Академический Документы

Профессиональный Документы

Культура Документы

Friction Factor

Загружено:

Clarissa GomezИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Friction Factor

Загружено:

Clarissa GomezАвторское право:

Доступные форматы

EXPERIMENT 4 FRICTION FACTOR

(Fluid Flow Set-up)

INTRODUCTION

When the fluid flows through a pipe, the amount of mechanical energt lost because of friction depends on the properties of thu flo*iog fluid and the extent of tbe pipe system. For the flow of nuid trrougtr r rtt"ight pipe wiih uniform diameter, the amount of ftiction loss is uf""t"J W fr" .Ir"tJ"ity of tne nula, the density of the fluid, rhe viscosity of the fluid, dre diameter of the pipe, ire lengrh of the pipe, and tre rouglrness of the pipe. The equivalent roughness ofthe pipe, e, represen8 lhe average nughness or dep& of the surface irregularities. Theoraically, the friction factor for lamioar flow is determined by the equatron:

-16 r=x;

While for a turbulnt flow, Reynolds number, togedrer wift the reldive rougbness of the pipe i.e., f = o (NRe, elD), play a big frctor on the friction factor as shown in the equation below:

#=-.{[,,';).[ft)']

mecbanical energy balance is applied to ttre fluid flowing through a straight pipe, an equation to calculde F can be derivod:

Ifa

(^

\z

n=-& =*"[!so ,][+l r -."[ e

)ls")

Where: F = total fluid friction losses through ihe pipe -6p = pressure drop over the system due to friction p = density of fre fluid

Ro = manometer resding Pr4 = densitY of mercury g = gravitation at acceleration D = inside diameter of rire piPe

I I

Sv applyrng dimensional analysis to these variables, the following relationship wtrich is knowr

as the Fanning oquation can be obtained:

r=#

I

i ,

*n-"'fl"1Yf'fl"fi?xross

&rough frepipe

i

OBJECTIVE

i-:fl$*"iit;fl:''

*" = force-mass conversion factor The Fannurg equation is used to compute for the friction factor b&sed on oryerimontal darl.It is clear that it is, likewise, a firnction of the Reynolds number and the relative roughness of tbe pipe. .

.

i

To determine the friction factor of the fluid moving through a straight pipe To determine tre effect of Reynolds Number and relative roughness on the friction factor

i i

i

ofthe fluid flow

i

l

:

EoutpMENT AND UATERIALS

o t . o L

2. 3.

fluid flow set-r4l

steel taps

'

stop walch

thermometer

PROCEDURE

Isolate the piping system to be considered.

Prime and start-up Sre pump to be used in the fluid flow set-up allowing the watr to pass througb &e pipeline. Stabilize dre system. Measure lhe leng& of the sfaight pipe mnsidered in dre system.

Xretemine dre amount of water volumetric flow late of water.

trat will be collected for one minu@.

Calcula.e the

4.

Determine the temperature theoretical frrction factor.

of the water. compute for the Reynolds Number and $e

5. Red

the manometer. Compute for the otal fiiction losses, F and the eriperimental friction

factor.

6.

7.

Determine percentage of error

Repeat procedure 3 to 6 for Trial 2.

28

0_

:l

rlll

lll lll

trJ

fiilI

ul F ut

-lll -lll

;il

;lll

School of Chenical Engineering and Chanis,ry Mapua lnsliute of Tecrmo lagy Chemical Engineering Laborutory

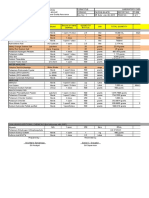

FINAL DATA SHEET Experiment 4 FRICTION FACTOR (Fluid Flow Set-up)

Student's Name

Instructor's Name

Subject and Section/ Group No.

Date of Submission

DATA AND RESULTS

Volumetric flow rate of the water, V Velocity of the water, u

Inside diameter ofthe pipe, D

m'ls

rnls

m'/s

m,/S

Temperatue of the water

Density of the water, p

"c kdm'

cP

t

keim''

cP

Viscosity of the water, p

Reynolds number, Nn. Manometer reading,

R-

cmHg l/r,g

m m

cm Hg

Mechanical energy lost due to friction, F Length ofthe straight pipe,

Roughness of the pipe, a

J^.e

m

Relative roughness ofthe pipe, elD Experimental Fanning friction factor, f,*pa-"'r'r

fheoretical Fmning fiiction frotor, fu.-.c*r

%o

enOt

30

Chem8try Jchool oJ Chemical Entlineefing 'rtd ,VaWa lnsrihtte oI Tc.ct6ologY Chemieal btgine ering l'abolarory l

STUDY QUESTIONS

l.

pipe having ut water at 25"C flows at a velocify of 5 m/s through a sfieight commrci8l steel loss inside diameter of 62.71 n,-. Ii th" pipe is I 9 m long, calculate tre mechsrical-energy due to friction.

2. A unit operations laboraory class desires i:o determine experimentally

the Fanning friction pipe used is a 2-in' factor lor a pipe flow system equipped wrth a mercury manometer' The ,rh"dul 40'slel pipe tra"lng " leog$ of l0 ft between pressure taps ^It ls horizontal and the dr"re is no bend, trtting, or di-ameter-chmge over its length. water t 8o"F flows rhrorrgh reading is 3 in., what is $e experimental Farning tuJi. rthe manometer prp.

"i","r" "r'g friction factor?

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Chocolate Fat Bloom ArticleДокумент4 страницыChocolate Fat Bloom ArticleClarissa GomezОценок пока нет

- Fs Topic FormatДокумент3 страницыFs Topic FormatClarissa GomezОценок пока нет

- ChemicalsДокумент6 страницChemicalsClarissa GomezОценок пока нет

- Flowchart Graduation Clearance - PaymentsДокумент1 страницаFlowchart Graduation Clearance - PaymentsClarissa GomezОценок пока нет

- Chap 7 Reynolds ExpДокумент2 страницыChap 7 Reynolds ExpClarissa GomezОценок пока нет

- Chap 7 Reynolds ExpДокумент2 страницыChap 7 Reynolds ExpClarissa GomezОценок пока нет

- Particle Problem SetДокумент1 страницаParticle Problem SetClarissa GomezОценок пока нет

- Exp 5 (From Omar)Документ5 страницExp 5 (From Omar)Clarissa GomezОценок пока нет

- Families of CirclesДокумент10 страницFamilies of CirclesClarissa GomezОценок пока нет

- Issues in The Solution of Equations in ModelДокумент10 страницIssues in The Solution of Equations in ModelClarissa GomezОценок пока нет

- Post Lab Report PDFДокумент15 страницPost Lab Report PDFClarissa Gomez0% (1)

- Experiment 1 Physical Constants of Solid and Liquid and Organic CompoundsДокумент7 страницExperiment 1 Physical Constants of Solid and Liquid and Organic CompoundsClarissa GomezОценок пока нет

- Kraft Pulping and Recovery Process BasicsДокумент50 страницKraft Pulping and Recovery Process BasicsPhilip MathewsОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Automatic Valve Gemue DB - 512 - GBДокумент6 страницAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- V NotchДокумент1 страницаV Notchcototo33Оценок пока нет

- Me 2351-Gas Dynamics and Jet Propulsion Unit-I PART-A (2 Marks)Документ14 страницMe 2351-Gas Dynamics and Jet Propulsion Unit-I PART-A (2 Marks)vsanthanamОценок пока нет

- Chapter 4 EORДокумент115 страницChapter 4 EORHidayahSazli100% (1)

- A Project Report On Hydraulic OptimisationДокумент10 страницA Project Report On Hydraulic OptimisationadeebОценок пока нет

- Groundwater Studies UNESCOДокумент423 страницыGroundwater Studies UNESCOSudharsananPRSОценок пока нет

- Globalvision, Inc. 8800 Jefferson Highway Osseo, MN 55369 Phone: 763-391-0990 Fax: 763-391-7668 Email: Info@Документ4 страницыGlobalvision, Inc. 8800 Jefferson Highway Osseo, MN 55369 Phone: 763-391-0990 Fax: 763-391-7668 Email: Info@FurqanОценок пока нет

- References 2009 Compressibility Turbulence and High Speed FlowДокумент27 страницReferences 2009 Compressibility Turbulence and High Speed FlowThePriusОценок пока нет

- Fines Migration in Two-Phase Flow: Amlt K. Sarkar, Mukul M. SharmaДокумент7 страницFines Migration in Two-Phase Flow: Amlt K. Sarkar, Mukul M. SharmaAnonymous 1Yc9wYDtОценок пока нет

- Fluid Mechanics PDFДокумент179 страницFluid Mechanics PDFNishchay Choudhary100% (1)

- ME Circular ClarifiersДокумент5 страницME Circular ClarifiersLien NguyenОценок пока нет

- Probability and Confidence IntervalsДокумент14 страницProbability and Confidence IntervalsKing EverestОценок пока нет

- Canute - Hydrostatics and Hydraulic CalculationsДокумент4 страницыCanute - Hydrostatics and Hydraulic CalculationsEdgardo EscobarОценок пока нет

- Course File Format Fluid MechanicsДокумент13 страницCourse File Format Fluid MechanicssidyantОценок пока нет

- PIPESIM 2017 Training ModuleДокумент38 страницPIPESIM 2017 Training Modulefelix wijayaОценок пока нет

- Penstock Thickness CalculationДокумент2 страницыPenstock Thickness Calculationrakesh1987_careers100% (6)

- Centrifugal PumpsДокумент8 страницCentrifugal Pumpsanto3harrish3fdoОценок пока нет

- Class A1A9Документ14 страницClass A1A9SalimОценок пока нет

- Basic Principles of Flight PDFДокумент36 страницBasic Principles of Flight PDFAttakaththi DineshОценок пока нет

- Fuel Pump CavitationДокумент3 страницыFuel Pump Cavitationstergios meletisОценок пока нет

- 2016 Gec Infosheet Rcp-Kinta 02Документ1 страница2016 Gec Infosheet Rcp-Kinta 02Chen YishengОценок пока нет

- Permintaan Material 2010Документ74 страницыPermintaan Material 2010suyutiОценок пока нет

- Extrusion Press Maintenance ManualДокумент55 страницExtrusion Press Maintenance ManualDejan Mitrović100% (6)

- BGAH Series: Medium Pressure Filters Max. 500 L/min. 25 BarДокумент6 страницBGAH Series: Medium Pressure Filters Max. 500 L/min. 25 BarKot878Оценок пока нет

- PET467E Derivation Radial Diffusivity Equation Handout 1Документ3 страницыPET467E Derivation Radial Diffusivity Equation Handout 1abdounouОценок пока нет

- Pump KnowledgeДокумент17 страницPump Knowledgesmupy_122Оценок пока нет

- 5009201082-Kintania Sisca Rivana-Tugas-PSHДокумент5 страниц5009201082-Kintania Sisca Rivana-Tugas-PSHKintania Sisca Rivana Part IIОценок пока нет

- G2C and G2S Series - Vertical Cantilever and Sump Pumps: Technical Specification PagesДокумент32 страницыG2C and G2S Series - Vertical Cantilever and Sump Pumps: Technical Specification PagesAndres GonzalezОценок пока нет

- What-Is-A-Watershed-Webquest StudentworksheetДокумент5 страницWhat-Is-A-Watershed-Webquest Studentworksheetapi-264220584Оценок пока нет

- B.3.8 - Safety Valves SpecДокумент8 страницB.3.8 - Safety Valves SpecEmiel RoestenburgОценок пока нет