Академический Документы

Профессиональный Документы

Культура Документы

Ratio Pressure Reducing Valves

Загружено:

kanem1Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ratio Pressure Reducing Valves

Загружено:

kanem1Авторское право:

Доступные форматы

SPECIFICATION SHEET

Philmac Ratio Pressure Reducing Valves

Philmac Ratio Pressure Reducing Valves accurately control service line pressure in fixed head water systems. Pressure is reduced by ratio to protect appliances from damage caused by excess pressure. The valves also protect pipework by reducing surge and water hammer.

Features

Precision engineered from high quality materials. Compact design makes valves easy to install. Only one moving part means high reliability and low maintenance. 35 bar pressure capacity. Low head loss and high flow characteristics. No external regulation devices. Wide range of configurations available. Thirty years proven usage world-wide. Quality endorsed manufacturer to ISO 9002.

Your Benefit

Able to withstand arduous working conditions. 360 degree valve orientation possible. Low maintenance required. Able to withstand high working pressure. Relatively small sized valves can be used for high cost efficiency. Vandalism proof. We have a valve to suit your specific requirements. Peace of mind.

Guarantee

Each valve is fully tested after manufacture. Flanged valves carry a 5 year guarantee on materials and workmanship.

*Note warranty on standard valve is void if used in a non-potable water application.

Direction of flow indicated on valve. Valve can be installed vertically or horizontally. All lines must be thoroughly flushed out prior to installation. Position valve to allow easy view of breather hole. Allow easy access to valves for future servicing. Screwed valves should be installed with at least one union. Protect valve from heat during welding, to prevent damage to seals. Breather hole must be kept free of obstruction. If line is buried protect breather hole from blockage. Pipe systems and fittings should be capable of withstanding full head pressure as stipulated by Water Authorities. Install pressure gauges in the system at each ratio valve station. Where two ratio valves per station are installed, rotate use periodically to allow spare valve to function.

Typical Applications

High rise buildings. Mines. Oil rigs. Flusherette systems. Cold & hot water systems (0-80C) Fire hydrant services.

Typical installations of Ratio Valves in High Rise Buildings

Principle of Operation

The flanged valve illustrated to the right has a ratio of 2:1. The down stream pressure is one half of the upstream pressure both under flow and static conditions. The piston surface areas on the upstream side are one half of the piston surface areas on the downstream side. Other ratios are obtained by altering the area relationship of the piston.

STATIC CONDITION

Valve Selection

The size and type of valve is determined by the operating environment, pipe size, pressure rating and flow capacity. The operating environment will determine if the valve should be standard (ie for use in potable water applications) or marine grade (for use in more aggressive applications such as salt water). In the interests of safety, if the operating environment is not potable water it is recommended you consult with Philmac customer service for material suitability. Specific valve selection can be established by referring to the flow and dimension charts. With flanged valves please specify the body control size, ratio, flange size and flange table. SCREWED VALVES can be supplied with either female BSP (to BS21 and AS1721) or NPT threads. FLANGED VALVES are supplied with a variety of flange patterns including AS2129 Table C/D/E/H, BS4504 Table II, JIS, DIN and ANSI 150. Other flange patterns can be supplied on demand.

Under no flow conditions the piston is closed. The downstream pressure is in accordance with the design ratio.

FLOW CONDITION

Body Size

Screwed (mm) 15, 20, 25, 32, 40, 50 Flanged (mm) 50, 80, 100, 150.

Ratio

The desired static outlet pressure will determine the ratio required. STANDARD RATIOS are 2:1 and 3:1 (Screwed) and 2:1, 3:2, 3:1, 4:1 and 5:1 (Flanged).

Operating Inlet Pressures

Screwed Range: Min. 200 kpa, Max 3500 kpa. Flanged Range: Min. 300 kpa, Max. 3500 kpa. Flanged valve ratios can be changed with an alternative piston and sleeve.

*Flow Litres per Minute

INLET PRESSURE kPa

15 200 300 500 1000 1500 2000 2500 3000 3500 25 30 40 55 70 80 85 95 100 20 30 35 45 65 80 90 100 110 120

SCREWED Nominal size (mm)

25 75 95 125 175 210 245 275 300 325 32 230 295 380 540 660 755 850 930 1000 40 375 470 605 660 1050 1215 1355 1485 1605 50 530 660 850 1205 1480 1705 1910 2090 2260 1350 1700 2500 3000 3500 3800 4200 4600 50

FLANGED BODY CONTROL SIZE Nominal size (mm)

80 100 150

Under flow conditions the piston opens. The downstream pressure still achieves a precise pressure ratio.

3100 4000 5600 6900 7900 8800 9700 10500

5650 7100 10000 12000 14000 15700 17300 18600

13400 17500 24800 30000 34700 38700 42500 46000

Flow figures are provided for use as a guide only. *Theoretical maximum water flow rate when outlet is open ended.

I

Part

1 2 3

C

Name

Body Seat Retainer Retaining Ring

T

Gunmetal LG2 Gunmetal 85-5-5

Material Standard Valve

Material Marine Grade Valve

Gunmetal BS1400G1 Copper Alloy Gunmetal BS1400G1 Copper Alloy Carpenter 20Cb-3 Industrial Grade Stainless Steel Chloroprene Gunmetal BS1400G1 Copper Alloy Chloroprene Gunmetal BS1400G1 Copper Alloy Chloroprene Chloroprene Carpenter 20Cb-3 Industrial Grade Stainless Steel Chloroprene

316 Stainless Steel

4 5 6 7 8 9 10

Seat Rubber Locking Bush Piston O Ring Ratio Sleeve

NBR Gunmetal NBR Gunmetal

Piston Sleeve O Ring NBR Ratio Sleeve O Ring Piston NBR 316 Stainless Steel

11

Static Seal O Ring

NBR

B

A

A

Valve Size (mm) 15 20 25 32 40 50 Thread Size (BSP)

1 3

Dimensions Screwed

Outside Dia. A (mm) 38 45 51 76 95 118 Overall. Length B (mm) 80 96 107 130 155 160

Dimensions Flanged

Body Control Size (mm) 50 Flange Size (mm) 50 65 80 80 100 100 150 150 Flange Dia. A (mm) 165 185 205 205 230 230 305 305

Overall. Length B (mm) 135

/2" /4"

1" 11/4" 11/2" 2"

80 100 150

155 200 200 230

Please note that the information, opinions, recommendations and advice given on this specification sheet are supplied only to provide an improved understanding of the technical aspects of Philmac products. So far as the law allows, Philmac Pty. Ltd. will not accept liability in respect of any loss or damage of any kind claimed to arise as a result of reliance upon any information contained on this specification sheet. Please refer to our Terms and Conditions of Supply of goods. LE/011/1-02

Philmac Pty Ltd 53-59 Deeds Road North Plympton SA 5037, Australia Telephone (08) 8300 9200 Facsimile (08) 8300 9390 Web: http://www.philmac.com.au

Вам также может понравиться

- TRG Control ValveДокумент13 страницTRG Control Valvemilton1987Оценок пока нет

- Viscous Pipe Flow GuideДокумент57 страницViscous Pipe Flow GuidehananОценок пока нет

- Pressure RegulatorДокумент4 страницыPressure RegulatorRICHIHOTS2Оценок пока нет

- HANDBOOK Blanket Gas Regulators PDFДокумент8 страницHANDBOOK Blanket Gas Regulators PDFfrankz89Оценок пока нет

- Improve The Efficiency of Heat Exchanger in Oil CoolerДокумент29 страницImprove The Efficiency of Heat Exchanger in Oil CoolerMuhammad RustamОценок пока нет

- Measurement of Condensation Heat Transfer Coefficient Inside A Vertical Tube in The Presence of Noncondensable Gas PDFДокумент11 страницMeasurement of Condensation Heat Transfer Coefficient Inside A Vertical Tube in The Presence of Noncondensable Gas PDFmintuОценок пока нет

- Refrigerated Gas PlantДокумент12 страницRefrigerated Gas PlantHiba GhandourОценок пока нет

- HP Regulators v2Документ9 страницHP Regulators v2Danny SánchezОценок пока нет

- 399AДокумент24 страницы399ADana Mera100% (2)

- Optimization of Equipment Used in Wastewater Treatment PlantДокумент3 страницыOptimization of Equipment Used in Wastewater Treatment PlantMatthew DelgadoОценок пока нет

- Aspen Tech Compressor Modeling in AspenДокумент16 страницAspen Tech Compressor Modeling in AspenDesiree MolinaОценок пока нет

- Manual Regulators Man Slamshut 2-4inchДокумент20 страницManual Regulators Man Slamshut 2-4inchDelfin Rosanieto TapiaОценок пока нет

- EZR Installation ManualДокумент40 страницEZR Installation ManualRoberto Aldayuz HerediaОценок пока нет

- API Standard 2000 - Venting Atmospheric and Low-Pressure Storage Tanks: Nonrefrigerated and RefrigeratedДокумент5 страницAPI Standard 2000 - Venting Atmospheric and Low-Pressure Storage Tanks: Nonrefrigerated and RefrigeratedNicolas CardonaОценок пока нет

- Type Ezr EstancoДокумент40 страницType Ezr EstancoJuan JuanОценок пока нет

- Hydralic Noise PDFДокумент16 страницHydralic Noise PDFTamil SelvanОценок пока нет

- GgsДокумент21 страницаGgsKrishna KumarОценок пока нет

- Sample Exam2cДокумент10 страницSample Exam2cnaefmubarakОценок пока нет

- 67Документ10 страниц67johnnylim456Оценок пока нет

- 750-326 Blowdown Separator 11 2015Документ10 страниц750-326 Blowdown Separator 11 2015osamaОценок пока нет

- Pressure-Operated Valves Series 290-390-298-398Документ8 страницPressure-Operated Valves Series 290-390-298-398Nelson AlvarezОценок пока нет

- Comparing CoalescersДокумент12 страницComparing Coalescersmohamed_sahnoun_enisОценок пока нет

- Solenoid Operated Valves: Nuclear Power GenerationДокумент12 страницSolenoid Operated Valves: Nuclear Power GenerationVeerabhadra BujurkeОценок пока нет

- Pipeline Cleaning Case StudyДокумент5 страницPipeline Cleaning Case StudyJason MooreОценок пока нет

- Rotork GP & GH RangeДокумент8 страницRotork GP & GH RangeJavier BarreraОценок пока нет

- FEPA Gas-over-oil ActuatorsДокумент4 страницыFEPA Gas-over-oil Actuatorstoader56Оценок пока нет

- Unit Comparison of Open Channel Flow With Pipe Flow: StructureДокумент6 страницUnit Comparison of Open Channel Flow With Pipe Flow: StructureChrisОценок пока нет

- Slam Shut Off FlowgridДокумент16 страницSlam Shut Off FlowgridmateuОценок пока нет

- Is 600 MM Sufficient To Keep BDV FunctionalДокумент4 страницыIs 600 MM Sufficient To Keep BDV FunctionalkronafОценок пока нет

- TankerДокумент60 страницTankerlopezdestructionОценок пока нет

- Manual Valvula PCVДокумент16 страницManual Valvula PCVzamirgothОценок пока нет

- Intro Process Xmitters (Suresh)Документ33 страницыIntro Process Xmitters (Suresh)sreeyukthaОценок пока нет

- GS02 directional proportional solenoid valve specifications and performance dataДокумент2 страницыGS02 directional proportional solenoid valve specifications and performance dataAdal VeraОценок пока нет

- Tutorial: Examples of Typical TasksДокумент420 страницTutorial: Examples of Typical TasksSUDHANSHU SHEKHARОценок пока нет

- High-pressure regulators for gas distributionДокумент6 страницHigh-pressure regulators for gas distributionManish SaraswatОценок пока нет

- 21314Документ5 страниц21314HirkanipatilОценок пока нет

- Natural Gas Chromatograph (NGC) 8206: Data Sheet 2101164-AGДокумент5 страницNatural Gas Chromatograph (NGC) 8206: Data Sheet 2101164-AGishibhoomiОценок пока нет

- Gorter r100 enДокумент6 страницGorter r100 enManish SaraswatОценок пока нет

- Thermodynamics QuestionsДокумент4 страницыThermodynamics QuestionsPiyush BaidОценок пока нет

- FloBoss IO ModulesДокумент5 страницFloBoss IO ModulesAdeel HassanОценок пока нет

- Vortex Pilot Gas Heater Over Temperature ProtectionДокумент17 страницVortex Pilot Gas Heater Over Temperature ProtectionDon BettonОценок пока нет

- 3B - Inst - Control ValveДокумент31 страница3B - Inst - Control ValveMystic AamirОценок пока нет

- Technical Specifications Valve Actuators ScopeДокумент6 страницTechnical Specifications Valve Actuators ScopeBilalPervezОценок пока нет

- CARTRIDGE FILTER TECHNICAL MANUALДокумент30 страницCARTRIDGE FILTER TECHNICAL MANUALabessiОценок пока нет

- Natural Gas Filter Technology GuideДокумент4 страницыNatural Gas Filter Technology GuideAriz Joelee ArthaОценок пока нет

- LPG - Vacuum Breaker Requirement For Pressurized VesselДокумент2 страницыLPG - Vacuum Breaker Requirement For Pressurized Vesselzorro21072107Оценок пока нет

- Natural Gas AssignmentДокумент9 страницNatural Gas AssignmentJagathisswary SatthiОценок пока нет

- CMPAPPP Separator Vessel and Filter Design GuideДокумент18 страницCMPAPPP Separator Vessel and Filter Design GuideJWilson73Оценок пока нет

- Understanding Operating DataДокумент6 страницUnderstanding Operating DataHsein WangОценок пока нет

- A Simplified Approach To Water-Hammer AnalysisДокумент4 страницыA Simplified Approach To Water-Hammer AnalysisChem.EnggОценок пока нет

- Basic Terms of The Trade: 1. Flow Coefficient (C)Документ4 страницыBasic Terms of The Trade: 1. Flow Coefficient (C)shahganОценок пока нет

- 16 PR Paper158175Документ5 страниц16 PR Paper158175Jomer J SimpsonОценок пока нет

- Valve CV Flow Rate FormlaeДокумент1 страницаValve CV Flow Rate Formlaelatasharma79Оценок пока нет

- I/p ConverterДокумент6 страницI/p ConverterAMIT KUMARОценок пока нет

- 650 01 GB 0111 01Документ12 страниц650 01 GB 0111 01Phan HaiОценок пока нет

- FluidFlow QuestionsДокумент2 страницыFluidFlow Questionssonaldiv100% (2)

- Pleated Filter Pressure Drop PDFДокумент12 страницPleated Filter Pressure Drop PDFAmbrish SinghОценок пока нет

- Electrical and InstrumentationДокумент50 страницElectrical and InstrumentationBZ SifdineОценок пока нет

- Visual Flow Indicator Guide from Flow-MonДокумент12 страницVisual Flow Indicator Guide from Flow-Mondhanu_aquaОценок пока нет

- Series 825Y Specification SheetДокумент2 страницыSeries 825Y Specification SheetFEBCOОценок пока нет

- Grinding Aid Performance Analysis for Three Cement MillsДокумент1 страницаGrinding Aid Performance Analysis for Three Cement Millsanurag soniОценок пока нет

- Manufacturing Problems and Metrics ReviewДокумент6 страницManufacturing Problems and Metrics ReviewAditi RayОценок пока нет

- China Vaseline White Petroleum Jelly - Snow White Vaseline - China Vaseline White, Petroleum Jelly PDFДокумент3 страницыChina Vaseline White Petroleum Jelly - Snow White Vaseline - China Vaseline White, Petroleum Jelly PDFIstianah Achy HaeruddinОценок пока нет

- 08 Network ModelsДокумент2 страницы08 Network ModelsJohn Carlo AmodiaОценок пока нет

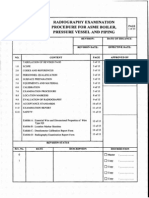

- Radiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingДокумент15 страницRadiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingEko Kurniawan100% (1)

- Volvo EeeeДокумент6 страницVolvo Eeeenarendra singh0% (1)

- Bosch Lean Manufacturing Guidebook-1Документ16 страницBosch Lean Manufacturing Guidebook-1minal potavatreОценок пока нет

- 12 - ToyotaДокумент87 страниц12 - Toyotawaddah100% (2)

- Maine Industrial Tire v. T.Y Cushion TireДокумент28 страницMaine Industrial Tire v. T.Y Cushion TirePriorSmartОценок пока нет

- Ten Rs of Efficient PurchasingДокумент3 страницыTen Rs of Efficient PurchasingBala FoundMylostОценок пока нет

- Sap MM TicketsДокумент9 страницSap MM TicketsSatyajit Sahoo100% (1)

- Googleplex, Mountain View: Designing Interior Spaces at An Urban Scale - Untapped CitiesДокумент11 страницGoogleplex, Mountain View: Designing Interior Spaces at An Urban Scale - Untapped CitiesDiogo Machado100% (1)

- Volvo Cars Sustainability Report 2013Документ64 страницыVolvo Cars Sustainability Report 2013JM MANOJKUMARОценок пока нет

- MMCA Kazcomak2019 Ex-List EngДокумент9 страницMMCA Kazcomak2019 Ex-List Engadamin biriОценок пока нет

- LMC Tablosu-AirbusДокумент1 страницаLMC Tablosu-AirbusefilefilОценок пока нет

- Data Governance Case Study Ciba FinalДокумент37 страницData Governance Case Study Ciba FinalAbdelhamid HarakatОценок пока нет

- Checklist For Selecting A CMMS Solution PDFДокумент4 страницыChecklist For Selecting A CMMS Solution PDFambuenaflorОценок пока нет

- MTM and Motion Economy in Industrial EngineeringДокумент12 страницMTM and Motion Economy in Industrial Engineeringmdravi89Оценок пока нет

- Air CompressorДокумент21 страницаAir CompressorAjayОценок пока нет

- CA7 CommandsДокумент9 страницCA7 CommandsArvindUpadhyayОценок пока нет

- Organisational StudyДокумент68 страницOrganisational StudyManuUdayanОценок пока нет

- Carrying Channel (1 1/2" X 0.6mm X 5m)Документ1 страницаCarrying Channel (1 1/2" X 0.6mm X 5m)Carl LeonardoОценок пока нет

- Elwy Melina-Sarah MHCДокумент7 страницElwy Melina-Sarah MHCpalak32Оценок пока нет

- Banner Buffalo BullДокумент3 страницыBanner Buffalo Bullanon_579800775Оценок пока нет

- Archicad Template Checklist v2 0Документ7 страницArchicad Template Checklist v2 0nedblaОценок пока нет

- FXG (FG-FXG) : Duplex Power PumpДокумент2 страницыFXG (FG-FXG) : Duplex Power PumpJose Alberto Escalante MedinaОценок пока нет

- Scrum Online Quiz - Testing ExcellenceДокумент16 страницScrum Online Quiz - Testing ExcellenceKRISHNAPRIYAОценок пока нет

- Business Challenges: Case StudyДокумент4 страницыBusiness Challenges: Case StudySanjay ThakkarОценок пока нет

- Microsoft Dynamics Ax InstallationДокумент22 страницыMicrosoft Dynamics Ax InstallationsacchishuklaОценок пока нет