, has a closed

GCB.

Page 22/29

Woodward

Manual 37442

LSG - Load Share Gateway

EGCP-2 Configuration

One EGCP-2 must be configured as the system master. It is recommended to configure the master unit

with device number 1 and priority number 1. The EGCP-2 device numbers must not be configured as 8,

because the LSG is using this device number.

The EGCP-2 must be operating in the automatic mode. The Auto discrete input #1 must be closed on

this unit at all times.

The configuration item Auto Sequencing must be set to disabled.

Please configure DIP switch of the EGCP-2s to a correct termination of the RS-485

The LSG is always slave

If reactive power needs to be shared, the parameters RATED KW and RATED KVAR must be configured to the same values within the EGCP-2.

Woodward

Page 23/29

Manual 37442

LSG - Load Share Gateway

Chapter 6.

Operation

Status LEDs

The three LEDs indicate the status of the module. The LEDs assist maintenance personnel in quickly identifying

wiring or communication errors.

A LED test is exercised at power-up. After power up the LEDs are building a running light until the correct

CAN baudrate is found.

RS485

CAN (1)

RS485/Analog (2)

CAN

Ground

0V

24V

V+

VShield

Failure (3)

Figure 6-1: Status LEDs

NOTE

The direction of the running light indicates, if the LSG is for active (light is running from LED1 to

LED3 ) part number 8440-1075 or reactive power (light is running from LED3 to LED1 ) part number

8440-1074.

LED

1

2

3

Red

Function

easYgen Status

(CAN bus)

EGCP-2 Status

(RS-485)

/ Analog line

Error indication

Condition

Off

Toggling

Off

Toggling (RS 485)

On (analog)

Off

On

Indication

No valid CAN bus messages are received

Valid CAN bus messages are received

No RS-485 messages are received / Analog line is on high impedance

RS485 messages are received

analog: LSG is sharing load on the Analog line

CAN is working properly and -if LSG is in RS-485 mode- RS485 is working properly

CAN timeout or RS-485 timeout

Table 6-1: Outlines the indicator condition and the corresponding status after the baud rate is found.

Page 24/29

Woodward

Manual 37442

LSG - Load Share Gateway

Functional Test

Testing the CAN Bus Communication

If the connection between the easYgen and the LSG is working properly, the LSG is recognized as a further easYgen by the easYgen devices. The LSG appears with the address 16. If a second LSG is used for analog reactive Load Share this will appear with address 15.

Testing the EGCP-2 Network Communication

If the connection between the EGCP-2 and the LSG is working properly and the easYgen is detected by the LSG,

the LSG is indicated on the EGCP-2 sequence display screen as an EGCP-2 Slave with device number 8.

Woodward

Page 25/29

Manual 37442

LSG - Load Share Gateway

Chapter 7.

Technical Data

Nameplate -----------------------------------------------------------------------------------------------------1

1

2

3

4

5

6

7

8

9

S/N

S/N

S/N

P/N

REV

Details

Type

Type

Approval

Serial number (numerical)

Date of production (YYMM)

Serial number (Barcode)

Item number

Item revision number

Technical data

Description (long)

Description (short)

Approvals

Ambient variables --------------------------------------------------------------------------------------------- Power supply (SELV) ................................................................. 12/24 Vdc (8 to 40.0 Vdc)

Intrinsic consumption

......................................................................... max. 3 W

- Degree of pollution ............................................................................................................. 2

- Maximum Altitude ..................................................................................................... 3000m

- Grounding ........................... Earth Ground Terminal # 3 galvanically connected to housing

Interface -------------------------------------------------------------------------------------------------------RS-485 interface ..................................................................................................... isolated

- Isolation voltage ....................................................................................................... 500 Vac

- Type ........................................................................................ Half duplex, max 38.4kBaud

- Shield Termination ...........................................internal R||C against Ground (Terminal # 3)

-

CAN bus interface .................................................................................................. isolated

Isolation voltage ....................................................................................................... 500 Vac

Version ................................................................................................................... CAN bus

Internal line termination ................................................................................... Not available

Shield Termination ...........................................internal R||C against Ground (Terminal # 3)

Analog Load Share Line -------------------------------------------------------------------------------------................................................................................................................................. isolated

- Isolation voltage ....................................................................................................... 500 Vac

- Input / Output type ............................................... Analog voltage in- / output, configurable

- Internal Resistance ............................................................................................ configurable

- Shield Termination ...........................................internal R||C against Ground (Terminal # 3)

Page 26/29

Woodward

Manual 37442

LSG - Load Share Gateway

Housing ---------------------------------------------------------------------------------------------------------- Type

aluminum .........................................................................

- Dimensions (W H D)

............................... approx. 141mm 98.5mm 21 mm

- Wiring ................................................................................... screw-plug-terminals 2.5 mm

- Recommended locked torque .......................................................... 4 inch pounds / 0.5 Nm

use 60/75 C copper wire only

use class 1 wire only or equivalent

- Weight

....................................................................approx. 280 g

Protection ------------------------------------------------------------------------------------------------------- Protection system

.................................................................................. IP20

- EMC test (CE) ................................................ tested according to applicable EN guidelines

Woodward

Page 27/29

Manual 37442

LSG - Load Share Gateway

Chapter 8.

Environmental Data

Vibration -------------------------------------------------------------------------------------------------------- Frequency Range Sine Sweep ...................................................................... 5Hz to 100Hz

- Acceleration ............................................................................................................. 4G

- Frequency Range - Random .......................................................................... 10Hz to 500Hz

- Power Intensity .......................................................................................... 0.015G/Hz

- RMS Value .................................................................................................. 1.04 Grms

- Standards ...............................................................................................................................

EN 60255-21-1 (EN 60068-2-6, Fc)

Lloyds Register, Vibration Test2

SAEJ1455 Chassis Data

MIL-STD 810F, M514.5A, Cat.4,

Truck/Trailer tracked-restrained

cargo, Fig. 514.5-C1

Shock ------------------------------------------------------------------------------------------------------------- Shock........................................................................................ 40G, Saw tooth pulse, 11ms

- Standards ...............................................................................................................................

EN 60255-21-2

MIL-STD 810F, M516.5, Procedure 1

Temperature ---------------------------------------------------------------------------------------------------- Cold, Dry Heat (storage) ........................................................ -30C (-22F) / 80C (176F)

- Cold, Dry Heat (operating) ..................................................... -20C (-4F) / 70 C (158F)

- Standards ...............................................................................................................................

IEC 60068-2-2, Test Bb and Bd

IEC 60068-2-1, Test Ab and Ad

Humidity --------------------------------------------------------------------------------------------------------- Humidity ........................................................................................... 60C, 95% RH, 5 days

- Standards ...............................................................................................................................

IEC 60068-2-30, Test Db

Page 28/29

Woodward

We appreciate your comments about the content of our publications.

Please send comments to: stgt-documentation@woodward.com

Please include the manual number from the front cover of this publication.

Woodward GmbH

Handwerkstrasse 29 - 70565 Stuttgart - Germany

Phone +49 (0) 711 789 54-0 Fax +49 (0) 711 789 54-100

stgt-info@woodward.com

Homepage

http://www.woodward.com/power

Woodward has company-owned plants, subsidiaries, and branches, as well as authorized

distributors and other authorized service and sales facilities throughout the world.

Complete address/phone/fax/e-mail information

for all locations is available on our website (www.woodward.com).

2009/07/Stuttgart

Вам также может понравиться

- Missouri Courts Appellate PracticeДокумент27 страницMissouri Courts Appellate PracticeGeneОценок пока нет

- State Immunity Cases With Case DigestsДокумент37 страницState Immunity Cases With Case DigestsStephanie Dawn Sibi Gok-ong100% (4)

- Kohler rsaII BulletinДокумент32 страницыKohler rsaII BulletinBrianHazeОценок пока нет

- .ArchivetempA034T572 I5 ManualServico PCC3201Документ60 страниц.ArchivetempA034T572 I5 ManualServico PCC3201Marneth RendonОценок пока нет

- G12-312 8 09 - Industrial - NIS Ind Catalog (5.5-700kVA)Документ16 страницG12-312 8 09 - Industrial - NIS Ind Catalog (5.5-700kVA)Vanisadied TujuhduaОценок пока нет

- Windows Finding Your COM Port Number: Smartvu Connectino SetupДокумент2 страницыWindows Finding Your COM Port Number: Smartvu Connectino SetuppaukpamОценок пока нет

- 2 Drawing AДокумент11 страниц2 Drawing ARene Ramos MenesesОценок пока нет

- Pib4169 Eam211 PDFДокумент2 страницыPib4169 Eam211 PDFÁngelОценок пока нет

- How To Install HASP MultiKey USB Dongle Emulator On Windows 7 64 Bit 2 PDFДокумент22 страницыHow To Install HASP MultiKey USB Dongle Emulator On Windows 7 64 Bit 2 PDFkarim3samirОценок пока нет

- Conext CL Firmware 2.6.4 Upgrade ProcedureДокумент15 страницConext CL Firmware 2.6.4 Upgrade Proceduremumi87Оценок пока нет

- Automatic Load Sharing of TransformersДокумент4 страницыAutomatic Load Sharing of Transformersmohit123ashuОценок пока нет

- AMMPS-Generator Operations SOДокумент36 страницAMMPS-Generator Operations SOGreenMountainGenerators100% (1)

- Atcommand Gprs PDFДокумент150 страницAtcommand Gprs PDFNyobi HeulaОценок пока нет

- Schneider Altistart 48Документ51 страницаSchneider Altistart 48Mas ChokyОценок пока нет

- GenComm 2Документ52 страницыGenComm 2Jose Tony Angulo SaborioОценок пока нет

- CL GigE User GuideДокумент118 страницCL GigE User GuideXiaobing daiОценок пока нет

- MC9S12XD128 ProcessadorДокумент1 350 страницMC9S12XD128 ProcessadorMarcelo OemОценок пока нет

- Helenos IIIДокумент54 страницыHelenos IIIPaulo MandingaОценок пока нет

- Deep Sea Electronics PLC: DSE7110 MKII & DSE7120 MKII Operator ManualДокумент100 страницDeep Sea Electronics PLC: DSE7110 MKII & DSE7120 MKII Operator ManualKelvinОценок пока нет

- Software RgamДокумент24 страницыSoftware RgammasanmartinfОценок пока нет

- GC1280 User ManualДокумент28 страницGC1280 User ManualgigiLombricoОценок пока нет

- Tlc511f Rev.1.105 Berger Lahr Manual DatasheetДокумент212 страницTlc511f Rev.1.105 Berger Lahr Manual Datasheetacm197621Оценок пока нет

- ZM305 GTN U en 501250Документ58 страницZM305 GTN U en 501250vjОценок пока нет

- Droop Mode Setting in Governor - CaterpillarДокумент36 страницDroop Mode Setting in Governor - CaterpillarSrinivasan TR100% (1)

- CAT Flash 2016Документ327 страницCAT Flash 2016cells-crosser0xОценок пока нет

- 11 Loadcell AccuracyДокумент32 страницы11 Loadcell AccuracyCecep AtmegaОценок пока нет

- Mentor II Manual PDFДокумент116 страницMentor II Manual PDFBuratti2010Оценок пока нет

- QUCM Domino Printer: Installation and Programming ManualДокумент20 страницQUCM Domino Printer: Installation and Programming ManualSadi Mert YILMAZОценок пока нет

- Click To Save As: Includes US and Canadian ModelsДокумент147 страницClick To Save As: Includes US and Canadian ModelsRyszard O100% (1)

- Inteligen: General Purpose High-End Gen-Set ControllerДокумент4 страницыInteligen: General Purpose High-End Gen-Set Controllermarius.chitigaОценок пока нет

- Laptop Repairing NotesДокумент70 страницLaptop Repairing NotesGilberto GomesОценок пока нет

- Bulkweighing Installation Manual 2004Документ99 страницBulkweighing Installation Manual 2004Oscar Giovani SosaОценок пока нет

- Tutorial - Using The USBDMДокумент27 страницTutorial - Using The USBDMAlfredo CruzОценок пока нет

- DG 09 006-E 12-09 HELENOS IДокумент61 страницаDG 09 006-E 12-09 HELENOS IBalu MОценок пока нет

- Can 01 - PDFДокумент98 страницCan 01 - PDFmesquitanmОценок пока нет

- Catalog Altistart 48 2006 enДокумент50 страницCatalog Altistart 48 2006 enwawinОценок пока нет

- LR200Документ21 страницаLR200atheb12345100% (1)

- EPQ96-2 Users Manual-Installation Note 4189320025 UKДокумент17 страницEPQ96-2 Users Manual-Installation Note 4189320025 UKСергей ГудинОценок пока нет

- DEIF TCM 2 Datasheet 4921240329ukДокумент6 страницDEIF TCM 2 Datasheet 4921240329ukAnonymous T3qDfvОценок пока нет

- How To Using TeraTermДокумент4 страницыHow To Using TeraTermMirul AkiaОценок пока нет

- DG 96 003-E 12-97 Helenos IVДокумент68 страницDG 96 003-E 12-97 Helenos IVBalu MОценок пока нет

- Trans-Auto Eng Man v16Документ77 страницTrans-Auto Eng Man v16asif MehmoodОценок пока нет

- Csyc12mkf Service ManualДокумент71 страницаCsyc12mkf Service ManualcoronaqcОценок пока нет

- TwinLine CANopen Man V101Документ274 страницыTwinLine CANopen Man V101Nader FarhatОценок пока нет

- 80c196 Users Guide PDFДокумент98 страниц80c196 Users Guide PDFGoutam Biswas100% (1)

- Emulator Set Up Procedure - Ver 2Документ10 страницEmulator Set Up Procedure - Ver 2Isura MalagalaОценок пока нет

- Buck Controllers Portfolio - 11-1-11Документ1 страницаBuck Controllers Portfolio - 11-1-11Mario MasettiОценок пока нет

- InteliMains 210 BTB 2 0 0 Global GuideДокумент576 страницInteliMains 210 BTB 2 0 0 Global GuideNatan Genao HdezОценок пока нет

- I613e V106 N3000-MODBUSДокумент18 страницI613e V106 N3000-MODBUSAyobo RolandОценок пока нет

- XTW100 Mini Programmer Schematic and Driver One TransistorДокумент1 страницаXTW100 Mini Programmer Schematic and Driver One Transistor1cvbnmОценок пока нет

- Gencomm Alarms: Dsegencomm ProtocolДокумент12 страницGencomm Alarms: Dsegencomm ProtocolFariz Nur100% (1)

- Kohler 20 RES Operation ManualДокумент40 страницKohler 20 RES Operation Manualhobermanb100% (2)

- Perkins New Diesel GeneratorsДокумент3 страницыPerkins New Diesel GeneratorsReginald D. De GuzmanОценок пока нет

- Priamos I SeriesДокумент59 страницPriamos I SeriesReza NadianОценок пока нет

- LXC9210 User Manual PDFДокумент46 страницLXC9210 User Manual PDFAnonymous vqsuRyОценок пока нет

- NB-Designer Operation Manual: Programmable TerminalsДокумент558 страницNB-Designer Operation Manual: Programmable TerminalsBouain AnisОценок пока нет

- DetCon2 InstalacionДокумент14 страницDetCon2 InstalacionMaia Naiara BarrientosОценок пока нет

- Dec3000 ControllerДокумент4 страницыDec3000 ControllerSyed Mohammad NaveedОценок пока нет

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusОт EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusОценок пока нет

- 37442AДокумент29 страниц37442AAsif ShahОценок пока нет

- Easy Genset Control: OperationДокумент51 страницаEasy Genset Control: OperationdonothearОценок пока нет

- Proddocspdf 2 378Документ340 страницProddocspdf 2 378Jangkluk HeryantoОценок пока нет

- FTSR Au5210Документ1 страницаFTSR Au5210TTIBCCAОценок пока нет

- Ce Aksa Ats Transfer PanelДокумент2 страницыCe Aksa Ats Transfer PanelTTIBCCAОценок пока нет

- FTSR7 Au5210Документ1 страницаFTSR7 Au5210TTIBCCAОценок пока нет

- g6016科勒蓄电池Документ2 страницыg6016科勒蓄电池TTIBCCAОценок пока нет

- Manual KWG Iso5 en v10 2018Документ11 страницManual KWG Iso5 en v10 2018TTIBCCAОценок пока нет

- CE AKSA AlternatorДокумент2 страницыCE AKSA AlternatorTTIBCCAОценок пока нет

- AKSA Battery ChargerДокумент2 страницыAKSA Battery ChargerTTIBCCAОценок пока нет

- 5th Wave StatisticsДокумент9 страниц5th Wave StatisticsTTIBCCAОценок пока нет

- AKSA Control ModuleДокумент2 страницыAKSA Control ModuleTTIBCCAОценок пока нет

- 05 DVR2000E Digital Voltage RegulatorДокумент1 страница05 DVR2000E Digital Voltage RegulatorTTIBCCAОценок пока нет

- Weidmuller-connectpower-converter CP DCDC 250W 24V 10A 订货号1313320010 (少了一个0)Документ2 страницыWeidmuller-connectpower-converter CP DCDC 250W 24V 10A 订货号1313320010 (少了一个0)TTIBCCAОценок пока нет

- 3KD95180 Datasheet enДокумент3 страницы3KD95180 Datasheet enTTIBCCAОценок пока нет

- 3KD52600RE200 Datasheet enДокумент6 страниц3KD52600RE200 Datasheet enTTIBCCAОценок пока нет

- 3KD95088 Datasheet enДокумент3 страницы3KD95088 Datasheet enTTIBCCAОценок пока нет

- Miniature Circuit Breaker - C60H - 1 Pole - 2 A - CДокумент3 страницыMiniature Circuit Breaker - C60H - 1 Pole - 2 A - CTTIBCCAОценок пока нет

- Emg22-Dio4e 2950048-1471201Документ6 страницEmg22-Dio4e 2950048-1471201TTIBCCAОценок пока нет

- Vigi Ic60 - Earth Leakage Add-On Block - 4P - 40AДокумент2 страницыVigi Ic60 - Earth Leakage Add-On Block - 4P - 40ATTIBCCAОценок пока нет

- 500 Kva-FoДокумент4 страницы500 Kva-FoTTIBCCAОценок пока нет

- Data Sheet: VPU AC II 3 R 300/50Документ5 страницData Sheet: VPU AC II 3 R 300/50TTIBCCAОценок пока нет

- ETR+3048 (3000W) Rectifier Module Rev07Документ2 страницыETR+3048 (3000W) Rectifier Module Rev07TTIBCCAОценок пока нет

- DIN Timers TD: Options and Ordering CodesДокумент6 страницDIN Timers TD: Options and Ordering CodesTTIBCCAОценок пока нет

- Export - RoHS - 20211218 - BATT1265MGE BATT 12V 65AH M2AL MGEДокумент2 страницыExport - RoHS - 20211218 - BATT1265MGE BATT 12V 65AH M2AL MGETTIBCCAОценок пока нет

- 4 Pole 2600 4019 2600 4030 2600 4039 2600 4079 2600 3119 2600 4119 Sirco - CDДокумент4 страницы4 Pole 2600 4019 2600 4030 2600 4039 2600 4079 2600 3119 2600 4119 Sirco - CDTTIBCCAОценок пока нет

- 11 - MGS0700BMG HC6H 0819 1Документ4 страницы11 - MGS0700BMG HC6H 0819 1TTIBCCAОценок пока нет

- D48401 - B AVR 4006-4008-4012 W 8000altДокумент1 страницаD48401 - B AVR 4006-4008-4012 W 8000altTTIBCCAОценок пока нет

- Harmony Control Relay Application Guide (Version 1)Документ22 страницыHarmony Control Relay Application Guide (Version 1)TTIBCCAОценок пока нет

- Miniature Circuit-Breaker, Acti9 iC60N, 4P, 32AДокумент3 страницыMiniature Circuit-Breaker, Acti9 iC60N, 4P, 32ATTIBCCAОценок пока нет

- Datenblatt: Surge Protection VPU II 3 R 280V/40KAДокумент4 страницыDatenblatt: Surge Protection VPU II 3 R 280V/40KATTIBCCAОценок пока нет

- D48187 - A Easygen Motorised BreakerДокумент1 страницаD48187 - A Easygen Motorised BreakerTTIBCCAОценок пока нет

- The CAN - BUS Has The Following Adjustment:: AB Volvo Penta, Göteborg, Sweden Can Messages - Edc4 1Документ31 страницаThe CAN - BUS Has The Following Adjustment:: AB Volvo Penta, Göteborg, Sweden Can Messages - Edc4 1TTIBCCAОценок пока нет

- 3125 Vitalogic 4000 PDFДокумент444 страницы3125 Vitalogic 4000 PDFvlaimirОценок пока нет

- How To Control A DC Motor With An ArduinoДокумент7 страницHow To Control A DC Motor With An Arduinothatchaphan norkhamОценок пока нет

- MRT Mrte MRTFДокумент24 страницыMRT Mrte MRTFJonathan MoraОценок пока нет

- Laporan Praktikum Fisika - Full Wave RectifierДокумент11 страницLaporan Praktikum Fisika - Full Wave RectifierLasmaenita SiahaanОценок пока нет

- Rebar Coupler: Barlock S/CA-Series CouplersДокумент1 страницаRebar Coupler: Barlock S/CA-Series CouplersHamza AldaeefОценок пока нет

- Republic of The Philippines National Capital Judicial Region Regional Trial Court Manila, Branch 1Документ4 страницыRepublic of The Philippines National Capital Judicial Region Regional Trial Court Manila, Branch 1brendamanganaanОценок пока нет

- Familiarization With Apparatus and Equipment Used in Testing of MaterialsДокумент5 страницFamiliarization With Apparatus and Equipment Used in Testing of MaterialsEmanoAce33% (6)

- CodebreakerДокумент3 страницыCodebreakerwarrenОценок пока нет

- Aisladores 34.5 KV Marca Gamma PDFДокумент8 страницAisladores 34.5 KV Marca Gamma PDFRicardo MotiñoОценок пока нет

- PCДокумент4 страницыPCHrithik AryaОценок пока нет

- Loading N Unloading of Tanker PDFДокумент36 страницLoading N Unloading of Tanker PDFKirtishbose ChowdhuryОценок пока нет

- Oem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Документ43 страницыOem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Farhad FarajyanОценок пока нет

- The Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and CountriesДокумент13 страницThe Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and Countriesluisbmwm6Оценок пока нет

- Form Three Physics Handbook-1Документ94 страницыForm Three Physics Handbook-1Kisaka G100% (1)

- ATPDraw 5 User Manual UpdatesДокумент51 страницаATPDraw 5 User Manual UpdatesdoniluzОценок пока нет

- Lockbox Br100 v1.22Документ36 страницLockbox Br100 v1.22Manoj BhogaleОценок пока нет

- General Diesel Engine Diagnostic Guide PDFДокумент3 страницыGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3Оценок пока нет

- Ingles Avanzado 1 Trabajo FinalДокумент4 страницыIngles Avanzado 1 Trabajo FinalFrancis GarciaОценок пока нет

- Reference Template For Feasibility Study of PLTS (English)Документ4 страницыReference Template For Feasibility Study of PLTS (English)Herikson TambunanОценок пока нет

- CANELA Learning Activity - NSPE Code of EthicsДокумент4 страницыCANELA Learning Activity - NSPE Code of EthicsChristian CanelaОценок пока нет

- Form16 2018 2019Документ10 страницForm16 2018 2019LogeshwaranОценок пока нет

- IdM11gR2 Sizing WP LatestДокумент31 страницаIdM11gR2 Sizing WP Latesttranhieu5959Оценок пока нет

- Sustainable Urban Mobility Final ReportДокумент141 страницаSustainable Urban Mobility Final ReportMaria ClapaОценок пока нет

- Mid Term Exam 1Документ2 страницыMid Term Exam 1Anh0% (1)

- Chapter 5Документ3 страницыChapter 5Showki WaniОценок пока нет

- On CatiaДокумент42 страницыOn Catiahimanshuvermac3053100% (1)

- Dr. Eduardo M. Rivera: This Is A Riveranewsletter Which Is Sent As Part of Your Ongoing Education ServiceДокумент31 страницаDr. Eduardo M. Rivera: This Is A Riveranewsletter Which Is Sent As Part of Your Ongoing Education ServiceNick FurlanoОценок пока нет

- Cabling and Connection System PDFДокумент16 страницCabling and Connection System PDFLyndryl ProvidoОценок пока нет