Академический Документы

Профессиональный Документы

Культура Документы

Welding

Загружено:

RENGANATHAN PИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Welding

Загружено:

RENGANATHAN PАвторское право:

Доступные форматы

.T..

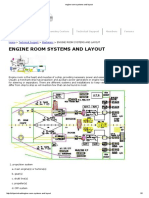

Faculty of Naval Architecture and Ocean Engineering Methods of Ship Production - GEM 314-E et ods o S p oduct o G 3143

Welding in Shipbuilding

Week 2

ARC WELDING BASICS

When the atoms at the edge of one piece of metal come close enough to the atoms at the edge of another piece of metal for inter-atomic interaction to develop, the two pieces become one. This is known as welding process. Most welding processes apply significant heat to the base material. This heat is a means to bring the atoms at the edge of one piece of material close enough to the atoms of another piece for inter-atomic interaction. As hot metal tends to oxidize, sufficient protection from oxidation must be provided by the welding process to prevent this detrimental reaction with ambient oxygen. The welding process to be applied varies with the material and thicknesses. The term arc welding applies to a large group of welding processes that use an electric arc as the source of heat. The arc is struck between the work piece and the tip of electrode. Filler metal may be used. The welding current is conducted through consumable electrodes which take the form of wire or rod, or non-consumable electrodes, consisting of carbon or tungsten rods.

WELDING POSITIONS

WELDING POSITIONS

Shielded Metal Arc Welding (SMAW)

SMAW is performed by a consumable electrode covered by flux which provides shielding of the welded area. It is also known as stick welding.

The electrode consists of a wire core surrounded by silicate binders and powdered material such as fluorides, carbonates, metal alloys and cellulose cellulose.

The covering serves as a source of arc stabilizers and vapors to displace air as well as metal and slug to protect, support and insulate the hot weld metal.

Electrodes are available in diameter from 2 mm. to 8mm. The smaller diameter are used with low currents for joining thin sections, limited access work and welding in vertical and overhead welding positions positions.

The amperage per mm2 of the electrode cross sectional area, is termed current density and must be optimized.

SMAW process yields a deposition efficiency of less than 60 per cent. Splatter is relatively high.

Submerged Arc Welding (SAW)

SAW effects the joining of metal by an arc formed between a ba metal electrode and the work piece. The process involves submergin the welding arc beneath granular flux particles.

The flow protects the arc and molten weld metal from ambie atmosphere. A part of the flux is melted in the process. The rest cleaned and re-used re used.

The welding positions best suited to SAW are the flat positions f fillet and grove welds. It can be also used in horizontal butt welds.

The electrode diameters range between 1 5 to 6 mm Due to the hig 1.5 mm. current and deep penetrations it is better suited to welding sectio thicker than 6 mm. Electrodes are in the form of coiled wire that fee into the arc.

High current densities are used to obtain high yield deposition rat and deep penetration. It can also be used with low current densiti with relatively low deposition rates and penetrations.

SAW can be performed mostly with single electrodes but it can al electrodes, be used with two arcs known as tandem arc process. Tandem a process is used in mechanized and automated welding to jo materials, thicker than 12 mm as many as five electrodes feeding in the same weld pool is need.

Gas Metal Arc Welding (GMAW)

GMAW involves the use of a metal arc and consumable electrode with internally added shielding gas. It is also known as MIG or wire feed welding.

It is a very versatile process with a wide selection of arc modes, electrode sizes and shielding gas mixtures, and can be use welding meta with thickness 0 5 mm and above 0.5 above. With the proper procedure, welding can be performed in all positions.

The shielding gas is often CO2 mixed with argon or several added gasse Small S ll quantities of O2 ( t 5%) are sometimes mixed with argon. titi f (up to ti i d ith

GMAW employs either a solid electrode wire or an electrode with a cor of powdered metal. Electrode sizes range from 0.5 mm to 3.2 mm. Spoo weights vary from 0.5 to 27 kg. The basic equipment consists of a welding gun (air or water cooled), electrode, an electrode feed unit, welding control, a power supply, shielding gas, cables and hoses, and in case of water cooled torches, a water circulation system. GMAW can be used as semi-mechanised, mechanised, automatic and robotic applications. Several types of metal transfer variations can be used. These include Se eral t pes ariations sed incl de spray, globular, short circuiting, pulsed arc, and high deposition and buried arc metal transfer modes.

Gas Metal Arc Welding: Spray Metal vs Granular Metal Transfer Mode a s e ode

Flux Cored Arc Welding (FCAW)

FCAW uses the same type of power sources, with feeders and welding guns as GMAW. However, FCAW uses a tubular electrode with a core containing flux. A variation, self-shielde flux g cored arc welding (FCAW-S) obtains its shielding gas from the electrode.

The flux in the core stabilised the arc, and contains deoxidisers, scavengers, scavengers slag and vapour-forming ingridents. Gas shielded vapour forming ingridents FCAW electrodes must be supplemented with shielding gas supply (Typically CO2). Electrode sizes range from 0.5 to 4 mm. FCAW require more electrod extention than GMAW due to the higher current density requirement. If the extention is not sufficient it can create porosity in the weld. Due to the higher current density deposition rates in FCAW is higher than GMAW. The presence of flux and consequential slug provide further protection. protection FCAW can be used outdoors outdoors. FCAW is suitable for mechanisation and automation.

Electrogas Welding (EG or EGW)

EGW is a mechanized arc welding process that utilizes either flux cored or solid electrodes. The shielding gas may be applied from external source or produced by flux or both. EGW is used to hold thick sections in vertical position. EG machines are usually automatic to maintain constant arc and vertical movement of welding head, and can be used to weld sections up to 76mm. thick, using single electrode. EGW machines create as high as 400A with solid electrode and 750A with flux cored electrodes. Deposition rates are typically in the range of 7 to 13 kg/hr. kg/hr EGW has the capacity to produce square grove and singleV butt joints. Single edge preparation minimizes the joint preparation costs. Weld transverse shrinkage is uniform, hence the joints are essentially free of angular distortion. Due to high current density EGW has high deposition rates. rates

Gas Tungsten Arc Welding (GTAW)

GTAW incorporates the use of a nonconsumable tungsten electrode which is shielded from atmosphere by externally added gas. Welds can be made with or without the filler metal. It is also known as .TIG welding GTAW can be used in all welding positions and can be used for very thin materials (less than 1mm.). It is suitable for automated and robotic applications applications. The shielding gas in GTAW is usually inert (i.e. it does not participate in the chemical reaction). Argon or ArgonHelium mixtures are usually used. Since some chemical reactions are desirable sometimes hydrogen or nitrogen is added. The greatest disadvantage of GTAW is its low productivity.

Stud Welding (SW)

SW is used to join innumerable devices (usually fasteners) j ( y ) to the base metal. This process utilizes an arc struck between a metal stud and the work piece and is applied without filler material, and with or without shielding gas. Pressure is applied when the faying surfaces are adequately pp y g q y heated. Studs are usually surrounded by graphite or ceramic ferrules for partial shielding. The arc created by SW creates molten metal and application of pressure creates a uniform cross section. For a stud of 9.5 mm. typical arc time is 1/3 second. SW skill requirement is minimal and the process lends itself to robotic welding. A limitation of the process involves the use of brittle base metal such as cast iron, in which metal shrinkage can not be tolerated and heat affected zone cracking occurs.

Plasma Arc Welding: Transferred or non-transferred Arc non-

Capabilities of Joining Processes

Table 1 : Arc Welding Cost Definitions Defini

Cos e Cost Definitions o s

Variable Deposition rate, D p Deposition efficiency, E Operator factor, K Labor rate, L Overhead rate, O Power cost, P Amperes, A A Volts, V Material cost, M Definition p (kg/h) (from data for 1 hour of continuous Rate of weld metal deposited, lb/h ( g ) ( welding without arc stoppage) Ratio of weld metal deposited to total weight of electrode used, % Ratio of arc hours to clock hours for a welder, % Welder wages, $/h Cost of other business expenses, $ $/h Electricity, $/kWh Vary according t specific welding procedure as well as electrode t V di to ifi ldi d ll l t d type and d diameter Electrodes, $/lb ($/kg); wire, $/lb ($/kg); and gas, $/ft3 ( $/m3 );

Table 2 : Manual Arc Welding Values for Steel

Manual Arc Welding Values for Steel* Process Deposition Efficiency (E) 65% 90% 95% 85% % 98% 25% 25% 35% 35% 50% % Operator Factor (K) Average

SMAW GTAW GMAW FCAW SAW

* Users are advised to use in-house time studies for actual values.

Table 3 : Equations

Flux and Copper Backing (FCB) ( C )

Flux and Asbestos Backing (FAB) ( )

Assembling Sequence from Plate Panels into Sections

Sport C.

Blocks Layout for a Bulkcarrier

Welding Processes for a Midship Section

Welding Processes for a Midship Section

Welding Processes for a Midship Section

Sport C.

Selection of Welding Processes in the Erection Stage: Horizontal and Flat Position o o ta a d at os t o

The notation of welding process is the same as before. Some new notation has been added. SAW One-sided submerged-arc welding EG Electrogas arc welding with copper slide shoe backing SEG Simplified electrogas arc welding with fixed ceramic backing G Gas metal arcwelding (semi-automatic) GSM Gas metal arc welding (simple mechanized) GMAW (Automatic with highly advanced functions) -Joint tracking GHA -Sequence controlled multipass welding system -Adaptive controlled welding system GOS GMAW One-sided (semi-automatic) + submerged-arc welding Welding Procedures in the Horizontal Position g G Widely applied. GSM Many cases for joints with thickness over 15 mm and length over 2 metres. GHA Few applications. Few cases for joints with medium thickness and long length Selection of welding procedures in the flat position 1. Plate thickness limitations: There is no technical limitation for plate thickness to apply G, GSM, or GHA. Application. of SAW to plate under 10 mm is limited to prevent severe deformation. Application to thicknesses over 35 mm is limited to prevent hot cracking in the root pass. To apply GOS, same passes of GMAW are required to prevent burn through by SAW. Therefore, applicatian to thin plate is limited. l f i d b h hb h f li i hi l i li i d 2. Economical limitations and/or manpower limitations: SAW has a high deposition rate, but it takes time and manpower to fit-up joints with high groove accuracy and to set-up heavy welding equipment in the erection stage. Therefore, economical limitation to the weld length exists for each plate thickness. 3. Technical limitations: GHA is applied in few cases. The accuracy of the weld joint in the erection stage is not good and the development of a sensing system for irregular joints, and a database which corresponds to irregular weld joints is expected.

Selection of Welding Procedures

Sport C.

Welding Time (Hours)

Sport C.

Welding Procedures in the Vertical Position

1. Plate thickness limitations: There is no technical limitation regarding p g g plate thickness for the application of G; pp ; GSM, or GHA. Application of EG to plate of under 10 mm in thickness is limited by controlling the position of the wire during welding. Since EG is carried out with fixed backing, SEG is applied for a wider backing range than EG. Same shipyards apply a two pass technique. 2. Economical limitations and/or manpower limitations: p EG or SEG is a high deposition rate process with a long joint preparation time to achieve high groove accuracy. Heavy welding equipment is required in the erection stage, and economical limitations to weld lengths therefore exist for each plate thickness. thickness 3. Technical limitations: GHA is applied in a few cases. As the accuracy of the weld joint in the erection stage is not good, development is expected of a sensing system and a database which corresponds to irregular weld joints.

Selection of Welding Procedures

Sport C.

Welding Time (Hours)

Welding Procedures in the Horizontal Position

Figure shows a summary of applications. 1. Plate thickness limitations: There are no technical limitations to plate thickness in applying G, GSM or GHA. 2. Economical limitations and/or manpower limitations: As there is no practical high deposition rate process for horizontal welding, only GMAW is applied at present. The cost of welding facilities increases in the order of G, GSM and GHA.

Selection of Welding Procedures

Sport C.

Shipyard Layout

Bas Bloklar

Ki Bloklar

A9/12

P2

B13

Egrisel Blok Montaj Perde & Gverte Hatti

Sperblok Montaj alani

13

Boya Holleri

fer H atti

2

Havuz

15 9

Buffer ff

Tran s

Besle me H

atti

19.76

Bina Giris

6.29

A9/3

6.29

A9/4

6.29

A9/5

P1

A9/15

14

styapi montaj alani

6.29

6.29

A9/6

6.29

6.29

1 n Imalat Atlyesi

1

Idari Bina Giris

6.29

P5

P6

A9/11

64.0

287. 76

297. 03

150.

A9/14

00

80.9

15

10

P3

Panel Hatti

Priz

A9/1

12

mati k

Blok

11

Sosyal

17

A9/2

A9/7

A9/8

A9/9

A9/10

Gvenlik Binasi

Giri is

18

Depolar Giris

16

Stock Area

Plate Lifting and Plasma Cutting

Marking

Submerged Arc Welding of Plates

Palet System for Stiffeners

Temporary Welding

Stiffeners Final Welding

Sub Assembly Examples

Panel Line

Panel and Bulkhead Line

Panel and Bulkhead Line: Main Components

Curved Panel Assembly

Sub Blocks

Blocks

Paint Hall

Paint Hall

End of Week 2

Questions Q estions ?

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Voice and Accent Training MaterialДокумент30 страницVoice and Accent Training MaterialAnwar GaffОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Marine Internal Combustion Diesel Egine I-SbrДокумент232 страницыMarine Internal Combustion Diesel Egine I-SbrRENGANATHAN P100% (1)

- Engine Room Systems and Layout PDFДокумент3 страницыEngine Room Systems and Layout PDFRENGANATHAN P33% (3)

- Welder Qualification (ALL CODES)Документ3 страницыWelder Qualification (ALL CODES)narutothunderjet216Оценок пока нет

- 'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Документ36 страниц'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Vinoth KannanОценок пока нет

- A340 SRM Ata 51-43Документ674 страницыA340 SRM Ata 51-43L1049A100% (6)

- Objective Questions - Bolted and Welded ConnectionsДокумент8 страницObjective Questions - Bolted and Welded ConnectionsVarun ShastryОценок пока нет

- 23 AuxiliaryMarineMachinery 000 PDFДокумент55 страниц23 AuxiliaryMarineMachinery 000 PDFLionel Richi100% (1)

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 2.6 ExerciseДокумент1 страницаCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 2.6 ExerciseElwathig BakhietОценок пока нет

- SWOT Analysis of AmulДокумент7 страницSWOT Analysis of AmulRENGANATHAN PОценок пока нет

- The Caliphate FilesДокумент7 страницThe Caliphate FilesRENGANATHAN PОценок пока нет

- 6b Engine Rooms and Machinery Space Intertanko K Koo PDFДокумент4 страницы6b Engine Rooms and Machinery Space Intertanko K Koo PDFRENGANATHAN PОценок пока нет

- Engine Room Arrangement PDFДокумент1 страницаEngine Room Arrangement PDFRENGANATHAN PОценок пока нет

- The Mahabharata of 2019Документ7 страницThe Mahabharata of 2019RENGANATHAN PОценок пока нет

- What Hindus Must Do Series 3 Whmd-IiiДокумент5 страницWhat Hindus Must Do Series 3 Whmd-IiiNaliniОценок пока нет

- Fire-Fighting Guidance Notes - E-Feb15Документ161 страницаFire-Fighting Guidance Notes - E-Feb15Moe LattОценок пока нет

- Machinery EquipmentДокумент2 страницыMachinery EquipmentFrano BokoОценок пока нет

- ARM Microprocessor PracticeДокумент1 страницаARM Microprocessor PracticeRENGANATHAN PОценок пока нет

- Academic Brochure 2016-17 PDFДокумент52 страницыAcademic Brochure 2016-17 PDFRENGANATHAN P0% (1)

- Chanakya's Management Lessons From Ancient India - Sanskriti - Indian CultureДокумент4 страницыChanakya's Management Lessons From Ancient India - Sanskriti - Indian CultureRENGANATHAN PОценок пока нет

- Physics - I PDFДокумент179 страницPhysics - I PDFRENGANATHAN PОценок пока нет

- Optimum Nutrition For Vigour and Vitality: Your Food Shall Be Your Medicine. - HippocratesДокумент22 страницыOptimum Nutrition For Vigour and Vitality: Your Food Shall Be Your Medicine. - HippocratesRENGANATHAN PОценок пока нет

- Cet June 2016 Results Ug 8jun16 PDFДокумент436 страницCet June 2016 Results Ug 8jun16 PDFRENGANATHAN PОценок пока нет

- What Hindus Must Do Series 2 WHMD IIДокумент22 страницыWhat Hindus Must Do Series 2 WHMD IIRENGANATHAN PОценок пока нет

- Basel III For Global Banks: Third Time's The Charm?Документ9 страницBasel III For Global Banks: Third Time's The Charm?RENGANATHAN PОценок пока нет

- What Hindus Must DoДокумент9 страницWhat Hindus Must DoNaliniОценок пока нет

- Basel III-AДокумент12 страницBasel III-ARENGANATHAN PОценок пока нет

- Intact Stability Code msc-267-85 08Документ94 страницыIntact Stability Code msc-267-85 08sugram100% (1)

- Kerala Government Holidays 2014Документ5 страницKerala Government Holidays 2014RENGANATHAN PОценок пока нет

- Lesson 1 - Master MindДокумент0 страницLesson 1 - Master MindRENGANATHAN P100% (1)

- Chip Formation and Tool LifeДокумент37 страницChip Formation and Tool LifeSquakx BescilОценок пока нет

- Draft Regulations On Tech and Prof EduДокумент28 страницDraft Regulations On Tech and Prof EduRENGANATHAN PОценок пока нет

- BASEL2Документ7 страницBASEL2RENGANATHAN PОценок пока нет

- White Paper Shipbuilding - EnglДокумент19 страницWhite Paper Shipbuilding - EnglRENGANATHAN PОценок пока нет

- Basel I Is The Round of Deliberations by Central Bankers From Around TheДокумент2 страницыBasel I Is The Round of Deliberations by Central Bankers From Around TheRENGANATHAN PОценок пока нет

- Lesson 3 - Covered Electrodes For Welding Mild Steels PDFДокумент1 страницаLesson 3 - Covered Electrodes For Welding Mild Steels PDFMelissa MurrayОценок пока нет

- CTS Welder (Pipe) NSQFДокумент33 страницыCTS Welder (Pipe) NSQFzaki amОценок пока нет

- Api 1104 1999-8Документ1 страницаApi 1104 1999-8Rohit KambleОценок пока нет

- Din2632 PN10 PDFДокумент2 страницыDin2632 PN10 PDFPablo TututiОценок пока нет

- HSE KIK Monitoring Hot Work Ceilling Dan OfficeДокумент13 страницHSE KIK Monitoring Hot Work Ceilling Dan Officeandri setiawanОценок пока нет

- DIN-6912-Socket Head Screw Low Head With Pilot Recess Mfa CatalogueДокумент4 страницыDIN-6912-Socket Head Screw Low Head With Pilot Recess Mfa CataloguevinodmysoreОценок пока нет

- BS en 287-6-2010Документ26 страницBS en 287-6-2010CocaCodaОценок пока нет

- GMAW CG With BUDGET PLAN SY. 2021-2022Документ1 страницаGMAW CG With BUDGET PLAN SY. 2021-2022Lyn VallesОценок пока нет

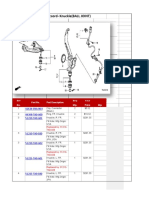

- 2008 Honda Accord-Knuckle (BALL JOINT) : 42524-SNA-003 44348-TA0-A00 51210-TA0-A01Документ2 страницы2008 Honda Accord-Knuckle (BALL JOINT) : 42524-SNA-003 44348-TA0-A00 51210-TA0-A01BrumeОценок пока нет

- Eversendai Offshore RMC Fze: Request For TestingДокумент1 страницаEversendai Offshore RMC Fze: Request For Testingbharani dharanОценок пока нет

- Lock Nut WasherДокумент3 страницыLock Nut WasherParmasamy SubramaniОценок пока нет

- Bolt TableДокумент1 страницаBolt TableErebert C. CaracasОценок пока нет

- Gas Metal Arc WeldingДокумент26 страницGas Metal Arc WeldingnansusanОценок пока нет

- Unit-Ii QBДокумент16 страницUnit-Ii QBAnonymous ZB6qyhD6Оценок пока нет

- Desarme y Despiece Wa17r3Документ8 страницDesarme y Despiece Wa17r3Christian DiazОценок пока нет

- SGP UpdДокумент1 585 страницSGP UpdBaraka MotorОценок пока нет

- BS en 1708-1-2010Документ76 страницBS en 1708-1-2010SERDARОценок пока нет

- Standar Undercut PorosДокумент5 страницStandar Undercut PorosRiska DamayantiОценок пока нет

- Benzi Sigil Ant Is I Membrane Ro 21Документ339 страницBenzi Sigil Ant Is I Membrane Ro 21Viziteu ValentinОценок пока нет

- Assumption College Welding Qualification TranscriptДокумент1 страницаAssumption College Welding Qualification TranscriptVillamor NiezОценок пока нет

- Portland Cement Clinker: The Bogue Calculation: Alite: C Belite: C Aluminate Phase: C Ferrite Phase: CДокумент3 страницыPortland Cement Clinker: The Bogue Calculation: Alite: C Belite: C Aluminate Phase: C Ferrite Phase: Cv1963Оценок пока нет

- Catalogo de Partes Ak 3w200 2014Документ44 страницыCatalogo de Partes Ak 3w200 2014Fredy Giovanny Parra Talero100% (1)

- Visual Weld InspectionДокумент53 страницыVisual Weld InspectionThiru RajaОценок пока нет

- MI L"STD-1595A 26 February 1982 Superseding MIL-STD-1 595 26 July 1977Документ72 страницыMI L"STD-1595A 26 February 1982 Superseding MIL-STD-1 595 26 July 1977Jay MillerОценок пока нет

- Din en 439 Iso 4035Документ5 страницDin en 439 Iso 4035ezequieltoniОценок пока нет