Академический Документы

Профессиональный Документы

Культура Документы

In Many Cultures It Was Shaped by Cold Hammering Into

Загружено:

Manikandan SriramИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

In Many Cultures It Was Shaped by Cold Hammering Into

Загружено:

Manikandan SriramАвторское право:

Доступные форматы

INTRODUCTION:

The use of alloys by humans started with the use of meteoric iron, a naturally occurring alloy of nickel and iron. As no metallurgic processes were used to separate iron from nickel, the alloy was used as it was. Meteoric iron could be forged from a red heat to make objects such as tools, weapons, and nails. In many cultures it was shaped by cold hammering into knives and arrowheads. They were often used as anvils. Meteoric iron was very rare and valuable, and difficult for ancient people to work Iron is usually found as iron ore on Earth, except for one deposit of native iron in Greenland, which was used by the Inuit people. Native copper, however, was found worldwide, along with silver, gold and platinum, which were also used to make tools, jewelry, and other objects since Neolithic times. Copper was the hardest of these metals, and the most widely distributed. It became one of the most important metals to the ancients. Eventually, humans learned to smelt metals such as copper and tin from ore, and, around 2500 BC, began alloying the two metals to form bronze, which is much harder than its ingredients. Tin was rare, however, being found mostly in Great Britain. In the Middle East, people began alloying copper with zinc to form brass Ancient civilizations

took into account the mixture and the various properties it produced, such as hardness, toughness and melting point, under various conditions of temperature and work hardening, developing much of the information contained in modern alloy constitution diagrams.

ALLOY:

An alloy is a homogenous mixture or metallic solid solution composed of two or more elements. Complete solid solution alloys give single solid phase microstructure, while partial solutions give two or more phases that may or may not be homogeneous in distribution, depending on thermal (heat treatment) history. Alloys usually have different properties from those of the component elements.

TERMINOLGY:

The term alloy is used to describe a mixture of atoms in which the primary constituent is a metal. The primary metal is called the base or the MATRIX. If there is a mixture of only two types of atoms, not counting impurities, such as a copper-nickel alloy, then it is called a BINARY ALLOY. If there are three different types of atoms forming the mixture, such as iron, nickel and chromium, then it is called a TERNARY ALLOY.

An alloy with four constituents is a QUATERNARY ALLOY. A five-part alloy is termed a QUINARY ALLOY. Since the percentage of each constituent can be varied, with any mixture the entire range of possible variations is called a system. All of the various forms of an alloy containing only two constituents, like iron and carbon, are called a BINARY SYSTEM All of the different alloy combinations possible with a ternary alloy, such as alloys of iron, carbon and chromium, are called a TERNARY SYSTEM. Alloys are often made in order to alter the mechanical properties of the base metal, to induce hardness, toughness, ductility, or other desired properties. While most metals and alloys can be work hardened by inducing defects in their crystal structure, caused by plastic deformation, some alloys can also have their properties altered by heat treatment. Nearly all metals can be softened by annealing, which repairs the crystal defects, but not as many can be hardened by controlled heating and cooling. Many alloys of aluminum, copper, magnesium, titanium, and nickel can be strengthened to some degree by some method of heat treatment, but few respond to this to the same degree that steel does.

At a certain temperature, the base metal of steel, iron undergoes a change in the arrangement of the atoms in its crystal matrix, called allotropy. This allows the small carbon atoms to enter the interstices of the crystal. When this happens, the carbon atoms are said to be in solution, mixed with the iron. If the iron is cooled slowly, the carbon atoms will be forced out of solution, into the spaces between the crystals. If the steel is cooled quickly, the carbon atoms become trapped in solution, causing the iron crystals to deform when the crystal structure tries to change to its low temperature state, inducing great hardness.

Advantage and Disadvantage of Alloy Steel: Advantages:

1. Greater hardenability 2. Less distortion and cracking 3. Greater ductility at high strength 4. Greater high temperature strength 5. Greater stress relief at given hardness 6. Better machinability at high hardness 7. High elastic ratio and endurance strength.

Disadvantages:

1. Tendency toward austenite retention 2. Cost 3. Special handling

4. Temper brittleness in certain grades.

Purpose of alloying:

Strengthening of the ferrite Improved corrosion resistance Better hardenability Grain size control Greater strength Improved machinability Improved ductility Improved toughness Better wear resistance. Improved cutting ability. Improved case hardening properties. Improved high or low temperature stability.

CLASSIFICATIONS OF ACCORDING TO COMPOSITIONS:

ALLOY STEEL CHEMICAL

Alloy steels are divided into three component steels, containing one alloying element in addition to iron and carbon: four components of steels, containing two alloying elements, etc.

CLASSIFICATION OF ALLOY STEEL ACCORDING TO STRUCTURAL CLASS:

Alloys steels may be classified on the basis of the structure that is obtained when specimens of small cross section are cooled in air. They are classified as: Pearlitic Martensitic Austenic Ferritic Carbidic

EXPERIMENTS:

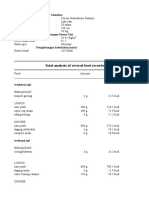

Analysis of composition of some alloy: EXPERIMENTS-1 AIM: To analyze a sample brass qualitatively

REQUIREMENTS: China dish, test-tube funnel, filter paper and common laboratory reagents. THEORY: Brass is an alloy of copper and zinc. With the following composition Cu=60-90% and Zn=10-40%. Thus Cu and Zn. Form the main constituents of brass. Both these metals dissolved in 50% of nitric acid due to formation of nitrates which are soluble. 3Cu + 8HNO3 (dil) 4Zn + 10H2O (dil)

3Cu (NO3)2 + 2NO + 4H2O 4Zn (NO3)2 + N2O + 5H2O

The solution is boiled to expel the oxides of nitrogen and the resulting solution is tested for Cu2+ and Zn2+ ions. PROCEDURE: ! Place a small piece of brass in a china dish and heat this with minimum quantity of 50% HNO3 so as to dissolve the piece completely. ! Continue heating the solution till a dry solid residue is obtained. ! Dissolve the solid residue in dil.HCL and filter. Add distilled water to the filtrate. ! Pass H2S gas through the filtrate. A black precipitate of copper sulphide is obtained. Separate the black ppt

and keep the filtrate for the test of Zn2+ ions dissolve black ppt by heating them with 50% HNO3. To this solution add ammonium hydroxide solution. Appearance of deep blue colouration in the solution shows the presence of copper ions in the solution. ! To test Zn2+ ions, boil the filtrate to remove H2S gas, then add solid NH4Cl to this and heat to dissolve NH4Cl. Add excess of NH4OH so that a solution is ammoniacal. Now pass H2S gas through this ammoniacal solution. Dirty white or grey precipitation indicates zinc. Separate the precipitates and dissolve it in minimum amount of dil.HCl. Boil to expel H2S gas and add potassium Ferro cyanide solution, white or bluish white ppt. confirm Zn2+ ions in the solution. RESULT: The given sample of brass contains copper and zinc metals as the main constituents.

EXPERIMENT-2 AIM: To analyze a sample of bronze qualitatively. REQUIREMENTS: China dish, test-tube funnel, filter paper and common laboratory reagents. THEORY:

Bronze is an alloy of copper and tin with the following composition Cu=88-96% and Sn=4-12%.Thus copper and zinc form the main constituents of bronze. Both these metals dissolved in nitric acid. 3Cu + 8H+ + 2NO3-

3Cu2++2NO +4H2O

4Sn + NO3-(conc.acid) + 10 H+ 4Sn2+ + NH4+ + 3H2O Sn + 4NO3- (conc.acid) + 4H+ H2SnO3 + 2NO2 + H2O Excess of nitric acid is removed by heating the solution. The resulting solution is acidified with dil.HCL and gas is passed when the sulphides of copper and tin are formed. Cu2+ + S2H2SnO3 + 2H2S

CuS (Black ppt) SnS2 (Black ppt) + 3H2O

The sulphide are separated by boiling the ppt. with yellow ammonium sulphide when SnS2 goes into solution as thiostannate where as CuS is not affected. SnS2 + (NH4)2S

(NH4)2SnS2

CuS (Black ppt) + (NH4)2S

CuS (unaffected)

The soluble black ppt. is tested for Cu2+ ions and the solution is tested for Sn2+ ions as in elementary qualitative analysis. PROCEDURE: ! Take about 1g of small pieces of bronze in a china dish and add to it 5-10ml of dil. . ! Heat the contents slowly to dissolve copper and tin completely and then boil the contents to a paste to remove excess of HNO3. All this is carried out in cup board. ! Dissolve this dry mass in distilled water containing HCL (1:1) to get a clear solution. ! Transfer the solution in a test tube and pass H2S in excess i.e. till the precipitation is complete. Filter and reject the filtrate. ! Take the black ppt in a test tube and add to it 2-3 ml of yellow ammonium sulphide and heat. Filter the contents. Black residue is tested for Cu2+ ions and filtrate is tested for Sn2+ ions. ! Analysis of black residue: Transfer a little of the black ppt into a test tube. Add to it 2-3 ml of 50% HNO3 and boil the contents of the tube. A light blue or green solution indicates the presence of Cu2+. Divide this solution into two parts.

(a) To one part add excess of NH4OH a deep blue colouration confirms the presence of Cu2+ ions. (b) Acidify the second part with the acetic acid and add K4[Fe(CN)6] i.e. potassium ferrocynaide solution. A reddish brown ppt confirms the presence of Cu2+ ions. ! Analysis of filtrate: Boil the filtrate with 1ml. conc. HCL. To this solution add 0.5g of zinc. Dust and boil it for 2-3 minutes. Filter and to filter add 1-2ml of mercuric chloride solution. A white ppt turns grey on standing confirms the presence of Sn4+ ions. RESULT: The given sample of bronze contains Cu and Sn as the main top or form.

SOME OF THE ALLOYS AND THEIR USES: A. Stainless Steel Alloy and its Uses:

This name stainless steel is commonly referred to those metal alloys comprising 10.5% or more Chromium (Cr) and 50% Iron (Fe) in it. There are different types of stainless steel depending on the amount of chromium, iron and other metals in them. The chromium present in it gives stainless steel its highly corrosion resistant property. Pure iron is unstable and corrodes naturally

by rust formation. By the addition of chromium, iron is prevented from combining with oxygen and water to formrust. This highly stain resistant alloy looks bright because of its ability to reflect light. It is used to make kitchen utensils, as stainless steel forms one of the most hygienic surfaces to store and prepare food in. Neither do they affect the flavor of the food, nor do they react with acidic foods during cooking. Moreover, since it has no pores in its surface it does not collect germs, dirt or grim, thereby making it very easy to clean. Besides cookware, stainless steel is also used for preparing surgical instruments, reinforcement bars, masonry support, washing machine drums, ships, chemical tankers,etc.

B.

Brass

Alloy

and

its

Uses:

Formed by a combination of zinc and copper, brass is a light yellowish to dark reddish brown colored alloy. The color range will deviate according to the amount of zinc present in brass. The higher the zinc content, the lighter will be the color. Brass is malleable, a good conductor of heat, resistant to salt water corrosion, etc. which is why it used to make items that come in contact with harsh environments such as tubes, pipes, weather stripping and several architectural trim pieces. Brass' excellent acoustic properties cause it to be used to make wind musical instruments. Instruments like euphonium, trombones, saxophone, tubas, horns, etc. are made from brass. Moreover, since brass does not

tarnish easily, it is also used to make utensils, cutlery and other small decorative items. Its thermal conducting property makes it useful in the manufacture of radiators and heat exchangers such as oil coolers, air conditioners and heater cores.

C. Sterling Silver Alloy and its Uses:

Silver in its purest form is malleable, ductile and extremely soft. This extreme softness makes it easy to work with; however, it also has its drawbacks. This cause silver to be scratched and deformed easily, thereby making it not suitable for manufacture of functional items. Thus, pure silver (92.5%) is combined with 7.5 % copper metal to get 925 sterling silver. The copper metal gives silver, the ample strength required. Besides copper, even germanium, platinum and zinc can be added to the silver to form sterling silver. Sterling silver is used to make 925 silver jewelry. Another popular use of sterling silver is for the manufacture of tableware. Silver knives, spoons, forks, trays and tea sets are made and used by the higher class of people. Since sterling silver is naturally aseptic and is also resistant to antiseptics, heat sterilization and body fluids, it is used in the manufacture of medical instruments. Moreover, it is also used to make musical instruments like flute and saxophones. These were just three types of alloys and their uses. Alloys are truly beneficial because metals in their pure form are mostly very delicate to be used to make

functional items. However, by alloy formation, we have been able to put all these metals to good use.

Вам также может понравиться

- School: Sta. Maria Integrated School Group No. Names: Energy Forms & Changes Virtual LabДокумент3 страницыSchool: Sta. Maria Integrated School Group No. Names: Energy Forms & Changes Virtual LabNanette Morado0% (1)

- Study of Constituents of Alloys - ChemistryInvestigatoryProjectДокумент17 страницStudy of Constituents of Alloys - ChemistryInvestigatoryProjectAnirudh Aurange75% (4)

- Anodes and Cathodes in Corrosion ReactionsДокумент10 страницAnodes and Cathodes in Corrosion ReactionsSyed50% (4)

- Diabetes Mellitus Nursing Care PlanДокумент7 страницDiabetes Mellitus Nursing Care PlanjamieboyRN91% (32)

- Writing The Motherland From The DiasporaДокумент23 страницыWriting The Motherland From The DiasporaIfeoluwa Watson100% (1)

- Study of Alloys On SubstituetsДокумент15 страницStudy of Alloys On Substituetsmilanraj9148Оценок пока нет

- Chemistry Project 2016Документ20 страницChemistry Project 2016Divya KumawatОценок пока нет

- ChemДокумент10 страницChemMEGH TRIVEDIОценок пока нет

- Study of Constituents of An AlloyДокумент9 страницStudy of Constituents of An AlloyShrikant ShendyeОценок пока нет

- Chemistry PPДокумент20 страницChemistry PPArmaan MunavvariОценок пока нет

- Certificate of Authenticity: Signature (Subject Teacher)Документ15 страницCertificate of Authenticity: Signature (Subject Teacher)Rizwana KowserОценок пока нет

- Bhartiya Vidya Bhavan Vidyashram: Chemistry Investigatory ProjectДокумент23 страницыBhartiya Vidya Bhavan Vidyashram: Chemistry Investigatory ProjectMudit MangalОценок пока нет

- Study of Constituents of AlloysДокумент17 страницStudy of Constituents of AlloysPrakash Giri100% (2)

- Chemistry 160130151053Документ16 страницChemistry 160130151053Ayush PattanayakОценок пока нет

- Vikash VermaДокумент12 страницVikash VermaShivansh NigamОценок пока нет

- Analysis of Alloys 3.preparation of Alloys 4.some Common Alloys 5.experiment 6.uses of Alloys 7.examiner's Remark 8.bibliographyДокумент15 страницAnalysis of Alloys 3.preparation of Alloys 4.some Common Alloys 5.experiment 6.uses of Alloys 7.examiner's Remark 8.bibliographyRanjana UpadhayayОценок пока нет

- Avishesh Chemistry AlloyДокумент22 страницыAvishesh Chemistry AlloyAdarsh HackologyОценок пока нет

- Alloy Analysis Class 12Документ18 страницAlloy Analysis Class 12TusharSharmaОценок пока нет

- Analysis of AlloyДокумент14 страницAnalysis of AlloysharvendambreОценок пока нет

- Chem 01Документ49 страницChem 01eniyan rОценок пока нет

- An Alloy Is A Homogenous Mixture of Two or More Metals or A Non-Metal. An A - 20231119 - 112653 - 0000Документ16 страницAn Alloy Is A Homogenous Mixture of Two or More Metals or A Non-Metal. An A - 20231119 - 112653 - 0000JOEL AОценок пока нет

- ChemДокумент15 страницChemSunitha JadhavОценок пока нет

- AlloysДокумент13 страницAlloysKshitiz SinghОценок пока нет

- Components of AlloyДокумент9 страницComponents of AlloyKanishk MehtaОценок пока нет

- Chemistryproject On Alloy Extraction Class 12Документ17 страницChemistryproject On Alloy Extraction Class 12Shobhit VarshneyОценок пока нет

- Metals and Non Metals - Shobhit NirwanДокумент17 страницMetals and Non Metals - Shobhit NirwanBhaskar 8287Оценок пока нет

- CBSE 2012 Physics ProjectДокумент13 страницCBSE 2012 Physics ProjectAnshumaan Singh0% (2)

- Project: Chem IstryДокумент17 страницProject: Chem IstryAman PandeyОценок пока нет

- DownloadedДокумент12 страницDownloadedAniket shuklaОценок пока нет

- Chemistry ProjectДокумент10 страницChemistry ProjectVineet Agarwal50% (4)

- Metals and Non Metals - NotesДокумент13 страницMetals and Non Metals - NotesmittalshivamОценок пока нет

- Project: ChemistryДокумент17 страницProject: ChemistryNilay BaranwalОценок пока нет

- 10 Unit 3 PrintДокумент10 страниц10 Unit 3 PrintClaresse NavarroОценок пока нет

- Chemistry Investigatory Project Study of Constituent of AlloysДокумент19 страницChemistry Investigatory Project Study of Constituent of AlloysVaishnavi.V NathanОценок пока нет

- Metals and Non MetalsДокумент15 страницMetals and Non Metals2erwr100% (2)

- Topic - Alloy Analysis: Year-2018-19 Roll no-Class-XII-bДокумент12 страницTopic - Alloy Analysis: Year-2018-19 Roll no-Class-XII-bajinkya tripathiОценок пока нет

- VEDANTДокумент15 страницVEDANTsujal deulkarОценок пока нет

- Chemistryproject 110823100248 PhpappДокумент17 страницChemistryproject 110823100248 PhpappAman SkОценок пока нет

- Chem Investory ProjectДокумент12 страницChem Investory ProjectRohit KumarОценок пока нет

- Chemistry: Preliminary Exam NotesДокумент25 страницChemistry: Preliminary Exam NotesHussainMohammedОценок пока нет

- Project Report On Constituents of An AlloyДокумент10 страницProject Report On Constituents of An AlloySrinjoy SahaОценок пока нет

- Metals OlevleДокумент9 страницMetals OlevleaayannisarОценок пока нет

- MetalДокумент14 страницMetalsusanОценок пока нет

- Metals and Non-MetalsДокумент23 страницыMetals and Non-MetalsAnonymous ufMAGXcskMОценок пока нет

- Metals (Key Points and Q&A)Документ7 страницMetals (Key Points and Q&A)wakakkaОценок пока нет

- Fdocuments - in Chemistry Investigatory Project Study of Constituent of AlloysДокумент19 страницFdocuments - in Chemistry Investigatory Project Study of Constituent of AlloysLogesh BalamuruganОценок пока нет

- Jain International School 2020 - 2021: A Project For Chemistry On "Study of Constituents & Analysis of An Alloy"Документ15 страницJain International School 2020 - 2021: A Project For Chemistry On "Study of Constituents & Analysis of An Alloy"anmolshubhamОценок пока нет

- Lecture04c - Main-Group - Elements-PART3 - PenДокумент48 страницLecture04c - Main-Group - Elements-PART3 - PenAaf AbdRashidОценок пока нет

- D-& F Block ElementsДокумент46 страницD-& F Block ElementsdetectionisimpressionОценок пока нет

- Metals and Non-Metals - Chemical Properties NotesДокумент13 страницMetals and Non-Metals - Chemical Properties NotesDhyan ShahОценок пока нет

- Chapter 23-Metals and MetallurgyДокумент25 страницChapter 23-Metals and MetallurgyBalakrishna ArpulaОценок пока нет

- Metals and PolymersДокумент37 страницMetals and PolymerscharlotteconsigoОценок пока нет

- Chemistry Investigatory ProjectДокумент17 страницChemistry Investigatory Projectcaptainclock50% (4)

- 3 NOV Class 10 Metals and Non-Metals ChemДокумент40 страниц3 NOV Class 10 Metals and Non-Metals Chemgourav kaliaОценок пока нет

- Chapter - 8 MetalДокумент12 страницChapter - 8 Metalamit_idea1Оценок пока нет

- General Principles ProcessesДокумент19 страницGeneral Principles ProcessesAnand MurugananthamОценок пока нет

- AlloysДокумент19 страницAlloysAditi KathaitОценок пока нет

- Metals PreliminaryДокумент26 страницMetals PreliminaryIra Katriel NunagОценок пока нет

- Chemistry ProjectДокумент18 страницChemistry ProjectSoumendu BiswasОценок пока нет

- Ballad May Alyssa G. MetalsДокумент18 страницBallad May Alyssa G. MetalsMay Alyssa BalladОценок пока нет

- Chapter 13, 14 - Metals PDFДокумент9 страницChapter 13, 14 - Metals PDFAarush SharmaОценок пока нет

- Metallurgy 2024Документ13 страницMetallurgy 2024pokeninjazxОценок пока нет

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelОт EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelОценок пока нет

- CW Catalogue Cables and Wires A4 En-2Документ1 156 страницCW Catalogue Cables and Wires A4 En-2Ovidiu PuieОценок пока нет

- C 08 S 09Документ8 страницC 08 S 09Marnel Roy MayorОценок пока нет

- Rekapan Belanja JKNДокумент5 страницRekapan Belanja JKNAPOTEK PUSKESMAS MALEBERОценок пока нет

- Review Factors Contributing To Medication Errors: A Literature ReviewДокумент9 страницReview Factors Contributing To Medication Errors: A Literature Reviewsoul_0602Оценок пока нет

- LR-360KAS-BROCHURE-LNG Sampling SystemsДокумент4 страницыLR-360KAS-BROCHURE-LNG Sampling SystemsIdehen KelvinОценок пока нет

- Food DirectoryДокумент20 страницFood Directoryyugam kakaОценок пока нет

- (PDF) Books Toxic Parents Epub Popular Download - by Susan ForwardДокумент1 страница(PDF) Books Toxic Parents Epub Popular Download - by Susan Forwardmartagonzalezbordonaba0% (3)

- Methods For The Assessment of Productivity of Small Hold FarmsДокумент49 страницMethods For The Assessment of Productivity of Small Hold FarmsMonaliz NagrampaОценок пока нет

- Fermentation Media: Agustin Krisna WardaniДокумент27 страницFermentation Media: Agustin Krisna WardaniYosiaОценок пока нет

- 13 Unit 5 PainДокумент4 страницы13 Unit 5 PainAndres SalazarОценок пока нет

- Level 9 - Unit 34Документ7 страницLevel 9 - Unit 34Javier RiquelmeОценок пока нет

- EarthWear Clothier MaterialsДокумент1 страницаEarthWear Clothier MaterialsZhining LimОценок пока нет

- Tugas Gizi Caesar Nurhadiono RДокумент2 страницыTugas Gizi Caesar Nurhadiono RCaesar 'nche' NurhadionoОценок пока нет

- ZX 470Документ13 страницZX 470Mohammed Shaheeruddin100% (1)

- Fundamental Unit of Life 1-25Документ25 страницFundamental Unit of Life 1-25Anisha PanditОценок пока нет

- Morita Therapy For Depression and AnxietyДокумент13 страницMorita Therapy For Depression and AnxietyPedro GuimarãesОценок пока нет

- JIDMR SCOPUS Ke 4 Anwar MallongiДокумент4 страницыJIDMR SCOPUS Ke 4 Anwar Mallongiadhe yuniarОценок пока нет

- Governance, Business Ethics, Risk Management and Internal ControlДокумент4 страницыGovernance, Business Ethics, Risk Management and Internal ControlJosua PagcaliwaganОценок пока нет

- Resume Rough DraftДокумент1 страницаResume Rough Draftapi-392972673Оценок пока нет

- WB Food Processing IndustryДокумент13 страницWB Food Processing IndustryRakesh KumarОценок пока нет

- Dearcán Ó Donnghaile: ProfileДокумент2 страницыDearcán Ó Donnghaile: Profileapi-602752895Оценок пока нет

- BU2508DFДокумент3 страницыBU2508DFRaduОценок пока нет

- The Stony Brook Press - Volume 11, Issue 4Документ28 страницThe Stony Brook Press - Volume 11, Issue 4The Stony Brook PressОценок пока нет

- Annual Sustainability Report 2022-23 FinalДокумент93 страницыAnnual Sustainability Report 2022-23 FinalLakshay JajuОценок пока нет

- Aphids and Ants, Mutualistic Species, Share A Mariner Element With An Unusual Location On Aphid Chromosomes - PMCДокумент2 страницыAphids and Ants, Mutualistic Species, Share A Mariner Element With An Unusual Location On Aphid Chromosomes - PMC2aliciast7Оценок пока нет

- Muet Topic 10 City Life Suggested Answer and IdiomsДокумент3 страницыMuet Topic 10 City Life Suggested Answer and IdiomsMUHAMAD FAHMI BIN SHAMSUDDIN MoeОценок пока нет

- Dyestone Blue MX SDS SA-0186-01Документ5 страницDyestone Blue MX SDS SA-0186-01gede aris prayoga mahardikaОценок пока нет