Академический Документы

Профессиональный Документы

Культура Документы

Bosch Maquinas

Загружено:

nomecИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bosch Maquinas

Загружено:

nomecАвторское право:

Доступные форматы

THIESEL 2002 Conference on Thermo- and Fluid-Dynamic Processes in Diesel Engines

Future and Potential of Diesel Injection Systems

B. Mahr1

1

Robert Bosch GmbH, Diesel Systems, DS-NF/SBN, Postfach 30 02 20, D-70469 Stuttgart, Germany.

E-mail: Bernd.Mahr@de.bosch.com Telephone: +(49) 711 811 311 27 Fax: +(49) 711 811 453 34

Abstract. Heavy duty diesel engines are in conflict between the goals of emission reduction and optimization of fuel consumption.To fulfill future more stringent exhaust gas limits further developments on diesel engine technology are necessary. The diesel injection system assists this development and becomes the decisive factor to reach the emission targets. In the last 30 years a trend to high pressure fuel injection systems with an increase of maximum injection pressure from 800 up to 2000 bar is visible. In future very flexible high pressure fuel injection systems are necessary with multiple injection and rate shaping capabilities and a maximum injection pressure beyond 2000 bar. Very important is a high efficiency of the fuel injection system itself to reach low fuel consumption. New product engineering like new nozzle design (k-factor, vario nozzle,..) or new developed actuators are key factors for the fuel injection development. With a flexible diesel injection system in each point of the engine map the optimum rate shaping, injection timing and multiple injection is possible to get the best compromise between emission trade off and fuel consumption. For example with exhaust gas recirculation (EGR) a rectangular type main injection with high injection pressures at full load is recommended. On the other hand without EGR in this point of the engine map a boot or ramp shape injection leads to the best emission results at constant or improved fuel consumption. With a coupled post injection the soot emission could be reduced. The late post injection is assisting the exhaust gas aftertreatment systems. The regeneration of the diesel particulate filter is for example because of too low exhaust gas temperature without the support of the injection system not under all circumstances possible. The exhaust gas temperature management by late post injection is a measure to improve the efficiency of catalyst systems at low exhaust gas temperatures. Very important in future is the capability of the electronic control unit (ECU) of the diesel injection system to control air management, exhaust gas emission management, tolerance reduction, diagnosis, vehicle functions and combustion process by the fuel injection system.

1. Introduction

Diesel engines are in a conflict between emission reduction and optimized fuel consumption. Especially the fuel consumption of heavy duty diesel engines has a big impact on the overall costs of the haulage business. Since end of the 80s we have a dramatic reduction of HC, CO, NOx and particulate mass emissions to fulfill the exhaust gas legislation, fig.1. NOx-emission was reduced about 72 percent from 1985 up to now. In the same period of time the CO-emission was reduced about 85 percent and the HC-emission about 81 percent. Additionally the diesel engine manufacturers reached a 86 percent reduction in the particulate mass emission since 1990. This was only possible with consequent optimization of the diesel engine technology. Examples of improvements are turbocharging, intercooling, four valve technology, EGR, combustion chamber design and high injection pressures. In future furthermore exhaust gas aftertreatment systems, low sulphur diesel fuel and further improvements on diesel engine technology are necessary to fulfill future stringent exhaust gas legislation. The change in the onhighway market from inline pump systems to high pressure fuel injection systems (VP44, UIS, UPS, CRS) is in figure 2 presented. This market is mainly driven by emissions. In the off-highway diesel engine market this injection system is also gradually replaced by the high pressure fuel injection systems.

B. Mahr

% 100 50 0 100 50 0 100 50 0 100

State of art 2002

3,5 ECE R49/00 2,4 1,1

HC

14 ECE R49/00 11,2 4,5

81%

0,66 0,46

87%

85%

4 1,5

89%

CO

18 ECE R49/00

2,1

Euro 0

14,4

Euro I

8

72%

Euro II

7 5

89%

NOX

0, 7

Euro Euro IV III 3,5

86%

0, 36

97%

50 0 1985

Particulate

1990 1995

0,15

0,10

0,02

2000

2005

2010 limits in g/kWh

Fig. 1. History of European emission standards

On-highway

RP

driven by emissions

VP44

UIS UPS

CRS

Off-highway

RP VE

driven by emissions and standardisation

PF

VP44, UIS, UPS, CRS

1990

2000

2010

Fig. 2. Change to high pressure fuel injection systems (Krieger and Maier 2001)

Future and Potential of Diesel Injection Systems 7

Fig. 3. One of the first applications of the inline pump in 1927

The inline pump system is in production at BOSCH since 1927. Figure 3 demonstrates one of the first applications of the inline pump. This fuel injection system was continuous updated and optimized and is since 75 years still in production. The development of the maximum injection pressure of heavy duty engines over the last 30 years is presented in figure 4. In average the pressure was increased from 800 (inline pump) to 2000 bar (high pressure fuel injection systems) in only three decades (Projahn 2002).

3000

2500

Injection Pressure [bar]

2000

1500

1000

500

0 1970

1975

1980

1985

1990

1995

2000 Year

2005

2010

Fig. 4. Development of injection pressure of HD engine

B. Mahr

2. Diesel injection system specification

The specification for all diesel engines are restricted more and more regarding exhaust gas limits, fuel consumption, noise and costs and this with increasing demands on driveability, lifetime, power output, service and diagnosis, Figure 5. Applying EGR or increased rated speed to a heavy duty diesel engine higher maximum injection pressures are essential . To achieve future more stringent exhaust gas limits additionally low sulphur diesel fuel is necessary. The flexible diesel fuel injection system is assisting this development with the measures multiple injection, rate shaping of the main injection and an increased maximum injection pressure. Furthermore high efficiency of the injection system itself is important. New developments on actuators (new solenoid and piezo technique), nozzle design and ECU control strategies also for exhaust gas aftertreatment are key factors for future diesel engine technology. Mixing of oil with the fuel must be reduced for more stringent exhaust gas limits due to the influence of sulphur content in the lubrication oil on the overall soot emissions with a downstream oxidation catalyst (Jacob et al. 2001).

Fig. 5. Key factors for diesel fuel injection system development

3. Optimum pressure and needle lift curve

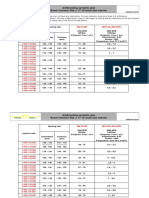

In several engine tests with pressure controlled and needle lift controlled development tools the system requirements for a future flexible diesel fuel injection systems were investigated on single cylinder diesel engine and multi cylinder engines. As a summary of the results the optimum needle lift and pressure curve in figure 6 was investigated. The upper curve in figure 6 shows the pressure at nozzle needle seat and the curve below the corresponding needle lift curve with multiple injections. To reduce noise and NOx-emissions one or two pilot injections at low pressure level should be possible. To control generating of NOx during the first phase of combustion a pressure controlled rate shaping of the main injection with boot shape, variable boot length, triangular (ramp) or rectangular shape at completely opened needle should be possible. A maximum injection pressure of at least 2000 bar is advantageous. The nozzle needle should be closed rapidly at the end of the main injection. Additionally the possibility of a coupled post injection under high pressure is necessary to reduce soot emission. With a late post injection at moderate pressure it is possible to manage exhaust gas temperature for regeneration of a diesel particulate filter or to provide hydrocarbons for NOx adsorber catalyst.

Future and Potential of Diesel Injection Systems 9

NOX Pressure at needle seat

Increased injection pressure

Noise

EGT

Soot Needle lift

Time

Fig. 6. Optimum pressure and needle lift curve for future heavy duty diesel engine FIE

4. Improvement of diesel injection system

With an analytic approach a new high pressure fuel injection system called APCRS was developed to fulfill these requirements (Mahr, Drnholz, Polach and Grieshaber, 2000). The hydraulic layout of the pressure amplified development tool is apart from the amplifier piston modules similar to the standard Common Rail System but with a middle rail pressure. In each injector amplifier modules are integrated to generate high injection pressures determined by a stepped piston. The amplifier is activated by a second solenoid valve in the injector. Without activating this solenoid the injection system acts as a standard common rail system because of the bypass path with non-return valve. Varying energizing timing of both solenoid valves flexible pressure curves from ramp to rectangular can be generated. Pilot injections and late post injections are possible without activating the amplifier piston at the intermediate pressure in the rail. With this reduced pressure of the late post injection the risk of oil dilution can be minimized. To fulfill future exhaust gas limits especially with EGR high injection pressures (2000 bar and more) are required. An increase of the system pressure with a standard common rail system for heavy duty engines leads to high effort on rail and high pressure pump design, lower efficiency and durability. High pressure pump and rail of the development tool APCRS are designed for intermediate pressure level and higher capacity depending on the ratio of amplifier piston. To avoid mixing of engine oil with fuel the high pressure pump for APCRS is fuel lubricated. The APCRS is designed for multiple injection, rate shaping, high injection pressure and high hydraulic efficiency of the injection system to reduce emissions and fuel consumption. 4.1 Rate shaping With a first prototype of the development tool APCRS, consisting of an amplifier piston module and a standard common rail injector, several engine tests were carried out to investigate the impact of rate shaping of the main injection on soot-NOx-trade-off and fuel consumption. In figure 7 engine results of a single cylinder engine with one liter displacement at 1400 rpm under full-load without EGR with variation of start of injection are compared. With the boot shaped pressure curve an advantage in soot-NOx-trade-off and specific fuel consumption was figured out in comparison to the rectangular shape of a typical common rail injection. Its possible to reach with rectangular injection shape as common rail type injection the same fuel consumption than with boot shape and the same injection duration (DoI), but higher soot and NOx-emission. With the boot shape injection an earlier start of injection is possible than with rectangular injection shape.

10

B. Mahr

Operating point: 1400 rpm, 100% load, w/o EGR g/kWh Boot Rectangular Rectangular pmax = 1440 bar pmax = 1000 bar pmax = 1400 bar 6 Soot 0.10 2 10 Dol = 24.5 KW Dol = 24.5 KW Dol = 20.0 KW g/kWh

0.15

260

240

0.05 -3 -9 0 0 4 8 NOX 12 g/kWh 0 4 8 NOX 12 g/kWh -6

220

200

Fig. 7. Comparison of boot shape injection with rectangular shape (CR) injection at a single cylinder engine with a displacement of approximately 1 l/cylinder

Without EGR at part load a common rail type pressure curve under moderate pressure or a ramp type injection is possible. At full-load without EGR the boot type injection curve demonstrates the best results. With EGR the common rail type pressure curve with a high injection pressure leads in a wide area of the engine map to the best emission results. Rate shaping of the pressure curve in this case is less important than the pressure level. At full-load and low speed the torque normally is limited by the maximum allowed cylinder peak pressure, therefore with boot shape injection higher mean effective pressures are feasible without EGR. With a flexible fuel injection system its possible to optimize the rate shaping of the pressure curve in each point of the engine map with and without EGR to get the best compromise between emissions and fuel consumption. To fulfill future exhaust gas limits exhaust gas aftertreatment systems are necessary. Euro 5 exhaust gas limits are for example possible with a SCR catalyst system with urea as reductant. This system allows NOx-reductionrates up to 90 percent. Applying a boot shape main injection in figure 8 lower NOx-emission in the European steady state cycle than with square or ramp shape injector are feasible. Alternative a lower urea consumption at equal NOx-emission is possible. With a SCR catalyst system using low sulphur fuel and an oxidation catalyst upstream the SCR system an additional soot reduction up to 40 percent is measured (Mahr, Polach and Ripper, 2000). 4.2 Coupled post injection The coupled post injection under high injection pressure is a measure to reduce the soot emissions (Mahr et al 2000). This is shown in left diagram of figure 9 at 1710 rpm and half-load at an single cylinder engine with two liter displacement with EGR. The influence of the coupled post injection on the soot emission is presented at a maximum injection pressure of 1800 bar and 2000 bar with a rectangular shape main injection. With the higher maximum injection pressure of 2000 bar the NOx-emission could be decreased. In the right diagram of figure 9 the specific fuel consumption for the different rail pressures with and without post injection are shown. No significant change in fuel consumption was found with changes in the EGR-rate. The fuel consumption with the higher injection pressure of 2000 bar is slightly higher than with 1800 bar. With the coupled post injection the fuel consumption was slightly reduced.

bsfc

Future and Potential of Diesel Injection Systems 11

PM < 0,02 g/kWh 12

w/o EGR

260 250

10

NOx / g/kWh

6 4 2 0

SCR 90 %

NOx limit EURO 4 NOx limit EURO 5

230 220 210 200

boot

ramp rectangle

boot

ramp rectangle

Fig. 8. Influence of rate shaping of main injection on NOx-emissions and fuel consumption with SCR catalyst application

Fig. 9. Engine results with rectangular shape injection with and without coupled post for a single cylinder diesel engine with a displacement of approximately 2 l/cylinder

sfc / g/kWh

240

12

B. Mahr

Beside the injection system the EGR-rate, the shape of the combustion chamber, the compression ratio, the air motion and the air-fuel-ratio are important measures to improve the combustion to reach low raw emissions of exhaust gas to meet the stringent exhaust gas limits of the future. The impact of a higher boost pressure together with a higher possible EGR-rate on the soot emission is visible in the left graph in figure 9 at 1800 bar without post injection. With higher boost pressure soot emission can be reduced significantly. Suitable changes on the engine are higher maximum combustion peak pressure, possibility of a higher EGR-rate and higher charge air pressures by VTG or even better with a two stage turbocharger systems. This requires a flexible high pressure fuel injection system with a high average fuel injection pressure combined with an efficient electronic control strategy. 4.3 Late post injection The regeneration of a diesel particulate filter (DPF) is not under all engine conditions possible because of too low exhaust gas temperatures. High exhaust gas temperatures for the regeneration of a DPF or the desulphurization of lean NOx catalysts are feasible with a late post injection, fig. 10. The exhaust gas temperature management at low exhaust gas temperatures is an important feature to increase the temperature to get higher efficieny of the exhaust gas aftertreatment system. Furthermore the generation of hydrocarbons for the regeneration of a adsorber catalyst system is assisted by the late post injection of a fuel injection system if nessesary. To avoid oil dilution a moderate injection pressure for the late post injection is recommended.

High exhaust gas temperatures for the regeneration of a DPF or desulphurization of lean NOx catalysts

Exhaust gas temperature management at low exhaust gas temperatures

Late post injection

at moderate pressure level

Generation of hydrocarbons for lean NOx catalysts

Fig. 10. Purpose of late post injection

Future and Potential of Diesel Injection Systems 13

4.4 Nozzle design The spray hole, as the precision geometry feature of the nozzle body, defines the spray characteristics and thus the emissions of the engine. The Spray characteristics of the nozzle are particulary influenced by the microgeometry of the spray holes. The parameters of the spray-hole (diameter, length, inlet edge, geometry, form and micro surface) work together for an optimal flow profile so that the injection spray requirements of the engine are met (Potz et al. 2000). With improved nozzle geometry the fuel injection system is adapted to the combustion chamber design to improve the combustion and to reduce emissions, fig. 11. The spray hole geometry has an impact on soot and NOx-emissions and the seat geometry on engine noise. With a reduced sac hole volume the hydrocarbon emission is decreased. The spray hole diameter is defined by number of spray holes, injection duration and injected fuel quantity at full load. Therefore the diameter of the spray hole is at part load to large for an optimum combustion with low soot formation. Vario nozzles or two phase nozzles are using the benefit of a reduced spay hole orrifice at part load to reduce particulate emission. With ks-nozzles and k-factor nozzles with conical spray hole, its possible to reduce cavitation effects in the spray hole and to increase the efficiency of fuel and air mixture. Addiditionally a reduced distribution of hydraulic flow at maximum needle lift is achieved, fig. 12. The influence of conic spray holes in comparison to cylindric spray holes on engine emissions are demonstrated in figure 13. With the conical spray holes a benefit in soot-NOx-trade-off and in the specific fuel consumption was found at part load and at full load at this four cylinder diesel engine with approx. 4 l displacement.

Fig. 11. Influence of nozzle design on exhaust gas emissions

14

B. Mahr

k-Factor and ks-Nozzle

Conical spray hole Target

k-Factor Increased efficency Avoid cavitation effects in the spray hole Reduced distribution of hydraulic flow at max. needle lift

Influence on emissions

Potential for the reduction of the particulate emissions ks-Nozzle

Fig. 12. Conical spray hole

operation speed: 2305 rpm

400 380 [g/kWh] 360 340 320 300 [g/kWh] 0.12 0.09 0.06 0.03 0.00 0 2 4 6 8 10 [g/kWh] 12

Euro 3 limits VCO nozzle with cylindric sprayholes 7 * 0,194 * 1,0 mm VCO nozzle with conic sprayholes 7 * 0,175 / 0,160 * 1,0 mm 300

260 240 220 200

bsfc

25 % load

100 % load

0.12 0.09 0.06 0.03

spec. soot em.

14

10 [g/kWh]

12

14

0.00

spec. NOx em.

spec. NOx em.

Fig. 13. Influence of conic sprayholes on engine emissions. (4 cylinder engine, 4 l displacement, Qhydr 600 cm3 at 100 bar)

spec. soot em.

[g/kWh]

bsfc

[g/kWh]

25 % load

100 % load

280

Future and Potential of Diesel Injection Systems 15

4.5 New and improved control strategies Since more than 25 years the diesel engine is equipped with an electronic engine control unit. New sensors and new developments at the engine itself (VTG, EGR, engine braking systems...) enable further improvement of the complete system with new engine control strategies in the ECU especially during transient engine conditions. In figure 14 the NOx-emission and opacity results in hot test heavy duty transient cycle (HDTC) are compared with and without the function transient rail pressure increase. During acceleration of the engine the maximum injected fuel quantity is reduced depending on the fuel-air-ratio to avoid soot formation. With a transient rail pressure increase of a common rail system during acceleration the soot emission (opacity) was reduced with a neclectable disadvantage on NOx-emissions (Becher et al. 2002). Another example for new control strategies is the transient, closed loop EGR correction. In figure 15 the hot test HDTC emission results are compared with and without this new control strategy. Without the transient closed loop correction high peaks in opacity (soot formation) are found because of a too high EGR rate at low fuel-air-ratios during acceleration. The control strategy is based on lambda sensor signal or on difference pressure measured with a venturi nozzle in the exhaust gas pipe. With the ECU tolerance reduction is achieved to reduce emissions. New control functions are for example zero fuel quantity calibration, fuel quality balancing control and single cylinder control for each cylinder. The potential for future diesel optimization is in the complete system control of the combustion process in the diesel engine, figure 16. Beside the control of the fuel injection system itself its more and more important to control additionally air management and exhaust emission management with the engine ECU to get the best compromise in soot-NOx-trade-off and fuel consumption in each point of the engine map and during transient conditions.

Rail pressure [MPa]

140 100 60 20 16

w/o Rail pressure increase Rail pressure increase 400 bar

Opacity [%] NOX [ppm]

12 8 4 0 1200 900 600 300 0 0 50 100 150 Time [s] 200 250 300

Fig. 14. Influence of transient rail pressure increase on emission results in hot test HDTC (approx.. 1 l/cyl.)

16

B. Mahr

w/o transient correction

EGR valve duty cycle [%] 100 80 60 40 20 8 6 4 2 0 800 NOX [ppm] 600 400 200 0 360 380 400

Time [s]

open

closed

with transient correction

Opacity [%]

420

440

460

Fig. 15. Influence of transient, closed loop EGR correction on emissions results in hot test HDTC (approx. 1 l/cyl.)

Fuel injection system

new generation injection rate shaping reduced tolerance optimized nozzle

Air management Throttle- /swirl valve Electric charger

Exhaust emission-management Exhaust emission aftertreatment with sensors - control

Combustion process

Tolerance reduction

zero fuel quantity calibr. fuel quantity balancing control single cyl. control

Fig. 16. Potential for future diesel system optimization

Future and Potential of Diesel Injection Systems 17

Conclusions

Beside the injection system the EGR-rate, the shape of the combustion chamber, the compression ratio, the air motion and the air-fuel-ratio are important measures to improve the combustion to reach low exhaust gas raw emissions to achieve future stringent exhaust gas limits for heavy duty engines. With higher boost pressure a significant reduction of soot emission is feasible. Suitable changes on the engine are higher maximum combustion peak pressure, higher EGR-rate and higher charge air pressures by VTG or even better with two stage turbocharger systems. In addition to engine internal measures for emission reduction exhaust gas aftertreatment systems are necessary to fulfill future exhaust gas limits. The exhaust gas aftertreatment system are assisted by the injection system by temperature management. This requires a very flexible fuel injection system with a high average injection pressure, rate shaping and multiple injection. Further development targets are reduced tolerances and optimized nozzle design. Beside the control of the fuel injection system itself with new control strategies its more and more important to control additionally air management and exhaust emission management with the engine ECU to get the best compromise in soot-NOx-trade-off and fuel consumption in each point of the engine map and during transient conditions.

References

Becher S, Forthmann S and Tichy B (2002) Abgasrckfhrregelung beim Nkw-Dieselmotor im dynamischen Betrieb, Tagung:Emission Control, Dresden Jacob E, Gotre W, Rothe D, Rammer F and Richter K.(2001) The influence of lubricating oil on the emissions of diesel engines with exhaust gas aftertreatment. 22. Internationales Wiener Motorensymposium, VDI Reihe 12 Nr. 455, pp 286-301 Krieger K and Maier R (2002) Challenges of global market requirements on diesel FIE, AVL International Commercial Powertrain Conference, Budapest. Mahr B, Polach W and, Ripper W(2000) Dosing system for reducing agent of SCR catalysts, VDA Technical Congress 2000 Mahr B, Drnholz M, Polach W and Grieshaber H (2000) Heavy Duty Diesel Engines - The potential of injection rate shaping for optimization of emissions and fuel consumption, 20. Internationales Motorensymposium, VDI Reihe 12 Nr. 376 Potz D, Christ W and Dittus B (2000) Diesel system The determining interface between injection system and combustion chamber, Thermo- and Fluid-dynamic Processes in Diesel engines, Springer, pp 133-143 Projahn U (2002) Requirements on diesel fuel injection equipment and fuel cleanliness under consideration of global market aspects, 5th International Filtration Conference

Вам также может понравиться

- Advanced Fuel Injection Technology for Future Diesel EnginesДокумент17 страницAdvanced Fuel Injection Technology for Future Diesel EnginesDan SerbОценок пока нет

- Common Rail Direct InjectionДокумент9 страницCommon Rail Direct InjectionJoe SparksОценок пока нет

- Diesel Common Rail SystemsДокумент2 страницыDiesel Common Rail SystemsmihajlovichenkelОценок пока нет

- TCT Segmentfolder 201409 en LowresДокумент80 страницTCT Segmentfolder 201409 en LowreszglogovicОценок пока нет

- Pizzo InjiДокумент3 страницыPizzo InjiprakashОценок пока нет

- Restore Piezo Stacks with RegenerationДокумент3 страницыRestore Piezo Stacks with RegenerationAbraaj-TTSОценок пока нет

- Fuel Injector Holes: (Fabrication of Micro-Orifices For Fuel Injectors)Документ23 страницыFuel Injector Holes: (Fabrication of Micro-Orifices For Fuel Injectors)DenisEcheverriОценок пока нет

- CRDiДокумент18 страницCRDiSuhel InamdarОценок пока нет

- Sabre Expert Brochure PDFДокумент6 страницSabre Expert Brochure PDFayaz100% (1)

- Ds-Datenbl Crs1 14up enДокумент2 страницыDs-Datenbl Crs1 14up encrastoverkillОценок пока нет

- DieselBrochure 10-2012Документ68 страницDieselBrochure 10-2012enriОценок пока нет

- Protocolo EPS 200: Prueba Inyector Common RailДокумент2 страницыProtocolo EPS 200: Prueba Inyector Common RailMauricio Navarro santanaОценок пока нет

- Bosch Injector Repair KitsДокумент25 страницBosch Injector Repair KitsRespaldo GregoryОценок пока нет

- Makalah Wirausahawan SuksesДокумент6 страницMakalah Wirausahawan SuksesSurya IrawanОценок пока нет

- Piezo Injector For Common-Rail Systems: Low Fuel ConsumptionДокумент1 страницаPiezo Injector For Common-Rail Systems: Low Fuel Consumptionalmia tronicsОценок пока нет

- 1day Piezo Training 2010Документ298 страниц1day Piezo Training 2010Chunxiao Yan67% (3)

- CRDi Full PDFДокумент20 страницCRDi Full PDFnikhil sengar75% (4)

- CRS950 User's Manual - WeightДокумент9 страницCRS950 User's Manual - WeightJuan GonzalezОценок пока нет

- Bosch ESI (Tronic) 1Q.2015 News PDFДокумент2 страницыBosch ESI (Tronic) 1Q.2015 News PDFAdrián Molina MiguelОценок пока нет

- InjpumpДокумент3 страницыInjpumpnico78000Оценок пока нет

- Solenoid Valve Colis For Siemens Continental VDO Common Rail Injector A2C59517051 BK2Q9K546AG and Other Vdo InjectorДокумент8 страницSolenoid Valve Colis For Siemens Continental VDO Common Rail Injector A2C59517051 BK2Q9K546AG and Other Vdo InjectorWinston Wolf0% (1)

- Bosch Inline Piezo Injector Delivery PlanДокумент9 страницBosch Inline Piezo Injector Delivery PlandieseldvОценок пока нет

- Manual DayelДокумент30 страницManual Dayelkittisak RunganothaiОценок пока нет

- Test BenchesДокумент7 страницTest BenchesAnderson LondonОценок пока нет

- Training Program For Automotive Technolog y 2019 - 2020: Southeast AsiaДокумент11 страницTraining Program For Automotive Technolog y 2019 - 2020: Southeast AsiaJanne PuhakkaОценок пока нет

- How A Turbo WorksДокумент2 страницыHow A Turbo WorksSubhojit SamontaОценок пока нет

- Delphi DieselMax and Turbocharger Extra Modules PDFДокумент3 страницыDelphi DieselMax and Turbocharger Extra Modules PDFSherita Thomas100% (1)

- SABRE BASE OPTIONS AND PARTSДокумент10 страницSABRE BASE OPTIONS AND PARTSHong Seok ChoiОценок пока нет

- MCRS enДокумент2 страницыMCRS enTamer Moustafa100% (1)

- China Factory Dlla149p1515 Nozzle Fit For Common Rail Volvo Fuel Injector 0445110259Документ4 страницыChina Factory Dlla149p1515 Nozzle Fit For Common Rail Volvo Fuel Injector 0445110259Alen HuangОценок пока нет

- Bosch Common - Rail Antiknocking Syntactic PlanДокумент6 страницBosch Common - Rail Antiknocking Syntactic PlandieseldvОценок пока нет

- The Advanced Diesel Engine Technology and Fuel Injection System TechnologyДокумент24 страницыThe Advanced Diesel Engine Technology and Fuel Injection System TechnologyMohamedBenMansourОценок пока нет

- Delphi DDU CRSДокумент2 страницыDelphi DDU CRSFaraz HaiderОценок пока нет

- Deteqstandart PDFДокумент4 страницыDeteqstandart PDFSoeAyeОценок пока нет

- FLC Tpms en PDFДокумент140 страницFLC Tpms en PDFPako PaezОценок пока нет

- Ima Info Piezo PDFДокумент14 страницIma Info Piezo PDF30106Оценок пока нет

- hk1400 - NMДокумент2 страницыhk1400 - NMAhmet BuyrucuОценок пока нет

- Operation 1Документ9 страницOperation 1Wbamlak AshebrОценок пока нет

- Bosch ECI Injection - ECIДокумент17 страницBosch ECI Injection - ECIBeTOОценок пока нет

- Diesel InjectorДокумент15 страницDiesel InjectorAlvin AuОценок пока нет

- Deteqstandart PDFДокумент4 страницыDeteqstandart PDFMoaed KanbarОценок пока нет

- The Common Rail Diesel Injection System Explained: Technical FeaturesДокумент3 страницыThe Common Rail Diesel Injection System Explained: Technical FeaturesDejan MihajlovicОценок пока нет

- Nantai Catalog NewДокумент30 страницNantai Catalog Newspalomos100% (1)

- TK1035 enДокумент2 страницыTK1035 enSutiknoОценок пока нет

- High-Pressure Pump HDP5Документ2 страницыHigh-Pressure Pump HDP5RICHARDОценок пока нет

- 2013 - Technical Service Bulletin - No 01 PDFДокумент2 страницы2013 - Technical Service Bulletin - No 01 PDFSutiknoОценок пока нет

- 2013 Technical-Service-Bulletin No-04 en PDFДокумент2 страницы2013 Technical-Service-Bulletin No-04 en PDFSutiknoОценок пока нет

- Manual Reparación Turbo GARRETДокумент24 страницыManual Reparación Turbo GARRETFelipe Lepe MattaОценок пока нет

- Modern Trends in Fuel Injection in Diesel EngineДокумент32 страницыModern Trends in Fuel Injection in Diesel EngineAJAY CHANDОценок пока нет

- Common RailДокумент30 страницCommon RailAnonymous 9QkTHFОценок пока нет

- Bosch Vp44 Diesel Pump Fitted To Vauxhall Astra Corsa Combo Frontera 10816147Документ3 страницыBosch Vp44 Diesel Pump Fitted To Vauxhall Astra Corsa Combo Frontera 10816147Duško GrbićОценок пока нет

- Stanadyne Pump Diagnostic Troubleshooting PDFДокумент3 страницыStanadyne Pump Diagnostic Troubleshooting PDFOctavio RamosОценок пока нет

- 1995 Model Series NSX/NSX-T Body Repair Manual: WarningДокумент1 страница1995 Model Series NSX/NSX-T Body Repair Manual: WarningCristian CernaОценок пока нет

- 2170Документ9 страниц2170ForteLubОценок пока нет

- The New 2.0 L and 2.2 L Four-Cylinder Diesel Engine Family of Hyundai-KiaДокумент6 страницThe New 2.0 L and 2.2 L Four-Cylinder Diesel Engine Family of Hyundai-Kiaqingcaohe75% (4)

- Common Rail High Pressure Fuel Injection 9-2010Документ33 страницыCommon Rail High Pressure Fuel Injection 9-2010gmmarinov100% (5)

- Bosch Paper On Fuel Injection 2005 PDFДокумент9 страницBosch Paper On Fuel Injection 2005 PDFiocsachinОценок пока нет

- The New Mercedes-Benz 4.0 L V8 Diesel EngineДокумент4 страницыThe New Mercedes-Benz 4.0 L V8 Diesel EngineEichi WatanabeОценок пока нет

- MTU White Paper Fuel InjectionДокумент4 страницыMTU White Paper Fuel InjectionDinesh JayasekaraОценок пока нет

- Delphi Diesel SystemsДокумент20 страницDelphi Diesel SystemsMelvin Cotrado100% (2)

- Toyota C-HR 2021Документ9 страницToyota C-HR 2021nomecОценок пока нет

- Stay Independent - CDCДокумент2 страницыStay Independent - CDCurielqpОценок пока нет

- Robust Model For Fatigue Life EstimationДокумент180 страницRobust Model For Fatigue Life EstimationnomecОценок пока нет

- Lec21 NotesДокумент37 страницLec21 NotesFaisal RizkiОценок пока нет

- Toshiba E-Studio 4515AC 5015AC BrochureДокумент6 страницToshiba E-Studio 4515AC 5015AC BrochureDavideDeRubeisОценок пока нет

- Effect of Dislocation Hardening On Monotonic and CДокумент25 страницEffect of Dislocation Hardening On Monotonic and CnomecОценок пока нет

- 2021 Subaru Outback BrochureДокумент13 страниц2021 Subaru Outback BrochurenomecОценок пока нет

- Stay Independent - CDCДокумент2 страницыStay Independent - CDCurielqpОценок пока нет

- Fatigue Life Assessment On An 2006-01-0977Документ12 страницFatigue Life Assessment On An 2006-01-0977nomecОценок пока нет

- Outokumpu Martensitic Grade 630 Data Sheet17 4Документ2 страницыOutokumpu Martensitic Grade 630 Data Sheet17 4nomecОценок пока нет

- A Novel Approach To The Estimation of Strain Life Fatigue ParametersДокумент10 страницA Novel Approach To The Estimation of Strain Life Fatigue ParametersnomecОценок пока нет

- A New Empirical Life Prediction Model For 9-12Cr SДокумент16 страницA New Empirical Life Prediction Model For 9-12Cr SnomecОценок пока нет

- Fatigue Life Estimates Using Goodman DiagramsДокумент11 страницFatigue Life Estimates Using Goodman Diagramsloveleshvarma100% (1)

- Fatigue Properties of JIS H3300 C1220 Copper For Strain Life PredictionДокумент10 страницFatigue Properties of JIS H3300 C1220 Copper For Strain Life PredictionnomecОценок пока нет

- In Common Rail Development: MilestonesДокумент3 страницыIn Common Rail Development: MilestonesTamer MoustafaОценок пока нет

- Piezo Adaptive Control MTZ 2006Документ3 страницыPiezo Adaptive Control MTZ 2006nomecОценок пока нет

- Fatigue Life Estimates Using Goodman DiagramsДокумент11 страницFatigue Life Estimates Using Goodman Diagramsloveleshvarma100% (1)

- Us Map With RoadsДокумент1 страницаUs Map With RoadsnomecОценок пока нет

- Denzo - 3000bar MTZ Jan 2011Документ6 страницDenzo - 3000bar MTZ Jan 2011nomecОценок пока нет

- 10 16 2007 Cummins CRS3.3iДокумент18 страниц10 16 2007 Cummins CRS3.3inomec100% (11)

- Powertrain: Type of Operating EPA Rated EPA Rated EPA RatedДокумент2 страницыPowertrain: Type of Operating EPA Rated EPA Rated EPA RatednomecОценок пока нет

- AgifilmlistДокумент1 страницаAgifilmlistnomecОценок пока нет

- Lea 201 Coverage Topics in Midterm ExamДокумент40 страницLea 201 Coverage Topics in Midterm Examshielladelarosa26Оценок пока нет

- Ielts Band 9 Sample Essay NoДокумент5 страницIelts Band 9 Sample Essay NoNhã NguyễnОценок пока нет

- Spain Price List With VatДокумент3 страницыSpain Price List With Vatsanti647Оценок пока нет

- CLC Customer Info Update Form v3Документ1 страницаCLC Customer Info Update Form v3John Philip Repol LoberianoОценок пока нет

- Hindustan Coca ColaДокумент63 страницыHindustan Coca ColaAksMastОценок пока нет

- 04 Activity 2Документ2 страницы04 Activity 2Jhon arvie MalipolОценок пока нет

- Sound Wave Interference and DiffractionДокумент79 страницSound Wave Interference and DiffractionMuhammad QawiemОценок пока нет

- Article 4Документ31 страницаArticle 4Abdul OGОценок пока нет

- RS-RA-N01-AL User Manual of Photoelectric Total Solar Radiation TransmitterДокумент11 страницRS-RA-N01-AL User Manual of Photoelectric Total Solar Radiation TransmittermohamadОценок пока нет

- Design of Shear Walls Using ETABSДокумент97 страницDesign of Shear Walls Using ETABSYeraldo Tejada Mendoza88% (8)

- "Corbel" - Concrete Corbel Analysis: Program DescriptionДокумент4 страницы"Corbel" - Concrete Corbel Analysis: Program DescriptioniuliandurdureanuОценок пока нет

- Request Letter To EDC Used PE PipesДокумент1 страницаRequest Letter To EDC Used PE PipesBLGU Lake DanaoОценок пока нет

- Responsibility Centres: Nature of Responsibility CentersДокумент13 страницResponsibility Centres: Nature of Responsibility Centersmahesh19689Оценок пока нет

- DS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENДокумент2 страницыDS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDragana SkipinaОценок пока нет

- 272 Concept Class Mansoura University DR Rev 2Документ8 страниц272 Concept Class Mansoura University DR Rev 2Gazzara WorldОценок пока нет

- 2016 04 1420161336unit3Документ8 страниц2016 04 1420161336unit3Matías E. PhilippОценок пока нет

- Method StatementДокумент11 страницMethod StatementMohammad Fazal Khan100% (1)

- Verifyning GC MethodДокумент3 страницыVerifyning GC MethodHristova HristovaОценок пока нет

- Savable Data Page - Its Configuration, Usage & ExecutionДокумент20 страницSavable Data Page - Its Configuration, Usage & ExecutionsurmanpaОценок пока нет

- SABIC Ethanolamines RDS Global enДокумент10 страницSABIC Ethanolamines RDS Global enmohamedmaher4ever2Оценок пока нет

- Kunci Jawaban Creative English 3BДокумент14 страницKunci Jawaban Creative English 3BLedjab Fatima67% (3)

- Critical Values For The Dickey-Fuller Unit Root T-Test StatisticsДокумент1 страницаCritical Values For The Dickey-Fuller Unit Root T-Test Statisticswjimenez1938Оценок пока нет

- Human Resource Management: Chapter One-An Overview of Advanced HRMДокумент45 страницHuman Resource Management: Chapter One-An Overview of Advanced HRMbaba lakeОценок пока нет

- FC Bayern Munich Marketing PlanДокумент12 страницFC Bayern Munich Marketing PlanMateo Herrera VanegasОценок пока нет

- KL Wellness City LIvewell 360 2023Документ32 страницыKL Wellness City LIvewell 360 2023tan sietingОценок пока нет

- C - Official Coast HandbookДокумент15 страницC - Official Coast HandbookSofia FreundОценок пока нет

- Shubh AmДокумент2 страницыShubh AmChhotuОценок пока нет

- Contemporary World Prelim Exam Test DraftДокумент5 страницContemporary World Prelim Exam Test DraftGian Quiñones93% (45)

- Dewatering Construction Sites Below Water TableДокумент6 страницDewatering Construction Sites Below Water TableSOMSUBHRA SINGHAОценок пока нет

- 3000W InverterДокумент2 страницы3000W InverterSeda Armand AllaОценок пока нет