Академический Документы

Профессиональный Документы

Культура Документы

Brevet de Inventie CSL

Загружено:

Apetrea AdrianОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Brevet de Inventie CSL

Загружено:

Apetrea AdrianАвторское право:

Доступные форматы

Brevet de inventie csl

Inventors: Invertori: Bradford, Marion M. (Decatur, IL) Bradford, Marion M. (Decatur, IL) Orthoefer, Frank T. (Decatur, IL) Orthoefer, Frank T. (Decatur, IL) Wright, Kenneth N. (Decatur, IL) Wright, Kenneth N. (Decatur, IL) Application Number: Numrul cererii: 06/552633 06/552633 Publication Date: Data publicrii: 12/04/1984 12.04.1984 Filing Date: Data de depozit: 11/16/1983 11.16.1983 View Patent Images: Vizualiza imagini de brevete: Download PDF 4486458 Download PDF 4486458 PDF help Ajutor PDF Export Citation: Referirea la export: Click for automatic bibliography generation Click pentru generarea automat a bibliografiei Assignee: Repartizat: AE Staley Manufacturing Company (Decatur, IL) AE Staley Manufacturing Company (Decatur, IL) Primary Class: Clasa primar: 426/618 426/618 Other Classes: Alte clase: 127/33, 426/623 127/33, 426/623 International Classes: Clase internationale: A23K1/14 ; A23K1/14; A23L1/10 A23K1/14; A23K1/14; A23L1/10 Field of Search: Domeniu de cutare: 426/271, 426/330, 426/623, 426/635, 426/807, 426/48, 426/618, 127/67, 127/68, 127/69, 127/70, 127/33, 252/1, 252/175, 252/180, 210/696, 210/697, 210/698 426/271, 426/330, 426/623, 426/635, 426/807, 426/48, 426/618, 127/67, 127/68, 127/69, 127/70, 127/33, 252 / 1, 252/175, 252/180, 210/696, 210/697, 210/698 Primary Examiner: Examiner primar: Corbin, Arthur L. Corbin, Arthur L. Attorney, Agent or Firm: Avocat, agent sau firma: Lammert, Steven R. Lammert, Steven R. Bateman, Philip L. Bateman, Philip L. Collins, Forrest L. Collins, Forrest L. Parent Case Data: Parent Cauza Data: CROSS-REFERENCE TO RELATED APPLICATION CROSS-referire la de cerere de

This application is a division of US patent application Ser. Aceast aplicaie este o divizie a SUA Ser. cererii de brevet. No. 06/415,192, filed Sept. 7, 1982, now US Pat. Nr 06/415, 192, a depus 7 septembrie 1982, acum US Pat. No. 4,440,792. 4440792 Nr. Claims: Creane: We claim: Noi cerere: 1. 1. A non-gelling corn steep liquor composition which comprises: A non-porumb de coagulare compoziie abrupte de buturi, care cuprinde: (a) corn steep liquor; and (un lichior) Porumb abrupte; i (b) an amount of a calcium complexing agent sufficient to prevent gelling of the corn steep liquor. (b) o sum de un agent de calciu de complexare suficient pentru a mpiedica de coagulare a lichior de porumb abrupte.

2. 2. The composition of claim 1 wherein the calcium complexing agent is an anion selected from the group consisting of phytate anions, citrate anions, oxalate anions, phosphate anions, metaphosphate anions, polyphosphate anions, phosphite anions, and anions derived from EDTA, EGTA, or NTA. Compoziia de cerere 1 unde agentul de calciu complexare este un anionic selectat din grupul format din anioni fitat, anioni citrat, oxalat de anioni, anioni fosfat, anioni metaphosphate, anioni polifosfat, anionii fosfit, i anioni derivate din EDTA, EGTA, sau NTA . 3. 3. The composition of claim 2 wherein the calcium complexing agent is present in an amount of about 1 to 15 weight percent based on the weight of the corn steep liquor. Compoziia de cerere 2 unde agentul de calciu de complexare este prezent ntr-o sum de aproximativ 1 la 15 procente n greutate n funcie de greutatea de lichior de porumb abrupte. 4. 4. The composition of claim 3 wherein the source of the calcium complexing agent is a conjugate acid of the anion or a salt of the conjugate acid. Compoziia de cerere 3 unde sursa de calciu agentului de complexare este un acid conjugat de anioni sau o sare a acidului conjugat. 5. 5. The composition of claim 4 wherein the source of the calcium complexing agent is an acid or salt selected from the group consisting of phytic acid, sodium phytate, citric acid, sodium monobasic citrate, oxalic acid, sodium oxalate, phosphoric acid, potassium monohydrogen phosphate, sodium metaphosphate, sodium dihydrogen phosphate, ammonium dihydrogen phosphate, EDTA, EDTA disodium salt, EGTA, EGTA disodium salt, EGTA dipotassium salt and nitrilotriacetic acid potassium salt. Compoziia de cerere 4 unde sursa de calciu agentului de complexare este un acid sau sare selectat din grupul format de acid phytic, fitat de sodiu, acid citric, citrat de sodiu monobazic, acid oxalic, oxalat de sodiu, acid fosforic, fosfat de potasiu monohydrogen, metaphosphate de sodiu,

fosfat de sodiu dihidrogenat, dihidrogen fosfat de amoniu, EDTA, sare de disodiu EDTA, EGTA, EGTA sare disodic, EGTA sare dipotasic i nitrilotriacetic sare de acid de potasiu. 6. 6. The composition of claim 5 wherein the pH of the composition is about 3.8 to 4.5. Compoziia de cerere 5 unde pH-ul compoziiei este de aproximativ 3.8 - 4.5. 7. 7. The composition of claim 6 wherein the calcium complexing agent is present in an amount of about 3 to 12 weight percent based on the weight of the corn steep liquor. Compoziia de cerere 6 unde agentul de calciu de complexare este prezent ntr-o sum de circa 3 la 12 procente n greutate n funcie de greutatea de lichior de porumb abrupte. 8. 8. The composition of claim 7 wherein the calcium complexing agent is a phosphate anion. Compoziia de cerere 7 unde agentul de calciu de complexare este un anioni fosfat. 9. 9. The composition of claim 8 wherein the source of the phosphate anion is phosphoric acid. Compoziia de cerere 8 unde sursa de anioni fosfat este de acid fosforic. 10. 10. The composition of claim 8 wherein the source of the phosphate ion is an ammonium or alkali metal mono-, di-, or tribasic phosphate salt. Compoziia de cerere 8 unde sursa de ioni este un fosfat de amoniu sau baze de metal mono-, di-, sau sare tribazic fosfat. Description: Descriere: BACKGROUND OF THE INVENTION CONTEXT de invenie Corn steep liquor is the first by-product of the corn wet-milling process. Corn de buturi abrupt este primul produs din porumb umed-frezat proces. In that process shelled, aircleaned corn is soaked or steeped at a temperature of 45-50 C. for 30 to 48 hours in water initially containing about 0.1 to 0.2% sulfur dioxide. n acest proces fr coaj, aer curate de porumb este mbibat sau adncit la o temperatur de 45 -50 C. de 30 pn la 48 de ore n ap, iniial, coninnd aproximativ dioxid de sulf 0.1 - 0.2%. During the steeping or soaking process soluble components of the corn are dissolved in the steeping liquid, and the corn is softened thus facilitating the subsequent grinding process. n timpul componentele nmuiere sau nmuierea proces solubil de porumb se dizolv n lichid nmuiere, i de porumb este nmoaie facilitnd astfel procesul ulterior de slefuire. The steeping liquid, sometimes called light steep water, is separated from the softened corn and concentrated by evaporation to a solids content of about 50%; the resulting concentrate is known in the art as "heavy steep water" or more commonly as "corn steep liquor", sometimes referred to herein as "CSL". Lichid nmuiere, numit uneori cu ap uoar abrupte, este separat de porumb inmuiat si concentrat prin evaporare la un coninut de substane solide de aproximativ 50%; concentrat rezultat este cunoscut n art ca "ap grea abrupte", sau mai mult commonly ca "porumb abrupte buturi alcoolice ", uneori

menionate n acest document ca" CSL ". Corn steep liquor contains dissolved minerals, carbohydrates, and corn proteins, as well as organic acids (particularly lactic acid) and modified corn proteins (amino acids and polypeptides) which result from the enzymatic activity associated with the one or more natural fermentations which take place during the corn steeping process. Lichior de porumb abrupte conine minerale dizolvate, carbohidrai, proteine i de porumb, precum si acizi organici (acid lactic n special) i proteine de porumb modificate (aminoacizi i polipeptide), care decurg din activitatea enzimatice asociate cu unul sau mai multe tipuri de fermentaie natural, care s aib loc n timpul procesului de porumb nmuiere. The composition of corn steep liquor varies with the type of corn, pH of the steeping liquid (usually 3.8-4.5), the content of the water used in the steeping process (it is often recycled from other steps of the corn-wet-milling process), steeping time and temperature. Compoziia de porumb lichior abrupte variaz n funcie de tipul de porumb, pH-ul lichidului de nmuiere (de obicei 3.8-4.5), coninutul de ap utilizate n procesul de nmuiere (este de multe ori reciclat de la celelalte etape ale porumb-ud-frezat procesului), timpul de nmuiere i de temperatur. Depending on the steeping conditions, which can vary greatly from time to time in any given plant, corn steep liquor can have significant variations in relative concentrations of corn extracts and fermentation products of corn extracts. n funcie de condiiile de nmuiere, care poate varia foarte mult din timp n timp, n orice instalaie de dat, lichior de porumb abrupte poate avea variaii semnificative n concentraiile relative de extracte de porumb i produse de fermentare a extraselor de porumb. Such compositional variations can have marked effects on the physical characteristics of individual lots of corn steep liquor. Astfel de variaii de compoziie pot avea efecte care sunt marcate pe caracteristicile fizice ale loturi individuale de rachiu de porumb abrupte. Corn steep liquor finds a wide variety of uses. Porumb de buturi abrupte gsete o gam larg de utilizri. Primarily it is utilized either alone or in combination with other products or by-products of the corn-wet-milling process as a binder and a valuable nutritive component in animal feeds and as a nutrient medium for commercial fermentations (particularly for antibiotic production). Primar este utilizat fie singur, fie n asociere cu alte produse sau subproduse de porumb-ud-freza proces ca un liant i o component de valoare nutritiv n furaje pentru animale i ca un mediu nutritiv pentru fermentaie comerciale (n special pentru producia de antibiotice). An industry-wide problem associated with the production and handling of corn steep liquor and liquid CSL-containing compositions is the tendency of some lots of CSL to "liver" or gel in the CSL evaporators as well as in storage, mixing, and transport tanks. O problem la nivel de industrie asociate cu producerea i manipularea lichior de porumb abrupte i CSL lichid-compoziii care conin este tendina unor loturi de CSL la "hepatice" sau gel, n boilere CSL, precum i de depozitare, de amestecare, i cisterne de transport . When this condition occurs, the CSL or CLS-containing liquid composition is difficult, if not impossible, to pump or otherwise handle. Atunci cnd aceast condiie apare, CSL sau CLS-compoziie care conin lichid este dificil, dac nu chiar imposibil, de a pompa sau n alt mod mner. This results in loss of employee time and loss of facilities and equipment use for both the CSL producer and CSL product customers. Aceasta duce la o pierdere de timp angajat i pierderea de faciliti i de a folosi echipamente pentru

ambele productor CSL i clienii de produs CSL. In instances where the livered CSL has gelled, sometimes to almost a rubber-like consistency, the only practical solution to the problem is the manual/mechanical disposal or removal of the gel. n cazurile n care CSL nger a gel, obinut, uneori, la aproape un cauciuc consisten asemntoare, singura soluie practic pentru problema este de manual / eliminare mecanice sau de tergere a gelului. Several solutions to the "livering" are related "scaling" problems which periodically attend the evaporation of light steep water and the storage and transport of corn steep liquor and liquid CSL-containing compositions have been proposed in the art. Mai multe soluii pentru a livering "" sunt legate de "scalarea", probleme care periodic asista la evaporarea apei lumina abrupte, precum i depozitarea i transportul de porumb lichior abrupte i CSL lichid cu coninut de compozitii au fost propuse la art. US Pat. US Pat. No. 2,515,157, issued Dec. 8, 1945 describes and claims a treatment of corn steep water with a source of aluminum ions which serves as a precipitant for the naturally occurring phytate in the corn steep water. No. 2515157, eliberat 8 decembrie 1945 descrie i cererile de un tratament de porumb de ap abrupte cu o surs de ioni de aluminiu, care servete drept precipitant pentru fitat gsesc n mod natural de ap de porumb abrupte. Precipitation of the phytates as the insoluble aluminum salts in accordance with the described process is said to provide a concentrated liquid nutrient for penicillinproducing molds which does not deposit an objectionable sludge during shipment or storage. Precipitarea phytates ca srurile de aluminiu insolubil n conformitate cu procesul descris se spune de a oferi un nutrient concentrat lichid pentru penicilin productoare de matrie, care nu depun un nmol nepermis timpul transportului sau depozitrii. US Pat. US Pat. No. 1,918,812 likewise acknowleges that "the boiling of the steep water is attended by an objectionable fouling and scaling of the interior of the evaporators. Apparently two kinds of scale are formed. One is called `rubber` scale and consists largely of protein material, with which other materials in suspension may be aggregated. The other is called `hard` scale and consists largely of mineral salts. Actually the deposits may be made up of both types of scale in intimate mixture . . . . " That patent discloses that the problem can be overcome by heating the steep water before evaporation to a temperature between 95 F. and 140 F. until the scale forming substances are converted by naturally occurring biochemical activity into non-scale forming substances and thereafter evaporating the steep water. No. 1,918,812, de asemenea, acknowleges c "de fierbere a apei abrupte este deservita de un miros neplcut i scalarea din interiorul evaporatoare. Se pare c dou tipuri de scar sunt formate. Una dintre ele este numita" de cauciuc "la scar i const n mare parte de materiale de proteine, cu care a altor materiale n suspensie pot fi cumulate. alt este numita "dur" la scar i const n mare msur, de saruri minerale. fapt depozitele poate fi format din ambele tipuri de scar n amestec intim.... "Aceasta brevet n eviden faptul c problem poate fi depit prin nclzirea apei abrupte, nainte de a evaporare la o temperatur cuprins ntre 95 F. i 140 F., pn la scar care formeaz substane sunt transformate de natural de activitate biochimice n substane care formeaz scar i, ulterior, evaporarea apei abrupte.

US Pat. US Pat. No. 2,298,623 describes a method for reducing scale forming tendencies of concentrated corn steep water which method comprises heating the steep water prior to concentration under pressure to temperatures ranging between 225 F. and 300 F. No. 2298623 descrie o metod de reducere la scar care fac tendine de ap de porumb concentrat abrupte, care cuprinde metoda de incalzire a apei abrupte, nainte de a concentrare sub presiune la temperaturi cuprinse ntre 225 F. i 300 F. SUMMARY OF THE INVENTION REZUMAT de invenie It has been found that the livering or gelling of corn steep liquor (CSL) or liquid CSLcontaining compositions can be reversed or prevented by the addition of an effective amount of a calcium (Ca++) complexing agent. Sa constatat c livering sau de coagulare buturilor alcoolice de porumb abrupte (CSL) sau CSL lichid-compoziii care conin poate fi anulat sau prevenit prin adugarea unei cantiti efective a unei calciu (Ca + +) agentului de complexare. The Ca++ complexing agent can be added to corn steep water before or after its concentration to the solids level characteristic of corn steep liquor. Ca + + agentului de complexare poate fi adugat la apa de porumb abrupte, nainte sau dup concentraia sa de a caracteristic solide nivelul de porumb lichior abrupte. Adjustment of the pH of corn steep liquor to below about 3.8 before, during or subsequent to the addition of the complexing agent is a preferred embodiment of the present invention. Ajustarea pH-ului de porumb lichior abrupte de mai jos pentru a aproximativ 3,8 nainte, n timpul sau dup adugarea a agentului de complexare este o ntruchipare preferat de inventie prezent. When gelled corn steep liquor is treated in accordance with the preferred embodiment of the present invention, its pH can be adjusted back to levels characteristic of untreated corn steep liquor (3.8-4.5) to provide corn steep liquor which has no tendency to gel on standing. Cnd lichior gelled de porumb abrupte, sunt tratate n conformitate cu ntruchiparea preferat de invenie prezent, pH-ul acestora poate fi ajustat la un nivel caracteristic de rachiu de porumb netratate abrupte (3.8-4.5), pentru a oferi buturi alcoolice de porumb abrupte, care nu are tendina de a gel pe picioare . DETAILED DESCRIPTION OF INVENTION DESCRIERE DETALIAT de invenie This invention is directed to a method for treating corn steep liquor either to prevent its gelling or "livering" if it has a tendency to do so, or to reverse the gelling, that is, to significantly lower the viscosity or "fluidize" corn steep liquor which has gelled. Aceasta inventie este direcionat ctre o metod de tratare a alcool porumb abrupte, fie pentru a preveni coagulare sau "livering", n cazul n care are tendina de a face acest lucru, sau de a inversa de coagulare, care este, pentru a reduce n mod semnificativ de vscozitate sau "fluidizeze" de porumb abrupte lichior care a gelled. The present method is carried out by the addition of an effective amount of a source of a calcium (Ca++) complexing agent to corn steep liquor, or to a liquid composition containing CSL. Metoda prezent se realizeaz prin adugarea de o sum efectiv de o

surs de calciu (Ca + +) agentului de complexare a buturilor alcoolice porumb abrupte, sau la o compoziie care conin lichide CSL. The term "calcium complexing agent" as it is used in defining the present invention refers to a source of multivalent anions which can react or complex with or otherwise sequester calcium ions in the corn steep liquor rendering such calcium ions unavailable or less available for interaction with anions or compounds bearing anionic functional groups occurring naturally in the corn steep liquor as a result of the corn steeping procedure and the attendant fermentation processes. Termenul "de calciu agentului de complexare", aa cum este folosit n definirea inventie prezent se refer la o surs de anioni multivalent, care pot reaciona sau complexe, cu sau n alt mod sechestru ionii de calciu n lichior de porumb abrupt de redare ionii de calciu, cum ar indisponibil sau mai puin disponibile pentru interaciunea cu anionii sau compui care poart grupe funcionale anionici care apar n mod natural n lichior de porumb abrupte, ca urmare a procedurii de porumb de nmuiere i procesele de insotitor de fermentaie. Suitable calcium complexing anions are those multivalent anions which combine with calcium ions in the corn steep liquor to form insoluble calcium salts or those anions which form soluble calcium salts or complexes in which the calcium ions are preferentially sequestered vis-a-vis naturally occurring compounds bearing anionic functional groups. Anionii de calciu sunt cele adecvate de complexare anioni multivalent care combin cu ionii de calciu n lichior de porumb abrupt, pentru a forma sruri de calciu insolubile sau cele care fac anioni sruri de calciu solubile sau complexe, n care ionii de calciu sunt sechestrate de preferin, visa-vis de natural compui care poart anionici grupe funcionale. Examples of anions which form substantially insoluble salts with available calcium ions are the phytate, citrate, oxalate, phosphate, metaphosphate, polyphospate and phosphite anions. Exemple de anioni care formeaz n mod substanial srurile insolubile cu ionii de calciu disponibile sunt fitat, citrat, oxalat, fosfat, metaphosphate, polyphospate i de anioni fosfit. Sources of Ca++ complexing anions are the conjugate acids of said anions or any soluble or partially soluble salt of said conjugate acids. Surse de Ca + + anioni de complexare sunt acizi conjugata a spus anioni sau orice solubile sau parial de sare solubil de a spus acizi conjugat. The term conjugate acids as used in the art and in the description of the present invention refer to the anions or acids formed by the combination of an anion and one or more hydrogen ions. Acizi termen conjugat, utilizat n art i n descrierea inventiei prezent se refer la anioni sau acizi format prin combinarea unui anionic i ionii de unul sau mai multe pe baz de hidrogen. For example, the conjugate acids of the phosphate anion, PO 4 De exemplu, acizi conjugatul de anioni fosfat, PO 4 are HPO 4 sunt HPO 4 =, H 2 PO 4 - and H 3 PO 4 . =, H 2 PO 4 - i H 3 PO 4. Exemplary of calcium ion sequestering or complexing agents which do not form insoluble salts but instead preferentially react with or complex calcium ions in solution are ethylenediamine tetra acetic acid (EDTA), ethylene glycol-bis-(beta-aminoethyl ether) N,N'-tetraacetic acid (EGTA), nitrilotriacetic acid (NTA) and salts thereof. Exemplar a secvestrani de ioni de calciu sau de ageni de complexare care nu fac srurile insolubile, dar n loc de preferin, reacioneaz cu ionii de calciu sau de complexe sunt ntr-o soluie de acid acetic etilendiamin tetra (EDTA), etilen-glicol-bis-

(beta-eter cloroetildiizopropilamoniu) N, N'- Acid tetraacetic (EGTA), acid nitrilotriacetic (ANT) i srurile acestuia. Preferred Ca++ complexing agents for the present process are the conjugate acids of Ca+ + complexing anions and the ammonium or alkali metal salts of such conjugate acids. Preferat Ca + + ageni de complexare pentru procesul de prezente sunt acizi conjugatul de Ca + + anionii de complexare i de amoniu sau sruri alcaline de metal de astfel de acizi conjugat. Illustrative of the preferred sources of calcium complexing anions for use in the present process are phytic acid, sodium phytate, citric acid, sodium monobasic citrate, oxalic acid, sodium oxalate, phosphoric acid, potassium monohydrogen phosphate, sodium metaphosphate, sodium dihydrogen phosphate, ammonium dihydrogen phosphate, EDTA, EDTA disodium salt, EGTA, EGTA disodium salt, EGTA dipotassium salt and nitrilotriacetic acid potassium salt. Anionii ilustrative pentru surse de preferat de calciu de complexare pentru a fi utilizate n procesul de prezente sunt: acid phytic, fitat de sodiu, acid citric, citrat de sodiu monobazic, acid oxalic, oxalat de sodiu, acid fosforic, fosfat de potasiu monohydrogen, metaphosphate de sodiu, dihidrogenofosfat de sodiu, amoniu dihidrogen fosfat, EDTA, sare de disodiu EDTA, EGTA, EGTA sare disodic, EGTA sare de dipotasiu i nitrilotriacetic sare de acid de potasiu. The phosphate anion is a preferred calcium complexing anion for the present process; phosphoric acid is the most preferred source of that complexing anion. Anioni fosfat de calciu este un preferat de anioni de complexare pentru procesul de prezent; acid fosforic este sursa cea mai preferat de pe care anioni de complexare. The Ca++ complexing agent can be added to corn steep water before or after its concentration by evaporation to the solids levels characteristic of corn steep liquor, or it can be added to liquid compositions containing corn steep liquor which compositions also may have some tendency to gel. Ca + + agentului de complexare poate fi adugat la apa de porumb abrupte, nainte sau dup concentraia acesteia prin evaporare la nivelurile solide caracteristic a buturilor alcoolice porumb abrupte, sau poate fi adugat la compoziii lichide cu coninut de alcool de porumb abrupte, care compoziii, de asemenea, poate avea unele tendina de gel. As mentioned hereinabove, corn steep liquor is often combined or blended with other nutrient-containing products or by-products from the corn wet-milling process, for use in animal feed applications and in nutrient media for commercial fermentations. Aa cum am menionat hereinabove, lichior de porumb abrupt este adesea combinat sau n amestec cu ali nutrieni produselor care conin sau subproduse de la porumb umed-frezat proces, pentru utilizarea n aplicaii hrana animalelor i n mass-media nutrienilor pentru fermentaie comerciale. For simplicity in describing the present invention such liquid products containing corn steep liquor are referred to herein as "liquid CSL compositions." Pentru simplitate, n care descriu invenia prezenta unor astfel de produse lichide care conin porumb lichior abrupte sunt menionate n acest document ca "compozitii lichid CSL." The livering or gelling of such liquid CSL compositions can be prevented in accordance with the present process by either treating the corn steep liquor with a source of calcium complexing anion before its blending with other products, or the source of complexing anion can be added directly to the liquid CSL compositions. Livering sau de coagulare unor astfel de compoziii lichide CSL poate fi prevenit, n conformitate cu procesul de prezenta fie prin tratarea lichior de

porumb abrupte, cu o surs de calciu anionului de complexare, nainte de combinare cu alte produse, sau sursa de anioni de complexare poate fi adaugat direct la compoziii lichide CSL. The source of Ca++ complexing anions can be added as a salt or acid, or it can be added as a solution of the salt or acid. Surs de Ca + + anioni de complexare poate fi adugat ca o sare sau acid, sau poate fi adugat ca o soluie de sare sau acid. Since it is desirable to maintain typical solids levels for corn steep liquor, it is preferred that water or other dilutants added in connection with the present method be kept to a minimum. Deoarece este de dorit s se menin niveluri solide tipice pentru porumb buturi alcoolice abrupte, este de preferat ca apa sau alte dilutants adugat n legtur cu metoda prezent s fie reduse la minimum. This is true whether the anion source is added before or after the evaporation of the corn steep water in the preparation of corn steep liquor or to liquid CSL compositions. Acest lucru este adevrat dac sursa anioni se adaug, nainte sau dup evaporarea apei de porumb abrupt n pregtirea de porumb lichior abrupte sau de a compoziii lichide CSL. The amount of complexing agent required to prevent or reverse the gelling of corn steep liquor or liquid CSL compositions depends to some extent on the solids level of the corn steep liquor, the composition of those solids, and concommitantly, the viscosity levels observed for the CSL or liquid CSL composition. Suma agentului de complexare necesare pentru a preveni sau a inversa de coagulare de porumb lichior abrupte sau lichid compoziii CSL depinde ntr-o oarecare msur la nivelul solide de lichior de porumb abrupte, componena acestor substane solide, precum i concommitantly, nivelurile de vscozitate observate pentru CSL sau compoziia lichid CSL. Generally about 1% to about 15% by weight (based on weight of corn steep liquor) of the calcium complexing agent is effective to reverse or prevent corn steep liquor gelation. n general, aproximativ 1% la aproximativ 15% din greutate (n funcie de greutatea de porumb lichior abrupte) din calciu agentului de complexare este eficient de a inversa sau de a preveni de porumb congelare abrupt buturi alcoolice. When the process of the present invention is utilized to break the gel (reverse the gelling) and decrease the viscosity of the gelled corn steep liquor, the inventors have found that over that described weight range (1%-15% by weight) of the calcium complexing agent, the decrease in viscosity is often proportionate to the amount of added complexing anion. n cazul n care procesul de inventie de fa este utilizat pentru a sparge gel (revers de coagulare), precum i scderea vscozitatea lichior de porumb gelled abrupte, inventatorii au descoperit c mai mult de cea descris n greutate intervalul (1% -15% din greutate) din agent de calciu de complexare, scderea n vscozitatea este adesea proporional cu valoarea adugat de anioni de complexare. Generally about 3% to 12% by weight of a Ca++ complexing agent (based on the weight of corn steep liquor) added to the corn steep liquor or to a liquid product containing corn steep liquor effects and maintains workable viscosities in corn steep liquor having a tendency to gel. n general, circa 3% la 12% din greutate o Ca + + agentului de complexare (n funcie de greutatea de porumb lichior abrupte) adugat la bautura porumb abrupte sau de la un produs lichid care conine porumb efecte abrupte, lichior i menine viscoziti funcional n porumb alcool abrupte care au o tendina de a gel.

As mentioned above, conjugate acids of Ca++ complexing anions are particularly preferred and effective for reducing the viscosity of gelled corn steep liquor as well as preventing gelation of corn steep liquor having some tendency to gel. Dup cum sa menionat mai sus, acizi conjugatul de Ca + + anioni de complexare sunt deosebit de preferat i eficiente pentru reducerea vscozitii buturilor alcoolice de porumb gelled abrupte, precum i pentru prevenirea congelare de rachiu de porumb abrupte unele avnd tendina de gel. With the addition of such acids, the pH of the treated corn steep liquor is lowered to below the typical pH levels of about 3.8 to 4.5. Cu un adaos de acizi asemenea, pH-ul de lichior de porumb tratate abrupte este cobort mai jos de nivelul pHul tipic de aproximativ 3.8 - 4.5. The superior effectiveness of the addition of a Ca++ complexing anion conjugate acid to corn steep liquor or liquid CSL compositions in accordance with this invention can be duplicated by adjusting the pH of the corn steep liquor or a liquid CSL composition with, for example, a mineral acid (other than a conjugate acid of a Ca++ complexing anion) to below about 3.8 prior to, during, or after the addition of a non-acid source of complexing anion. Eficacitatea superioara a adugarea unui Ca + + de acid anionic de complexare conjugat la porumb bautura abrupte sau lichide compoziii CSL, n conformitate cu aceast invenie poate fi duplicat prin ajustarea pH-ul de lichior de porumb abrupte sau o compoziie CSL cu lichid, de exemplu, un mineral de acid (alta dect un acid conjugat al unui Ca + + anioni de complexare) la aproximativ 3,8 de mai jos nainte, n timpul, sau dup adugarea de un non-surs de acid de anioni de complexare. For example, a livered CSL sample can be acidified to a pH of about 2.8 with hydrochloric acid and then treated with sodium trimetaphosphate to reduce the viscosity of the CSL to a water-like fluidity. De exemplu, un eantion nger CSL poate fi acidulat la un pH de aproximativ 2,8 cu acid clorhidric i apoi tratate cu trimetaphosphate de sodiu pentru a reduce vscozitatea CSL la o ap-ca fluiditate. The lowering of the pH of the corn steep liquor appears to enhance the effect of the Ca++ complexing anion in reducing the viscosity of gelled corn steep liquor. Scdere a pH-ului de lichior de porumb abrupt pare a spori efectul de Ca + + anioni de complexare n reducerea vscozitatea buturilor alcoolice de porumb gelled abrupte. Thus, it is preferred in the process of the present invention to lower the pH of the corn steep liquor to a value of about 1.5 to about 3.5 before, during or after the addition of the source of complexing polyvalent anion. Astfel, este de preferat n procesul de invenie s prezinte mai mici pH-ul a buturilor alcoolice porumb abrupt la o valoare de aproximativ 1,5 pn la aproximativ 3,5 nainte, n timpul sau dup adugarea sursei de anioni de complexare polivalent. Of course, when a conjugate acid of a complexing anion is used as the source of the complexing anion, the pH of the corn steep liquor or liquid CSL composition is lowered directly as a result of the addition of the acid. Desigur, atunci cnd un acid conjugat al unui anioni de complexare este folosit ca surs de anioni de complexare, pH-ul de lichior de porumb abrupte sau compoziia lichid CSL este cobort direct ca rezultat al adugarea de acid. Following treatment of corn steep liquor or a liquid CSL composition, in accordance with the present process and typically after agitation for about 1-60 minutes, the pH of the CSL can be adjusted with base to about 3.8-4.5, the pH levels characteristic of corn steep liquor. n urma tratamentului de porumb lichior abrupte sau o compoziie lichid CSL, n conformitate cu procesul de prezent i de obicei dup agitare timp de aproximativ 1-60

minute, pH-ul CSL pot fi ajustate cu baza la aproximativ 3.8-4.5, nivelul pH-ului caracteristice ale lichior de porumb abrupte. Adjustment of pH of the de-livered CSL back to the 3.8-4.5 range is accompanied by no significant increase in viscosity. Ajustarea pH-ul de-CSL nger napoi la intervalul 3.8-4.5 este nsoit de nici o cretere semnificativ n viscozitate. The following examples are illustrative of the method of the present invention. Urmtoarele exemple sunt ilustrative a metodei de inventie prezent. They are not to be considered as a limitation on the scope of the claimed invention. Acestea nu sunt considerate ca o limitare a domeniului de aplicare a invenia revendicat. EXAMPLE I EXEMPLU I To a 50 ml sample of livered corn steep liquor (pH about 4.3) was added with stirring 2 ml of 85% phosphoric acid. ntr-o prob de 50 ml de rachiu de porumb nger abrupte (pH-ul aproximativ 4.3) a fost adaugat cu agitare 2 ml de 85% acid fosforic. Immediately the viscosity of the corn steep liquor was reduced to that of a pourable liquid which did not gel on standing, even after adjustment of the pH of the phosphoric acid-treated corn steep liquor to 4.3 with 50% caustic solution. Imediat vscozitate de lichior de porumb abrupt a fost redus la cel al unui lichid pourable care nu gel pe picioare, chiar i dup ajustarea pH-ul acid fosforic tratate cu lichior de porumb abrupte, la 4,3 cu 50% soluie caustic. EXAMPLE II EXEMPLU II Three 50 ml samples of livered corn steep liquor were obtained. Trei 50 de probe ml de lichior de porumb nger abrupte au fost obinute. To one sample was added approximately 0.5 grams of sodium phytate. Pentru un eantion a fost adugat de aproximativ 0,5 grame de fitat de sodiu. To the second was added approximately 0.5 grams of sodium hexametaphosphate. Pentru a doua a fost adugat de aproximativ 0,5 grame de Hexametafosfat de sodiu. The third 50 ml sample served as the control. Cea de a treia prob 50 ml, a servit drept de control. Each of the samples were stirred and warmed in a microwave oven for ten seconds to about 50 C. The viscosity of the livered CSL was reduced initially in each case. Fiecare dintre probe au fost agitat i nclzite ntr-un cuptor cu microunde timp de zece secunde pn la aproximativ 50 C. Viscozitatea CSL nger a fost redus iniial n fiecare caz. The viscosity reduction in the sodium hexametaphosphate-treated sample was most pronounced. De reducere a vscozitii n Hexametafosfat de sodiu tratai cu proba a fost cea mai pronunat. The samples were then allowed to stand overnight at ambient temperature. Probele au fost apoi permis s stea peste noapte la temperatura ambiant. The control sample solidified to a nonpourable gel. Eantionului de control solidificat la un gel nonpourable. The samples containing sodium phytate and sodium hexametaphosphate, however, remained pourable. Probele care conin fitat de sodiu i Hexametafosfat de sodiu, cu toate acestea, a rmas pourable. EXAMPLE III EXEMPLU III

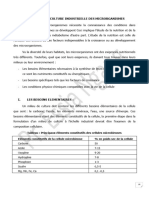

Two 50 ml portions of livered corn steep liquor were obtained. Dou poriuni de 50 ml de lichior de porumb nger abrupte au fost obinute. To one portion was added about 2 grams of sodium monohydrogen phosphate with stirring. Pentru o parte a fost adaugat in aproximativ 2 grame de fosfat de sodiu monohydrogen cu agitare. To the other was added 2 ml of phosphoric acid with stirring. Pentru celelalte a fost adaugat in 2 ml de acid fosforic cu agitare. Dramatic viscosity reduction was noted in each of the samples. Reducere dramatic vscozitate a fost observat n fiecare dintre probe. The phosphoric acid-treated sample assumed a water-like consistency. Acid fosforic, tratate a asumat un eantion de ap consisten asemntoare. EXAMPLE IV EXEMPLU IV Individual samples of livered corn steep liquor having a Brookfield viscosity of 35,000 cps at 115 F. were treated with varying amounts of 85% phosphoric acid. Eantioane individuale de lichior de porumb nger abrupte, cu o vscozitate Brookfield, de 35,000 cps la 115 F. au fost tratai cu cantiti variabile de 85% acid fosforic. The results are presented in Table I. Adjustment of the pH after phosphoric acid addition to about 4.1 with 50% caustic resulted in no significant increase in viscosity. Rezultatele sunt prezentate n Tabelul I. Ajustarea pH-ului dup adugarea de acid fosforic la aproximativ 4.1 cu 50% caustic a dus la nici o cretere semnificativ n viscozitate. TABLE I Tabelul I ______________________________________ ______________________________________ Viscosities Obtained on CSL Treated With 85% Phosphoric Acid % Phosphoric Acid pH Brookfield Viscosity (by wt. based on wt. of CSL) (after acid) After acid 115 F. Viscoziti obinut la CSL tratat cu 85% fosforic% acid fosforic Acid pH-ul Vascozitate Brookfield (de greutate. Bazat pe greutate. De CSL) (dup acid) Dup Acid 115 F. ______________________________________ ______________________________________ 2.66 3.86 15,600 2,66 3,86 15.600 5.33 3.6 9,000 5,33 3,6 9.000 10.66 2.8 725 10,66 2,8 725 ______________________________________ ___

Вам также может понравиться

- Acide PhosphoriqueДокумент6 страницAcide PhosphoriqueChaimaa WajidОценок пока нет

- Hal 00929067Документ12 страницHal 00929067AKIR HamzaОценок пока нет

- CXS 282fДокумент4 страницыCXS 282fDINA MPOUPE GuillaumeОценок пока нет

- Chapitre 3 - LA CULTURE INDUSTRIELLE DES MICRORGANISMESДокумент9 страницChapitre 3 - LA CULTURE INDUSTRIELLE DES MICRORGANISMESjeanmarctang76Оценок пока нет

- 4.1.1-Les Mésures Préventives Contre Les Attaques Phagiques - MarocДокумент37 страниц4.1.1-Les Mésures Préventives Contre Les Attaques Phagiques - MarocTayeb BouazizОценок пока нет

- Formation Pratique en Boisson Et BiereДокумент21 страницаFormation Pratique en Boisson Et BiereFranck KenduОценок пока нет

- Bouraoui TCM 3 Milieux de CultureДокумент5 страницBouraoui TCM 3 Milieux de CultureAya BoucharebОценок пока нет

- OuldsadellahNawelRehabFaziaetAmirYoucef PDFДокумент78 страницOuldsadellahNawelRehabFaziaetAmirYoucef PDFAbdouli RoukayaОценок пока нет

- Acide PhosphoriqueДокумент10 страницAcide PhosphoriqueSimo HoussaineОценок пока нет

- Rapport de StageДокумент31 страницаRapport de StageChaimaa WajidОценок пока нет

- Chapitre IДокумент20 страницChapitre IGedion DouaОценок пока нет

- 222Документ5 страниц222Timo ShmittОценок пока нет

- Milieux CultureДокумент47 страницMilieux Cultureadamo2Оценок пока нет

- Rapport OCPДокумент22 страницыRapport OCPMc YahyaОценок пока нет

- Rapport-Descriptif-De - IMACID PETROL-Jorf-LasfarVrДокумент44 страницыRapport-Descriptif-De - IMACID PETROL-Jorf-LasfarVrSoufiane El AoumarieОценок пока нет

- Caractères Physico-Chimiques, Microbiologiques Et Nutritionnels PDFДокумент21 страницаCaractères Physico-Chimiques, Microbiologiques Et Nutritionnels PDFChantal D'HulsterОценок пока нет

- CXS 207fkikkkДокумент6 страницCXS 207fkikkkFouratZarkounaОценок пока нет

- Rapport OCP Groupe AsservissementsДокумент34 страницыRapport OCP Groupe AsservissementsRania Sab89% (9)

- TD06 11Документ78 страницTD06 11Mohammed BouamОценок пока нет

- Acide SucciniqueДокумент6 страницAcide SucciniqueTasnim Tas NimОценок пока нет

- View On Whey PermeatДокумент30 страницView On Whey PermeatOmrani NouhaОценок пока нет

- Procédé PhosphoriqueДокумент22 страницыProcédé PhosphoriqueAbaghough Brahim0% (1)

- Rapport de HROURA Mourad - X3070 - New1Документ46 страницRapport de HROURA Mourad - X3070 - New1Abderrahim BelmJouJОценок пока нет

- Rapport Ali SIDI BABAДокумент20 страницRapport Ali SIDI BABAEl Aouali AymanОценок пока нет

- EtudierДокумент8 страницEtudierJire Taye Challa0% (2)

- Brapport de Stage de Fin D'etudesДокумент69 страницBrapport de Stage de Fin D'etudesELOTHMANI9350% (2)

- Milieux de Culture BacДокумент7 страницMilieux de Culture Bacagag.salahОценок пока нет

- TP MicrobiologieДокумент28 страницTP MicrobiologieAbdèl IlahОценок пока нет

- Cours N°2 Acide LactiqueДокумент16 страницCours N°2 Acide LactiqueFella lilia TalebОценок пока нет

- Projet NourДокумент7 страницProjet NourOussama BouhriaОценок пока нет

- Description Du Procede de Fabrication D'acide PhosphoriqueДокумент32 страницыDescription Du Procede de Fabrication D'acide PhosphoriqueMOHAMED EL BACHIR BERRIOUAОценок пока нет

- Fabrication Fromage Saint-NectaireДокумент8 страницFabrication Fromage Saint-NectairesouheilОценок пока нет

- Microbiologie IndustrielleДокумент59 страницMicrobiologie IndustrielleImane RahОценок пока нет

- Rapport Stage OCPДокумент38 страницRapport Stage OCPIhsan AfriadОценок пока нет

- Stabilité de La Vitamine en Solution, Extraction de L'amidon de Mais, Qualification Des MaterielsДокумент4 страницыStabilité de La Vitamine en Solution, Extraction de L'amidon de Mais, Qualification Des MaterielsPhilippe MukumbayiОценок пока нет

- PHAGES Dans Le LaitДокумент20 страницPHAGES Dans Le Laitcortizone31Оценок пока нет

- Atelier Phosphorique Production Dacide PhoisphoriqueДокумент54 страницыAtelier Phosphorique Production Dacide Phoisphoriqueintissar loughlaimiОценок пока нет

- Norme Codex Pour Les Concentrés de Tomate Traités FДокумент6 страницNorme Codex Pour Les Concentrés de Tomate Traités FstrapolОценок пока нет

- Rapport de Stage MouradiДокумент43 страницыRapport de Stage MouradiAbderrahim BelmJouJ100% (1)

- Processus de Fabrication de La Bire - A149Документ4 страницыProcessus de Fabrication de La Bire - A149Matt BerryОценок пока нет

- Fermentations Industrielles S1Документ27 страницFermentations Industrielles S1Mourad JridiОценок пока нет

- BiotechnologieДокумент18 страницBiotechnologieYounesElBekkaoui0% (1)

- 209Документ11 страниц209Fousseyni TRAOREОценок пока нет

- Fabrication de L'acide Phosphorique 0Документ13 страницFabrication de L'acide Phosphorique 0lina ferjaouiОценок пока нет

- Rapport de Stage LP-MécatroniqueДокумент53 страницыRapport de Stage LP-MécatroniqueIhsan Afriad0% (1)

- EP1517856B1Документ16 страницEP1517856B1FerdawsОценок пока нет

- Dokumen - Tips Rapport de Stage Fatima ZahraДокумент58 страницDokumen - Tips Rapport de Stage Fatima Zahrarajid oumaimaОценок пока нет

- Emd 2016Документ2 страницыEmd 2016Djihane RamdaniОценок пока нет

- Process +présentation SociétéДокумент14 страницProcess +présentation SociétéGhaith SoudaniОценок пока нет

- Melieu de CultureДокумент13 страницMelieu de Cultureni hadОценок пока нет

- Valorisation Des Rebuts de Dattes Par La Production de La Levure Boulangère de L'alcool Et Du VinaigreДокумент9 страницValorisation Des Rebuts de Dattes Par La Production de La Levure Boulangère de L'alcool Et Du VinaigreJorge Andres Uchima MartinОценок пока нет

- PFEДокумент8 страницPFEGOUAREF SAMIRОценок пока нет

- Rapport de Stage Effectué 1er AnneeДокумент22 страницыRapport de Stage Effectué 1er AnneeAyoub ZnОценок пока нет

- CHP IДокумент12 страницCHP IAmmar BachirОценок пока нет

- Rapport de StageДокумент52 страницыRapport de StageAbderrahim BelmJouJОценок пока нет

- Utilisation Du Produit Marchand Calciné Pour L'obtention Des Superphosphates Simples (SSP)Документ60 страницUtilisation Du Produit Marchand Calciné Pour L'obtention Des Superphosphates Simples (SSP)meddah.mohamed.dzОценок пока нет

- Fabrication D'acide PhosphoriqueДокумент18 страницFabrication D'acide PhosphoriqueAbbassi100% (1)

- Diana Ghat T AsДокумент47 страницDiana Ghat T AskhoolimovskyОценок пока нет

- Rapport de Stage Ocp Soukaina Raki (Enregistré Automatiquement) (Enregistré Automatiquement)Документ26 страницRapport de Stage Ocp Soukaina Raki (Enregistré Automatiquement) (Enregistré Automatiquement)Ihsan AfriadОценок пока нет

- Corrige Serie5Документ4 страницыCorrige Serie5Chef FatimaОценок пока нет

- Programme Maths cm2Документ1 страницаProgramme Maths cm2gorguy100% (1)

- 5-Focales-Episode-2-Planification Et RégulationДокумент42 страницы5-Focales-Episode-2-Planification Et RégulationTaffyd MaertinsОценок пока нет

- QP1C General 1 PDFДокумент5 страницQP1C General 1 PDFSamson KlouganОценок пока нет

- Serveur D'impression Sous Windows 2003Документ6 страницServeur D'impression Sous Windows 2003Issam BammouОценок пока нет

- Manuel C2Документ140 страницManuel C2Daniel AndriamananaОценок пока нет

- Examen Blanc Physique Chimie Bac DДокумент4 страницыExamen Blanc Physique Chimie Bac Dkouassi hermann ulrich koffi100% (1)

- Exercice 3Документ1 страницаExercice 3test lili100% (1)

- ProjetДокумент4 страницыProjetEya AwadiОценок пока нет

- 2M120 TD 2016 ch1 Codes CorrecteursДокумент2 страницы2M120 TD 2016 ch1 Codes CorrecteurskokiОценок пока нет

- Laboratoire Biolab Bamako - Recherche GoogleДокумент1 страницаLaboratoire Biolab Bamako - Recherche GoogleAlou CoulibalyОценок пока нет

- Les Corriges Essai District Kanel Jan 2024 - 061004Документ8 страницLes Corriges Essai District Kanel Jan 2024 - 061004souleymanehousnaОценок пока нет

- Les Approches Managériales Basées Sur Les Parties PrenantesДокумент4 страницыLes Approches Managériales Basées Sur Les Parties PrenantesNohaila BencherquiОценок пока нет

- Phrases À Remettre Dans L'ordreДокумент9 страницPhrases À Remettre Dans L'ordreSylvie DinisОценок пока нет

- RIB CopieДокумент1 страницаRIB CopieAbdoulaye CisséОценок пока нет

- ContexteДокумент2 страницыContextehibaouafi502Оценок пока нет

- Chapitre 3 Ressources Réserves PlanificationДокумент10 страницChapitre 3 Ressources Réserves PlanificationAdlaneОценок пока нет

- Laddition Des Nombres Entiers CM2Документ8 страницLaddition Des Nombres Entiers CM2chantal.aboujaoudehОценок пока нет

- MicrobiologieДокумент5 страницMicrobiologieInes FirasОценок пока нет

- DRAFT - Cours OCO - Part1Документ32 страницыDRAFT - Cours OCO - Part1Khennoune WissamОценок пока нет

- World of Warcraft - Wrath of The Lich King - Arthas, My SonДокумент4 страницыWorld of Warcraft - Wrath of The Lich King - Arthas, My SonAdrian Angel LagrecaОценок пока нет

- 1 - Cours2 Hydraulique Et Pneumatique (2éme Année Électromécanique)Документ16 страниц1 - Cours2 Hydraulique Et Pneumatique (2éme Année Électromécanique)Mohamed Hechmi JERIDIОценок пока нет

- EKIP360 PrestationsTarifications LFRДокумент30 страницEKIP360 PrestationsTarifications LFRtouzanimahdiОценок пока нет

- Catalogue OKOFEN 2018 2019Документ68 страницCatalogue OKOFEN 2018 2019joseph38Оценок пока нет

- Biochimie 08 - Réplication Et Réparation Des Erreurs AssociéesДокумент14 страницBiochimie 08 - Réplication Et Réparation Des Erreurs AssociéesNathan CohenОценок пока нет

- Secours en Cours de RouteДокумент32 страницыSecours en Cours de Routeantonio59100Оценок пока нет

- CH1 (Introduction Au SI) PDFДокумент17 страницCH1 (Introduction Au SI) PDFEL OUAZZANI PRINTОценок пока нет

- Examen Corrigé Marketing - Questionnaire À Choix Multiple (QCM)Документ7 страницExamen Corrigé Marketing - Questionnaire À Choix Multiple (QCM)Mar IemОценок пока нет

- RapportДокумент125 страницRapportKawtar L AzaarОценок пока нет

- Formation - PDF - Robotique - Mécatronique PDFДокумент9 страницFormation - PDF - Robotique - Mécatronique PDFHachicha SaberОценок пока нет