Академический Документы

Профессиональный Документы

Культура Документы

Medimurec Gaurina N Pasic B Simon K Matanovic D Malnar M

Загружено:

stevebeardsleyИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Medimurec Gaurina N Pasic B Simon K Matanovic D Malnar M

Загружено:

stevebeardsleyАвторское право:

Доступные форматы

Rudarsko-geoloko-naftni zbornik

Vol. 20

str. 41 - 49

Zagreb, 2008.

UDC 622.244.442

UDK 622.244.442

Preliminary communication Prethodno priopenje

Language/Jezik:English/Engleski

FORMATE-BASED FLUIDS: FORMULATION AND APPLICATION ISPLAKE NA BAZI FORMIJATA: SASTAV I PRIMJENA

NEDILJKA GAURINA-MEIMUREC; BORIVOJE PAI; KATARINA SIMON; DAVORIN MATANOVI, MATIJA MALNAR

University of Zagreb, Faculty of Mining, Geology and Petroleum Engineering, Pierottijeva 6, 10000 Zagreb, Croatia

Key words: formate-based fluids, temperature, fluid properties, drilling

potassium

formate,

high

Kljune rijei: isplake na bazi formijata, kalijev formijat, visoka temperatura, svojstva fluida, buenje

Abstract Formate-based fluids has been successfully used in over hunders HPHT well operations since they introduced in field practice. They have many advantages when compared with conventional HPHT drilling and completion fluids such as: minimal formation damage, maintenance of additve properties at high temperatures, reduced hydraulic flow resistance, low potential for differential sticking, naturally lubricating, very low corrosion rates, biodegradable and pose little risk to the environment etc. Formate-based fluids can be applied during deep slim hole drilling, shale drilling, reservoir drilling, salt and gas hydrate formations drilling. The laboratory research was carried out to evaluate the rheological behavior of formate-based fluids as a function of temperature. Formate-based fluids were formulated using potassium formate brine, xanthan polymer, PAC, starch and calcium carbonate. Experimental results show that potassium formate improves the thermal stability of polymers.

Saetak Isplake na bazi formijata uspijeno se primjenjuju tijekom razliitim radova u buotinama s visokim tlakom i temperaturom. One imaju nekoliko prednosti u odnosu na standardne isplake koje se koriste tijekom buenja i opremanja buotina s visokim tlakom i temperaturom, kao npr.: minimalno oteenje formacije, ouvanje svojstava aditiva kod visokih temperatura, smanjenje trenja, smanjenje opasnosti od diferencijalnog prihvata, poboljana mazivost, smanjena korozivnost, biorazgradivost i neznatan utjecaj na okoli. Isplake na bazi formijata nale su svoju primjenu tijekom izrade dubokih buotina malog promjera, buenja kroz naslage ejla, buenje kroz leita ugljikovodika, te tijekom izrade kanala buotine kroz naslage soli i plinskih hidrata. Provedena su laboratorijska ispitivanja kojima je utvrena ovisnost promjene reolokih svojstva isplaka na bazi formijata u ovisnosti o temperaturi. Isplake na bazi formijata sastojale su se od kalij formijata, xanthan polimera, polianionske celuloze, kroba i kalcijevog karbonata. Ispitivanja su pokazala da kalij formijat poboljava temperaturnu stabilnost polimera.

Introduction The formate salts of the formic acid have very high solubilities in water, creating dense, alkaline brines of relatively low viscosity with a range of beneficial properties, such as reduced rate of hydrolytic and oxidative degradation of many viscosifiers and fluid loss agents at high temperatures, which make them ideally suited for use as drilling and completion fluids (Downs, 1992., 1993; Howard, 1995.; Gallino, 1997.). The three monovalent formate salts considered most useful to the oil industry are sodium formate, potassium formate and cesium formate (Table 1) (Downs, 1992. 1993.). In addition to that, they are biodegradable, have a low toxicity to aquatic organisms and display very little corrosiveness towards ferrous-based metals used in oilfield tubulars and auxiliary hardware. Formate brines were used as the basis of low-solids drilling fluids for deep and slim hole drilling, as a drilling fluid in drilling through very plastic shales, as a high temperature reservoir drilling fluid, and as a completion and workover fluid (Abou-Sayed, 1996.; Downs 1992.; Sundermann 1996.; Gallino, 1997.; Bungert, 2000.; Gilbert, 200.; Al Otaibi et al., 2008).

Rud.-geol.-naft. zb., Vol. 20, 2008. Gaurina-Meimurec, B. Pai, K. Simon, D. Matanovi, M. Malnar: Formate-based fluids

Table 1. Typical properties of near-saturated formate brines Tablica 1. Osnovna svojstva zasienih formijata Brine density Kinematic viscosity pH

2

Brine

Formate concentration (% w/w)

Temperature (20 C) (kg/m3) (10 m /s) 7.1 10.9 2.8

-6

Sodium formate Potassium formate Caesium formate monohydrate

45 76 83

1338 1598 2367

9.4 10.6 12.9

The advantages of formate brines in these applications were: o o o o o o o o o o o Effective hole cleaning at high downhole temperatures Elimination of solids sag at high downhole temperatures Excellent polymer stability up to 154 C Minimal circulating pressure losses Low differential sticking potential (thin, easily removable filter cakes) Low ECDs in long/narrow boreholes Maximum power transmission to mud motors and bits Reduced drilling time, time spent for bit balling and time spent on reaming Non-hazardous Compatible with reservoir minerals and liquid phases (no formation damage) Good inhibition of formation clays (increased hole stability and reduction in wastes produced/hole volume) Compatible with drilling/completion hardware and elastomers (no corrosion) Increased ROP Low treatment costs during drilling Environmentally responsible and readily biodegradable (savings on waste disposal)

Field experience Solids-free formate brines were introduced in practice in the early 1990s (Downs, 1993.; Bungert et al., 2000.; Al Otaibi et al., 2008.). Formate fluids have been used in hundreds wells across the world since their comercial introduction in 1993. Table 2 presents different data colected from the published literature regarding field experience in formate based fluids application.

Laboratory testing - Fluid formulation and results In laboratory, three fluids (marked as DIF-1, DIF-2, and DIF-3) were prepared, with 50 % w/w potassium formate and one fluid without potassium formate (marked as WBF) (Table 3). Fluid formulations shown in Table 2 contain base fluid and four components: viscosifying biopolymer, fluid loss polymers (starch and PAC) and sized calcium carbonate. A viscosifying biopolymer (xanthan gum) provides thixotropic properties and solid carrying capacity. Fluid loss polymers provide filtration control. Sized calcium carbonate is necessary as solid particulates for bridging purposes. Dilution water was necessary to decrease the base fluid density. The polymers were hydrated in the dilution water and that mixture was added to the base saturated brine. Water based fluid was chosen and tested to allow comparison of effectivity of formate based fluids.

o o o o

Generally, formate-based fluids can solve the problems routinely encountered with the temperature limited, calcium carbonate weighted, and water-based polymer drilling fluids such as inadequate solids suspension, poor solids transport, stuck pipe, and tight holes.

Rud.-geol.-naft. zb., Vol. 20, 2008. N. Gaurina-Meimurec, B. Pai, K. Simon, D. Matanovi, M. Malnar: Formate-based fluids Table 2 Formate based fluids application data Tablica 2. Podaci o primjeni fluida na bazi formijata

Year 1994. 1994.

Country/ Area North Sea The Netherlands

Company

Fluid Sodium formate Sodium/potassium formate

Purpose Drill-in and completion fluid Drill-in and completion fluid Drill-in and completion fluid

Well type Offshore open-hole horizontal oil wells Horizontal open-hole gas wells

Formation

Source Byrne et al. 2002. Byrne et al. 2002.

1994.

Norway

Statoil

Potassium formate weighted with manganese tetraoxide

Well C-18

The reservoir consisted of relatively shallow, highly porous, poorly consolidated sand. The reservoir matrix contained a significant percentage of reactive clays. Rotliegend sand formations, Formation temperature - 150 C

Downs et al. 2005.; Howard 1995.; Svendsen et al. 1995. Bungert et al. 2000.; Byrne et al. 2002.; Downs et al. 2006. Downs et al. 2005. Downs et al. 2005. Downs et al. 2005.; Howard 1995. Downs et al. 2005. Downs et al. 2006. Downs et al. 2005. Downs et al. 2006.

1995.

Northern Germany

Mobil Germany and M-I Drilling Fluids Germany ExxonMobile Oriente NAM

K-formate, saturated NaCl+CaCO3, formate blend, Naformate Biopolymer, fluid-loss agents, CaCO3 (1-3%), Na-formate, Kformate or their blend Sodium formate Na-formate and Na/K-formate, CaCO3, purified xanthan biopolymer, modified strach Na/K-formate, biopolymer viscosifer, modified strach, sized CaCO3 Cesium formate Potassium formate

Drill-in fluid (10 wells), workover/completrion (6 wells) and fracturing (1 well) Drill-in and completion fluid Drill-in fluid Drill-in and completion fluid Drill-in and completion fluid Perforating fluid Drilling fluid Completion and workover fluid

15 gas wells, deep horizontal gas well

1996.-2000. 1997.

Germany Ecuador The Netherlands

More than 15 wells Several horizontal wells Gas well (K14-FB 102) High-angle well

Blackstone, Fernie and Fort Simpson shales

Rotliegend sand formations Sand/shale sequences with a high level of reactive smectite clay (80% of the clay content) Formation temperature - 185 C

1999. 1999. 1999. 1999

UK UK Western Canada UK

BP Shell

Over 300 wells Formation temperature - 207 C

Total

Cesium formate

Rud.-geol.-naft. zb., Vol. 20, 2008. Gaurina-Meimurec, B. Pai, K. Simon, D. Matanovi, M. Malnar: Formate-based fluids Table 2 Formate based fluids application data (continued) Tablica 2. Podaci o primjeni fluida na bazi formijata (nastavak)

Year

Country/ Area Norway

Company Statoil

Fluid Cesium formate Na-formate, and Na/K-formate, KCl+polymer, NaCl+polymer, LTOBM, CaCO3 Potassium/cesium formate

Purpose Drill-in and completion fluid Drill-in and completion fluid Drilling fluid Drilling and perforation fluid Completion and workover fluid Drill-in and completion fluid

Well type 6 wells (45-55 inclination) Three horizontal wells

Formation Form. temperature - 150 C

Source Downs etal. 2005.; Downs et. al. 2006. Downs et al. 2005.

2000.-2001.

UK

Shell

2001.

UK

BP

Sandstone Horizontal HPHT appraisal/developmen t well Offshore HTHP well Gas wells

2002. 2002. 2003.

Norway USA Norway Saudi Arabia Saudi Arabia Norway

Norsk Hydro BP Statoil

Potassium formate Cesium formate Cesium formate Solids-free formate brines - (XCpolymer, strach, polyanionic cellulose, relatively small amount of CaCO3)

Formation temperature - 115 C Formation temperature - 177 C Formation temperature - 170 C Deep sandstone reservoir, Form. temperature -154,44 C Hard and abrasive sandstone with interbedding of shale, Form. temperature -121C - 177 C

Downs et al. 2005.; Downs et al. 2006. Downs et al. 2005.; Downs et al. 2006. Downs et al. 2006. Downs et al. 2006. Al Otaibi et al. 2008. Downs et al. 2005.; Downs et al. 2006. Downs et al. 2006. Downs et al. 2006. Downs et al. 2005. Downs et al. 2005. Byrne et al. 2002.

2004.

Gas wells

2004./2005. 2004./2005. 2005.

Saudi Aramco Cesium formate MOL Cesium formate Potassium/cesium formate

Drilling fluid Drill-in and completion fluid Completion and perforating fluid Completion fluid Drill-in and completion fluid Potassium/caesium formate blend Drill-in and completion fluid 6 wells Onshore well Vetyem-1 HTHP well Horizontal sidetracks drilled with couled tubing HT/HP gas wells

Form. temperature - 145

UK USA Alaska North Sea

Rud.-geol.-naft. zb., Vol. 20, 2008. N. Gaurina-Meimurec, B. Pai, K. Simon, D. Matanovi, M. Malnar: Formate-based fluids Table 3. Potassium formate based fluid composition Tablica 3. Sastav isplake na bazi kalij formijata

Formulation Water K-formate Xanthan gum Starch PAC CaCO3 Defoamer

Units ml ml g/l g/l g/l g/l

WBF 1000 0 4 14 20 30

Potassium formate based fluids DIF-1 DIF-2 DIF-3 500 500 500 500 500 500 4 4 4 14 14 14 0 10 20 30 30 30 As required

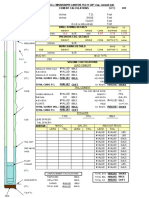

Rheological properties at temeratures up to 160 C (plastic viscosity, yield point, gel strenghts, index of consistency, flow index) were determined from readings of shear stress data at different shear rates obtained by using HPHT viscometer - OFITE Model 1000 and

presented in the Table 4 and Figures 1 to 6 as well as API fluid loss, filter cake thickness and friction coefficient data presented in the Table 4 and Figure 7.

0,14 WBF 0,12 DIF-1 DIF-2 Plastic Viscosity (P a.s) 0,1 DIF-3

0,08

0,06

0,04

0,02

0 50 75 100 Temperature (C) 125 150

Figure 1 Influence of temperature on plastic viscosity of potassium formate based fluids Slika 1. Utjecaj temperature na plastinu viskoznost isplaka na bazi kalij formijata

80 WBF 70 60 Yield Point (Pa) 50 40 30 20 10 0 50 75 100 Temperature (C) 125 150 DIF-1 DIF-2 DIF-3

Figure 2 Influence of temperature on yield point of potassium formate based fluids Slika 2. Utjecaj temperature na naprezanja pri pokretanju isplaka na bazi kalij formijata

Rud.-geol.-naft. zb., Vol. 20, 2008. Gaurina-Meimurec, B. Pai, K. Simon, D. Matanovi, M. Malnar: Formate-based fluids

25,00 WBF DIF-1 20,00 10 Gel Strength (Pa) DIF-2 DIF-3

15,00

10,00

5,00

0,00 50 75 100 Temperature (C) 125 150

Figure 3 Influence of temperature on 10-s gel strength of potassium formate based fluids Slika 3. Utjecaj temperature na deset sekundnu vrstou gela isplaka na bazi kalij formijata

25,00 WBF DIF-1 20,00 10 Gel Strength (Pa) DIF-2 DIF-3

15,00

10,00

5,00

0,00 50 75 100 Temperature (C) 125 150

Figure 4 Influence of temperature on 10-min gel strength of potassium formate based fluids Slika 4. Utjecaj temperature na deset minutnu vrstou gela isplaka na bazi kalij formijata

18 WBF 16 14 Consistency index (Pa.s n ) 12 10 8 6 4 2 0 50 75 100 Temperature (C) 125 150 DIF-1 DIF-2 DIF-3

Figure 5 Influence of temperature on flow index of potassium formate based fluids Slika 5. Utjecaj temperature na indeks toka isplaka na bazi kalij formijata

Rud.-geol.-naft. zb., Vol. 20, 2008. N. Gaurina-Meimurec, B. Pai, K. Simon, D. Matanovi, M. Malnar: Formate-based fluids

18 WBF 16 14 Consistency index (Pa.s n ) 12 10 8 6 4 2 0 50 75 100 Temperature (C) 125 150 DIF-1 DIF-2 DIF-3

Figure 6 Influence of temperature on consistency index of potassium formate based fluids Slika 6. Utjecaj temperature na indeks konzistencije isplaka na bazi kalij formijata

0,900 Filter cake thickness (mm) 0,800 0,700 0,600 0,500 Friction coefficient (-) API Ffluid loss (ml)

6,000

5,000

4,000

3,000 0,400 0,300 0,200 1,000 0,100 0,000 WBF DIF-1 DIF-2 DIF-3 0,000 2,000

Figure 7 API fluid loss, filter cake thickness and friction coefficient of potassium formate based fluids Slika 7. API filtracija, debljina isplanog obloga i koeficijent trenja isplaka na bazi kalij formijata

Rheological properties (plastic viscosity and yield point,) of water based fluid (WBF) and potassium formate based fluids decrease with increasing temperature. Potassium formate based fluid DIF 3, that contains the same amount of additives as WBF fluid shows higher values than it that means potassium formate stabilizes polymers at higher temparatures. Potassium formate based fluid (DIF-1) designed without addition of polyanionic cellulosic polymer (PAC) shows very low values of rheological properties. Increasing of PAC concentration in potassium formate based fluids (DIF-2 and DIF-3) results in higher values of plastic viscosity and yield point at same temperature.

Figure 7 presents API fluid loss, filter cake thickness and friction coefficient data. Potassium formate based fluids show lower values of API fluid loss and friction coefficient than water based fluid. Potassium formate based fluid (DIF-2) with 10 g/l PAC shows lower values of API fluid loss and friction coefficient and thiner filter cake than fluid DIF-3 prepared with higher concentration of PAC. Generally, potassium formate based fluids gave a thin filter cake of <0,5 mm in API fluid loss test.

Rud.-geol.-naft. zb., Vol. 20, 2008. Gaurina-Meimurec, B. Pai, K. Simon, D. Matanovi, M. Malnar: Formate-based fluids Table 4. Fluid properties of tested fluids at temperatures up to 160 C Tablica 4. Svojstva ispitivanih isplaka kod temperatura do 160 C

Conclusions The comparison of the laboratory research results shows that potassium formate based fluid DIF-3 shows better rheological and filtration properties than water based fluid, especially at higher temperatures. This fact allows to conclude that potassium formate stabilizes viscosifiers and fluid loss polymers enabling better rheological properties at higher temperatures. WBF and potassium formate based fluids without PAC (DIF-1) have inadequate rheological properties at temperatures higher than 125 C. Generally, the most acceptable results have achieved with formate based fluid DIF-2 that contain 10 g/L PAC. The better results have not achieved by further increasing of PAC concentration (DIF-3). Acknowledgement This paper is based on work financed by the Croatian Ministry of Science, Education nad Sports under project 195-1951390-1394 Rocks/Drilling Fluids Interaction Studies.

Mud

WBF Temperature C 50 125 150 160 Temperature C 50 125 150 160 Temperature C 50 125 150 160 Temperature C 50 125 150 160 Temperature C 50 125 150 160 Temperature C 50 125 150 160 Temperature Room temperature Temperature Room temperature Temperature Room temperature 0,2342 mm 0,220 Pas 0,05108 0,01789 0,01125 0,00818 Pa 15,843 9,283 4,84 0,35 Pa 7,64 8,93 0,87 0,00 Pa 8,2 10,4 7,25 0 0,323 0,177 0,144 0 Pasn 8,525 10,637 7,704 0 ml 5,900 DIF-1 DIF-2 Plastic Viscosity Pas Pas 0,02006 0,04404 0,01281 0,02142 0,01118 0,01893 0,00976 0,01713 Yield Point Pa Pa 9,849 34,025 4,079 15,729 2,607 12,645 2,674 12,382 Gel Strength (10) Pa Pa 3,57 22,64 0,39 15,87 0,00 13,61 0,00 14,10 Gel Strength (10") Pa Pa 3,71 17,63 0,82 15,37 0,24 14,36 0 14,06 Flow index 0,539 0,306 0,731 0,231 0 0,219 0 0,206 Consistency index Pasn Pasn 1,401 15,952 0,235 12,03 0 11,054 0 11,394 API fluid loss ml ml 3,000 2,600 Filter cake thickness mm mm 0,120 0,200 Friction coefficient 0,2015 0,1466 DIF-3 Pas 0,11959 0,08215 0,05815 0,05815 Pa 67,451 17,473 12,431 10,389 Pa 23,07 6,77 5,30 1,75 Pa 3,94 2,08 5,37 5,12 0,493 0,505 0,496 0,471 Pasn 11,448 3,195 2,561 2,666 ml 3,000 mm 0,400 0,1943

Accepted: 02.11.2008. Received:15.07.2008.

References

Al Otaibi, M.B., Nasr-El-Din, H.A., Hill, A.D., (2008.): Characteristics and Removal of Filter Cake Formed by Formate-Based Drilling Mud; paper SPE 112427, presented at the 2008 SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, Louisiana, USA, 1315 February.

Bungert, D., Maikranz, S.,. Sundermann, R, Downs, J., Benton, W., Dick, M.A. (2000.): The Evolution and Application of Formate Brines in High-Temperature/High-Pressure Operations; SPE 59191, presented at 2000 IADC/SPE Drilling Conference, New Orleans, Louisiana, USA, 23-25 February. Byrne, M., Patey, I., George, L., Downs, J., Turner, J., (2002.): Formate Brines: A Comprehensive Evaluation of Their Formation Damage Control Properties Under Realistic Reservoir Conditions; SPE 73766, presented at the SPE International Symposium and Exhibition on Formation Damage Control held in Lafayette, Louisiana, 20-21 February. Downs, J.D., (1992.): Formate Brines: New Solutions to Deep SlimHole Drilling Fluid Design Problems; paper SPE 24973, presented at the European Petroleum Conference, Cannes, France, 16-18 November. Downs, J.D., (1993): Formate Brines: Novel Drilling and Completion Fluids for Demanding Environments; paper SPE 25177, presented at the SPE International Symposium on Oilfield Chemistry, New Orleans, LA, USA, 2-5 March. Downs, J.D., Killie, S., Whale, G.F., Inglesfield, C., (1994.): Development of Environmentally Benign Formate-Based

Rud.-geol.-naft. zb., Vol. 20, 2008. N. Gaurina-Meimurec, B. Pai, K. Simon, D. Matanovi, M. Malnar: Formate-based fluids Drilling and Completion Fluids; paper SPE 27143, presented at the Second International Conference on Health, Safety & Environment in Oil & Gas Exploration & Production, Jakarta, Indonesia, 25-27 January. Downs J.D., Howard S.K., Carnegie A. (2005.): Improving Hydorcarbon Production Rate Through the Use of Formate Fluids A Rewiev; SPE 97694, presented at International Improved Oil Recovery Conference in Asia Pacific, Kuala Lumpur, Malaysia, 5-6 December. Downs, J.D., Blaszczynski, M., Turner, J., Harris, M., (2006.): Drilling and Completing Difficult HP/HT Wells With the Aid of Cesium Formate Brines A Performance Review; paper IADC/SPE 99068, presented at the IADC/SPE Drilling Conference, Miami, Florida; USA; 21-23 February. Gallino, G., Guarneri, A., Maglione, R., Nunzi, P., Xiao, L. (1997.): New Formulations of Potassium Acetate and Potassium Formate Polymer Muds Greatly Improved Drilling and Waste Disposal Operations in South Italy, paper SPE 37471, presented at the 1997 Production Operations Symposium, Oklahoma City, Oklahoma, 9-11 March. Gaurina-Meimurec, N., Tuschl, M., Simon, K. (1999): Formate Brines Environmentally Acceptable Solution for Off-shore Drilling, Offshore mediterranean Conference OMC99, Ravenna, 24-26 March. Gilbert, Y., Pessala, P., Vaahtera, A., Raivio, T., (2007.): Formate Fluids and Environmental Regulations: A Global View of Benefits and Challenges; paper SPE 110891, presented at the 2007 SPE Annual Technical and Exhibition, Anaheim, California, USA, 11-14 November. Howard S.K. (1995.): Formate Brines for Drilling and Completion: State of the Art; SPE 30498, presented at SPE Annual

Techical Conference & Exhibition, Dallas, USA, 22-25 October. Javora, P. H, Mingjie, Ke, Stevens, R.F., Berry, S.L. (2003.): The Chemistry of Formate Brines at Downhole Conditions; SPE 80211, presented at SPE International Symposium on Oilfield Chemistry, Huston, Texas, USA, 5-7 February. Pedersen, B.K., Pedersen, E. S., Moriss, S., Constable, M. V., Vissapragada, B., Sibbit, A., Stoller, C., Almaguer, J., Evans, M., Shray, F., Grau, J., Fordham, E., Minh, C. C., Scott, H., McKeon, D. (2006.): Understanding the Effects of Cesium/Potassium Formate Fluid on Well Log Response A Case Study of the Kristin and Kvitebjorn Fields, Offshore Norway; SPE 103067, presented at the 2006 SPE Annual Technical Conference and Exhibition, San Antonio, Texas, U.S.A., 24-27 September. Shaughnessy, J.M., Romo, L.A.,. Soza, R.L (2003.): Problems of Ultra-Deep High-Temperature, High-Pressure Drilling; SPE 84555, presented at the SPE Annual Technical Conference and Exhibition, Denver, Colorado, USA, 5-8 October. Svendsen, O., Toften, J.K., Marshall, D.S., Hermansson, C.L., (1995.): Use of a Novel Drill-In/Completion Fluid Based on Potassium Formate Brine on the First Open Hole Completion in the Gullfaks Field; paper SPE/IADC 29409, presented at the 1995 SPE/IADC Drilling Conference, Amsterdam, 28 February 2 March. Zuvo, M., Bjornbom, E., Ellingsen, B., Buffagni, M., Kelley, A., Trannum, H.C., (2005.): High-Resolution Environmental Survey around an Exploration Well Drilled with Formate Brine in the Barents Sea, Norway; paper SPE 94477, presented at the 2005 SPE/EPA/DOE Exploration and Production Environmental Conference, Galveston, Texas, USA, 7-9 M

Вам также может понравиться

- Diaseal M PresentationДокумент22 страницыDiaseal M PresentationstevebeardsleyОценок пока нет

- Well Control Worksheet - Surface BOPДокумент2 страницыWell Control Worksheet - Surface BOPstevebeardsleyОценок пока нет

- TVD NeededДокумент2 страницыTVD NeededstevebeardsleyОценок пока нет

- Mud Engineer User ManualДокумент48 страницMud Engineer User ManualstevebeardsleyОценок пока нет

- Squeeze Cementing JobДокумент1 страницаSqueeze Cementing JobstevebeardsleyОценок пока нет

- Spot Heavy MudДокумент1 страницаSpot Heavy MudstevebeardsleyОценок пока нет

- Nozzle SelectionДокумент1 страницаNozzle SelectionstevebeardsleyОценок пока нет

- Leak-Off Test Analysis: Well: RigДокумент5 страницLeak-Off Test Analysis: Well: RigstevebeardsleyОценок пока нет

- Lubricate and Bleed ProcedureДокумент1 страницаLubricate and Bleed ProcedurestevebeardsleyОценок пока нет

- Maximum Casing Pressure and Pit GainДокумент1 страницаMaximum Casing Pressure and Pit GainstevebeardsleyОценок пока нет

- Bit RecordДокумент1 страницаBit RecordstevebeardsleyОценок пока нет

- Mud Solids AnalysisДокумент1 страницаMud Solids AnalysisstevebeardsleyОценок пока нет

- Hydraulics AnalyzedДокумент1 страницаHydraulics AnalyzedstevebeardsleyОценок пока нет

- Swab and Surge Pressures SHBДокумент1 страницаSwab and Surge Pressures SHBstevebeardsleyОценок пока нет

- Filling The HoleДокумент1 страницаFilling The HolestevebeardsleyОценок пока нет

- Bit HydraulicsДокумент1 страницаBit HydraulicsstevebeardsleyОценок пока нет

- Bop DrawingДокумент9 страницBop DrawingstevebeardsleyОценок пока нет

- Total Slurry Vol.: Bbls. Total Cubic FT.: Cu/Ft Sacks: Cased AnnulusДокумент3 страницыTotal Slurry Vol.: Bbls. Total Cubic FT.: Cu/Ft Sacks: Cased AnnulusstevebeardsleyОценок пока нет

- 09 Bit Balling Summary GuidelinesДокумент1 страница09 Bit Balling Summary GuidelinesCerón Niño SantiagoОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Gases Ideal Gases Kinetic Theory Model: Ap06/P1/Thermal/Pte - GasesДокумент24 страницыGases Ideal Gases Kinetic Theory Model: Ap06/P1/Thermal/Pte - GasesABDULMAJEED YAHYA MOQBEL SALEH AL-SABAHIОценок пока нет

- PermeabilityДокумент6 страницPermeabilitytwinklecawas099Оценок пока нет

- Mechanics of Deformable Bodies Solved ProblemsДокумент10 страницMechanics of Deformable Bodies Solved ProblemsYan NieОценок пока нет

- Modeling &analysis of Aluminum Alloy Crankshaft For Optimization of Weight Using FeaДокумент7 страницModeling &analysis of Aluminum Alloy Crankshaft For Optimization of Weight Using FeadarkruseОценок пока нет

- Chap 13 BucklingДокумент36 страницChap 13 BucklingMujtabaRafiqueОценок пока нет

- Steel Frame Design Manual: Italian NTC 2008Документ99 страницSteel Frame Design Manual: Italian NTC 2008Angel VargasОценок пока нет

- 02 Phase DiagramsДокумент24 страницы02 Phase DiagramsPalash SwarnakarОценок пока нет

- Endplmc9 AsdДокумент25 страницEndplmc9 AsdmangeshОценок пока нет

- Reciprocating Pump Power Required Density G Q (Suction Head + Discharge Head)Документ2 страницыReciprocating Pump Power Required Density G Q (Suction Head + Discharge Head)AmalОценок пока нет

- 13 14 15 Specific Heat Capacity and Latent Heat GGДокумент36 страниц13 14 15 Specific Heat Capacity and Latent Heat GGNauman QureshyОценок пока нет

- 3.0 Hvac Heating, Ventilating, Air Conditioning: 3.1 Key WordsДокумент20 страниц3.0 Hvac Heating, Ventilating, Air Conditioning: 3.1 Key WordsJuan Daniel RamosОценок пока нет

- COACHING NOTES MATH 2.pptx Version 1Документ221 страницаCOACHING NOTES MATH 2.pptx Version 1AjayBravoОценок пока нет

- M8 - Vapor Absorption RefrДокумент29 страницM8 - Vapor Absorption RefrAbraham KhaleedОценок пока нет

- Compiled FluMach Problems - GROUP6 - BSME31Документ58 страницCompiled FluMach Problems - GROUP6 - BSME31Jhun Briones100% (1)

- Fluid Mechanics ReviewДокумент17 страницFluid Mechanics ReviewquanОценок пока нет

- MIT2 080JF13 Recitation2Документ9 страницMIT2 080JF13 Recitation2Sudipta NathОценок пока нет

- Hydrotest and Pneumatic Test of Piping Systems-Hydrotest Vs Pneumatic Test With PDFДокумент16 страницHydrotest and Pneumatic Test of Piping Systems-Hydrotest Vs Pneumatic Test With PDFGunawanОценок пока нет

- EFMДокумент2 страницыEFMMurugan ShanmugamОценок пока нет

- PVT Analysis. Binary System.Документ4 страницыPVT Analysis. Binary System.Mukhtarov PgОценок пока нет

- ENCI 317 - Lab 2 Material - Fall 2022Документ17 страницENCI 317 - Lab 2 Material - Fall 2022Sherry YousafОценок пока нет

- LVR200 SwishДокумент2 страницыLVR200 SwishAlfredo GarciaОценок пока нет

- Unit III Heat Exchange EquipmentДокумент17 страницUnit III Heat Exchange EquipmentaberraneОценок пока нет

- Lecture Plate Girder Intro DSS 2Документ37 страницLecture Plate Girder Intro DSS 2Amarendra KojjaОценок пока нет

- Compressibility of SoilДокумент22 страницыCompressibility of SoilJohn Dave pogiОценок пока нет

- Design of A SILOДокумент21 страницаDesign of A SILOAkhilprasad Sadige100% (1)

- Tank Anchor Bolt DesignДокумент9 страницTank Anchor Bolt Designgon972001100% (1)

- Calculation of Retaining RingsДокумент7 страницCalculation of Retaining RingsDobrica PetrovicОценок пока нет

- Design and Experimental Results For The S825 AirfoilДокумент89 страницDesign and Experimental Results For The S825 AirfoilTakaya SakuraiОценок пока нет

- Progress in Aerospace Sciences: Brian R. Hollis, Salvatore BorrelliДокумент15 страницProgress in Aerospace Sciences: Brian R. Hollis, Salvatore BorrelliZeeshan KhanОценок пока нет

- Optimization of Thermal Design of Heat Sinks A ReviewДокумент25 страницOptimization of Thermal Design of Heat Sinks A ReviewTiến MinhОценок пока нет