Академический Документы

Профессиональный Документы

Культура Документы

Mps Feb03 Article

Загружено:

ghezelasheghiИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mps Feb03 Article

Загружено:

ghezelasheghiАвторское право:

Доступные форматы

STEAM TURBINE TECHNOLOGY

Bigger blades cut costs

This year will see the commercial introduction of the worlds largest steel last-stage blades for steam turbines.

Amir Mujezinovic, GE, Schenectady, NY, USA

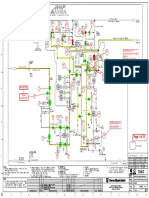

Figure 1. Last stage blade turbine are from 5 to 21 kg/s/m2 (3 500 to 15 000 lbm/h/ft2) end load; from 150 to 300 m/s (500 to 1000 ft/s) annulus velocity; and from 4 to 10 per cent exit moisture. Based on a review of market needs, GE and Toshiba chose the primary design point for the 40 in and 48 in last stage blades to be 11 kg/s/m2 and 225 m/s annulus velocity (8000 lbm/h/ft2, 750 ft/s annulus velocity), and 8 per cent exit moisture. In addition to this primary design point, two secondary design points were selected: 8 kg/s/m2 and 200 m/s annulus velocity (6000 lbm/h/ft2, 650 ft/s annulus velocity); and 20 kg/s/m2 and 275 m/s annulus velocity (15000 lbm/h/ft2, 900 ft/s annulus velocity). The design is optimised at the primary design point while the secondary design points are monitored to ensure that no performance problems are introduced at these points.

he shape and design of a steam turbine blade determine how much of the energy of the steam is turned into work. A longer last stage blade increases the power output capability of the steam turbine, which in turn leads to improved power plant efficiency and a lower electricity production cost. In the 1980s most turbine manufacturers had developed and put into service titanium blades with similar annulus areas. Due to subsequent improvements in both design methodology and material characteristics, GE Power Systems and the Toshiba Corporation made the decision to develop new blades using steel as a blade material. The use of steel results in a lower cost to the customer and avoids uncertainty in the supply, and therefore price, of high quality titanium forgings. GE and Toshiba recently completed the development of new 40 in and 48 in steel laststage blades for steam turbine applications worldwide. In terms of annulus area, the 48 in blade is the largest steel 3000 rpm last stage blade in the world.

Aerodynamic design

The last three stages work together as a system and are designed aerodynamically using a combination of streamline curvature design methods, two-dimensional cascade analysis, and state-of-the-art three-dimensional computational fluid dynamics analysis techniques. This design employs advanced aerodynamic features including meridional flowpath contouring, axial and tangential compound lean of the L-0 nozzle, and tailored exit profiles from the L-1 stage to allow a radius ratio of 0.43 in the L-0 blade. To further reduce the radial pressure gradient at the L-0 nozzle exit, compound tangential lean is employed in the last stage nozzle. This tangential lean has the effect of introducing an inward radial force on the flow forcing more flow into the hub region and increasing the pressure in this region. Combined with the flowpath contouring, the L-0 nozzle lean reduces the radial pressure gradient at the nozzle exit, raises the root reaction, and allows for a lower hub/tip ratio. Axial compound lean is applied to the L-0 nozzle in addition to the compound lean in the tangential direction. The primary purpose of the axial lean is to increase the nozzle-toblade spacing at the tip while maintaining a smaller axial spacing over the remainder of the

Increasing the annulus area

One of the loss mechanisms in the steam turbine is the kinetic energy of the steam as it leaves the last stage blade. The lower the kinetic energy, the higher the steam turbine efficiency will be. The magnitude of loss is proportional to the square of the ratio of the volume flow rate of the steam through the last stage of the steam turbine and the annulus area of the turbine exit. To decrease the loss, a larger turbine exit annulus area is needed. An increase in the last stage blade annulus area can be accomplished by either using shorter blades mounted on a larger diameter rotor (larger hub) or by using longer blades mounted on a smaller diameter rotor. These opposing approaches yield different radius ratios, a key parameter in the aerodynamic and mechanical design of the last stage blade. In the GEToshiba development project, an optimisation of the aerodynamic and mechanical considerations of the design resulted in: A new last stage (L-0) blade length of 1016 mm (40 in) for 60 Hz application and 1219 mm (48 in) for 50 Hz application. A hub diameter of 1565 mm (61.6 in) and 1880 mm (74 in), for 60 Hz and 50 Hz L-0 blades, respectively. Steam turbine last stage blades typically are applied to different machine configurations with varying outputs and operating points. This approach requires a robust design for a wide range of operating conditions. Typical ranges of operation for the last stage of steam

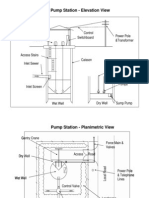

Steam conversion valve Boiler HP turbine LP turbine

Dynamometer A Spray water Flow meter

Figure 2. Test steam turbine system

Dynamometer B

Condenser

February 2003 Modern Power Systems

25

STEAM TURBINE TECHNOLOGY

2. Analysis using a reduced frequency analysis calibrated to empirical data. 3. Validation testing in a subscale test rig, where the last three rotating and stationary stages were tested in actual steam conditions, at a variety of operating conditions (combinations of the steam axial exit velocity and condenser pressure). Blade mounted dynamic strain gauges were used to measure blade vibration.

Testing

The experimental verification of the overall stage efficiency of the new steel last stage blade was performed in an experimental lowpressure model turbine. A schematic diagram of the 10 MW model steam turbine facility used is shown in Figure 2, and a photograph of the model turbine train used in this system is shown in Figure 3. Model turbine tests have been performed with several different end load conditions. The LP end exit axial flow velocity conditions varied from 94 to 212 m/s (310 to 700 ft/s). The results show that the newly developed steel 48/40 in last stage blade has excellent efficiency at the design condition and also in the partial load conditions. Mechanical testing confirmed the mechanical design calculations described above. The running speed to zero speed airfoil transformation, static design and the dynamic design (blade natural frequencies) were validated in a wheel box test. The test set-up consisted of a full-size single flow rotor with the last three stages of blades (also full size) assembled on it (Figure 4). The blades are instrumented with strain gauges and the entire assembly is put into a spin cell basically, a bunker from which air can be evacuated. The test rotors are spun to the desired speed using a drive turbine, the blades excited and blade frequencies measured at various speeds. In addition to the blade frequency measurement, a rotor end mounted torsional shaker was used to measure coupled rotor blade torsional frequencies. To confirm the calculated blade untwist, a strobe light was used to visualise the cover untwist. Results confirmed the rotating speed at which adjacent covers engage and from that, it was inferred that the analytical transformation of the airfoil from running airfoil to the zero speed airfoil was correct. During wheel box testing, both static and dynamic strain gauges were used for blade instrumentation. Static gauges were mounted both on the airfoil and in the wheel and blade dovetail to measure static stress level. The results correlated very well with the analytical results. The dynamic strain gauges measured blade-vibrating frequency and coupled rotor blade torsional vibration. The measured blade frequencies confirmed the analytical predictions and the measured coupled blade rotor torsional vibrations confirmed the predicted margins from two times electrical frequency.

Figure 3. Test model turbine

height. A larger axial spacing is desired at the tip to allow additional time for the water droplets torn from the trailing edge of the nozzle to accelerate to flow velocity before entering the L-0 blade. Better matching of the droplet and flow velocity reduces erosion and contributes to the long-term reliability of this design.

Mechanical design of stages

On the last stage blade the most important mechanical design features are the curved axial entry dovetail (a portion of the blade that mates with the rotor), nub and sleeve as a part span damper, and an integral blade cover (see Figure 1). The mechanical design consists of several interconnected steps: transforming an aerodynamic shape of the airfoil into an as-machined shape; static design; dynamic design (or aeromechanics design); and erosion design. The airfoil shape used in the aerodynamic calculations is the one that the airfoil will assume at the running speed. The low-pressure blades untwist during acceleration from rest to running speed. A necessary step during the mechanical design is to follow a process that determines the zero-speed airfoil shape that yields the desired aerodynamic shape at operating speed. The basic premise in the static design of the airfoil and its accompanying rotor wheel is that both the maximum average stress in all the wheel and blade sections and the maximum local stress throughout the blade and the wheel are kept under a certain level, established to ensure substantial margin to failure under all operating conditions and extreme faulted conditions. The maximum average stress (assuming fixed material properties) determines the overspeed margin: when compared to the yield strength of materials (blade and wheel) it determines the overspeed at which section gross yielding would occur; and when compared to the ultimate strength, it determines the overspeed at which ductile failure would occur. In contrast, the maximum local stress determines the low cycle fatigue life (number of cycles to a crack initiation) and also plays a role in the level of stress corrosion cracking (SCC) risk. The 40 in and 48 in last stage blades were designed to conservative stress and overspeed criteria in order to ensure safe and reliable service for the life of the machine. The basic premise in the dynamic design

(aeromechanical design) of the airfoil is that the blade natural frequencies those frequencies at which vibration will take place in the absence of any continuing excitation at running speed must have a margin from a range of multiples of engine speeds (so-called per-rev lines). The per-rev excitation comes from different sources, most of which are associated with the non-uniform flow in the steam path, either upstream or downstream from the blade row. In addition to the per-rev excitation, long low-pressure blades (in particular last stage blades in some of the off-design operating regimes) can experience vibration induced by flow (aeroelastic instability). Design solutions dealing with aeroelastic instability have been primarily empirical in nature and specific to application. The risk of aeroelastic instability is greatest

Figure 4. New blades installed on a rotor in the region of low flow (low steam axial exit velocity) and high condenser pressure (a faroff-design condition). In such conditions a massive flow separation from the hub of the last stage blade forces the migration of the steam flow to the upper portion of the last stage blade. Flow separation from the airfoil then can cause blade stall flutter, and flow instability can cause buffeting of the blades. GE and Toshiba took a three-fold approach to guard against such instability: 1. Use of a last stage blade design that employs integral covers and part span dampers. This construction increases the frequency of the row of blades (when compared to free-standing blades) and is a well recognised mitigation against instability. In addition, this construction provides additional damping at the locations of contact between adjacent blades.

Market introduction

Overall, the newly developed 40/48 in last stage group is a significant contribution to steam turbine performance and reliability. Beginning in 2003, GE and Toshiba expect to offer the new blades on their steam turbines for both combined cycle and fossil power MPS plant applications.

February 2003 Modern Power Systems

27

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Introduction To Oil & Gas ManualДокумент95 страницIntroduction To Oil & Gas ManualPradeep Mani100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- HWH Joystick-Controlled 200/210 Series Leveling SystemДокумент40 страницHWH Joystick-Controlled 200/210 Series Leveling SystemEdward Tillman100% (3)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Kisssoft-Anl-072-E-Contact Analysis in The Cylindrical Gear CalculationДокумент40 страницKisssoft-Anl-072-E-Contact Analysis in The Cylindrical Gear Calculationanush_swaminathanОценок пока нет

- Sample of P&ID Marked Up DrawingДокумент11 страницSample of P&ID Marked Up DrawingToniОценок пока нет

- Defects and CausesДокумент58 страницDefects and CausesPrasannaVenkatesan100% (2)

- Sea Water Intake DrawingДокумент2 страницыSea Water Intake DrawingghezelasheghiОценок пока нет

- FRACCIONAMIENTO de Aceite de PalmaДокумент8 страницFRACCIONAMIENTO de Aceite de PalmaJame QFОценок пока нет

- 072-090 2Документ15 страниц072-090 2hishammahrousm89100% (1)

- d4 Intake DesignДокумент5 страницd4 Intake DesignchoibeОценок пока нет

- 1,1,6 Precalciner KilnsДокумент39 страниц1,1,6 Precalciner KilnsMohamed Saad100% (1)

- Material Safety Data SheetДокумент2 страницыMaterial Safety Data SheetghezelasheghiОценок пока нет

- Constructal Multi-Scale Structure For Maximal Heat Transfer Density - BejanДокумент11 страницConstructal Multi-Scale Structure For Maximal Heat Transfer Density - BejanghezelasheghiОценок пока нет

- Submersible Non-Clog Pumps Minimum Submergence ConsiderationsДокумент4 страницыSubmersible Non-Clog Pumps Minimum Submergence ConsiderationsghezelasheghiОценок пока нет

- Condensate Oxygen Control in A Combined Cycle SystemДокумент8 страницCondensate Oxygen Control in A Combined Cycle SystemghezelasheghiОценок пока нет

- Exp 1 Cross Flow Heat ExchangerДокумент6 страницExp 1 Cross Flow Heat ExchangerChristopher SequeraОценок пока нет

- What Is A Safe NPSH Margin For A Centrifugal PumpДокумент6 страницWhat Is A Safe NPSH Margin For A Centrifugal PumpghezelasheghiОценок пока нет

- FW Optivent System BrochureДокумент5 страницFW Optivent System BrochuremajortayОценок пока нет

- Asko D5424 ManualДокумент36 страницAsko D5424 ManuallksmrОценок пока нет

- Tigris Gas Manual en FinalДокумент14 страницTigris Gas Manual en FinalLuis13956353Оценок пока нет

- CD150MV Wellpoint Pump: FeaturesДокумент2 страницыCD150MV Wellpoint Pump: FeaturesAbcehmu EgiОценок пока нет

- Vacuum InterruptersДокумент17 страницVacuum InterruptersCARLOS LÓPEZОценок пока нет

- PURY-P400-500YEM-A Service Manual EstaДокумент145 страницPURY-P400-500YEM-A Service Manual EstamikeОценок пока нет

- Distillation Column Tray Selection & Sizing - 1 - Separation TechnologiesДокумент30 страницDistillation Column Tray Selection & Sizing - 1 - Separation TechnologiesHuzefa Calcuttawala0% (1)

- Advanced Lattice Support Structures For Metal Additive ManufacturingДокумент8 страницAdvanced Lattice Support Structures For Metal Additive Manufacturinghadi32Оценок пока нет

- Final Report 3D Chocolate PrintingДокумент20 страницFinal Report 3D Chocolate PrintingPrathamesh PatilОценок пока нет

- PM KPI TrackerДокумент7 страницPM KPI TrackerAmit Kumar UkeОценок пока нет

- Bill of Mat - BlankДокумент6 страницBill of Mat - BlankAlvin AbilleОценок пока нет

- Knauf Sheetrock Firestop 12.5mm-16mm - Technical Datasheet - PB02 - LE - FL - 0422 - V1Документ2 страницыKnauf Sheetrock Firestop 12.5mm-16mm - Technical Datasheet - PB02 - LE - FL - 0422 - V1Matt WilliamsОценок пока нет

- CHE3044F, 2013: Reactor Design 1: TUTORIAL 8: K 0.1 Mi N K 0.1 Mi NДокумент2 страницыCHE3044F, 2013: Reactor Design 1: TUTORIAL 8: K 0.1 Mi N K 0.1 Mi NnmhatityeОценок пока нет

- Inspection & Testing Plan For Sub Base Laying Material: INF-AP-QUA-ITP-06 Rev. 0 Date: 03.07.2018Документ2 страницыInspection & Testing Plan For Sub Base Laying Material: INF-AP-QUA-ITP-06 Rev. 0 Date: 03.07.2018jerin sam kurianОценок пока нет

- Jorge e Ramalho, Lda.: High Standard CutleryДокумент6 страницJorge e Ramalho, Lda.: High Standard CutleryGeafir NicoletaОценок пока нет

- Transmission Towers DetailingДокумент38 страницTransmission Towers DetailingFeleki AttilaОценок пока нет

- Te 710 WebДокумент57 страницTe 710 WebRoman KrautschneiderОценок пока нет

- Accessories For 8 Oc's For TalkalДокумент5 страницAccessories For 8 Oc's For Talkalhanu sunilОценок пока нет

- Alf3 2 - AlufluorodeДокумент15 страницAlf3 2 - AlufluorodeKOUSHIKОценок пока нет

- Plasterboard ImpactchekДокумент3 страницыPlasterboard ImpactchekEdwardLuОценок пока нет

- Siemens Flender Ptimum - Gear - Units - For - The - Palm - Oil - Industry PDFДокумент6 страницSiemens Flender Ptimum - Gear - Units - For - The - Palm - Oil - Industry PDFasiapowerdrive0% (1)

- Cryo CarДокумент21 страницаCryo CarAnup PatilОценок пока нет