Академический Документы

Профессиональный Документы

Культура Документы

Recommendations For VRLA Batteries Handling-1

Загружено:

mvs_hydИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Recommendations For VRLA Batteries Handling-1

Загружено:

mvs_hydАвторское право:

Доступные форматы

RECOMMENDATIONS FOR VRLA BATTERIES HANDLING/MAINTENANCE

VRLA Battery is an electro chemical device and having fixed amount of capacity. Battery is a highly temperature sensitive device and performance is affected accordingly. Performance and Life of VRLA batteries depend on how frequently batteries are drained and recharged. To avoid premature failure of batteries kindly ensure the implementation of below recommendations at site. STORAGE PERIOD: a) Batteries should be stored in a cool (27C) & dry location, protected from direct sunlight and rain. b) Do not stack the packing boxes one on top of the other since this may cause damage to the batteries. c) Batteries upon storage loose capacity due to self discharge & this may increases with temperature rise & longer storage period. d) Batteries need to be charged periodically on storage for prolonged periods, failing which the battery capacity may become irrecoverable due to irreversible sulphation. e) In case of longer storage (Six Months) or fall in OCV below 2.1 volts/cell which ever is earlier, a freshening charge must be given to batteries. f) Under no circumstances the OCV of the Battery under storage shall reach a value less than 1.93 volts/celI. If reached, the battery will be permanently damaged. g) If the ambient temperature during storage is above 27C, the batteries must be given a freshening charge at shorter intervals. In general, a 7C to 10C in ambient temperature will have the storage time is reduced from 6 months to 3 months. BATTERY INSTALLATION AND COMMISSIONING: a) Ensure Battery installation & commissioning at the earliest (within one month). Please follow the provided General Assembly Drawing and O&M Manual before starting the Battery installation b) Operating temperature of batteries should be controlled around 27C for best performance and life. c) Battery should not be installed at an airtight area. There should be adequate ventilation. d) Keep the B.B away from heat generating sources, so as to avoid temperature variation of the cells within the battery. e) Dont use the tap connection with in the battery bank as this can influence negatively for the internal voltage variation and capacity of overall bank will degrade drastically. f) Use insulated tools during I&C. g) All vent plugs and ICCs of battery cells should be tightened properly. CHARGING CAUTION: a) Do not put tools or other equipment over the battery. b) Be sure the charger should turned off before making electrical connections between the battery and the Power Plant.

CHARGER SETTINGS: a) Float voltage: 2.25 VPC at the battery terminals at 27C. b) Boost voltage: 2.30 VPC at the battery terminals at 27C. c) Auto-Boost change over criteria: Batteries should be charged in boost voltage when the batteries are drawing a current equal to or exceeding 5% of the rated capacity (AH). SMPS should be enabled to go to boost automatically depending on the above settings. d) Auto-Float resume criteria: Charger should resume float charging only when the battery draws a current less than 3% of the rated capacity of the battery (AH). SMPS should be enabled to go to float from boost automatically depending on the above settings. e) Battery Path Current Limit: Current limit for the charging should be limited to a maximum of 20% of the rated capacity of the battery (AH). However a charging current of 10 % of the rated Ah capacity is recommended for better charging in float application. f) Low Voltage disconnect: Ensure this setting for subject system, by keeping per cell voltage equals to 1.85 Volts. g) Temperature compensation: This feature of Power Plant should be in active mode always to control the charging voltage for Battery. For each degree Celsius rise in temperature, voltage in the SMPS should reduce (at the battery terminals) @ 3mv/ cell and vice versa. Above charger settings should be ensured at sites for 100% state of charge of batteries failing which battery will work in partial state of charge (PSOC) and over the period, battery will get permanent sulphation and will result into permanent loss of capacity.

PRECAUTIONS REQUIRED FOR ACCEPTANCE TEST. a) AT of batteries should be conducted immediately after installation. b) Site should not be commissioned (on-air) before conducting the AT. c) Battery should be charged completely prior to conduct the discharge test to avoid failures. Pls refer the O&M manual for detailed charging instructions. d) Ensure the charging of batteries even after AT test.

NOTE Batteries should be charged upto 100% SOC before taking next discharge to avoid premature failure of Batteries.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Littelfuse Product Selection Guide PDFДокумент26 страницLittelfuse Product Selection Guide PDFcool_saklshpurОценок пока нет

- Pressure SwitchДокумент1 страницаPressure SwitchBiswanath LenkaОценок пока нет

- Single Phasing of Three Phase Induction MotorДокумент33 страницыSingle Phasing of Three Phase Induction MotorOsama RashaydaОценок пока нет

- WS3418 WinsemiДокумент8 страницWS3418 WinsemiPaul MejiaОценок пока нет

- Ps10ex Pressure Switch PresostatoДокумент1 страницаPs10ex Pressure Switch PresostatoJULIO AREVALOОценок пока нет

- Wiring: Digital Controller Instruction ManualДокумент1 страницаWiring: Digital Controller Instruction ManualEdy WijayaОценок пока нет

- Field Effect Transistors (FET) : Examples Frequency ResponseДокумент19 страницField Effect Transistors (FET) : Examples Frequency ResponseJayashree MoorthyОценок пока нет

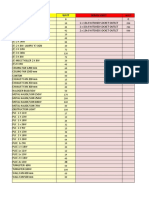

- Load Schedule: General NotesДокумент1 страницаLoad Schedule: General NotesMark Stephen FelipeОценок пока нет

- Contract0r AgreementДокумент13 страницContract0r AgreementramadhanОценок пока нет

- UCI224G - Technical Data SheetДокумент8 страницUCI224G - Technical Data SheetAsandoval12345Оценок пока нет

- Cat6 STP Keystone Jack Tool Free PDFДокумент4 страницыCat6 STP Keystone Jack Tool Free PDFAnonymous 1xDxbkTz2Оценок пока нет

- Report 1 - FinalДокумент18 страницReport 1 - Finalvaibhav bariОценок пока нет

- Grid Tie Inverter Schematic and Principals of OperationДокумент6 страницGrid Tie Inverter Schematic and Principals of Operation31482Оценок пока нет

- Power Supply RequirementДокумент3 страницыPower Supply Requirementnatrix029Оценок пока нет

- Install Electrical Metallic - Nonmetallic (PVC Conduit)Документ13 страницInstall Electrical Metallic - Nonmetallic (PVC Conduit)Rex Chambers LadaoОценок пока нет

- PW24Документ2 страницыPW24farid-00526475Оценок пока нет

- Unit-IV - OP-AMP and Its ApplicationsДокумент64 страницыUnit-IV - OP-AMP and Its ApplicationsJadhav BhagavatОценок пока нет

- Cummins DMCДокумент7 страницCummins DMCShakeel Ahmad100% (1)

- RF Based Home Security System: Presented byДокумент14 страницRF Based Home Security System: Presented byAamirОценок пока нет

- QO312L125G: Product Data SheetДокумент2 страницыQO312L125G: Product Data SheetMiguel Bartolo CruzОценок пока нет

- E 7 Elec Spec ListДокумент3 страницыE 7 Elec Spec ListMARIMUTHUОценок пока нет

- Solution Sheet 2 Electronic CircuitsДокумент15 страницSolution Sheet 2 Electronic CircuitsWajdi BELLILОценок пока нет

- New 600 Amp Loadbreak Technology Provides Efficient, Reliable Visible Break and Visible GroundДокумент4 страницыNew 600 Amp Loadbreak Technology Provides Efficient, Reliable Visible Break and Visible Groundsincos1983Оценок пока нет

- Jenis Beban Lampu Watt Beban SoketДокумент9 страницJenis Beban Lampu Watt Beban SoketMike BravoОценок пока нет

- Asr 1005 Aps 900 Ima 08Документ21 страницаAsr 1005 Aps 900 Ima 08Anonymous vguPVDzZ7TОценок пока нет

- Push Pull Power AmplifierДокумент4 страницыPush Pull Power AmplifierSwarnali NathОценок пока нет

- 1.1 Electrical Machines: Specification and Design of Dynamo-Electric Ma'chinery (Longman GreenДокумент2 страницы1.1 Electrical Machines: Specification and Design of Dynamo-Electric Ma'chinery (Longman Greenrajesh jОценок пока нет

- EV-100ZX Motor Controller Description & RepairДокумент95 страницEV-100ZX Motor Controller Description & RepairMario Aguirre100% (1)

- MTO Instr Cable TrayДокумент22 страницыMTO Instr Cable TrayGuru KathirОценок пока нет