Академический Документы

Профессиональный Документы

Культура Документы

Final Report

Загружено:

gogubila2501Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Final Report

Загружено:

gogubila2501Авторское право:

Доступные форматы

FINAL RAPORT Research, development and technologies for liquid hydrogen sulphide fuel cells to generate clean energy

CCH2SEE

320 / 04. 10. 2006 CEEX Contractor principal: University Politehnica Bucharest Project manager: Partner Institutes: UPB

Eng. PhD. Adrian Teodorescu Ciocanea Partener 1 CO - University Politehnica Bucharest UPB, Partner 2 UB,

Mathematics Institute of Romanian Academy Partner 4 - INCDTCI - ICSI Rm. Valcea

IMAR, Partner 3 - University Bucharest

The main objective of the project consisted in research and developing technologies for a new fuel cell able to work with hydrogen sulphide. The target was to electrochemical oxidise the H2S from the Black Sea deep waters in-situ, in its liquid form, dissolved in salted water, at low concentrations and temperatures, 10C or less and high pressures, more than 2 MPa. The process is clean and neither specific forerunner operations (extraction, transportation, storage, fuel cleaning, fuel forming) nor risk of toxic effluents are involved. Project current stage: All the aimed specific objectives were reached. Thus: A scientific and technologic procedure for experiments was developed for various fuel cells to be tested, aiming the electrochemical oxidising of H2S from the Black Sea deep waters in-situ. A laboratory stand was realised for testing various pairs of electrodes and catalysts at variable H2S concentrations and ambient pressures. An autonomous submersible installation was designed and manufactured for in-situ testing of H2S fuel cell stacks. The fuel stack was made in conformity with the patent that originated the project. The installation was developed in accordance with the specifications for the above procedure implementation. It is able to perform at 200 meters depth and has few days autonomy. Porous and smooth electrodes loaded with specific catalysts for electrochemical oxidising of H2S (consisting in mixed MexSy, Me = Mo, Ni, W) were developed and tested. These studies initiated two new solutions in the thematic area. One refers to a method to obtain porous materials having pores controlled geometry. It makes the subject of the patent application submitted at OSIM, no A/00112/11.02.2008, title: Method to obtain porous electrodes , authors: O. Pacala, I. Stamatin, A. Teodorescu Ciocanea, M. Pacala. The other one refers to a method to load catalysts on smooth anodes (underway of checking before to be submitted at OSIM). All partners were equally been offered this opportunity. A H2S fuel cell stack was designed. It consists in sequential repeated modules, following the patented solution. (Pacala, O., Pacala, M., Ciocanea, A., Method and fuel cell to generate power RO 120736 B1/ 06. 2006).

The fuel cell stack was manufactured and tested. Various fuel cells behaviour were studied, all cells been dedicated to those cases when the fuel (H2S) is already mixed with the electrolyte. Cells having only one active electrode in PAFC configuration and PEM standard configuration have been tested. A methanol versus H2S dissolved in the electrolyte fuel cell comparative study was performed, in PEM standard configuration. Prototypes inherent technological problems were spotlighted. Since the problem supposes the miscible displacement of the electrolyte by the hydrogen sulphide, a first paperwork describing multiphase flows in porous medium was elaborated. By following the direction opened by the papers of Chavent, we gave a new formulation of the equations for the two-phase flows in the case of miscible fluids. In the non-miscible case, we showed that, for incompressible fluids, by introducing the classical hypotheses of relative permeability and capillary pressure, one could bring the equations in the same form as the equations for miscible fluids. Through an adequate management a technological network has been developed. The consortium partners are the main nodes of this network aiming clean power systems developing, improvement and innovation, as they were conceived during the common project activities. In this way, the competencies were identified: Theoretical research and mathematical simulation, Applied research at the physical and chemical phenomenon level, Porous electrodes manufacture, Manufacture of fuel cell stack constituent modules and testing on the reactor vessel, Ex-post analyses of the technological solutions.

Each phase notable results were disseminated through communications and articles within the framework of internal seminars, conferences and branch publications. A dedicated web page is under construction. Project contribution to the research infrastructure developing: A. Since special requests concerning both health legal providing and technical conditions had to be considered, the research infrastructure development has been directed as follows: 1. ICSI Rm. Valcea - FC Laboratories for tests and verifying, including simulation of work conditions (flows, temperatures, pressures); 2. UB 3 Nano Sae from Faculty of Physics Laboratories for electrodes preparing,

catalysts loading, preliminary tests and FC ex-post studies; 3. UPB Regenerative Power Supplies Laboratories from Faculty of Energetic for design

and verifying the new tests stand for in-situ experiments. The first two laboratories performed comparative experiments upon both standard configurations FC and patented one new. B. A stand for laboratory experiments was developed at ICSI Rm. Valcea. It was endowed with specific equipment able to ensure: the pressures control on both sides of membrane, electrolyte, fuel and air flows control data acquisition.

C. RAMAN Spectrophotometer, FEI Quanta 400 electronic microscop with scanner, Set Logger Temperature, carbon paper, Nafion Membrane, Si plates, TEFLON solution, W, Mo, Ni, etc. were purchased for obtaining and verifying the experimental electrocatalysts. D. The first stack with four modules each having a double fuel cell around one smooth anode and a mixture of Me1xSy as anodic catalyst was designed and realized, accordingly with the patented embodiment. E. In the view of proceeding to the in-situ experiments, an autonomous submersible installation was designed and manufactured for testing of H2S fuel cell stacks. It is able of data acquisition in various working regimes, data storage on several thousands measuring cycles and marine water samples deduction for further chemical analysis and accompanying data acquisition. It is endowed with a complete automation using OMRON Data Acquisition System with facilities for programming the acquisition cycles and a flexible hosting zone for various stacks that are to be tested. Opportunities for consortia building-up in the view of FP7 joining 1. CD&T activities conducted in the project framework proved the viability of a new class of fuel cells working with hydrogen sulphide as an alternative clean power source.

2. The conducted research pointed that waste consuming through electrochemical oxidising is a valid way to eliminate waste simultaneously with power generating. Thus, cleaning costs may be lowered. 3. New study theme in the FC area has been opened having a positive impact on environment. Low concentrated fuels in various liquids may be electrochemically oxidised, leading to different target media cleaning, such as sour gases and sulphide waters. 4. New methods are the object of patent applications in a European research thematic area nano sciences, nano technologies, new materials and new production processes . 5. Through oriented research, the project opens a way towards immediate technologic applications co generative power supplies for buildings or residential districts, hybrid

applications such as solar/ wind and fuel cells, etc. 6. Theoretical and experimental researchers from Romania had the opportunity of specialising in the view of becoming partners to the future European Community Enterprise for Hydrogen and Fuel Cells, whose regulation is to be approved in the European Parliament. 7. The existing consortium wishes to begin a collaboration with The Black Sea Institute from Turkey, aiming the extension of research and experimental achievements. Conclusions The reached solution might be enlarged, generating a new vision upon different types of waste electrochemical oxidation, in a zone of compromise between power efficiency and cleaning efficiency of the target medium. Finally, the procedure is an alternative to the waste burning in the air, for a large class of those that fit the described procedure, and leads to waste processing costs deductions from the generated power.

Me Mo, Ni, W, etc.

This document was created with Win2PDF available at http://www.win2pdf.com. The unregistered version of Win2PDF is for evaluation or non-commercial use only. This page will not be added after purchasing Win2PDF.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- EHS Guidelines Offshore Oil and Gas June2015Документ42 страницыEHS Guidelines Offshore Oil and Gas June2015IFC Sustainability100% (3)

- Introduction To Storage TanksДокумент49 страницIntroduction To Storage TanksMachineryeng100% (2)

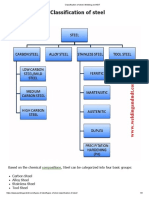

- Classification of Steel - Welding and NDTДокумент3 страницыClassification of Steel - Welding and NDTAshif Iqubal100% (1)

- Organic Chemistry Carbonyl CompoundsДокумент34 страницыOrganic Chemistry Carbonyl CompoundsLovely Joysweet100% (2)

- Ripening of CheeseДокумент18 страницRipening of CheeseHASVRDОценок пока нет

- Gas Sweetening TotalДокумент62 страницыGas Sweetening TotalMehdi AlizadОценок пока нет

- All About Fatty AlcoholДокумент43 страницыAll About Fatty Alcoholrpyjcth100% (1)

- Electrochimica Acta: N.M. Farandos, L. Kleiminger, T. Li, A. Hankin, G.H. KelsallДокумент8 страницElectrochimica Acta: N.M. Farandos, L. Kleiminger, T. Li, A. Hankin, G.H. Kelsallgogubila2501Оценок пока нет

- BD 9778 FДокумент17 страницBD 9778 Fgogubila2501Оценок пока нет

- The 90 Day Social Web Brand Management Plan Managing Content Marketing EditionДокумент22 страницыThe 90 Day Social Web Brand Management Plan Managing Content Marketing Editiongogubila2501Оценок пока нет

- Adam 6017Документ1 страницаAdam 6017gogubila2501Оценок пока нет

- Adam 6017Документ1 страницаAdam 6017gogubila2501Оценок пока нет

- Country Profile Romania Federal Research DivisionДокумент25 страницCountry Profile Romania Federal Research DivisionAida Maria PascoviciОценок пока нет

- Country Profile Romania Federal Research DivisionДокумент25 страницCountry Profile Romania Federal Research DivisionAida Maria PascoviciОценок пока нет

- PFT Practice Excercise 11Документ4 страницыPFT Practice Excercise 11Biniyam haileОценок пока нет

- Analisis de Gas de Aceite de Transformador Utilizando Una Columna de Separacion Astm d3612 KasalabДокумент2 страницыAnalisis de Gas de Aceite de Transformador Utilizando Una Columna de Separacion Astm d3612 KasalabJohnatan HernándezОценок пока нет

- Methods For Diffusion Welding The Superalloy Udimet 700Документ9 страницMethods For Diffusion Welding The Superalloy Udimet 700Enary SalernoОценок пока нет

- E.Sci9 - Q2 - Week 2Документ10 страницE.Sci9 - Q2 - Week 2HersheyОценок пока нет

- What Are Some of The Best Interview Questions Asked For A Mechanical Engineering Student - Quora PDFДокумент17 страницWhat Are Some of The Best Interview Questions Asked For A Mechanical Engineering Student - Quora PDFPavansatya AdabalaОценок пока нет

- Integración IV: Introducción A DWSIM 2018Документ55 страницIntegración IV: Introducción A DWSIM 2018willycoyote1990-1Оценок пока нет

- Afa Reviewer AДокумент28 страницAfa Reviewer AJane CastroОценок пока нет

- Journal of Controlled Release: Alexander Wei, Jonathan G. Mehtala, Anil K. PatriДокумент11 страницJournal of Controlled Release: Alexander Wei, Jonathan G. Mehtala, Anil K. Patriprakush_prakushОценок пока нет

- Editorial Board of IJAR (International Journal of Advanced Research, ISSN: 2320-5407)Документ9 страницEditorial Board of IJAR (International Journal of Advanced Research, ISSN: 2320-5407)Jiban ShresthaОценок пока нет

- Effect of PC Electrodeposition On The Structure and Tribological BehaviorДокумент10 страницEffect of PC Electrodeposition On The Structure and Tribological BehaviorMohammad Nasfikur Rahman KhanОценок пока нет

- Canadian Coast Guard Welding SpecificationДокумент39 страницCanadian Coast Guard Welding Specificationalvin dueyОценок пока нет

- ApcolДокумент25 страницApcolJAGADISH PADHYОценок пока нет

- Pta Petrochemical ProcessДокумент27 страницPta Petrochemical ProcessMugiiz BhattiОценок пока нет

- CNS: GEAS 2 Review Questions and SolutionsДокумент5 страницCNS: GEAS 2 Review Questions and SolutionsEdward Roy “Ying” AyingОценок пока нет

- Wolkite University Museum Technique Group AssignmentДокумент23 страницыWolkite University Museum Technique Group AssignmentNatnael SisayОценок пока нет

- Lattice VibrationДокумент21 страницаLattice VibrationPandu lalОценок пока нет

- Pesticides: - Are Compounds Used To Control Pest (The Latin Word Cida Means To Cut or Kill) - It Could BeДокумент13 страницPesticides: - Are Compounds Used To Control Pest (The Latin Word Cida Means To Cut or Kill) - It Could BeEzra EzraОценок пока нет

- Kinetics of The Selective Hydrogenation of Phenol To Cyclohexanone Over A Pd-Alumina CatalystДокумент8 страницKinetics of The Selective Hydrogenation of Phenol To Cyclohexanone Over A Pd-Alumina CatalystTaylor PennaОценок пока нет

- Philippine Coconut Authority: Coconut Methyl Ester (Cme) As Petrodiesel Quality EnhancerДокумент37 страницPhilippine Coconut Authority: Coconut Methyl Ester (Cme) As Petrodiesel Quality EnhancerAnthony MoraОценок пока нет

- 9 Nomenclature of Inorganic CompoundsДокумент42 страницы9 Nomenclature of Inorganic CompoundsGlen MangaliОценок пока нет

- IR Inspection Program For Fired Heater Mechanical Integrity: New Product!Документ1 страницаIR Inspection Program For Fired Heater Mechanical Integrity: New Product!bazil17Оценок пока нет

- Fluid Mechanics Lab: Flow Rate Measurement FundamentalsДокумент18 страницFluid Mechanics Lab: Flow Rate Measurement FundamentalsBillu RocxОценок пока нет

- Orchid Business Group Djibouti Sarl Site Purchase Request Quantity Request in PCS Store Reference Quantity PurchaseДокумент2 страницыOrchid Business Group Djibouti Sarl Site Purchase Request Quantity Request in PCS Store Reference Quantity PurchaseSadik BhaiОценок пока нет