Академический Документы

Профессиональный Документы

Культура Документы

Lecture 2

Загружено:

Fazal AhmadИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lecture 2

Загружено:

Fazal AhmadАвторское право:

Доступные форматы

Lecture # 2 B.

COMPONENT CONTINUITY EQUATIONS (Component balance)

Unlike mass, chemical components are not conserved. If a reaction occurs inside a system, the number of moles of an individual component will increase if it is product

of the reaction or decrease if it is a reactant. Therefore the component continuity equation of thejth chemical species of the system says:

The units of this equation are moles of component j per unit time. The flows in and out can be both convective (due to bulk flow) and molecular (due to diffusion). We can write one component continuity equation for each component in the system. If there are NC components, there are NC component continuity equations for any one system. However, the

one total mass balance and these NC component balances are not all independent, since the

sum of all the moles times their respective molecular weights equals the total mass. Therefore a given system has only NC independent continuity equations. We usually use the total mass balance and NC - 1 component balances. For example, in a binary (two-component) system, there would be one total mass balance and one component balance.

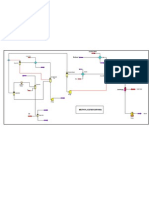

Example 2.3. Consider the same tank of perfectly mixed liquid that we used in Example 2.1 except that a chemical reaction takes place in the liquid in the tank. The system is now a CSTR (continuous stirred-tank reactor) as shown in Fig. 2.3. Component A reacts irreversibly and at a specific reaction rate k to form product, Component B.

Let the concentration of component A in the inflowing feed stream be CA, (moles ofA per unit volume) and in the reactor CA. Assuming a simple first-order reaction, the rate of consumption of reactant A per unit volume will be directly proportional to the instantaneous concentration of A in the tank. Filling in the terms in Eq. (2.9)

for a component balance on reactant A, the instantaneous concentration of A in the tank. Filling in the terms in Eq. (2.9) for a component balance on reactant A,

The minus sign comes from the fact that A is being consumed, not produced. The units of all these terms must be the same: moles of A per unit time. Therefore the VKCA term must have these units, for example (ft3)(min-1)(moles of A/ft3). Thus the units of k in this system are min- 1.

We have used an ordinary derivative since t is the only independent variable in this lumped system. The units of this component continuity equation are moles of A per Unit time. The left-hand side of the equation is the dynamic term. The first two terms on the right-hand side are the convective terms. The last term is the generation term. Since the system is binary (components A and B), we could write another component continuity equation for component B. Let CB be the concentration of B in moles of B per unit volume

Note the plus sign before the generation term since B is being produced by the reaction. Alternatively we could use the total continuity equation [Eq. (2.3)] since CA, , CB , and p are uniquely related by:

Example 2.4.

Suppose we have the same macroscopic system as above except that now consecutive reactions occur. Reactant A goes to B at a specific reaction rate but B can react at a specific reaction rate k, to form a third component C.

The component concentrations are related to the density:

Three component balances could be used or we could use two of the component balances and a total mass balance.

Example 2.5:

Instead of fluid flowing down a pipe as in Example 2.2, suppose the pipe is a tubular reactor in which the same reaction A B of Example 2.3 takes place. As a slice of material moves down the length of the reactor the concentration of reactant CA decreases as A is consumed. Density p, velocity V, and concentration CA can all

vary with time and axial position z. We still assume plug-flow conditions so that there are no radial gradients in velocity, density, or concentration. The concentration of A fed to the inlet of the reactor at z = 0 is defined as:

We now want to apply the component continuity equation for reactant A to a small differential slice of width dz, as shown in Fig. 2.4. The inflow terms can be split into two types: bulk flow and diffusion. Diffusion can occur because of the concentration gradient in the axial direction. It is usually much less important than bulk flow in most practical systems, but we include it here to see what it contributes to the model. We will say that the diffusive flux of A, N, (moles of A per unit time per unit area), is given by a Ficks law type of relationship:

where fD, is a diffusion coefficient due to both diffusion and turbulence in the fluid flow (so-called eddy diffusivity). fDA has units of length per unit time. The terms in the general component continuity equation [Eq. (2.9)] are: Molar flow of A into boundary at z (bulk flow and diffusion)

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Ex450-5 Technical DrawingДокумент12 страницEx450-5 Technical DrawingTuan Pham AnhОценок пока нет

- Parts Manual Z-45Документ240 страницParts Manual Z-45John Forero PinzonОценок пока нет

- Nomad Pro Operator ManualДокумент36 страницNomad Pro Operator Manualdavid_stephens_29Оценок пока нет

- Business Process MappingДокумент14 страницBusiness Process MappinghanxinОценок пока нет

- Grade-9 (3rd)Документ57 страницGrade-9 (3rd)Jen Ina Lora-Velasco GacutanОценок пока нет

- Wireline Works Tech-BulletinsДокумент25 страницWireline Works Tech-BulletinsRio de Mario100% (1)

- Introduction To PercolationДокумент25 страницIntroduction To Percolationpasomaga100% (1)

- SPE-183743-MS Maintaining Injectivity of Disposal Wells: From Water Quality To Formation PermeabilityДокумент19 страницSPE-183743-MS Maintaining Injectivity of Disposal Wells: From Water Quality To Formation PermeabilityAminОценок пока нет

- Fisher Paykel SmartLoad Dryer DEGX1, DGGX1 Service ManualДокумент70 страницFisher Paykel SmartLoad Dryer DEGX1, DGGX1 Service Manualjandre61100% (2)

- The Biological Diversity Act, 2002 PDFДокумент28 страницThe Biological Diversity Act, 2002 PDFSamuel BhukyaОценок пока нет

- Environmental Laws of In... - Definitions and ActsДокумент2 страницыEnvironmental Laws of In... - Definitions and ActsFazal AhmadОценок пока нет

- Civil3 8Документ47 страницCivil3 8rnjtyadav5Оценок пока нет

- Read MeДокумент2 страницыRead MemosijenkoleonidОценок пока нет

- Biodiesel Methyl Ester DryingДокумент1 страницаBiodiesel Methyl Ester DryingFazal AhmadОценок пока нет

- (WWW - Entrance-Exam - Net) - Accenture Sample Paper 4Документ1 страница(WWW - Entrance-Exam - Net) - Accenture Sample Paper 4Fazal AhmadОценок пока нет

- Higher Algebra - Hall & KnightДокумент593 страницыHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Electrostatic Precipitator$$Документ6 страницElectrostatic Precipitator$$Fazal AhmadОценок пока нет

- Cep MPДокумент1 страницаCep MPAzmat HabeebОценок пока нет

- Specializations MTech Software SystemsДокумент5 страницSpecializations MTech Software SystemsAkanksha SinghОценок пока нет

- Nursing Research Lecture 4aДокумент26 страницNursing Research Lecture 4asyamsul anwarОценок пока нет

- Network Command - HPUXДокумент5 страницNetwork Command - HPUXRashid NihalОценок пока нет

- DC Power Supply and Voltage RegulatorsДокумент73 страницыDC Power Supply and Voltage RegulatorsRalph Justine NevadoОценок пока нет

- CHM170L Exp3 Surface TensionДокумент5 страницCHM170L Exp3 Surface TensionKaiser SaltoОценок пока нет

- The Big TEGO. Products Services Data Sheets-75-150-16!76!31-61Документ31 страницаThe Big TEGO. Products Services Data Sheets-75-150-16!76!31-61DWI RAHMASARI FATMAWATIОценок пока нет

- Corner ReflectorДокумент1 страницаCorner ReflectorYashОценок пока нет

- Student - The Passive Voice Without AnswersДокумент5 страницStudent - The Passive Voice Without AnswersMichelleОценок пока нет

- Cópia de Teste Excel - Intermediário (5166) .XLS: BIM Technology For EngineersДокумент6 страницCópia de Teste Excel - Intermediário (5166) .XLS: BIM Technology For EngineersFernanda AzevedoОценок пока нет

- 10 2Документ26 страниц10 2cristinatubleОценок пока нет

- Ways To Multiply and Divide: Maniratnam - The CashierДокумент17 страницWays To Multiply and Divide: Maniratnam - The CashierSundari MuruganОценок пока нет

- TitleДокумент142 страницыTitleAmar PašićОценок пока нет

- Review Problems Chapter 4 Solutions PDFДокумент4 страницыReview Problems Chapter 4 Solutions PDFAntoninoОценок пока нет

- CSC:361-Software Engineering: Semester: Fall2020Документ39 страницCSC:361-Software Engineering: Semester: Fall2020hamsfayyazОценок пока нет

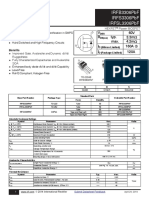

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120AДокумент12 страницIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligОценок пока нет

- DA Savitz - Interpreting Epidemiologic Evidence - Strategies For Study Design and Analysis 2003 PDFДокумент329 страницDA Savitz - Interpreting Epidemiologic Evidence - Strategies For Study Design and Analysis 2003 PDFrindy_bilhaniОценок пока нет

- Atmel 2565 Using The Twi Module As I2c Slave - Applicationnote - Avr311Документ14 страницAtmel 2565 Using The Twi Module As I2c Slave - Applicationnote - Avr311m3y54mОценок пока нет

- Formula Sheet: Basic Trigonometric IdentitiesДокумент4 страницыFormula Sheet: Basic Trigonometric Identitieschetan temkarОценок пока нет

- Che 410 ................... Transition Metal ChemistryДокумент13 страницChe 410 ................... Transition Metal ChemistryElizabeth AnyangoОценок пока нет

- X500Документ3 страницыX500yu3zaОценок пока нет