Академический Документы

Профессиональный Документы

Культура Документы

FEM9.311 Engl

Загружено:

Pınar SunИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

FEM9.311 Engl

Загружено:

Pınar SunАвторское право:

Доступные форматы

Rules for the Design of Storage and Retrieval Machines

Structures

FEM

9.311

02.1978 (E)

1 . Calculation

1.1 . General

The calculations must be in compliance with accepted

rules of statics, dynamics, and theoretical mechanics.

Provided that identical factors of safety are adhered to,

the calculations may also be based on the results of tests

carried out for determining the stresses which are pro-

duced in a structure under the assumed load conditions.

The data concerning system, dimensions, and cross'

sections shown in calculations and drawings must be in

agreement. Discrepancies are not permissible unless

these have the effect of increasing beyond any doubt

the safety of all components.

1.2 Calculation method

For the loads assumed as explained in section 2, the

three possible causes of failure are taken into account

as follows:

A Overstraining of materials.beyond t ~ e elastic limit

B Overstraining of structures beyond the critical

buckling stresses .

C Overstraining of materials i:leyond the fatigue

strength

1.3 . Permissible stresses

Details on thepermissible stresses concerning A, B, and

C above can be seen from the future FEM design rules

for crane structures.

Relevant national standards apply for the transition

period.

2 Assumed loads

Structures are subjected to the folloiNing load categories:

main loads,

additional loads and

special loads.

Main loads:

- Deadloads,

- lifted loads (lifting carriage deadweight and weight of

the load unit),

- horizontal forces of inertia produced by drive units,

- statical stabilizing forces.

Additional loads:

Forces due to running askew,

- effects due to temperature,

- loads 'on walkways, stairs, platforms, and handrails.

Special loads:

- Buffer forces,

- test loads,

emergency catch loads.

2.1 Categories cif main loads

2.1.1 Deadloads

Deadloads are the forces due to the weight of all fixed

and moving parts which are permanent operational

components of the mechanical and electrical equipment,

and of the proportionate share of the load supporting

means such as-ropes but with the exception of the loads

listed in 2.1.2.

2.1.2 Lifted loads

. The lifted loads comprise the weight of the load unit

and the deadweight of assemblies receiving the load unit

such as telescopic load fork and roller table, the dead-

weight of the lifting carriage, and the proportionate

share of the weight of the load supporting means such

as ropes, chains, etc. '

2.1.3 Effects of vertical forces of inertia .

The effects of vertical forces of innertia produced when

moving the lifting carriage and the loads listed i.n sections

2.1.1 and 2.1.2 are taken into account by applying .

..deadload coefficients" l{J and ,.I ifted load coefficients" 1/1.

~ . 1 . 3 . 1 Deadload coefficients l{J

The deadloads of SiR machines in motion (see section

2.1.1) a'nd the corresponding stress resultants or stresses

shall be multiplied by a deadload coefficientl{J selected

from table 1. .

Table 1

Travel speed Ut in m/min Deadload

Runways 1 coefficient

with joints without joints l{J

up to 63 up to 100 1.1

above 63 to 125 above 100 to 200 1.2

above 125 above 200 ' 1.3

In the case of live loads on a SiR machine running on

springloaded, plastic, etc. wheels l{J = 1.1 may be used for

calculation independent of the travel speed and the type

of runway.

Taking an SiR machine on steel rim travel wheels as an

example:

a) Travel speed Ut = 125 m/min, l{J = 1.2

b) Travel speed Ut = 50 m/min, l{J = 1.1

2.1.3.2 Lifted load coefficient 1/1 and lift,ing classes

The lifted loads according to section 2.1.2 or the stress

resultants or the corresponding stresses must be multi-

plied by a lifted-load coefficient 1/1 accord)ng to table 2.

Its value depends on the su rge to be expected from the

load lifting means when lifting starts and thus on the

nominal lifting speed UH; it is the smaller the more

flexible hoist unit and structure and the lower and more'

Continued on pages 2 to 5

Federation Europeenne de la Manutention

COP,yright by FEM Section IX. Available in English (El, French (F), German ([)l, Italian (I); sources of supply see back page.

The integration constants c, and C2 are determined

from the initial conditions:

Y(O) = 0

Page 2 FEM 9.311

constant acceleration and deceleration are when the

vertical motion is reversed.

The SiR machines are therefore classified into lifting

classes H1, H2, and H3, each of wh ich has a different

load coefficient I/J assigned to it according to table 2.

Table 2

y(O)

. a

c, x 0 + c2 - -

w

2

o = w xc, - C2 X 0

c, o

Lifting Lifted load coefficient I/J Average main hoist

class for a lifting speed VH .' acceleration

of up to 90 mlmin am in m/s

2

Thus, the oscillation equation is:

o x sin w t + x cos w t - JL.

w

2

w

2

1) am 1.3 m/s

2

max. if persons ride on the iifting carriage

during vertical motions

Y(t) = x(coswt-1) or

w

2

x (cos w t - 1)

H1

H2

H3

1.1 + 0.0022 x VH

1.2 +0.0044 x VH

1.3 + 0.0066 x VH

0.6

1.3

> 1.3')

Y(t)

dynamic

deformation

l!LX.Jl

c

static

deformation x

oscillation

coefficient Sw

where:

m dynamic equivalent mass of the flexible masses

c spring constant of the structure

a mean deceleration (acceleration) of the

horizontal motion.

sa - braking (path of acceleration)

t

a

period of deceleration (period of acceleration)

Ytt) dynamic deformation

2.1.4 Horizontal forces of inertia producedby drive

units .

2.1.4.1 Dynamic oscillation coefficient

The forces of inertia affecting the structure of an SIR

machine due to acceleration and deceleration of motions

such as horizontal travel, lifting, and telescoping shall

be determined on the basis of the maximum forces pro-

duced by the respective drive units in regular service. To

simplify the calculation for taking into account the

dynamic effects, the "quasistatic" forces affecting the

structure may be multiplied by the coefficient Sw, the

"quasistatic" forces being those which result when con,

sidering the system's centre-of-mass motion under the.

effects of the drive forces, of the resistances to motion .

and of the forces of inertia. Application of the coefficient

Sw is subject to the condition that the driving forces act

on the SiR practically without any play.

For dimensioning the SiR machines it is necessary to

know exactly the stresses due to oscillations caused by

travel motions. Deflections, stresses, and stress result-

ans shall be multiplied by the dynamic oscillation

coefficient Sw'

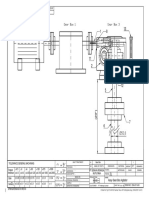

Figure 1. Dynamic equivalent system

Figure 2. Oscillation coefficient Sw

+2

+1

le

cos w t - 1

(5)

(4)

'm/s

2

a

I

t- ta S

Om

Sa

c

(1) maximum amplitude of oscillation during deceleration

(-) Sw max

(2) "quasi static" mean position during deceleration

(3) position of rest

(4) "quasi static" mean position during acceleration

(5) maximum amplitude of oscillation during aceleration

. (+)

The integral function of the above differential equation

is:

a

Y(t) c, xsin w t + C2 X cos w t - w

2

mji+c xy+m x a = 0

y +

L

Y

+ a = 0

m

Y

+ w

2

X y.+ a = 0

y + w

2

xy . = -a

w2 =

m

Assumptions:

damping is ignored

constant deceleration (or acceleration)

ta > Ta

(Ta = natural oscillating period of the structure)

The oscillation function

Y(t) = m C

X

a x (cos w t - 1)

reaches its maximum if the expression (cos w t - 1)

assumes the value (-2).

Since the stresses to which the structure is subjected are

directly proportional to the dynamic deformations, the

oscillation coefficient Swmax = 2 must be used for

further calculations of deformations, stresses, and stress

. resultants.

R

min

= R

stat

FEM 9.311 Page 3

F,xh,+ F

2

xh

2

+ F

3

xh

3

r

2.1.4.2 Effect of horizontal forces of inertia

Without the coefficients l{) and t/J according to section

2,1.3 but with the oscillation coefficient according to

section 2.1.4.1, the dynamic effects of the masses re-

sulting from structure flexibility shall be assumed to be

appl ied to the individual centres of gravity (5, 52. 53.

etc.).

Example':

F, horizontal dynamic force of acceleration due to the

load unit and the weight of the lifting carriage

F2 horizontal force of dynamic acceleration due to the

distributed load of the mast

F

3

horizontal force of dynamic acceleration due to the

weight of bottom carriage, travel mechanism and

attachments (e. g. control cubicle, hoist mechanism,

etc.)

The masses shall: be considered according to their dis-

tribution in each particular case.

Figure 3.

-

F1 /V

.

"-----'

F2

t-S2

N

.r:::.

F

3 rn I,

I't-.I

.r:::.

r

Rl R2

Depending on the direction of acceleration, the dynamic

forces of inertia tend to increase or to decrease the wheel

loads R, and R

2

.

For SIR machines, the stability is defined as follows:

Stability:

v = L stabilising momentS

L overturning moments

R.tatx r

The stability v shall be 1.5 under service conditions;

in exceptional situations, e. g. for emergency braking, it

shall be at least 1.1 (leaving the safety claws out of con-

sideration) .

For SiR machines which are positively prevented from

tilting (e. g. by positively guided travel wheels), the

stability analysis is omitted if the negative wheel loads

. are completely absorbed by the guiding members and

transmitted to the rack or building structure.

2.1.4.3 Friction force coefficient Ji

.,

The driving forces on the travel wheel periphery are

limited by the friction coefficient applicable to the

travel wheel/rail pair. .

The driving force which can be continuously trans-

mitted is thus R

min

x J.L. For pairs,

J.L = 0.2 shall be used as a maximum...'

2.1.4.4 Lateral forces Sz

If, due to forces of inertia, lateral forces occur trans-

versely to the runway centre line, these shall be trans-

mitted to the rails by form and friction grip in line

with the.guiding members and the systems of the

structure and travel mechanism.

2.2 Categories of additional loads

2.2.1 Forces due to running askew

Depending on the systems of travel mechanism and

structure, form grip forces are produced which act

on the guiding members (wheel flanges or guide rollers)

of an SIR machine by running' askew at an angle a,

and from these frictional rubbing forces result which

act on the contact surfaces of the travel wheels.

where:

,mL mass of the load unit

mH mass of the lifting carriage

ms mass of the mast

me mass of bottom carriage

mA mass of the attachments to the bottom carriage

am mean acceleration

F, = (mL + mH) x 2 x am,

F

2

=. m. x 2 x a

m

F

3

= (me + mAl x am,

since Sw

since Sw

since Sw

2

2

1 (unsprung)

For the generally accepted tolerances of travel wheel

diameter, parallelism of the wheel bore axes and run-

way alignment, a linear law of friction forces applies

to the longitudinal and transverse slip of two travel

wheels of ferrous material on a steel rail:

f = 0.30 x (1 _ e-

O

,25x a)

where:

e = base of the natural logarithms 2.71828

a = angle of skew in 0/00

Page 4 FEM 9.311

Table 3. Friction force coefficient f as depending on the angle of skew 0:

0: 0/00 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 6.0 7.0 8.0 9.0 10.0 15.0

f

0.035 0.066 0.094 0.118 0.139 0.158 0.175 0.190 0.203 0.214 0.233 0.248 0.259 0.268 0.275 0.300

S = f . R

st8t

(force due to running askew)

where:

wheel load due to deadloads and lifted load

without the' coefficients according to sections

2.1.3 and 2.1.4

, ~ o

O:F + ~ v + 0:

0

+ O:s _' 10 loo

angle of skew in relation to the spacing of the guide

members which give rise to the frictional forces, the

sum total of all possible misalignments transverse to

the runway when the SiR machine takes up a skewed

position.

O:F angle of s ~ e w due to the clearance between straight

rail and form grip guide members, i. e. at least

5 mm for wheel flanges and 3 mm for guide rollers.

O:v angle of skew due to wear. At least 1.5 %of the rail

head width in the case of guide rollers and at least

5 %of the rail head width in the case of wheel

" flanges.

0:

0

~ 1 iot, angle of skew due to SIR machine tolerances

O:s ~ 1 0/00 angle of skewdue to tolerances of the rail

laid on the floor

2.2.2 Temperature effects

Temperature effects must be taken into consideration

only in special cases. Based on an assumed temperature

of + 10 C during erection, variations in temperature

of 35 K or, in the case of an uneven temperature rise

in individual sub-assemblies, variations of 15 K shall

be assumed for an SIR machine operating in an open

building.

These values must be adequate for local conditions in

the case of SiR machines operating in plants with a hot

atmosphere or in low-temperature warehouses.

A coefficient of elongation

O:t = 12 ',10-

6

mm/mm xK (for steel)

shall be used for the calculations.

2.2.3 Loads on platforms and handrails

In addition to the deadloads, a single live load shall be

assumed for platforms, i. e.

300 kg for persons walking on it and carrying a load

150 kg for persons walking on it without a load.

A concentrated live load applied horizontally to the out-

side or to the inside shall be assumed for handrails, i. e.

30 kg for persons carrying a load and

15 kg for persons without a load.

These concentrated loads need not be taken into account

in the case of structural members subjected to loads

lifted according to section 2.1.2.

2.3 Categories of special loads

2.3.1 Buffer forces

For this special case of loading'it is assLimed that during

regular service collisions of SiR machines do not occur.

The buffer forces Fp, which occur when SIR machines

impact against runway stops, shall be limited by pro-

viding adequ!lte buffers or similar means of dissipating

energy. The required working capacity for energy dis-

sipation and the maximum,buffer forces Fp shall be

determined for SIR machines on the basis of 100 %

nominal travel speed.

, If automatic means 2) ensure a reduction of the travel

speed; the required working capacity of the buffers for

energy dissipation and the maximum buffer forces Fp

may be calculated taking the then fastest possible travel

speed, but at least 70 %of the nominal speed, as a basis.

The kinetic energy shall be assumed to be

'm x v

2

Wkin = 2

For an analysis of the buffers and the strength of the

structure the forces due to the moving masses of the

deadloads and of the guided lifted loads 3) shall be

assumed to be effective in their respective least favour-

able position, but without the coefficients according to

sections 2.1.3 and 2.1.4. '

A corresponding equivalent mass has tobe introduced

into the calculation for rotating parts of the travel

mechanism. The buffer forces shall be distributed

according to the buffer characteristics and the freedom

of movement of the structure.

If energy converting buffers are provided, an amount of

10 % may be deducted from the total energy for the

free dying down of structure oscillations.

In the case of a simplified analysis of the stresses in the

structure,the' buffer end forces shall be multiplied by

an oscillation coefficient selected from table 4 in

accordance with the shape and area below the buffer

characteristic.

Table 4. Oscillation coefficients for simplified

calculation

The area below the buffer Oscillation coefficient

characteristic resembles Sp at SiR machine

approx. impact

Triangle 1.25

Rectangle 1.50

,

2) In the case of electric means at least 2 safety devices shall' be provided which monitor each other.

3) The maximum possible friction force between load unit and load handling accessory shall be assumed for the load unit as a non-

guided lifted load.

The travel wheels of SiR machines with or without a

payload shall not lift off the rail due to the 110 % buffer

force and the above-mentioned deadloads and lifted

loads. Reaction pressure rollers or safety claws shall be

provided as required for absorbing negative wheel loads.

The buffer stops shall be dimensioned for absorbing at

least the actual buffer end force Sp.

2.3.2 Test loads

2.3.2.1 General function test

The functions of load pick-up, lifting, lowering, and

travelling of SIR machines are tested by applying the

following load: '

test load: P

k

= 1.25 payload

For the analysis of stresses (overstraining beyond the

elastic limit) and of stability the test load P

k

shall be

multiplied by the reduced lifted load coefficient

,I,' = !.....Jk.'

'I' 2'

, The assumed load makes it necessary to proceed as

follows for applying the test load:

With the test load applied, all motions shall be individu-

ally tested with reasonable care and with the'load in the

least favourable positions. A motion may not be

initiated before the oscillations caused by the previous

motion' have died down.

2.3.3 Emergency catch loads

2.3.3.1 Function teSt of the catching device

On SiR machines equipped with a speed controlled

catching device, the function test of this device is

carried out by applying the catch load P

k

= 1.25 . pay-

load. '

The catch load shall, be positioned centrally on the load

pick-up device. '

The following tests shall be carried out:

1) function test of the overspeed governor by lowering

the lifting carriage at excessive speed or by a

simulation of this condition;

2) 'function test of the catching device by manual

locking of the overspeed,governor during the lowering

motion;

3) free-fall stop test of the lifting carriage lifted up

with the catch load.

The free-fall stop' test according to 3) above can be

omitted if the catching device is built up of function-

tested components for which an official certificate has

been issued.

For the stress analyses according to section 1.2 A "Over-

straining of materials beyond the elastic limit"and B;,Over-

straining of structures beyond the critical buckling

stresses" the catch load shall be multiplied by the in-

creased lifted load coefficient t/J ".

For specifying the increased lifted load values I/J" it has

been taken into account that the actual speed for tripping

the catching device v

ab

considerably exceeds the nominal

lifting speed VH' which is espressed by the following

equation:: .

Vab = -J v

g

2

+ 2xgxSR + 2xgxSF

FEM 9.311 Page 5

where:

Vg preset trip,ping speed of the overspeed governor

1.4 x VH

SR spacing of the notches of the overspeed governoor

in relation to the vertical path of the lifting carriage

SF idle path of the catching mechanism until braking

starts

g 9.81 m/s

2

The energy equation indicates the mean deceleration

during the catching operation:

m

2 + m x g x h --'- m x am x h = 0

hence:

where:

am mean deceleration I

h catching or braking path of the lifting carriage

m mass of the test load and of the lifting carriage

dead ' weight

The maximum deceleration a

max

in the event of

catching results from the characteristic curve of the'

working diagram for the catching device and by taking

into account an oscillation coefficient according to

table 4.

Table 5.

2 x am triangular diagram

a

max

' 1.75 x am trapezoidal diagrljm

1.5 x am

rectangular diagram

The increased lifted load coefficient I/J" results from the

relationship between the maximum deceleration due to

braking and acceleration due to gravity.

I/J" = a;ax

If an exact calculation of the increased lifted load

coefficient is omitted, the calculation may be simplified

by taking I/J" from table 6.

Table 6. Approximate figures for I/J"

Increased Iifted load Lifting speed VH (m/min)

coefficient I/J" 4)

for catcning approx. work-

>50

by ingdiagram '

Clamping

roller

triangular 5 6 - -

catching

device

Brake type

catching trapezoidal 2.5 3 3.5 -

device

Cushioning

catching rectangular 2, 2 2 2

device

41 The above values for I/J" can be influenced by varying the

design of the catching device (angle of the sloping surface

in the catching block, width and diameter of the catching

roller)

Depending on particular applications, additional calcula;-

tlons regardingoscillation dynamics may be advisable if due

to its flexibility the structure is definitely capable of ab-

sorbing a certain part of the energy produced by catching.

F6d6ration Europ6enne

de la Manutention

(FEM) ,

Erstellt durch den technischen UnterausschuB Regal bediengeriite und Stapelkrane" der Sektion I X der }

Prepared by the Technical Sub-Committee "Storage and Retrieval Machines and Stacker Cranes" of

Section IX of the

Etabli par le sous-comit6 technique .. Transtockeurs et 1Xlnts gerbeurs" de la section IX de la

Emesso della sottocommissione tecnica ..Trasloelevatori e gru impilatrici'aella sezione IX della

--_-::.-_-------

Sekretariat:

Secretariat:

Secr6tariat:

Segretariato:

Sekretariat der FEM Sektion IX

cIa VOMA

Fachgemeinschaft Fordertechnik

Postfach 71 01 09

0-6000 Frankfurt 71

Zu beziehen durch das oben angegebene Sekretariat oder durch die folgenden Nationalkomitees der FEM

Available from the above secretariat oi from the following national committees of the FEM

En vente auprAs du secr6tariat QU des comit6s nationaux suivants de la FEM

Da richiedere attraverso il su citato segretariato 0 i comitati nazionali della FEM

Belgique

Comite National Beige de la FEM

Fabrimetal

Rue des Drapiers 21

B-1050 Bruxelles

Danmark

-Dansk National Komite FEM

Transportmaterial Foreningen

Lille Kirkestraede 3

DK - 1072 Kopenhagen K

Deutschland

Deutsches Nationalkomitee der FEM

VDMA .

Fachgemeinschaft Fordertechnik

Postfach 71 01 09

D '- 6000 Frankfurt 71

Espana

Comite Nacional Espanolde la FEM

Associaci6n Nacional de Ingenieros Industriales

Via Layetana 39 (bajos)

E - Barcelona 3

France

Comite National Francais de la FEM

SIMMA - Syndicat des industries de materiels

de manutention

10, avenue Hoche

F --;- 75 382 Paris cedex 08

Great Britain

British National Committee of FEM

Messrs. Peat, Marwick, Mitchell & Co.

7 Ludgate Broadway

GB - London EC 4V 6DX

Ireland

Irish National Committee of FEM ,

Institute for Industrial Research and Standards (11 RS)

Ballymun Road

IRL - Dublin 9

Italia

Comitato Nazionale Italiano de la FEM

Associazione Nazionale Industria

Meccanica Varia et Affine (ANIMA)

Piazza Diaz 2

I - 20123 Milano

Luxembourg

Comite National Luxembourgeois de la FEM .

Groupement des Constructeurs et Fondeurs

du Grand-Duche' de Luxembourg

Rue Alcide de Gasperi 7

Plateau de Kirchberg

Boite postale No. 1304

L - Luxembourg

Nederland '

Nederlands National Comite bij de FEM

GKT-Vereniging van Metaal industrleen

Postbus 190

NL - 2700 Ad Zoetermeer

Norge

Norwegian FEM Groups

Norsk Verkstedsindustris

Standardiseringssentral NVS

Box 7072 H '

N - Oslo 3

Portugal

Commissao Nacional Portuguesa da FEM

CEMUL - Prof. Eng. L. O. Faria

Avenida Ant6nio Jose de Almeida - I.S. T.

P - 1000 Lisboa

Schweiz / Suisse / Svizzera

Comite National Suisse de la FEM

Verei n Schwei zerischer Maschinen-I ndustrieller

Kirchenweg 4

CH - 8032 Zurich

Suomi

Finnish National Committee of FEM

Federation of Finnish Metal and Engineering Industries

Etelaranta 10 '

SF - 00130 Helsinki 13

Sverige

Swedish National Committee of FEM

Materialhanteringsgruppen Inom Sveriges Mekanforbund

Box 5506

S - 11 485, Stockholm

Вам также может понравиться

- Structural Health MonitoringОт EverandStructural Health MonitoringDaniel BalageasОценок пока нет

- Loads Acting On Crane Structure During TravelДокумент11 страницLoads Acting On Crane Structure During Travelaiyubi2Оценок пока нет

- FEM 9 222 EnglischДокумент20 страницFEM 9 222 EnglischEmílio BeckerОценок пока нет

- Vishwanat Kanal, Vinod Nirale, Ravindra Kondaguli: Impact Factor: 1.479Документ4 страницыVishwanat Kanal, Vinod Nirale, Ravindra Kondaguli: Impact Factor: 1.479divjak70Оценок пока нет

- Carbon Steel Tee Rails: Standard Specification ForДокумент7 страницCarbon Steel Tee Rails: Standard Specification ForAAYОценок пока нет

- Idea - Wheel CalculationДокумент35 страницIdea - Wheel Calculationbambang satryojatiОценок пока нет

- Conveyor Industry Conveyors PDF: Uploads 2012/06Документ6 страницConveyor Industry Conveyors PDF: Uploads 2012/06diego cadenaОценок пока нет

- Din 471 Ext CirclipsДокумент5 страницDin 471 Ext Circlipschaitanya_kumar_13Оценок пока нет

- Assy Gear Box AgitatorДокумент1 страницаAssy Gear Box Agitatorer_winwibowoОценок пока нет

- Paper Gondola WagonДокумент2 страницыPaper Gondola WagonrentizahariaОценок пока нет

- Precise Finite-Element Model For Pulleys Based On The Hamiltonian Form of ElasticityДокумент13 страницPrecise Finite-Element Model For Pulleys Based On The Hamiltonian Form of ElasticityShamik ChowdhuryОценок пока нет

- Eot Crane During SeismicДокумент12 страницEot Crane During SeismicboyzesОценок пока нет

- Emm 3506 - Group 3Документ132 страницыEmm 3506 - Group 3Griffin ThomasОценок пока нет

- DesignДокумент4 страницыDesignJigneshkumar PatelОценок пока нет

- E1102m PDFДокумент283 страницыE1102m PDFBhawani Singh RajawatОценок пока нет

- Difference Beetween Is 800-2007 & Is 800-1984Документ96 страницDifference Beetween Is 800-2007 & Is 800-1984ayazmadОценок пока нет

- Austenitic Cast IronДокумент2 страницыAustenitic Cast Ironkatchani123Оценок пока нет

- Chassis MechanicsДокумент37 страницChassis Mechanicsneerajsingh000007Оценок пока нет

- Narrow V Belt Pulleys Din 2211Документ1 страницаNarrow V Belt Pulleys Din 2211TudorОценок пока нет

- Load Sharing Methods of Backstops 2004 01Документ10 страницLoad Sharing Methods of Backstops 2004 01Ruben SalgadoОценок пока нет

- Insulated Conductor Rail Single Powerline Program 0812: WWW - Conductix.UsДокумент36 страницInsulated Conductor Rail Single Powerline Program 0812: WWW - Conductix.UsHéctor FuentesОценок пока нет

- Crane Guide Chap-1Документ1 страницаCrane Guide Chap-1Jayadev PalaiОценок пока нет

- Wright CranesДокумент13 страницWright Craneslandshark004100% (1)

- Integral Analysis of Conveyor Pulley Using ®nite Element MethodДокумент30 страницIntegral Analysis of Conveyor Pulley Using ®nite Element MethodEsteban CorderoОценок пока нет

- Scheuerle Intercombi: Dimensions and SpecificationsДокумент2 страницыScheuerle Intercombi: Dimensions and SpecificationsSebastian ZarzyckiОценок пока нет

- Wire Ropes Drive Mechanism For Reciprocating Linear MotionДокумент5 страницWire Ropes Drive Mechanism For Reciprocating Linear MotionSachin KumawatОценок пока нет

- Brugg Catalog enДокумент28 страницBrugg Catalog enSinoj V AntonyОценок пока нет

- Design Analysis and Improvement of EOT Crane WheelДокумент4 страницыDesign Analysis and Improvement of EOT Crane WheelIJSTEОценок пока нет

- KBK Brochure PDFДокумент12 страницKBK Brochure PDFMahendran KuppusamyОценок пока нет

- KranДокумент7 страницKranMarioОценок пока нет

- 40 Ton Capacity Motor DataДокумент2 страницы40 Ton Capacity Motor DataRajveer SinghОценок пока нет

- DSTV eДокумент55 страницDSTV eperoooОценок пока нет

- Crane Tips: Overhead Crane Vibration, Natural FrequencyДокумент3 страницыCrane Tips: Overhead Crane Vibration, Natural FrequencySACHINОценок пока нет

- Component Parts: DZW Position Measuring SystemДокумент12 страницComponent Parts: DZW Position Measuring SystemBang OchimОценок пока нет

- Conveyor Horizontal CurveДокумент3 страницыConveyor Horizontal Curverobbie312Оценок пока нет

- ARRIUM - Standards For Crane Anti-Derailment Final R4Документ18 страницARRIUM - Standards For Crane Anti-Derailment Final R4YOO SHIN0% (1)

- Worm and Worm Wheel NomenclatureДокумент1 страницаWorm and Worm Wheel NomenclaturemuhdqasimОценок пока нет

- STAHL Crane PDFДокумент18 страницSTAHL Crane PDFJustin AlwarОценок пока нет

- 02 Mechanical BasicsДокумент29 страниц02 Mechanical BasicsVLADIMIR YOLVIS CHOQUEHUANCA GALINDOОценок пока нет

- C1 30 - 3 EN Crane Wheel SystemsДокумент16 страницC1 30 - 3 EN Crane Wheel SystemsKovács EndreОценок пока нет

- Jib Crane BrochureДокумент18 страницJib Crane BrochureoniОценок пока нет

- Demag Vinç BilgileriДокумент28 страницDemag Vinç BilgileriZahid ArıcıОценок пока нет

- ISO Gear StandardsДокумент6 страницISO Gear StandardsEslam YehiaОценок пока нет

- Iso 5293 1981Документ8 страницIso 5293 1981Rajaram JayaramanОценок пока нет

- Md-17 Shaft Design StepsДокумент12 страницMd-17 Shaft Design StepsRamji RaoОценок пока нет

- WEG Roller Table 50040456 Brochure EnglishДокумент12 страницWEG Roller Table 50040456 Brochure EnglishjmartinezmoОценок пока нет

- Bushman C HookДокумент2 страницыBushman C Hookperdhana2000100% (1)

- ABB CatalogueДокумент6 страницABB CatalogueNavneet SinghОценок пока нет

- Designing of Cranes With StandardsДокумент95 страницDesigning of Cranes With Standardsank_mehraОценок пока нет

- EN ISO 11542-2 PropertiesДокумент17 страницEN ISO 11542-2 Propertieschaminda nayanajithОценок пока нет

- 080M40 (EN8) Specification Chemical CompositionДокумент1 страница080M40 (EN8) Specification Chemical CompositionAmar ThakurОценок пока нет

- Spur Gear Design by IIT MadrasДокумент28 страницSpur Gear Design by IIT MadrasC.S.ABHILASHОценок пока нет

- EOT Crane Mechanical Equipment Calculation 2Документ17 страницEOT Crane Mechanical Equipment Calculation 2satendra sharmaОценок пока нет

- Non-Driven Wheel DIN15090 Series 223 EN PDFДокумент1 страницаNon-Driven Wheel DIN15090 Series 223 EN PDFayavuzbvsОценок пока нет

- Shaft Design - Overheads PDFДокумент20 страницShaft Design - Overheads PDFRyan BaleОценок пока нет

- Eurobloc VT 9 10 11 12 GBДокумент6 страницEurobloc VT 9 10 11 12 GBToni RenedoОценок пока нет

- Unit Influence Lines FOR Statically Determinate Beams: StructureДокумент34 страницыUnit Influence Lines FOR Statically Determinate Beams: StructureRaj BakhtaniОценок пока нет

- Fem9311 EnglДокумент6 страницFem9311 EnglSawan PatilОценок пока нет

- Flight Control Design Using Backstepping PDFДокумент8 страницFlight Control Design Using Backstepping PDFIvan RamirezОценок пока нет

- Jack-Up Legs Structural Strength Analysis. DQC-PTHДокумент10 страницJack-Up Legs Structural Strength Analysis. DQC-PTHHoang Tien DungОценок пока нет

- CFX MultiphaseДокумент2 страницыCFX MultiphaseNiamul Baqui100% (1)

- Digital To Analog Converter (DAC)Документ32 страницыDigital To Analog Converter (DAC)Rajesh PaudyalОценок пока нет

- Siemens SONOLINE SL-1CДокумент37 страницSiemens SONOLINE SL-1CCosty100% (2)

- Sika Membrane 2000Документ6 страницSika Membrane 2000Anonymous 2Dz4Kq9M7Оценок пока нет

- Introduction BearingДокумент4 страницыIntroduction BearingtonojsgpОценок пока нет

- SEM 1 MCA 11 MathematicsДокумент379 страницSEM 1 MCA 11 MathematicsMalatesh HavanagiОценок пока нет

- Heat SPM Mind MapДокумент6 страницHeat SPM Mind MapAzaizulAhmadОценок пока нет

- Turbulence Openfoam PDFДокумент31 страницаTurbulence Openfoam PDFMidhun MvОценок пока нет

- 2014-04-11 The Very Big and The Very Small, OptimizationДокумент5 страниц2014-04-11 The Very Big and The Very Small, OptimizationsamjshahОценок пока нет

- Mathematical ModelsДокумент8 страницMathematical ModelsSteve manicsicОценок пока нет

- DLM ValidationДокумент7 страницDLM ValidationSandilya KambampatiОценок пока нет

- Experimental Aerodynamic Analysis of Delta WingДокумент8 страницExperimental Aerodynamic Analysis of Delta WingShiva UОценок пока нет

- Applied Thermodynamics C211 PDFДокумент173 страницыApplied Thermodynamics C211 PDFSubham AcharyaОценок пока нет

- Computer Project # 1 - Interpolation, Differentiation and IntegrationДокумент1 страницаComputer Project # 1 - Interpolation, Differentiation and IntegrationKetan RsОценок пока нет

- Identification and Elimination of Hygro-Thermo - Mechanical Stress-Effects in A High-Precision MEMS Pressure Sensor - IEEE Xplore DocumentДокумент2 страницыIdentification and Elimination of Hygro-Thermo - Mechanical Stress-Effects in A High-Precision MEMS Pressure Sensor - IEEE Xplore DocumentEnrique OsorioОценок пока нет

- Comparison of Digestion Methods For Determination of PB (II), CR (VI) and CD (II) Contents in Some Ethiopia Spices Using Atomic Absorption SpectrosДокумент12 страницComparison of Digestion Methods For Determination of PB (II), CR (VI) and CD (II) Contents in Some Ethiopia Spices Using Atomic Absorption SpectrosijasrjournalОценок пока нет

- MatrixДокумент20 страницMatrixrohitjdbi83Оценок пока нет

- Exam Chapter Wave and Vibration (A)Документ2 страницыExam Chapter Wave and Vibration (A)Senny Ummu AlMuharrom100% (1)

- Kepes Gyorgy 1967 Light and DesignДокумент31 страницаKepes Gyorgy 1967 Light and DesignAnonymous TOMo4s100% (1)

- Mil HDBK 505 PDFДокумент9 страницMil HDBK 505 PDFCORAL ALONSOОценок пока нет

- Private - Lost Secrets of The Sacred Ark (16288949)Документ10 страницPrivate - Lost Secrets of The Sacred Ark (16288949)Gordon Scott TaylorОценок пока нет

- HW 14 SolutionsДокумент8 страницHW 14 SolutionsSeleneblueОценок пока нет

- Mark Scheme (Results) January 2007: GCE Mathematics Core Mathematics C3 (6665)Документ7 страницMark Scheme (Results) January 2007: GCE Mathematics Core Mathematics C3 (6665)Fahema ShafiОценок пока нет

- Science For Kids Workbook Essential Oil EditionДокумент58 страницScience For Kids Workbook Essential Oil EditionEscambo Sitedobem100% (2)

- Development of A Basic Electro-Pneumatic Control TrainerДокумент7 страницDevelopment of A Basic Electro-Pneumatic Control TrainerJeff PereyrasОценок пока нет

- Two Phase Vertical Separator SizingДокумент4 страницыTwo Phase Vertical Separator Sizingkamal100% (2)

- Introduction To ANSYS WorkbenchДокумент29 страницIntroduction To ANSYS WorkbenchSudhanwa KulkarniОценок пока нет

- Scientific Instruments PDFДокумент3 страницыScientific Instruments PDFSiv SivaОценок пока нет

- Pressure SlidesДокумент43 страницыPressure SlidesBjorn Low100% (1)

- Art 1 Jeopardy Final ReviewДокумент53 страницыArt 1 Jeopardy Final Reviewapi-243273616Оценок пока нет

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsОт EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsРейтинг: 4 из 5 звезд4/5 (16)

- To Engineer Is Human: The Role of Failure in Successful DesignОт EverandTo Engineer Is Human: The Role of Failure in Successful DesignРейтинг: 4 из 5 звезд4/5 (138)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresОт EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresРейтинг: 1 из 5 звезд1/5 (2)

- Piping Engineering Leadership for Process Plant ProjectsОт EverandPiping Engineering Leadership for Process Plant ProjectsРейтинг: 5 из 5 звезд5/5 (1)

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesОт EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesРейтинг: 4.5 из 5 звезд4.5/5 (13)

- Mechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsОт EverandMechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsОценок пока нет

- Non-destructive Testing and Evaluation of Civil Engineering StructuresОт EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacОценок пока нет

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsОт EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsРейтинг: 5 из 5 звезд5/5 (3)

- Structural Cross Sections: Analysis and DesignОт EverandStructural Cross Sections: Analysis and DesignРейтинг: 4.5 из 5 звезд4.5/5 (19)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesОт EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Earthquake-Resistant Structures: Design, Build, and RetrofitОт EverandEarthquake-Resistant Structures: Design, Build, and RetrofitРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОценок пока нет

- Structural Steel Design to Eurocode 3 and AISC SpecificationsОт EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsОценок пока нет

- Net Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and ImplementationОт EverandNet Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and ImplementationРейтинг: 5 из 5 звезд5/5 (1)

- Super Structures: The Science of Bridges, Buildings, Dams, and Other Feats of EngineeringОт EverandSuper Structures: The Science of Bridges, Buildings, Dams, and Other Feats of EngineeringРейтинг: 4 из 5 звезд4/5 (1)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsОт EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsОценок пока нет