Академический Документы

Профессиональный Документы

Культура Документы

Industrial Experimental Plant - 1ICSCM

Загружено:

Fundación CtapИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Industrial Experimental Plant - 1ICSCM

Загружено:

Fundación CtapАвторское право:

Доступные форматы

INDUSTRIAL EXPERIMENTAL PLANT

Technologies for R&D in the stone industry

Sandra Lpez Molina Industrial Management Engineer Alfonso Corts Izurdiaga Process Engineer

Summary

General Summary

1. 2. CTAP Introduction Industrial Experimental Plant i. ii. iii. 3. What is the Industrial Experimental Plant? Industrial Experimental Plant values Industrial Experimental Plant Technologies

Successful Projects

Introduction

CTAP Introduction

01

The Technological centre for stone is a private foundation created in 2002 with thanks to entrepreneurial drive and the collaboration of The Economic, Innovation and Science Council. Occupying a position within the Andalusian system of knowledge and as a National Technological Centre approved by The Ministry of Science and Innovation, developing our activities at a national and international level.

Mission:

Our mission is to improve the competitiveness of businesses in the sector, through the generation and transfer of knowledge and the implementation of new business models.

ctap

CTAP Introduction

01

Areas of work

The activity in Ctap is organised into three interrelated working areas. The working areas are composed of highly specialised professionals in different disciplines, investigational departments and strategy experts. Each working area has its own differentiated lines of work and in turn carries out successful projects, which are transferred and implemented within businesses.

-The R&D Working Area The -Eco-sustainability EcoEco -Businesses and competitiveness Businesses

Technological Centres, Institutes and Universities

CTAP Introduction

01

TECHNOLOGICAL CENTRES Spanish TC CTMNC, CTMNC, France CTP, CTP, Belgium ESBULCO, Bulgary CETEMCO, CETEMCO, Morocco CETEMAG, CETEMAG, Brazil MQTC, MQTC, Egypt CVALOR, CVALOR, Portugal UNIVERSITIES: School of Mechanical Ingenieers of Metz (France) University of Gante (The Netherlands) Spanish and Andalucian Universities

Enterprises

CTAP Introduction

01

CTAP Introduction

01

Ctap grows with the industry

624 Clients 70 private projects since 2007 21 internal R&D projects since 2007 9.849.280,15 of investment in equipment and technological infrastructure since 2002. 4 known patents 5 patents on course R&D Laboratory for resins and polymers

CTAP is a member of Fedit (The Spanish Federation of Technology Centres).

ctap

Industrial Experimental Plant

Industrial Experimental Plant

02

1. What is the Industrial Experimental Plant? 2. Objectives and values of the Industrial Experimental Plant 3. Industrial Experimental Plant Technologies for R&D

What is the industrial experimental plant?

Industrial Experimental Plant

1. WHAT IS THE INDUSTRIAL EXPERIMENTAL PLANT?

02

The Industrial Experimental Plant is the best place where Knowledge Agents, Enterprises and Technology Developers can join and work togehter for the development of new products, new processes and new technologies for the natural and artificial stone sector.

The Industrial Experimental Plant is not a production factory!

Objetives and values of the Industrial Experimental Plant

Industrial Experimental Plant

2. OBJECTIVES AND VALUES OF THE INDUSTRIAL EXPERIMENTAL PLANT

02

FIGURES: Installed in 100% business environment Accounting for 10.000 m2 of buildings More than 22.960 m2 of land Investment of 7.5 M in High Technology

3 DISTINCT AREAS Traditional stone processes Quality and Production control processes Confidential R&D processes

Objetives and values of the Industrial Experimental Plant

Industrial Experimental Plant

02

TARGET 1: To deeply develop knowledge of the stone transformation process. Deepen knowledge in stone processing TARGET 2: To become a training centre of excellence for human resources in the sector. The human factor: from Operator to Stone Specialist TARGET 3: To create a common space where enterprises have the possibility to improve their productive processes and generate new uses. Up to date technologies for Stone Innovation

Objetives and values of the Industrial Experimental Plant

Industrial Experimental Plant

TARGET 4: To be the major shuttle of industrial development projects

02

Technology transfer to companies as the final purpose TARGET 5: To establish a culture of cooperation between public and private agents and businesses. Together we can go further TARGET 6: To attract investment for knowledge generation. Future: the Industrial Experimental Plant as the hub of stone R&D

Industrial Experimental Plant Technologies

Industrial Experimental Plant

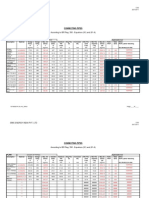

3. INDUSTRIAL EXPERIMENTAL PLANT TECHNOLOGY SUMMARY

02

Surface Technology

Chemical

Treatment

Surface Mechanical Treatment and Texturing Technology Stone Block Sawing Technology Industrial Mixing Laboratory for Composites

Industrial Experimental Plant Technologies Machinery VS Technology concepts

Maximum open operating parameters Whichever type of fungible and tools can be used Tools change will be very simple both to minimize time and procedures The machinery must be compatible with any stone material or material derived from stone (at least covering the largest possible range) Evolving Technologies Machinery suppliers must Technologies: be open to further cooperation in order to carry out modification / improvements to the existing technologies

Industrial Experimental Plant

02

OPEN INNOVATION PROCEDURE

Industrial Experimental Plant Technologies

Industrial Experimental Plant

1. Surface Chemical Treatment Technology Limitations of current technologies

02

Actual chemical treatment lines are composed mainly by one or, at most, two curing systems Industrial systems. application processes are defined based on laboratory tests and resin suppliers recommendations. Limitations in Vertical Thermal Ovens:

Just two independent sections no matter the number of floors available: drying section and curing section. sections, No air control (humidity and flow). Limitation of maximum operating temperature at 60C 60C C.

Theres no scientific evidence to demonstrate the advantage provided by a vacuum unit unit. Dosage, mixture and application automated systems are not versatile (for fillers and resin change). UV and IR ovens do not permit a wide range of parameterization. Process parameter definition and modification is hard with actual interfaces interfaces.

Industrial Experimental Plant Technologies

Industrial Experimental Plant

02

Surface Chemical Treatment Technology

Selected supplier for technology:

Main characteristics:

Three kinds of oven available: thermal, UV and IR Thermal oven with 8 independent sections (5 floor each). Temperature and air regulation (flow, humidity and inversion period of circulation). Automated and versatile system for resin dosing, mixing and application (work in progress). Easy user interface for process cycles definition.

Industrial Experimental Plant Technologies

PARAMETERS MAP: MAP

Industrial Experimental Plant

02

Industrial Experimental Plant Technologies

Industrial Experimental Plant

2. Surface Mechanical Treatment and Texturing Technology

02

Limitations of current technologies

Machines available are not versatile to work with both marble and granite (heads and polishing systems are completely different). Individual pressure control available per head but always above the head weight (the minimum pressure is the one caused by the head weight). Rotation speed of heads fixed. Refrigerating water flow completely uncontrolled and unmeasured. No slab thickness calibration system available for natural stone slabs.

Industrial Experimental Plant Technologies

Industrial Experimental Plant

Surface Mechanical Treatment and Texturing Technology

02

Selected supplier for technology:

Main characteristics:

Two kinds of head available marble and granite type. available: Fast tool change for heads and abrasives. Control of main process parameters, including: Absolute pressure of the head on the stone slab Water flow per head (work in progress) Rotation speed per head (in both calibrating and polishing heads) Easy user interface for process cycles definition

Industrial Experimental Plant Technologies

PARAMETERS MAP: MAP

Industrial Experimental Plant

02

Industrial Experimental Plant Technologies

Industrial Experimental Plant

02

3. Stone Block Sawing Technology

Limitations of current technologies

Sawing loom changing and distance regulation is very time consuming. The loom beats are unable to be controlled and also the frequency of the main motor motor. Block sawing process demands high energy consumption consumption. Refrigerating water flow is completely uncontrolled and unmeasured.

Industrial Experimental Plant Technologies

Industrial Experimental Plant

Selected supplier for technology: Main characteristics:

Download speed of loom frame variable between 0 100 cm/h. frames. Two detachable loom frames Fast loom frame change (under two hours). Frequency variator for main engine with two principal advantages: Number of frame beats adjustable Recovery of connecting rod

02

power, dropping power usable in the connection rod rising (50% power saving). Refrigerating water flow control (work in progress)

Industrial Experimental Plant Technologies

Industrial Experimental Plant

4. Industrial Mixing Laboratory for composites formulation Selected supplier for technology: Main characteristics:

Rotating and inclined mixing pan This promotes material pan. transportation towards the center of the pan and the mixing tool. Excellent for powder and solid mixing It also allows liquid addition mixing. during the mixing process. Easy user interface for process cycle definition, including the following parameters (work in progress): Rotating mixing tool speed Power consumption Automatic filler addition Compressing unit and molds for composite conforming (Work in progress).

02

SUCCESFUL PROJECTS

Surface Chemical Treatment Technology

Successful projects

03

P-201100470: 201100470: APPLICATION PROCESS FOR A BRAND OR LOGO OVER NATURAL OR ARTIFICIAL STONE SURFACES

Definition of the diamond tool and the machining process Exclusive resin formulation for high transparence and gloss Water proof Polishing process definition for a two phase material (resin + stone)

Surface Mechanical Treatment and Texturing Technology

Successful projects

03

Gutirrez Mena

Different surface finishes to define a family of products derived from a single and exclusive material Surface process treatment definition: types of abrasives, sequences of abrasives and machine parameters Process optimization to minimize operating costs Brand definition positioning and market

Surface Chemical Treatment Technology

Successful projects

03

Idispaces

R&D + Design applied for spa and wellbeing equipments made of stone. Development of completely new technologies for stone heating, water flow system along stone components and lighting stone components. Chemical protections for water and oil environments. Industrial protection pending for every product and two patents for the general technology.

Industrial Mixing Laboratory for Composites

Successful projects

Industrial Wastes Reuse

03

P-201100356 y P-201100355

Characterization and analysis of industrial wastes from the Andalusian Stone industry. Definition of a preparation method for these wastes towards their reuse in the formulation of new materials. Development of a new formulation of bituminous materials including these wastes (2 patents generated).

New technologies in the stone industry

Successful projects

Indlica del Diamante

03

Design and construction of pilot plant for the production of electroplated diamond tools. Process parameterization and definition for each geometry and size. Development of all tools needed for the processes (control systems for chemical baths, piece holders and chemical contacts, quality control systems based on computer vision). Specific tool design for any need.

New technologies in the stone industry

Successful projects

03

Tarsia

P-200502077: 200502077: Stone manufacturing system. system.

mosaics

automatic

Automated manufacturing system based on multiple piling up and stacking stages. Exclusive formulation for a high mechanical resistance and waterproff adhesive. Use of stone industry by products Robotization of stone processes (loading and piling up of slabs and resine application).

New technologies in the stone industry

Successful projects

P-201001319 Recognition System for natural and tiles. artificial stone tiles. U201001042 Dimensional Control Machine

New processes for quality control for stone products: computer vision and automatic measurement. Exclusive computer operators to determine main characteristics of stone tiles. Identification VS classification to give the stone a unique visual identity. Fully compatible with current production technologies.

Computer Vision and dimensional control

03

New technologies in the stone industry

Successful projects

New possibilities for stone classification and stone compositions

Computer Vision and dimensional control

03

Stone composition based on Computer Vision every tile is worth it!

New technologies in the stone industry

Successful projects

A new concept for stone and arquitecture

Computer Vision and dimensional control

03

THANKS FOR YOUR ATTENTION! See you at the Industrial Experimental Plant! acizurdiaga@ctap.es sandralopez@ctap.es

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- FPS Errata 07-15Документ39 страницFPS Errata 07-15William Lopez AyalaОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Test Bank For General Organic and Biochemistry 10th Edition Katherine Denniston Joseph Topping Danae Quirk DorrДокумент24 страницыTest Bank For General Organic and Biochemistry 10th Edition Katherine Denniston Joseph Topping Danae Quirk DorrRichardDiazsedi100% (44)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Steel Making PresentationДокумент80 страницSteel Making PresentationAlvin Garcia PalancaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Suspension ExamplesДокумент6 страницSuspension ExamplesDivaan Raj KarunakaranОценок пока нет

- Ball Bearing Cages, Retainers, and Ball SeparatorsДокумент5 страницBall Bearing Cages, Retainers, and Ball SeparatorsGamini SureshОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- AllenДокумент40 страницAllenDhanpat RaiОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Sika Injection 20Документ3 страницыSika Injection 20the pilotОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- GenChem Activity 3Документ3 страницыGenChem Activity 3Xheena SarabiaОценок пока нет

- Iron Ore Reduction With CO and H Gas Mixtures - Thermodynamic and Kinetic ModellingДокумент13 страницIron Ore Reduction With CO and H Gas Mixtures - Thermodynamic and Kinetic ModellingAmit Kumar DasОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Volume 1Документ378 страницVolume 1Avinash RajuОценок пока нет

- Matter (Science Form 1 - Short Notes)Документ1 страницаMatter (Science Form 1 - Short Notes)jrpyroОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Problem Set 3-Chapter 6 - Failure Theories-Selected ProblemsДокумент22 страницыProblem Set 3-Chapter 6 - Failure Theories-Selected ProblemsIsmail DoğanОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Experiment 2: Quantitative Color ReactionsДокумент5 страницExperiment 2: Quantitative Color ReactionsIson DyОценок пока нет

- BAKER Drilling - Products Fluid End Expandable Parts PDFДокумент56 страницBAKER Drilling - Products Fluid End Expandable Parts PDFAnonymous GjCOVlgОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- BioRes 11 2 5452 Review EspinozaAcosta TRLM Antioxidant Antimicrobial Tech Lignins Appln 8447 PDFДокумент30 страницBioRes 11 2 5452 Review EspinozaAcosta TRLM Antioxidant Antimicrobial Tech Lignins Appln 8447 PDFStelyca MihalutiОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- G. James Glass Handbook Part AДокумент34 страницыG. James Glass Handbook Part AOvidio CalvoОценок пока нет

- Investigating Anglo-Saxon Population Movement Using Strontium Stable Isotope AnalysisДокумент58 страницInvestigating Anglo-Saxon Population Movement Using Strontium Stable Isotope AnalysisAnnemieke DoornbosОценок пока нет

- Hair Straightening CompositionДокумент13 страницHair Straightening Compositionzorro21072107Оценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Direct Shear Box TestДокумент9 страницDirect Shear Box TestMuhammad Yusoff Zakaria100% (1)

- TM422Документ34 страницыTM422karamisin4274100% (1)

- Connecting Piping IBRДокумент5 страницConnecting Piping IBRgopaltryОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Antibiotic Selection Guide PosterДокумент1 страницаAntibiotic Selection Guide PosterjbenedicОценок пока нет

- BiodataДокумент13 страницBiodatasoumyamukherjeeОценок пока нет

- Engine Performance and Exhaust Gas Emissions of Methanol and Ethanol-Diesel Blends - Cenk SayinДокумент6 страницEngine Performance and Exhaust Gas Emissions of Methanol and Ethanol-Diesel Blends - Cenk SayinTan Khai HeanОценок пока нет

- Dover NJ - Ulster Iron WorksДокумент10 страницDover NJ - Ulster Iron WorksDarrin Chambers100% (1)

- Lead Removal Mechanism Using MgO NpsДокумент11 страницLead Removal Mechanism Using MgO NpsKarthikeyan SОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Sop PH Meter.Документ4 страницыSop PH Meter.Brian HawkinsОценок пока нет

- Design of A Gauge MetrologyДокумент8 страницDesign of A Gauge MetrologyQuality HosurОценок пока нет

- Hydraulic Oil Hy-Gard Transmission John DeereДокумент7 страницHydraulic Oil Hy-Gard Transmission John DeereLuis Sanchez LlicoОценок пока нет

- Review Proses CumeneДокумент15 страницReview Proses Cumenerachma tiaОценок пока нет