Академический Документы

Профессиональный Документы

Культура Документы

Job Procedure Index: 01 Piling Work

Загружено:

raghavaklИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Job Procedure Index: 01 Piling Work

Загружено:

raghavaklАвторское право:

Доступные форматы

Lift Irrigation Project

Construction Methodology

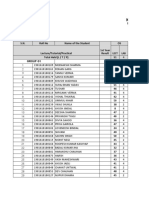

JOB PROCEDURE INDEX Sl. No. 01 Description piling Work

02

Excavation Work

03

WBM Site Grading Work Survey Work Back Filling Work Sand Filling Work Plain Cement Concrete Reinforced Cement Concrete Brick Work

04 5 6 7 8 9 10

JOB PROCEDURE FOR PILING WORK

[Type text]

Page 1

Lift Irrigation Project

Construction Methodology

1.0

PURPOSE The purpose of this Procedure is to ensure that a standard construction and workmanship can be achieved up to the satisfaction of client/consultant.

2.0

SCOPE This procedure is applicable to the execution of piling work. It intends to correlate and control all the tasks needed to be done in order to get a satisfactory product. In brief, it controls the following activities:

2.1.

PILING 2.1.1 Setting up of piling location. 2.1.2 Preparation of bentonite slurry. 2.1.3 Fabrication of reinforcement cage. 2.1.4 Installation of temporary casing. 2.1.5 Boring. 2.1.6 Lowering of reinforcement cage. 2.1.7 Cleaning of bore. 2.1.8 Concreting. 2.1.9 Withdrawal of temporary casing.

3.0 1. 2. 3. 4. 5. 6. 7. 8. 9.

REFERENCES/IS codes Contract Specifications./Technical requirement Approved for Construction Drawings. IS: 2911 (Part 1/Section 2) Code of practice for design and construction of pile foundations. IS: 2911 (Part 4) - Code of practice for design and construction of pile foundations - Load test on pile. IS: 2502 Code of practice for bending and fixing of bars for concrete reinforcement. IS: 456 - Code of practice for plain and reinforced concrete. IS: 10262 Recommended guidelines for concrete mix design. IS: 2386 (Part I to VIII) Methods of tests for aggregates for concrete. IS: 383 Specification for Coarse and fine aggregates from natural sources for concrete.

Page 2

[Type text]

Lift Irrigation Project

Construction Methodology

10. IS: 516 - Methods of tests for strength of concrete.

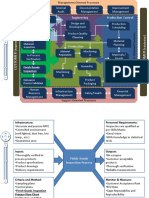

4.0 METHODOLOGY 4.1 PILING

General The purpose of this method is to describe the construction of bored pile with temporary collar casing followed by stabilization of the borehole by bentonite suspension. The working sequence is as follows: 4.1.1 Setting up of piling location The work shall be carried out in accordance with the drawings approved by the client/ consultant for construction. The surveyor shall check all reference points before starting the survey work. The survey work shall be carried out from whole-to-the-part method as far as possible. Only calibrated and approved instruments shall be used. The pile locations shall be set out accurately using suitable surveying techniques and clearly marked using steel pins. All points shall be firmly fixed and guarded against any disturbance Reference points shall be established for each pile point, preferably equidistant from the pile point, to facilitate identification of the pile points at the time of execution as well as to check the installation of the casing. Care shall be taken to identify all utilities that may obstruct execution of work. 4.1.2 Preparation of bentonite slurry Position of the tank shall be finalized keeping in view the capacity of the installed pump and the distance between the tank and the piling location. Capacity of the tank shall be such that it can store sufficient quantity of slurry for the number of piles that can be done in a day.

[Type text]

Page 3

Lift Irrigation Project

Construction Methodology

Depth of the tank shall be such that if required a person can stand and work in the tank when it is full. Bentonite slurry shall be prepared using bentonite mixer or bentonite pump. Care shall be taken to maintain the required consistency of bentonite slurry in the tank. The concreting operation should not be taken up when the specific gravity of the bottom slurry is more than 1.2. Where bentonite suspension is used to maintain the stability of the bore hole, its essential that the properties of the materials be carefully controlled at stages of mixing, supply to the bore hole and immediately before concrete is laid. The density of Bentonite suspension is 1.05 gm/cc. 4.1.3 Fabrication of reinforcement cage Reinforcement bars shall be stored carefully on a raised platform so as to prevent contact with soil. Reinforcement fabrication shall be carried out as per approved drawing. If the length of the entire cage is more than the boom length of the crane/winch or the basic length of individual reinforcement bars, the cage shall be fabricated in parts. Cage shall be fabricated firmly, using binding wire and tack welded as per drawing. Cover blocks of required size shall be provided. 4.1.4 Installation of temporary casing The Tripod shall be brought to the pile location and properly aligned to the pile point, adjusting the tripod legs. Pile point may be confirmed by lowering the bailer on the ground covered with thin layer of sand from a height to get the impression. A single wall casing of suitable length shall be driven through keeping the top edge 20Cm above ground level.

[Type text] Page 4

Lift Irrigation Project

Construction Methodology

4.1.5 Boring After installation of the casing, excavation shall be carried out by bailer. The bore-hole shall be kept filled up with bentonite slurry throughout the process of boring. During the boring operation the fluid level inside the hole has to be kept about 1 M to 1.5 M above the ground water level. 4.1.6 Lowering of reinforcement cage The cage in single length shall be handled with crane/winch. The cage will then be lowered gradually with utmost precautions. 4.1.7 Lowering of tremie pipe Tremie lowering shall be taken up after cage lowering is over. Total length of tremie pipes shall be such that on lowering, the bottom of the pipe shall be above the founding level. The tremie pipes shall be internally free of any old and hardened concrete. O-rings shall be inserted to the joints of the tremie pipes to ensure adequate water-tightness. The tremie-joints shall be properly lubricated with grease. The tremie shall be suspended with a tremie-fork from the top of the casing. A tremie-head shall be fixed with the tremie at the top.

4.1.8 Concreting

4.1.8.1

Approved cement, aggregate, water and admixture shall be used. Concreting will be done by batching plant or

tilting type pan mixer at site.

[Type text]

Page 5

Lift Irrigation Project

Construction Methodology

4.1.8.2 Approved Concrete Design Mix shall be used in

accordance with IS-10262 & SP-23. 4.1.8.3 Minimum cement content & maximum water cement ratio is as per most specification (Clause no. 1703-1) for different grade of concrete. B Concrete mixing, transporting and placing.

Concrete shall be transported by means of transit mixers, when concreting will be done by batching plant and placed as near as practicable to its final position. So that no contamination

segregation or loss of its constituents material take place or when concreting will be done by mixer machine, concreting shall only commence when sufficient number of mixer machines are available at site in running condition. Other arrangements for concreting, i.e., supply of water, electricity, ingredients for concrete must be ensured to be satisfactory. The tremie should be large enough with due regard to the size of the aggregate. For 20mm aggregate the tremie pipe should be of diameter not less than 150 mm. Aggregates of size more than 20 mm shall not be used. The tremie head shall be removed from the tremie assembly and the concrete hopper of adequate capacity shall be fixed to the tremie pipes. The hopper and the tremie should be a closed system through which water cannot pass. After filling up the hopper with the first charge of concrete, it will be ensured that the concrete passes through the tremie

uninterruptedly, forcing the bentonite slurry out of the tremie pipes. The next and the subsequent charges of concrete shall then be poured in the hopper and the concreting shall be carried out with small jerks so as to facilitate the flow of concrete and simultaneous compaction. The tremie pipes shall be

[Type text]

Page 6

Lift Irrigation Project

Construction Methodology

gradually removed one by one, ensuring that it shall always penetrate well into the concrete with an adequate margin of safety against accidental withdrawal of the pipe. Normally, the tremie shall be inserted into the concrete for at least a length of 1 M at any stage of the operation. Throughout the concreting operation, the slump of concrete shall be checked at intervals to ensure proper slump in order to avoid choking of tremie. All tremie pipes shall be scrupulously cleaned after use. Displaced bentonite from the bore shall be collected back into the bentonite tank, where it shall be descended and made re-usable. The top of concrete in a pile shall be brought above the cut-off level to permit removal of all laitance and weak concrete before capping and to ensure good concrete at the cut-off level for proper embedment into the pile cap. 4.1.9 Withdrawal of temporary casing Once the concreting is finished the withdrawal of temporary casing shall commence. The casing shall be withdrawn with winch.

4.2 Sampling & Testing : The Minimum frequency of sampling of concrete of each grade shall be in accordance as Quantity work, M3 of below: in No of Samples 1 2 3 4 4 + one additional sample for each additional 50 m3 or part there of.

Concrete

1-5 6-15 16-30 31-50 51 & above

[Type text]

Page 7

Lift Irrigation Project

Construction Methodology

Three test specimens shall be made as per sampling plan of concrete for testing at 28 days. Additional cubes may be required for various purposes such as to determine the strength of concrete at 7 days. The test strength of sample shall be the average of the strength of three cubes.

Job Procedure for Excavation PURPOSE THE PURPOSE OF THIS PROCEDURE IS FOR SUPERVISION OF ALL EXCAVATION WORKS AND TO ENSURE THAT PROPER QUALITY CONTROL IS EXERCISED AT SITE. SCOPE: THIS PROCEDURE COVERS SUPERVISION AND METHODS OF RECORD KEEPING FOR ALL EXCAVATION WORKS.

[Type text]

Page 8

Lift Irrigation Project

Construction Methodology

REFERENCE DOCUMENTS: SPECIFICATIONS: AS PER OF TENDER DOCUMENT. PROCEDURE: 1. LAYOUT PLAN ALONG WITH SURVEY SCHEME OF SURVEY PILLARS SHALL BE SUBMITTED TO EIL FOR CHECKING. THE CONTRACTOR FOR THE PROTECTION OF MAIN SURVEY PILLARS SHALL MAKE NECESSARY ARRANGEMENTS. 2. CLASSIFICATION OF SOIL SHALL BE CARRIED OUT AS PER ANNEXURE E OF TENDER DOCUMENT EXCAVATION SHALL BE DONE AS PER DRAWING AND AS DIRECTED BY ENGINEER-IN-CHARGE. 3. NECESSARY CHECK FOR SUB SOIL WATER AND DEWATERING ARRANGEMENTS TO BE MADE. ARRANGEMENT FOR SHORING AND STRUTTING SHALL BE MADE IF REQUIRED. 4. EXCAVATED LEVEL AND SIZE OF EXCAVATION SHALL BE CHECKED AS PER DRAWING. 6. IN CASE OF CONFLICT BETWEEN PROCEDURE AND SPECIFICATION, SPECIFICATION SHALL SUPERSEDE PROCEDURE.

JOB PROCEDURE FOR WBM 01 PURPOSE The purpose of the procedure is for supervision of all WBM works & to ensure that proper quality control is exercised at site.

02

SCOPE This procedure covers supervision & method of record keeping for all WBM works. Specifications : As per Tender Document.

03

REFERENCE DOCUMENTS :

[Type text]

Page 9

Lift Irrigation Project

Construction Methodology

04 PROCEDURE i) Before starting of work, source of coarse aggregate, screening materials & binding materials shall be identified & shall be approved by Engineer - in - Charge ii) iii) Subgrade will be prepared as per AFC drawings. Gradation & Physical requirements of materials shall be as per specification. Then the aggregate shall be spread by layer as per AFC Drawing. After spreading the aggregate, the same has to be rolled to ensure a finish surface. After the Coarse aggregate has been rolled, screening materials shall be applied uniformly and gradually over the surface to completely fill the interstices. Then the dry rolling shall be carried out. After completion of dry rolling, the surface shall be After the application of screenings, the Binding materials shall be applied at a uniform & slow rate and the surface shall be copiously sprinkled with water and shall be swept so as to fill the voids properly. Before laying the subsequent layer of WBM, the surface shall be scarified and reshaped to get the required camber & profile.

iv)

v) vi)

vii)

viii)

ix)

In case of conflict between procedure and specification, specification shall supersede procedure.

[Type text]

Page 10

Lift Irrigation Project

Construction Methodology

JOB PROCEDURE FOR SITE GRADING PURPOSE The scope of this job procedure is to provide approved, predetermined & controlled methodology for execution of various earth work activities in site grading SCOPE The procedure deals with the Earth work in excavation & filling for embankments etc. This also gives a guideline regarding record keeping. REFERENCE DOCUMENTS As per tender document.

PROCEDURE

[Type text]

Page 11

Lift Irrigation Project

Construction Methodology

Before starting the Earth work in excavation or filling, the area will be surveyed. After completing the checking procedure of survey work, area has to be cleaned & stripped as per specification.The areas coming under filling has to be compacted to obtain 90% of maximum lab dry density of soil as per IS :2720 part VII No. of samples shall be one for each 500 M2 area or part there of.After clearing, stripping of areas for excavation & filling spot levels will be taken at intervals & pattern as directed by EIC. After taking spot levels, excavation will be started true to its lines, levels & contours as shown in the drwg. & the excavated soil will be transported to the filling area by dumper / truck / any other transport mode simultaneously & laid in uniform layers not exceeding 30 cms in loose depth.The layer shall be compacted with watering & rolling by manual / mechanical means to obtain 90% of laboratory maximum dry density ( standard proctor ) In case of conflict between procedure and specification, specification shall supersede procedure.

JOB PROCEDURE FOR SURVEYING

PURPOSE THE PURPOSE OF THIS PROCEDURE IS TO ENSURE PROPER CONTROL IN SURVEY WORKS. SCOPE: THIS PROCEDURE COVERS ACTIVITIES FOR CARRYING OUT SURVEY WORKS.

REFERENCE DOCUMENTS TENDER DOCUMENT.

: SPECIFICATIONS: AS PER ANNEXURE E OF

[Type text]

Page 12

Lift Irrigation Project

Construction Methodology

PROCEDURE: WORK SPOT. A) TRANSFER THE BENCHMARK/GRID PILLAR NEARER TO

REFERENCE PILLARS TO BE CONSTRUCTED TO FACILITATE EASY CONSTRUCTION. THESE PILLARS ARE TO BE CHECKED BY THEODOLITE AND PROTECTED UNTIL THE COMPLETION OF MAJOR ACTIVITIES. LEVELS OF EXISTING GROUND TO BE TAKEN JOINTLY BEFORE COMMENCING OF EARTHWORK. DURING CONSTRUCTION, LEVELS AT REQUIRED STAGES TO BE TAKEN AND CHECKED BY LEVELING, INSTRUMENTS. THE SURVEY WORK TO BE CARRIED OUT BY AN EXPERIENCED SURVEYOR AND TO BE CHECKED BY CONSTRUCTION ENGINEER AND IN LINE WITH THE INSTRUCTIONS OF ENGINEER-IN-CHARGE. PERMANENT GRID PILLARS TO BE APPROVED BY CONCERNED ENGINEER AND TO BE MAINTAINED UNTIL COMPLETION OF THE JOB. IN CASE OF CONFLICT BETWEEN PROCEDURE AND SPECIFICATION, SPECIFICATION SHALL SUPERSEDE PROCEDURE.

B)

C)

D)

E)

G)

[Type text]

Page 13

Lift Irrigation Project

Construction Methodology

JOB PROCEDURE FOR BACKFILLING

PURPOSE: TO ADOPT PREDETERMINED & CONTROL METHODOLOGY FOR CARRYING OUT THE ACTIVITY. SCOPE: THE SCOPE THIS PROCEDURE INCLUDES SELECTION OF SUITABLE EARTH FOR

REFERENCE DOCUMENTS : TENDER DOCUMENT.

SPECIFICATION: AS PER ANNEXURE E OF

PROCEDURE: BACKFILLING AROUND COMPLETED FOUNDATION STRUCTURES, TRENCHES AND IN PLINTH SHALL BE DONE TO THE LINES & LEVELS SHOWN ON DRAWINGS INCLUDING ANY TRIMMING SURFACES AS MAY BE NECESSARY. THIS SHALL BE DONE WITH THE SELECTED & APPROVED EARTH FROM

[Type text]

Page 14

Lift Irrigation Project

Construction Methodology

EXCAVATION OR OTHERWISE WITH MATERIALS AS DIRECTED BY THE ENGINEER-IN-CHARGE. WHERE SUFFICIENT SUITABLE MATERIAL IS NOT AVAILABLE FROM THE EXCAVATION THE ENGINEER-IN-CHARGE MAY DIRECT TO IMPORT SUITABLE EARTH FROM OTHER SOURCES. THE FILLING SHALL BE DONE IN LAYER OR OF THICKNESS NOT EXCEEDING 15 CM WITH WATERING, ROLLING & RAMMING BY MANUAL METHODS, MECHANICAL COMPACTOR TO GRADE AND LEVEL AS SHOWN ON DRAWINGS TO OBTAIN 90% OF MAXIMUM DENSITY.

JOB PROCEDURE FOR SAND FILLING

PURPOSE : THE SCOPE OF THIS JOB PROCEDURE IS TO PROVIDE APPROVED PREDETERMINE & CONTROLLED METHODOLOGY FOR EXECUTION OF THE ACTIVITY. SCOPE: THE PURPOSE DEALS WITH THE SAND FILLING IN BLANKET COURSE IN ROADS & DRAINS WORKS ETC.

REFERENCE DOCUMENTS: AS PER THE TENDER DOCUMENT

PROCEDURE: SAND FILLING IN PLINTH/FOUNDATION/BLANKET COURSE SHALL BE AS PER SPECIFICATION AS MENTIONED IN THE ANNEXURE E OF TENDER DOCUMENT. FILLING SHALL BE CARRIED OUT IN LAYER NOT EXCEEDING 15 CM AND SHALL BE COMPACTED MECHANICALLY OR BY SATURATION TO SPECIFIED

[Type text] Page 15

Lift Irrigation Project

Construction Methodology

GRADE AND LEVEL AND TO OBTAIN 90% LABORATORY MAXIMUM DRY DENSITY OR AS SPECIFIED IN SCHEDULE OF RATES. COMPACTION BY FLOODING MAY BE ACCEPTED AT THE DISCRETION OF THE ENGINEER-IN-CHARGE, PROVIDED THE REQUIRED COMPACTION IS ARCHIVED. THE CONTRACTORS SHALL NOT COMMENCE FILLING IN AND AROUND ANY WORK UNTIL IT HAS BEEN PERMITTED BY THE ENGINEER-IN-CHARGE IN CASE OF CONFLICT BETWEEN PROCEDURE AND SPECIFICATION SHALL SUPERSEDE PROCEDURE.

JOB PROCEDURE FOR P.C.C.

PURPOSE: THE PURPOSE OF THIS PROCEDURE IS FOR SUPERVISION OF ALL PCC WORKS AND TO ENSURE THAT PROPER QUALITY CONTROL IS EXERCISED AT SITE. SCOPE: THIS PROCEDURE COVERS SUPERVISION AND METHODS OF RECORD KEEPING FOR ALL PCC WORKS.

REFERENCE DOCUMENTS: TENDER DOCUMENT.

SPECIFICATIONS AS PER ANNEXURE-E OF

MATERIAL: ALL MATERIALS LIKE FINE AGGREGATE, COARSE AGGREGATE, CEMENT SHALL BE APPROVED AND TESTED AND SHALL CONFIRM TO SPECIFICATION AS MENTIONED IN THE TENDER DOCUMENT. THE FREQUENCY OF TESTS SHALL BE AS PER ABOVE SPECIFICATION OF ANNEXURE-E.

[Type text]

Page 16

Lift Irrigation Project

Construction Methodology

PROCEDURE:

1. EXCAVATED SURFACE SHALL BE CHECKED BEFORE PCC. IT SHOULD BE WELL COMPACTED & FREE FROM STANDING WATER, MUD OR DEBRIS. 2. EXCAVATED LEVEL SHALL BE CHECKED AS PER DRAWING / STRUCTURE. 3. PCC SHALL BE AS PER SPECIFICATION & AFC DRAWINGS. 4. TOP LEVEL OF PCC SHALL BE CHECKED BEFORE RCC AND SHALL BE RECORDED ON THE POUR CARD. 5. CURING SHALL BE DONE AS PER SPECIFICATION. 6. WHEREVER GRADE OF PCC IS MENTIONED, NUMBER OF CUBES SHALL BE TAKEN AS PER REQUIREMENTS AND TESTED FOR ACCEPTANCE. 7. IN CASE OF CONFLICT BETWEEN PROCEDURE AND SPECIFICATION, SPECIFICATION SHALL SUPERSEDE PROCEDURE.

JOB PROCEDURE FOR RCC

PURPOSE: THE PURPOSE OF THIS PROCEDURE IS FOR SUPERVISION OF CONCRETING WORKS AT SITE AND TO ENSURE THAT PROPER QUALITY CONTROL IS MAINTAINED. SCOPE: THIS PROCEDURE COVERS SUPERVISION AND METHODS OF RECORD KEEPING FOR CONCRETING WORK AT ALL STAGES.

REFERENCE DOCUMENTS: SPECIFICATIONS AS PER ANNEXURE E OF TENDER DOCUMENT.

PROCEDURE: BEFORE CONCRETING: 1. MATERIAL SHALL BE TESTED IN LAB AS PER SPECIFICATION AND AS DIRECTED BY ENGINEER-IN-CHARGE. 2. AVAILABILITY OF VIBRATORS, WATER, LIGHTING ARRANGEMENT, ETC. SHALL BE ENSURED. 3. POUR CARD SHALL BE SUBMITTED BY THE CONTRACTOR AFTER CHECKING.

[Type text] Page 17

Lift Irrigation Project

Construction Methodology

4. REINFORCEMENT PLACING AND FORM WORK SHALL BE DONE AS PER DRAWING / STANDARDS. WHILE CONCRETING: 1. CONCRETING SHALL BE DONE BY CONCRETE MIXERS AND WEIGH BATCHER IN GENERAL. 2. CONCRETE SHALL BE POURED BEFORE INITIAL SETTING TIME AND COMPACTION SHALL BE DONE BY VIBRATOR. 3. SAMPLING OF TEST CUBES SHALL BE DONE JOINTLY. 4. CONSTRUCTION JOINT SHALL BE PROVIDED AS DIRECTED. AFTER CONCRETING: 1. FRESH CONCRETE SHALL BE COVERED WITH JUTE GUNNY BAGS AND SHALL BE PROTECTED FROM DAMAGE. 2. POCKET (IF ANY) SHALL BE REMOVED AFTER INITIAL SETTING TIME WITHOUT DAMAGING THE CONCRETE. 3. DE-SHUTTERING SHALL BE DONE AFTER MINIMUM PERIOD SPECIFIED AND AS DIRECTED BY ENGINEER-IN-CHARGE. 4. ANY HONEYCOMB APPEARED SHALL BE FINISHED PROPERLY AS DIRECTED. 5. CURING SHALL BE DONE AS PER SPECIFICATIONS. 6. CUBES SHALL BE KEPT TOTALLY IMMERSED IN WATER TANK AND SHALL BE TESTED AS PER SPECIFICATION PRECAST CONCRETING CASTING OF PRECAST CONCRETE WILL BE IN THE SAME MANNER AS DESCRIBED REGARDING CONCRETING. NECESSARY LIFTING HOOKS OF SUITABLE DIAMETER SHALL BE PROVIDED FOR HANDLING UNLESS OTHERWISE SPECIFIED, EXPOSED SURFACE OF PRECAST MEMBERS SHALL BE INTEGRALLY FINISHED SMOOTH. THE TOP SURFACE SHALL BE MARKED WITH T TO IDENTIFY THE TOP SURFACE AT THE TIME OF ERECTION. ALL SAFETY PRECAUTIONS SHALL BE TAKEN AT THE TIME OF ERECTION. IT SHALL BE ERECTED CAREFULLY SO THAT IT CANNOT GET DAMAGED. RECORDS 01. POUR CARD SHALL BE MAINTAINED

[Type text]

Page 18

Lift Irrigation Project

Construction Methodology

02. MATERIAL TEST RECORDS AS PER FREQUENCY SHALL BE MAINTAINED. 03. CUBE TEST RESULTS SHALL BE MAINTAINED FOR 07 DAYS AND 28 DAYS RESULTS. 04. IN CASE OF CONFLICT BETWEEN PROCEDURE AND SPECIFICATION, SPECIFICATION SHALL SUPERSEDE PROCEDURE.

JOB PROCEDURE FOR BRICK WORK

PURPOSE: THE PURPOSE OF THIS PROCEDURE IS FOR SUPERVISION OF ALL BRICKWORK AND TO ENSURE THAT PROPER QUALITY CONTROL IS EXERCISED AT SITE. SCOPE : THIS PROCEDURE COVERS SUPERVISION AND METHOD OF RECORD KEEPING FOR ALL BRICK WORKS.

REFERENCE DOCUMENTS: SPECIFICATIONS AS PER ANNEXURE- E OF TENDER DOCUMENT. PROCEDURE:

1)

2)

3)

4) 5) 6)

APPROVED BRICKS SHALL BE SOAKED IN WATER BEFORE USE AT SITE FOR A PERIOD THAT IS SUFFICIENT FOR WATER TO PENETRATE IN TO THE FULL DEPTHS OF BRICKS IN STACK. THE SURFACE OF R.C.C. SHALL BE WELL CLEANED FROM DUST/DIRT PARTICLES APPLYING WATER AND WIRE BRUSH IF NECESSARY BEFORE COMMENCEMENT OF BRICK WORK . PROPER HACKING OF R.C.C. SURFACE SHALL BE DONE AT JOINTS OF BRICK WORK WITH RCC BEFORE COMMENCEMENT OF MASONRY WORK. BRICK WORK SHALL BE DONE IN ENGLISH BOND PATTERN. CEMENT MORTAR SHALL MEET THE REQUIREMENTS OF IS 2250 AND SHALL BE PREPARED BY MIXING CEMENT AND SAND BY VOLUME. MORTAR SHALL BE MIXED IN PROPORTIONS AS SPECIFIED IN DRAWING SPECIFICATION.

[Type text]

Page 19

Lift Irrigation Project

Construction Methodology

MORTAR SHALL BE APPLIED OVER THE BRICKS WITH FROG FACING UPWARD. 8) AFTER COMPLETION OF REQUIRED COURSES ALL VERTICAL JOINTS SHALL BE FILLED WITH CEMENT MORTAR. 9) ALL JOINTS SHALL BE PROPERLY RAKED AFTER FILLING CEMENT MORTAR. 10) CURING SHALL BE DONE AFTER 24 HRS OF COMPLETION OF WORK AND SHALL BE DONE FOR AT LEAST SEVEN DAYS AFTER COMPLETION OF WORK. 11). IN CASE OF CONFLICT BETWEEN PROCEDURE AND SPECIFICATION, SPECIFICATION SHALL SUPERSEDE PROCEDURE. 7)

[Type text]

Page 20

Вам также может понравиться

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringОт EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringРейтинг: 4 из 5 звезд4/5 (5)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- The Views Tangent Pile-Method StatementДокумент5 страницThe Views Tangent Pile-Method Statementaliengineer953Оценок пока нет

- PileДокумент5 страницPileSuman NakarmiОценок пока нет

- Cut-Off Wall Diapragm Wall of CFRD DamДокумент4 страницыCut-Off Wall Diapragm Wall of CFRD DamVinodh Kumar YallaОценок пока нет

- Bored Pile Construction MethodДокумент5 страницBored Pile Construction MethodVijay Jamadar100% (2)

- Method Statement For Bored PilingДокумент5 страницMethod Statement For Bored PilingAhmed KassemОценок пока нет

- General SpecificationДокумент3 страницыGeneral SpecificationKakoliОценок пока нет

- Construction Methodology For Test PIle NPBДокумент8 страницConstruction Methodology For Test PIle NPBSheikh Nouman Mohsin RamziОценок пока нет

- Methodology JettyДокумент4 страницыMethodology JettyPriodeep ChowdhuryОценок пока нет

- Methodology For PIpe Culvert, Box-Culvert, Slab Drain, Minor Bridge & Major Bridge.Документ57 страницMethodology For PIpe Culvert, Box-Culvert, Slab Drain, Minor Bridge & Major Bridge.Abhi100% (1)

- Methodology For Piling WorkДокумент5 страницMethodology For Piling WorkAftab AlamОценок пока нет

- DMC Pile MethodologyДокумент6 страницDMC Pile MethodologyKaustav Sain100% (3)

- Particular Specification For Non-Percussion Cast In-Situ Concrete PilesДокумент11 страницParticular Specification For Non-Percussion Cast In-Situ Concrete Pilesagoul81Оценок пока нет

- Concrete ReportДокумент11 страницConcrete ReportSANTOSH GAIKWADОценок пока нет

- Cement Bentonite Slurry Wall Trenching MethodДокумент3 страницыCement Bentonite Slurry Wall Trenching MethodNemanja BralovicОценок пока нет

- 1183 Vol - IIBДокумент152 страницы1183 Vol - IIBVishal PatelОценок пока нет

- Development Constructions LTD.: Construction Methodology - (On Land) For Jetty Extension Project at Meghnaght-01Документ6 страницDevelopment Constructions LTD.: Construction Methodology - (On Land) For Jetty Extension Project at Meghnaght-01Priodeep ChowdhuryОценок пока нет

- Work Methodology Pipe CulvertДокумент11 страницWork Methodology Pipe CulvertAbhiОценок пока нет

- (O) - 1 Bored PileДокумент16 страниц(O) - 1 Bored Pileautienhai100% (4)

- Atk SSA Presentation R2Документ38 страницAtk SSA Presentation R2Gaurav MathurОценок пока нет

- Method Statement of Diaphragm Wall - Bored PileДокумент45 страницMethod Statement of Diaphragm Wall - Bored PileKelvin Tsoi100% (1)

- 4 Phases Involved in Bored Cast inДокумент3 страницы4 Phases Involved in Bored Cast inRajesh KhadkaОценок пока нет

- Concrtee Transportation and PlacingДокумент8 страницConcrtee Transportation and PlacingIm ChinithОценок пока нет

- Method Statement of Concreting Pile Cap Rev02Документ3 страницыMethod Statement of Concreting Pile Cap Rev02Mohd Hafizul Hj Tanalol75% (4)

- Construction Method Statements for Bored PilingДокумент5 страницConstruction Method Statements for Bored PilingLin ChayОценок пока нет

- MS OF Raft & Water ProofingДокумент4 страницыMS OF Raft & Water ProofingnipunОценок пока нет

- PQC Methodology-2Документ7 страницPQC Methodology-2venkateswara rao Pothina100% (1)

- METHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The ViewsДокумент6 страницMETHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The Viewsaliengineer953Оценок пока нет

- MS For Reinforcement Cement ConcretingДокумент6 страницMS For Reinforcement Cement ConcretingShan THALAОценок пока нет

- BP (Method Statement) - 2Документ5 страницBP (Method Statement) - 2khraieric16Оценок пока нет

- Method PileДокумент3 страницыMethod Pileavisek_basu100% (1)

- Precast Concrete Pipe Culvert InstallationДокумент4 страницыPrecast Concrete Pipe Culvert InstallationDanny NguОценок пока нет

- Method Statement - Structural ConcreteДокумент7 страницMethod Statement - Structural Concretearif_rubinОценок пока нет

- Methodology For Convreting WorksДокумент7 страницMethodology For Convreting WorksLokesh SaranОценок пока нет

- 1.1 Consumable Materials (All Details To Be in Appendix)Документ17 страниц1.1 Consumable Materials (All Details To Be in Appendix)Thimira Bandara EkanayakeОценок пока нет

- Work Methodology for VDFДокумент4 страницыWork Methodology for VDFrahulОценок пока нет

- Qcs 2010 Section 5 Part 8 Transportation and Placing of ConcreteДокумент7 страницQcs 2010 Section 5 Part 8 Transportation and Placing of Concretebryanpastor106Оценок пока нет

- 500 StructuresДокумент13 страниц500 StructuresSuranga ManuОценок пока нет

- Concrete Works Method StatementДокумент6 страницConcrete Works Method StatementmemekenyaОценок пока нет

- Method Statement For Bored Pile: Nam Fatt Construction Sdn. BHDДокумент5 страницMethod Statement For Bored Pile: Nam Fatt Construction Sdn. BHDMohamad Syafiq Bin A.Rashid100% (1)

- Bored Cast in Situ PilesДокумент6 страницBored Cast in Situ Piles123epcОценок пока нет

- Cover Page Only 1Документ15 страницCover Page Only 1Zelalem TeshomeОценок пока нет

- Specification Jila Seva Sadan - 3Документ176 страницSpecification Jila Seva Sadan - 3Jignesh P KoratОценок пока нет

- Diaphragm Wall PresentationДокумент52 страницыDiaphragm Wall PresentationGagan Goswami100% (11)

- DLC 2 19Документ18 страницDLC 2 19MOHANSHU BHARDWAJ 22910013Оценок пока нет

- Bored Piling Method StatementДокумент4 страницыBored Piling Method StatementCharith SubasingheОценок пока нет

- Technical Specification For BridgeДокумент5 страницTechnical Specification For BridgeRichard WestonyОценок пока нет

- FRESH CONCRETE BATCHINGДокумент10 страницFRESH CONCRETE BATCHINGsydney augustОценок пока нет

- Diaphragm WallДокумент4 страницыDiaphragm Wallリムスィギャン瑞娴Оценок пока нет

- Pipe CoatingДокумент51 страницаPipe CoatingAndy ChongОценок пока нет

- CONSTRUCTION DRAINAGE WORKS STATEMENTДокумент5 страницCONSTRUCTION DRAINAGE WORKS STATEMENTYin Mohd100% (4)

- QC CONTROL CONCRETE STRUCTURESДокумент57 страницQC CONTROL CONCRETE STRUCTURESMohammad Ali Salem Mauna100% (4)

- Anchor TrenchДокумент4 страницыAnchor TrenchAlbertyОценок пока нет

- Method of Construction for Administration Building SubstructureДокумент7 страницMethod of Construction for Administration Building SubstructureM.ZEKEBA50% (2)

- Bihar Urban Infrastructure Development Corporation Ltd. Drinking Water Supply SchemeДокумент19 страницBihar Urban Infrastructure Development Corporation Ltd. Drinking Water Supply Schemesumit249100% (1)

- Pile Foundation MethodologyДокумент3 страницыPile Foundation MethodologyLokesh SaranОценок пока нет

- Sewage Disposal Works: Their Design and ConstructionОт EverandSewage Disposal Works: Their Design and ConstructionОценок пока нет

- MSP Webinar Slide DeckДокумент28 страницMSP Webinar Slide DeckraghavaklОценок пока нет

- Course SummaryДокумент45 страницCourse SummaryraghavaklОценок пока нет

- Health and Safety Test in ConstructionДокумент7 страницHealth and Safety Test in ConstructionraghavaklОценок пока нет

- Science of Palmistry by M.A.DevacharyaДокумент140 страницScience of Palmistry by M.A.Devacharyasharath kumar.r100% (5)

- Design Basis Report Zone 1Документ7 страницDesign Basis Report Zone 1raghavaklОценок пока нет

- Aquasim ManualДокумент219 страницAquasim Manualpsbc9Оценок пока нет

- Hydraulic Statement Zone 1 Islotaed Network Rev1Документ19 страницHydraulic Statement Zone 1 Islotaed Network Rev1raghavaklОценок пока нет

- William Lilly - Christian Astrology FacsimileДокумент444 страницыWilliam Lilly - Christian Astrology FacsimileMikael SebagОценок пока нет

- Bund FormationДокумент1 страницаBund FormationraghavaklОценок пока нет

- Let Us Install Jyoti VT PumpsДокумент55 страницLet Us Install Jyoti VT Pumpsraghavakl100% (3)

- CivilEngineer For ADV Geo StructuralДокумент15 страницCivilEngineer For ADV Geo StructuralraghavaklОценок пока нет

- Prenatal Exercise GuidelinesДокумент1 страницаPrenatal Exercise GuidelinesraghavaklОценок пока нет

- Antiquities of BidarДокумент46 страницAntiquities of BidarraghavaklОценок пока нет

- Primary Clarifier Aeration Tank Secondary Clarifier Chlorine Contact TankДокумент1 страницаPrimary Clarifier Aeration Tank Secondary Clarifier Chlorine Contact TankraghavaklОценок пока нет

- Ancient Monuments and Archaeological Sites and Remains Rules 1959Документ31 страницаAncient Monuments and Archaeological Sites and Remains Rules 1959raghavaklОценок пока нет

- Boundary WallДокумент1 страницаBoundary WallraghavaklОценок пока нет

- Materials System SpecificationДокумент6 страницMaterials System SpecificationCherukunnon JubuОценок пока нет

- Amie Lab ProjectguideДокумент8 страницAmie Lab ProjectguidekskumargieОценок пока нет

- I&EC Quality Inspector or ConsultantДокумент5 страницI&EC Quality Inspector or Consultantapi-121403460Оценок пока нет

- Presentation For MTR VisitДокумент12 страницPresentation For MTR VisitA. K. mauryaОценок пока нет

- Lean Models Classification Towards A Holistic ViewДокумент9 страницLean Models Classification Towards A Holistic ViewbayramОценок пока нет

- Estimating Two-Way Slab Deflections: Spreadsheet Includes Construction Load EffectsДокумент6 страницEstimating Two-Way Slab Deflections: Spreadsheet Includes Construction Load EffectsKojo AsareОценок пока нет

- Daftar Pustaka: RICKY ALGIFFARY H, Ashar Saputra, S.T., M.T., PH.DДокумент2 страницыDaftar Pustaka: RICKY ALGIFFARY H, Ashar Saputra, S.T., M.T., PH.DradhiaОценок пока нет

- Jntua r13 Eee SyllabusДокумент116 страницJntua r13 Eee SyllabusRayapati Devi PrasadОценок пока нет

- SIRIUS Motor Management and Control Devices: Wiring Diagrams 3UF70.0-1A00-0 Basic Unit 3UF7400-1AA00-0 Analog ModuleДокумент1 страницаSIRIUS Motor Management and Control Devices: Wiring Diagrams 3UF70.0-1A00-0 Basic Unit 3UF7400-1AA00-0 Analog ModulesanastasОценок пока нет

- Elcometer P700Документ2 страницыElcometer P700Ngan Lam DoОценок пока нет

- Istanbul Bilgi University Associate and Undergraduate Programs' Tuition Fee StructureДокумент3 страницыIstanbul Bilgi University Associate and Undergraduate Programs' Tuition Fee StructureAISHA AHAMMEDОценок пока нет

- Computer System MaintenanceДокумент4 страницыComputer System MaintenanceJeruОценок пока нет

- General Electric - Breaker CodigoДокумент1 страницаGeneral Electric - Breaker CodigoJoel Paucar RuizОценок пока нет

- Instruments Used in Engineering DrawingДокумент15 страницInstruments Used in Engineering Drawingasus nyahendraОценок пока нет

- Koseki-4paper Seismic Stability of Reinforced Soil Walls PDFДокумент28 страницKoseki-4paper Seismic Stability of Reinforced Soil Walls PDFpabulumzengОценок пока нет

- Cooling Tower Pt2 Engineering Data 20110523Документ10 страницCooling Tower Pt2 Engineering Data 20110523ofitecnicajgОценок пока нет

- Projecte#: Subject: 98Th Upgrading of Rank of AccreditedДокумент2 страницыProjecte#: Subject: 98Th Upgrading of Rank of Accreditedbrian paul ragudoОценок пока нет

- IStrucE Detailing Manual BS8110Документ1 страницаIStrucE Detailing Manual BS8110Thoong Yew Chan0% (1)

- Assignment 5 - Machine DesignДокумент1 страницаAssignment 5 - Machine DesignmrinalsinghrawatОценок пока нет

- Aakash (1) 2Документ4 страницыAakash (1) 2Mandar OzaОценок пока нет

- 2nd Year Weekly Attendance Even Sem 2020-2021Документ608 страниц2nd Year Weekly Attendance Even Sem 2020-2021Jos BatlarОценок пока нет

- The Three Phase System Delta To Wye Balance and Unbalanced LoadДокумент7 страницThe Three Phase System Delta To Wye Balance and Unbalanced LoadNiño John JaymeОценок пока нет

- Checklist of Mandatory Documentation Required by IATF 16949 enДокумент3 страницыChecklist of Mandatory Documentation Required by IATF 16949 enKristof MC100% (1)

- Construction Workers Fall Accidents from ScaffoldingДокумент5 страницConstruction Workers Fall Accidents from ScaffoldingNikola LopacaninОценок пока нет

- AutoForm Software Solutions en PDFДокумент3 страницыAutoForm Software Solutions en PDFBASKARAN SELVARAJОценок пока нет

- Frontier Works Organisattion (Fwo)Документ2 страницыFrontier Works Organisattion (Fwo)Shahrukh Shaikh50% (2)

- Resume - Mark Edison D Fellone - 2014Документ2 страницыResume - Mark Edison D Fellone - 2014api-262936729Оценок пока нет

- ESR 2539 ChemofastДокумент15 страницESR 2539 ChemofastEduardo Antonio Duran SepulvedaОценок пока нет

- GB STD Steel PDFДокумент7 страницGB STD Steel PDFBapu612345100% (1)

- Elastic Architecture: A B C D E F GДокумент0 страницElastic Architecture: A B C D E F GNandhitha RajarathnamОценок пока нет