Академический Документы

Профессиональный Документы

Культура Документы

Perkin Expert Report

Загружено:

OSDocs2012Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Perkin Expert Report

Загружено:

OSDocs2012Авторское право:

Доступные форматы

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

2 |

TableofContents

INTRODUCTION.................................................................................................................................................3

AUTHORQUALIFICATIONS...................................................................................................................................5

FINDINGS:........................................................................................................................................................6

BACKGROUNDANDDISCUSSIONOFTHEMACONDOWELLANDHORIZONSBOP:...................................................10

OPINIONS&CONCLUSIONS:..............................................................................................................................14

CONCLUSION:.................................................................................................................................................22

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

3 Introduction|

RE: BEEPWATER B0RIZ0N Explosion on Apiil 2u, 2u1u

Repoit of uiegg S. Peikin, P.E.

INTRODUCTION

Engineering Partners International, L.L.C. (EPI) was retained by the Plaintiffs

Steering Committee (PSC) with respect to the DEEPWATER HORIZON Explosion in

the Gulf of Mexico on April 20, 2010. Specifically, you requested that Gregg S.

Perkin, P.E. of EPI review and analyze certain facts and issues concerning the

design, assembly, testing, installation, maintenance, repair, modifications and use

of the subsea blowout preventer (BOP) and its related control systems (CS)

which had been utilized on the mobile offshore drilling unit (MODU) DEEPWATER

HORIZON (HORIZON). You also asked that I review and analyze issues related to

the BOP and its CSs role in the explosions and fire which occurred during the

evening of April 20, 2010 while the HORIZON was drilling and temporarily

abandoning BPs Macondo deepwater well (Macondo) in the Gulf of Mexico

(GoM). Further, what roles the BOP and its CS had in preventing the sinking of

the HORIZON two days later.

Each of the opinions I express herein are based upon my education, training,

knowledge and experience in the areas of mechanical engineering and the design,

application and use of oilfield equipment, such as BOPs and their CS, used in both

onshore and offshore oil and gas drilling and operations.

My opinions are based upon the information and materials which I have reviewed

which are set out in Appendix M and other appendices. They are also based upon

certain regulatory requirements governing offshore oil and gas exploration, drilling

and production activities as well as industry standards including normal and

customary practice for those operating companies (operators) pursuing these

activities. I am familiar with these particular regulations, standards and

recommended practices for the relevant time frame between 2001 to the present.

These materials are commonly and routinely relied upon by Operators in the GoM

when determining both the configuration and the utilization of their BOP and the CS

they choose when planning and conducting the drilling of deepwater wells, such as

Macondo. All of the materials cited herein in the both the endnotes and references

are materials that are relied upon in the ordinary course of business of Operators,

such as BP, and their working interest owners who drill deepwater wells in the GoM.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

4 Introduction|

I have not been asked to make any assumptions, nor have I presumed any facts

beyond those which are evidenced by the reliance materials identified in this Expert

Report, the endnotes and the appendices.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

5 AuthorQualifications|

AUTHORQUALIFICATIONS

Gregg Perkin has been involved in oil and gas drilling equipment

design and oilfield operations since 1968. He has authored

technical papers on equipment design, well control and oilfield

safety including having developed a number of equipment and

systems patents.

While in college, he was employed by a major oil and gas service

company. In 1973, he graduated with a Bachelor of Science in

Mechanical Engineering from California State University at Long

Beach. He became a registered Professional Engineer by

examination in the State of California in 1978 and is currently

registered as a Professional Engineer in good standing by

examination, experience & comity in thirteen (13) states

including Louisiana.

Mr. Perkins Oilfield Service Industry experience included working as a Design Engineer,

Engineering Manager, Manager of Technical Services, Chief Engineer, Vice President of

Engineering and also as a Director of Manufacturing. Mr. Perkin also worked as a

Roughneck or Floorman and Derrickman on an onshore drilling rig and as Serviceman and

Field Engineer in both offshore and onshore drilling and completion operations.

In mid-1987, Mr. Perkin began work as an independent professional mechanical engineering

consultant. In 1995, Mr. Perkin co-founded Engineering Partners International, L.L.C.

(EPI). Mr. Perkin is presently employed by EPI as its President and also as an

independent consultant and Professional Engineer in the areas of domestic and international

onshore and offshore Oil & Gas Drilling and Production operations including the design, use

and application of the equipment and systems used in oilfield exploration.

While at EPI, Mr. Perkin has been retained to conduct product design analysis, equipment

design, perform failure analysis, review claim elements of intellectual property and provide

other independent engineering consulting services related to mechanical equipment and

systems including the design, application, use, testing of BOPs and their related CS used

both onshore and offshore. Mr. Perkins full curriculum vitae and other biographical

materials are attached as Appendix L.

Respectfully Submitted -

Gregg S. Perkin, P.E.

President and Principal Engineer

Engineering Partners International, L.L.C.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

6 Findings:|

Based on my education, training, knowledge and experience in oilfield equipment

design, application and use in oilfield operations, such as Deepwater drilling

operations, and based upon the information I have reviewed and the work I have

conducted, I presently have found the following to be true, supplemented and

explained in the remainder of this Expert Report and its appendices, regarding

HORIZONS BOP and its control systems including the subsequent explosion and fire

on the HORIZON on April 20, 2010, and major contributing factors leading thereto.

FINDINGS:

1. BP management controlled the configuration, testing, and safety profile of

HORIZONS BOP and its control systems (CS) under the well control

conditions being experienced on April 20, 2010 and before Macondo flowed

uncontrollably to the surface (blowout).

2. BP management knew all of the capabilities and the limitations of the

HORIZONS BOP before the blowout on April 20, 2010.

3. BP management misrepresented data to the Minerals Management Service

(MMS) regarding the well conditions which Macondo could produce.

4. BP management knew that a single BOP component used in HORIZONs BOP,

its blind shear ram (BSR), was incapable of being successfully actuated

under the well control conditions being experienced on April 20, 2010 and

knew that Macondo could produce these actual well conditions.

5. Other BOP components used in HORIZONS BOP included two annular BOPs

(annular), the single BSR, a casing shear ram (CSR), two variable bore

rams (VBR) and a test ram. On April 20, 2010, as the well control

emergency became greater in both size and proportion, both annulars and

the VBRs were closed. But the emergency continued to grow, exceeding the

operational envelope of the BOP. Due to known deficiencies pertaining to

both of HORIZONS annulars and its BSR, BP Management should not have

used this BOP as it was configured. The pressures that Macondo produced

could and did overwhelm the annulars and could and did overwhelm its BSR.

6. BP and Transocean management failed to competently train and supervise

their employees pertaining to deepwater well control issues on the design,

use, assembly, testing, application and maintenance of HORIZONS BOP.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

7 Findings:|

7. BP and Transocean Management failed to adequately inspect, test, maintain

and repair the BOP and keep it in proper working order.

8. BP management ignored safety concerns pertaining to the design, use,

assembly, testing, application and maintenance of HORIZONS BOP and failed

to recognize its limitations as a well control device.

9. On April 20, 2010, BP management had a faulty well control policy in-place

whereby the annulars were to be closed first to shut-in and seal-off

Macondos wellbore. BP management should have known that bottom hole

pressures could be as high as 11,000 pounds per square inch ("psi") or more.

If the annulars could not shut-in and seal-off Macondos wellbore,

hydrocarbons could reach HORIZONS rig floor. In the event either/both

annulars could not shut-in and seal-off Macondos wellbore, the BSR below

the annulars would be subjected to shut-in wellbore pressures of up to

11,000 psi or more including the unknown flow conditions present within the

wellbore. BP management knew that closing the BSR under high flow rates

within Macondos wellbore could jeopardize its ability to shut-in and seal-off

Macondo. Under either well control scenario, BP Managements well control

policies placed the HORIZON and all of its personnel in grave danger. Had

BP management implemented realistic and competent well control policies,

Macondo should have been contained on April 20, 2010.

10. BP management failed to use the Best Available and Safest Technology

("BAST") on the BOP system.

11. BP management failed to utilize audible and visual alarm systems with preset

limits regarding pressure, temperature, flow and other parameters, such as

sound, vibration, etc. within the BOP which would have alerted competent

and responsible personnel on the HORIZON that a potential well control

event was occurring;

12. BP management also failed to provide a realistic means to monitor, test and

recharge the batteries in the HORIZON BOPs control pods. The batteries

used were not rechargeable. They could discharge without any audible and

visual alarm at the surface. BP management needed to install a means to

monitor critical battery charges with preset limits. If battery charges went

into alarm modes sufficient charge would remain to activate critical systems

while they were being recharged and/or replaced.

13. The BOP had two (2) redundant and independent operator control systems.

Each system utilized one set of Multiplex Electronic Control (MUX) cables.

The rigs MUX cables laid in close proximity to each other in the moon pool,

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

8 Findings:|

an area which is classified as a hazardous area. The moon pool is the

entrance to the wellbore on the surface of the ocean. On April 20, 2010,

explosions knocked-out the MUX cables. Subsequently, there was no BOP

control from the rig. BP management failed to provide a backup control

system, such as an acoustic trigger, which was available from the BOPs

original equipment manufacturer (OEM); Cameron International

Corporation (Cameron). Utilizing an acoustic trigger would have been a

realistic and meaningful back-up to control the BOP if the MUX cables were

lost. Placing both of the MUX cables in the same hazardous area made it

such that a single event, could eliminate both systems. BP management

knew that the MUX cables could become a single point of failure (SPOF)

and they should have anticipated and guarded against not only this but all

SPOFs;

14. BP management failed to identify all relevant SPOFs in the BOP assembly and

its control system. Since BP management failed to do so and because the

BOP had limited well control capabilities, other automatic BOP actuation

systems, such as the BOPs autoshear and Automatic Mode Function (AMF),

failed to shut-in and seal-off Macondo.

15. The BSR was the BOPs last resort to shut-it-in and seal-it-off should all else

fail to control it. As a result of the blowout, an assembly of pipe was in

Macondos wellbore and its BOP. If the BSR was called-upon with this pipe in

the wellbore, this single BSR had to shear this pipe in two, either centered

within the BSR or off-center, and then shut-in and seal-off Macondos

wellbore. BP management knew that Macondos BSR was incapable of

shearing certain sizes, weights and grades of pipe under certain and known

well control conditions. Further, BP management failed to provide the proper

cutting blades within the BSR to completely shear off-centered pipe including

having sufficient hydraulic energy available to actuate it.

16. BP management knew that ROV intervention to shut-in and seal-off Macondo

in the event that an uncontrolled blowout occurred would be virtually useless

particularly of the BSR had not been activated or needed to be further

activated, i.e., had been partially closed but not completely closed.

17. BP management knew that an appropriate capping BOP was necessary and

should have been available on the HORIZON in the event that an

uncontrolled blowout occurred and the BOPs LMRP and the HORIZON was

successfully disengaged from the BOP. Even though Macondo would have

been blowing out uncontrollably, the capping stack could have been deployed

from the HORIZON, or another vessel, and placed atop the BOP. Activating

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

9 Findings:|

the capping BOP should then have stopped the uncontrolled flow from

Macondo. Macondo would then have blown out of control for a considerably

less period of time than the 83 days which it did blow out.

18. BP management was aware of the catastrophic consequences that would

follow a failure of the BOP to contain a blowout, and had no plan to address

that eventuality.

19. The BSR failed because of a) the inability of the accumulator to provide

sufficient force; b) the inability of the BSR to shear off-center pipe; and c)

erosion washout as a result of dynamic conditions.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

10 BackgroundandDiscussionoftheMacondoWellandHORIZONsBOP:|

BACKGROUNDANDDISCUSSIONOFTHEMACONDOWELLANDHORIZONSBOP:

1. The DEEPWATER HORIZON (HORIZON) was a fifth generation, 396 foot

long, dynamically positioned MODU owned by Transocean. The HORIZON,

built for $350 million in the Hyundai Shipyard in South Korea in 2000, was an

ultra-deepwater and dynamically positioned semisubmersible in Transoceans

fleet. It was capable of operating in water depths down to 8,000 feet.

HORIZON was originally commissioned by R&B Falcon. R&B Falcon later

became part of Transocean;

2. Since HORIZONS maiden voyage in 2001, it was under contract to Vastar

and then subsequently, BP. BP later acquired Vastar;

3. BPs leasing of the HORIZON was renewed in 2009 for three more years.

Since its commissioning the HORIZON drilled an average of three wells per

year. All but one of the wells drilled since 2001 were for BP;

4. A critical and essential safety feature of any MODU involved in deepwater

drilling operations is its BOP and control system. Individual BOP elements

assembled into the HORIZONs BOP system failed on April 20, 2010;

5. This BOP system was designed to assist in offshore drilling operations to

control flows from subsea wellbores, such as the Macondo well, for oil & gas

exploration. The opening or cavity through the inside diameter of the

HORIZONs BOP system was 18. Individual BOP components were

assembled together into what is referred to as a subsea BOP stack. The

maximum allowable (or operating) working pressure (MAWP or MAOP) of

some, not all, of the BOP components was 15,000 pounds per square inch

(psi);

6. Each of HORIZONS BOP components was a subsea, high pressure valve

which can be opened and closed. BOP components are nothing more than

shut-off valves used to control the flow of oil and gas.

7. A BOP system on an a MODU such as the HORIZON consisted of a system of

integrated BOP components designed to stop any uncontrolled flow of

hydrocarbons from reaching the surface and the MODU;

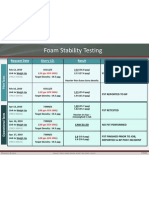

8. The HORIZONs BOP included a Lower Marine Riser Package (LMRP) and a

Lower BOP Stack. The LMRP included two annulars. The lower BOP stack

included the single BSR, a casing shear ram (CSR), two variable bore rams

(VBR) and a test ram as well as various connectors mounted to a structural

frame. Refer to the figure below. Also, a more complete explanation of the

BOP, its components and how it works is contained in the Appendices.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

11 BackgroundandDiscussionoftheMacondoWellandHORIZONsBOP:|

ImageSource:EngineeringPartnersInternational,LLC

9. Cameron International Corporation (Cameron) designed, manufactured and

sold the BOP system. However, Vastar Resources Incorporated, and its

corporate successor BP, were heavily involved in the design, choice of

components and control systems and the configuration of the BOP system.

Among the decisions made by BPs predecessor in the design and

configuration of the BOP, Vastar:

a. Specified a 5 cavity BOP;

b. Specified a 30 second LMRP disconnect with the lower BOP Stack in

connection with its Automatic Mode Function (AMF) or Deadman

system;

UpperAnnular

LowerAnnular

CSR

VBR

VBR

TestRam

BSR

LMRP

LowerBOPStack

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

12 BackgroundandDiscussionoftheMacondoWellandHORIZONsBOP:|

c. Decided against equipping the BOP with an acoustic trigger, i.e.,

remote control;

d. Required certain adjustments to be made by Cameron before

accepting the BOP into service after the factory acceptance test;

e. Specified the location of the MUX cables in a hazardous area;

f. Specified Emergency Disconnect System 1 (EDS-1) which activates

only the BSR instead of EDS-2 which activates of the CSR first,

followed by the BSR to shut-in and seal-off the well in primary

emergency LMRP disconnect mode.

1

10.BP exercised operational control over the drilling activities conducted on the

HORIZON through the leadership of BPs Well-Site Leaders (WSL) and other

BP employees on board the HORIZON, and a team of BP employees in BPs

Houston office;

11.BP made all the significant and key decisions regarding HORIZONs BOP on

Macondo. With respect to the BOP and its control system, while the

HORIZON was under charter to BP, its testing protocol was determined by

BP, not Transocean;

2

12.During the course of the operations of the HORIZON, BP management made

modifications to the BOP;

13.Deepwater wells in the GoM present specific risks which are relevant to the

requirement for a properly chosen, properly designed and properly

functioning BOP and control system. The Macondo well was a deepwater well

located in over 5,000 feet of water;

14.In an Application for Permit to Drill (APD) submitted by BP to the United

States Minerals Management Service (MMS), BP misrepresented the

characteristics of Macondo which were relevant to the kind of BOP system

that would be necessary to control the well.

15.BP management sought and subsequently gained their permission to exempt

HORIZONS BOP from certain required tests and testing;

16.BP began drilling the Macondo well in in October of 2009 using the

Transoceans MODU MARIANAS, which was another semisubmersible.

Because of damage done to the MARIANAS by Hurricane Ida, BP

management replaced the MARIANAS with the HORIZON to complete

Macondo. HORIZON began its drilling of Macondo on February 6, 2010;

1

ForamorecompletediscussionofBPsroleinthedesignandconfigurationoftheBOPsystem,seeAppendixF.

2

ForamorecompletediscussionofBPsroleintesting,maintenanceanddecisionsregardingtheBOP,see

AppendixG.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

13 BackgroundandDiscussionoftheMacondoWellandHORIZONsBOP:|

17.Macondo suffered a number of well control events during drilling operations.

For deepwater drilling operations, well control efforts are intended to be

competent and preventative measures taken to avoid an offshore blowout

catastrophe. These measures entail the prevention of fluids, i.e., formation

liquids and gas, from entering the wellbore. The entrance of formation fluids

and gas into the wellbore is referred to as a kick. Kicks must first be

recognized and then controlled. Conversely, a well control event can occur

from the loss of drilling fluids in the wellbore. Wellbore kicks and circulation

losses are discussed in more detail in attached Appendices.

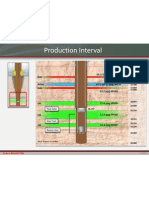

18.On April 9, 2010, Macondo had been drilled to a total depth of 18,360 feet

where another kick was experienced. At this time, the well was months

behind and well over budget.

19.On April 20, 2010, BP management had already decided to temporarily

abandon Macondo. During this process, Macondo went out of control.

Despite efforts to activate the BOP, the well suffered a blowout followed by

explosions and fires and the ultimate sinking of the HORIZON and release of

oil into the GoM.

3

20.The explosions disabled the MUX communication cables, the means by which

the crew would otherwise have been able to activate the BOPs EDS from

various locations on the HORIZON. The Autoshear Function, part of the

BOPs CS, should have activated the BSR and released the LMRP allowing the

HORIZON to drift off site. This did not occur and, as a result, the HORIZON

remained connected to Macondo until it sank. The piping which connected

the LMRP (Riser) bent and broke.

21.After the HORIZON sank, efforts were made to activate the BOP using an

ROV. These efforts failed for reasons which are stated in more detail at

Appendix J.

3

Foramorecompletediscussionoftheeventsleadinguptoandfollowingtheexplosion,seeAppendixI&J.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

14 Opinions&Conclusions:|

OPINIONS&CONCLUSIONS:

OPINION 1: HORIZONS BOP AND ITS CONTROL SYSTEM FAILED TO PERFORM ITS INTENDED

FUNCTIONOFPREVENTINGABLOWOUT.

A. The HORIZON BOP failed to prevent the blowout despite efforts to activate

the various BOP components;

B. Attempts after the explosions to use the ROV to activate the BOP were

likewise unsuccessful;

1. Many ROV used post blowout were not working and the others lacked

sufficient hydraulic power to be effective.

2. ROVs are not effective when a well is flowing through the BOP.

OPINION 2: BP MANAGEMENT DID NOT ADEQUATELY PERFORM ITS RISK ASSESSMENT REGARDING

MACONDOSWELLCONTROLANDITSBOPANDCONTROLSYSTEM.

A. BP managements own guidelines required that the risks associated with the

drilling of a specific well be identified, evaluated, addressed and mitigated.

Even without written guidelines, a prudent operator should, prior to

commencing a drilling operation, identify, assess, and manage risks of the

operation;

B. BP management did not consider the safety and functionality risks associated

with the BOP and its control system in its Risk Register, instead focused on

the financial impact of non-productive time. The only risk BP management

identified with respect to its BOP and its control system was non-productive

time;

C. BP managements risk assessment violated industry standards by failing to

consider the risks associated with the hazards of well control, uncontrolled

blowout, personal injury, death and environmental damage caused by a

blowout;

D. If BP had performed an industry standard risk assessment, the assessment

would have identified, assessed and managed at least the following issues;

1. The adequacy of the design and configuration of the BOP system;

2. The appropriateness of the HORIZONs BOP for the Macondo well

given the characteristics of that well;

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

15 Opinions&Conclusions:|

E. Had these risks been adequately addressed and managed, the April 20, 2010

blowout of Macondo would have been averted or significantly reduced.

1. Had these risks been adequately assessed and managed, the BOP

would have been upgraded and the blowout would have never

happened.

OPINION3:BPMANAGEMENTKNEWORREASONABLYSHOULDHAVEKNOWNTHATHORIZONSBOP

ANDCONTROLSYSTEMWASNOTSUITABLEANDSAFEFORUSEINALLFORESEEABLEWELLCONTROLAND

BLOWOUT CONDITIONS. BP MANAGEMENT SHOULD HAVE UPGRADED MACONDOS BOP WITH BAST

FROMCAMERONBEFOREITWASPLACEDONITSWELLHEADONTHEOCEANFLOOR.

A. BP management failed in its responsibility to accurately determine critical

well conditions and to ensure that the equipment being used, i.e.,

HORIZONS BOP and its control system was fit for its intended purpose.

B. As a part of insuring that Macondo could be drilled safely, an operator such

as BP must insure that the equipment it is going to use in connection with

drilling and well control operations is suitable and safe for the purpose for

which it will be used. If it is not suitable to a specific well, the BOP should not

be assigned to that well. This requires that the operator determine the

conditions of the well to be drilled and given those conditions, choose

equipment which is suitable and safe to use;

C. BP management failed to design, assemble, install, test, use and maintain in

such a way as to ensure well control under all predictable circumstances. The

maximum allowable or operating pressure ratings for each BOP component

must be greater the maximum allowable and/or anticipated surface pressure

(MASP), i.e. the maximum pressure that the well can produce at the

wellhead;

D. BP management failed to competently calculate and provide the MMS with

Macondos MASP at the mud line as required by the MMS for permission to

drill the Macondo well;

E. BP misrepresented Macondos MASP to the MMS. BP management

represented that the worst-case MASP was 8,904 psi at the mud line. BP

knew, from information available, it misrepresented the MASP because the

Macondo well was capable of producing pressures in the wellhead in excess

of 11,000 psi, or greater;

F. BP management knew that it was probable that the annulars would become

less capable of sealing Macondo with wellhead pressures in excess of 10,000

psi;

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

16 Opinions&Conclusions:|

G. BP management knew that it was probable and highly likely that the BSR

would be incapable of cutting the DP in two, shutting-in and sealing-off

Macondo, given the drill pipe (DP) inside the BSR on April 20, 2010, i.e.

5 outside diameter (OD), 21.9 lbs/ft, Grade S135, wellhead pressure in

excess in 10,000 psi, and flow;

H. As an operator, BP management was required to determine whether the DP

across the BSR, at any time, could be sheared;

I. BP management failed to take reasonable steps to determine the shearability

of the DP being utilized on the HORIZON prior to and on April 20, 2010. The

following are examples supporting this opinion:

1. BP management never conducted shear tests on the assemblies of DP,

i.e. drill string, being utilized on Macondo even though such tests are a

recommended practice and that BP changed from 5 DP to stronger

6 DP to conduct drilling operations;

2. BP used an obsolete shearing chart to determine whether the DP was

shearable;

3. The shearing chart employed incorrect calculations. The shearing

chart analysis referred to the use of a 5,000 psi accumulator system

(accumulators). Accumulators provide the hydraulic pressure and

flow to actuate all of the BOP components in the BOP. HORIZONs

accumulators to actuate the BSR had only 4,000 psi available, perhaps

less;

4. BP Management had to request information, after the explosion, about

the shearability of the DP that was being used in Macondo;

5. BP never investigated the shearability of 6 DP by the HORIZON

BOP. 6 DP was specifically requested by BP to be placed on the

HORIZON and was the DP primarily used in Macondos drilling

operation.

J. Transocean Management should have verified the shearability of all DP sizes,

weights and grades using the BSR in HORIZONs BOP;

K. If BP management would have taken reasonable steps to determine the

shearability of its DP, it would have discovered that, given the limitations of

the BOPs accumulators and its BSR, and given the wellbore conditions that

Macondo could and would produce as it was being drilled, BP management

would have reached the conclusion that HORIZONS BOP could not reliably

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

17 Opinions&Conclusions:|

shear the DP being used. Therefore, HORIZONS BOP was not suitable and

safe for its intended use;

L. BP management should have upgraded the BOP. The following are specific

examples of options which were available to BP from Cameron to upgrade it:

1. Add tandem boosters, which would have effectively doubled the

shearing capacity of the blind shear ram. Tandem Boosters which

would increase the shearing capability of the BSR and allow for higher

forces to shear DP;

2. Add another BSR, a preferable configuration;

3. Install more efficient ram blocks in the BSR, such as Double V Shear

(DVS or CDVS) ram blocks. Double V Shear Rams shear DP with

greater efficiency and can cover the entire 18 BSR cavity in the

event that DP was off-center;

4. Install a larger subsea Accumulator system thereby giving greater

regulated flows and pressures to actuate critical BOP components;

5. Use EDS-2 instead of EDS-1. This modification would have cost BP

management nothing. It would also have protected the BSR by closing

the CSR first;

6. Install an Acoustic Control System (ACS) which could have

automatically actuated the LMRP disconnect sequence from the

HORIZON;

7. Install monitoring systems on the BOP. Install instrumented audible

and visual preset alarms;

8. A 5,000 psi subsea accumulator;

OPINION 4: HORIZONS BOP AS ORIGINALLY DESIGNED AND CONFIGURED ON APRIL 20, 2010 WAS

DEFECTIVE. THESE DEFECTS WERE SIGNIFICANT AND CONTRIBUTING CAUSES TO THE BOP AND ITS CS

TOPERFORMITSINTENDEDFUNCTION:

A. The failure of the BOP to have cutting blades that extend across the well

bore;

1. Both BP and Cameron knew that off-center pipe within the cavity of a

BOP component, such as the BSR, is a common occurrence in offshore

drilling. Therefore, Cameron and BP knew or reasonably should have

known that it is when pipe is off-center inside the BOP, HORIZONS

BSR would likely not completely shear the pipe and thus not seal the

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

18 Opinions&Conclusions:|

well. Thus, the failure of the BSR to have cutting blades that do not

fully cover and extend across the wellbore was a design flaw rendering

the BOP not reasonably safe. The risk of occurrence could have been

avoided or significantly reduced by a reasonable alternative design,

namely providing a set of BSR cutting blades which extended across

the 18 opening;

B. The failure of HORIZONS BOP to have an adequate system for conveying

pressure, flow, temperature, vibration, battery charge, critical equipment

operational status information, etc. data to the rig;

1. Both Cameron and BP knew or reasonably should have known of the

importance and need for pressure, flow, temperature, vibration data

which may audibly and/or visually dictate the activation of the BOP to

rig personnel. The failure of the BOP to have a mechanism for the

transmission of such data to the rig floor and bridge it with adequate

alarms constitutes a design flaw rendering the BOP not reasonably

safe. Reasonable alternative designs existed that would have allowed

for the transmission of this data to rig personnel during a well control

event which would have avoided or reduced the risk of the BOP system

not being activated in a timely fashion.

C. The failure to properly segregate and/or otherwise protect the MUX cables

which provide power to BOP controls so as to preserve the integrity and

redundancy of the BOP controls in case of an explosion;

1. HORIZONS BOP had two independent BOP operating systems. The

primary system to operate HORIZONS BOP on the seafloor was

through the use of a multiplex electronic control (MUX) system. The

HORIZON had three separate panels from which personnel could

activate certain BOP controls. When activated, the command was

transmitted from the panel to a junction box, onto a MUX cable reel

and then through MUX cables to two separate control pods on the

LMRP; i.e. the yellow and blue pods. Electronic signals were then

converted to hydraulic signals which would activate components of

HORIZONS BOP. The separate panels and pods were provided so as to

give redundancy to the controls such that the BOP could continue to be

operated in the event one of the panels or pods became disabled.

2. However, the MUX cables which transmitted the commands from each

of the three panels to the blue and yellow pods were strung through a

single and classified hazardous area called the moon pool. The moon

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

19 Opinions&Conclusions:|

pool is an area at the top of the well above the surface of the ocean, a

direct conduit from the well bore and thus an area which is subject to

explosion and fire. The design and construction of the system so as to

route both the yellow and blue MUX cables through the moon pool

created a SPOF. By running both blue and yellow MUX cables through

the same hazardous area, both cables are subjected to loss or

compromise in the event of an explosion in the moon pool, thus

defeating the purpose of these dual and redundant controls. As

designed and configured, the BOP and its CS was unreasonably safe.

S. The decision of BP, Transocean and Cameron to place the MUX cables

in the moon pool without protection from explosion and fire was

unreasonably dangerous;

4. The possibility of an explosion in the moon pool was entirely

foreseeable and there were reasonable alternative designs which

would have eliminated or significantly reduced the risk of losing the

control of HORIZONS BOP included:

a. The consideration of routing one of the MUX cables through a

non-hazardous area;

b. Providing exterior protection to both MUX cables thus increasing

their ability to reliably function in a classified hazardous area

and;

c. Providing ACS (Acoustic Trigger) as a means of activating the

BOP wirelessly.

D. The failure to have a wireless method to activate and control emergency

functions;

1. As explained above, there was a need for a remote control wireless

method of activating BOP controls in the event the MUX cables or

other elements within the BOP system were disabled or destroyed.

Such a method, i.e. an ACS (Acoustic Trigger) was available in 2001,

Such a device should have been a part of HORIZONS BOP and its CS.

E. The inability to monitor, test, charge, and/or change the batteries which

powered certain Blue and Yellow Pods while HORIZONS BOP was on the

seafloor;

1. HORIZONS BOP had batteries in its blue and yellow pods which were

necessary for the activation of the BOPs AMF/Deadman systems and

were a critical component of the BOPs CS;

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

20 Opinions&Conclusions:|

2. As designed and manufactured, the batteries in the subsea pods could

not be monitored, tested, charged, and/or changed while HORIZONS

BOP was on the ocean floor creating a risk that the batteries would

have insufficient charge and quit functioning. Such a condition would

go undetected. This represented a design flaw which rendered

HORIZONS BOP not reasonably safe;

3. There were reasonable alternative designs that would have eliminated

this risk or have significantly reduced it.

4. BP, Cameron and Transocean knew or reasonably should have known

of this hazard pertaining to the blue and yellow pod batteries.

However, nothing was done to address this deficiency. Such conduct

falls below the standard of care of a reasonably prudent operator, BOP

Equipment Provider and Drilling Contractor in the GoM.

F. The failure to have redundancy in the emergency activation systems by

relying on a single component for all pipe shearing and well bore shutting-in

and sealing functions, namely the single BSR. There were five emergency

activation systems on HORIZONS BOP. Each system utilized the same BOP

component to seal it, namely the BSR and the accumulator necessary to

energize it. If the BSR failed to function, for whatever reason, it essentially

disables every emergency function of the BOP.

OPINION 5: BP MANAGEMENT FAILED TO HAVE AN ADEQUATE WELL CONTROL POLICY PERTAINING TO

HORIZONSBOP.

A. BP management had a faulty well control policy in-place whereby HORIZONS

annulars were to be closed first to shut-in and seal-off the wellbore;

B. BP management knew that closing the BSR under high flow rates within

Macondos wellbore could jeopardize its ability to shut-in and seal-off the

wellbore.

C. By regulation, BP was responsible for competently calculating MASP, a

regulatory requirement relating to the BOP per 30 CFR 250.446;

D. By making the lower ram a test ram, BP management violated its own well

control policy which stated that: "the lowermost ram be preserved as a

master component and only used to close in the well when no other ram is

available for this purpose."

E. BP failed to adequately supervise and oversee Transocean with regards to

BOP operations.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

21 Opinions&Conclusions:|

Opinion 6: BP management and Transoceans Management failed to have and enforce a

program for training and supervising their personnel who would be responsible to operate

HORIZONSBOP.

A. MMS Regulations require adequate personnel training per 30 CFR 250.1503

and 250.1506;

B. By its own admission, BP management had no enforceable GoM safety

system in-place with regard to subsea BOP safety, BOP personnel training,

BOP equipment testing, BOP mandatory regulatory compliance, internal BOP

audits and/or usage of a BOP such as the one used on Macondo;

C. BPs WSLs and other personnel were not adequately trained regarding BOPs

and;

D. BP employees received no training as to whether they should close the

Annulars first, or the VBRs first, or close them simultaneously. BPs Well

Control Manual states that the annulars should be closed first. BPs manuals

also stated that BP should ensure that their contractors follow BPs well

control policy. If HORIZONS upper Annular was rated at 10,000 psi and this

well was capable of producing MASP mud line pressures in excess 10,000 psi.

Macondo could not have been reliably shut-in and sealed-off.

OPINION7:BPMANAGEMENTANDTRANSOCEANSMANAGEMENTFAILEDTOADEQUATELYINSPECT,

TEST,MAINTAINANDREPAIRHORIZONSBOP,UPGRADEITASREQUIREDANDMAINTAINITINITS

PROPERWORKINGORDER.

A. A preventative maintenance and complete overhaul of HORIZONS BOP and

its CS was required under MMS Regulations at least once a year and tested

to its MAWP or MAOP. No documentation has been provided to substantiate

that these tests were actually performed by BP management;

B. Transoceans Management relied on condition based maintenance or simply;

maintenance when the need arose. Transocean monitored the maintenance

on the HORIZON with a condition-based monitoring system, i.e. Rig

Maintenance System ("RMS");

C. RMS-II had been implemented as a result of the merger of Transocean and

GlobalSantaFe in September of 2009. However, RMS-II was reported to be a

work in progress at the time of this incident on April 20, 2010.Some of the

maintenance could only be performed when the HORIZON was moving, out-

of-service and/or in dry dock. The HORIZON had never been to dry dock.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 EXPERTREPORTMACONDO

22 Conclusion:|

Instead of dry dock, Transocean performed Underwater Inspections in Lieu of

Dry-docking ("UWILD") and other at-sea inspections;

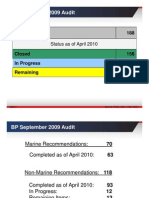

1. Both the three (3) and five (5) year certifications of the Ram-Type BOP

bonnets were identified in the BP's September 2009 audit as never

having been completed.

D. The HORIZON had been under continuous contract to BP and had never been

to dry dock for shore-based repairs in the nine years since it was built.

OPINION8:THEACCIDENTOFAPRIL20,2010WASENTIRELYFORESEEABLEANDPREVENTABLE,AND

WASCAUSEDBYTHEFAILURESDETAILEDABOVE.

CONCLUSION:

These are my opinions within a reasonable degree of probability, based upon the

materials referenced in Appendix M, as well as the other appendices. Further

elaboration of my opinions can be found in the chart located at Appendix K and

other attached Appendices.

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 BLOWOUTPREVENTERMACONDO

2 AppendixA: AbbreviationsandAcronyms|

TableofContents

AppendixA: AbbreviationsandAcronyms..............................................................................................3

AppendixB: DeepwaterDrilling..............................................................................................................6

AppendixC: WellControl........................................................................................................................8

AppendixD: BlowoutPreventers&Systems.........................................................................................13

AppendixE: BOPRegulatoryCompliance.............................................................................................20

AppendixF: ResponsibilityforBOPConfiguration...............................................................................27

AppendixG: DEEPWATERHORIZON'SSubseaBOP...............................................................................32

G.1 Modifications....................................................................................................................47

G.2 Testing...............................................................................................................................48

G.3 Training.............................................................................................................................52

G.4 BOPMaintenance.............................................................................................................57

G.5 BestAvailableandSafestTechnology("BAST")................................................................59

AppendixH: BP'sMacondoWell...........................................................................................................67

H.1 ApplicationforPermittoDrill...........................................................................................67

H.2 MaximumAllowableSurfacePressure(MASP):............................................................71

H.3 WellControlResponsibilities............................................................................................81

AppendixI: EventsLeadingUptoBPsMacondoBlowout..................................................................86

AppendixJ: PostBlowout....................................................................................................................95

AppendixK: MacondoDesignandImplementationFailures................................................................97

AppendixL: Mr.GreggS.Perkin,C.V.andrelatedinformation.......................................................104

AppendixM:SourcesandInformation..................................................................................................114

EndNotes ........................................................................................................................................223

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 BLOWOUTPREVENTERMACONDO

3 AppendixA: AbbreviationsandAcronyms|

AppendixA: AbbreviationsandAcronyms

ACS ....................... Acoustic Control

System

AMF ....................... Automatic Mode

Function

APD ....................... Authorization for

Permission to Drill

API ........................ American Petroleum

Institute

Autoshear ............... An Emergency BOP

system on the

HORIZON, activated

when

BAST ...................... Best Available and

Safest Technology

Beach ..................... On shore

BHA ....................... Bottom Hole Assembly

BHPM ..................... Bottom Hole Assembly

Pressure Method

BOEMRE ................. Bureau of Ocean

Energy Management,

Regulation and

Enforcement, formerly

MMS

BSR ....................... Blind Shear Ram

BOP ....................... Blowout Preventer

Casing .................... Pipe used to line the

hole

CCU ....................... Central Control Unit

CFR ....................... Code of Federal

Regulations

Deadman ............... An alternative term

for the AMF System.

DP ......................... Drill Pipe

DS ......................... Drill String

DVS ....................... Double V Shear (Ram)

DWOP .................... BPs Drilling and Well

Operations Practices

Dynamic Event ........ Flow

EB ......................... Engineering Bulletins

EDS ....................... Emergency Disconnect

System

EP ......................... Initial Exploration Plan

EPI ........................ Engineering Partners

International, L.L.C.

ER ......................... Emergency Response

FAT ....................... Factory Acceptance

Test

Fishing ................... Pulling disconnected

material out of the

wellbore

FMECA ................... Failure Mode, Effect

and Criticality Analysis

ft ........................... Foot or feet

gpm ....................... gallons per minute

GoM....................... Gulf of Mexico

Hot Stab ................. ROV Connection

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 BLOWOUTPREVENTERMACONDO

4 AppendixA: AbbreviationsandAcronyms|

HORIZON ................ DEEPWATER

HORIZON

HP ......................... High Pressure

HPU ....................... Hydraulic Power Unit

Hydrocarbons .......... Deposits beneath the

earths surface such

as oil and gas

IADC ...................... International

Association of Drilling

Contractors

In .......................... Inch or inches

ID .......................... Inside diameter

Joints ..................... Individual sections of

drill pipe

Kick ....................... Unexpected flow of

hydrocarbons into the

wellbore

LDS ....................... Lock Down Sleeve

LIT ........................ Lead Impression Tool

LMRP ..................... Lower Marine Riser

Package

Long String ............. Long String of

Production Casing

MASP ..................... Maximum Anticipated

Surface Pressure

MAWP .................... Maximum Allowable

Working Pressure

MC252 ................... Mississippi Canyon

Block #252 location

of the Macondo well

MD ........................ Measured depth

MGS ....................... Mud-gas separator

MMS ...................... Minerals Management

Service, now BOEMRE

MODU .................... Mobile Offshore

Drilling Unit

Mud ....................... Drilling mud

MUX ...................... Multiplex

MW ........................ Mud Weight

NDT ....................... Non-Destructive

Testing

NPT ....................... Non-Productive Time

OCS ....................... Outer Continental

Shelf

OD ........................ Outside diameter

OEM ...................... Original Equipment

Manufacturer

OIM ....................... Offshore Installation

Manager

PLC........................ Programmable Logic

Controller

ppf ........................ Pounds per foot

ppg ....................... pounds per gallon

psi ......................... Pounds per square

inch

Riser ...................... Marine Riser System

RMS ....................... Rig Maintenance

System

ROV ....................... Remotely operated

vehicle

RP ......................... Recommended

Practice

GreggS.Perkin,P.E.

EngineeringPartnersInternational

August26,2011 BLOWOUTPREVENTERMACONDO

5 |

SEM ....................... Subsea Electronic

Module

SPOF ...................... Single Point of Failure

ST Lock .................. Hydro-mechanical ram

locking mechanism

TA ......................... Temporary Abandon

TD ......................... Total Depth

TVD ....................... Total Vertical depth

UMRP ..................... Upper Marine Riser

Package

UWILD ................... Underwater Inspection

in Lieu of Dry-Dock

V ........................... Volt

VBR ....................... Variable Bore Ram

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

6 AppendixB: DeepwaterDrilling|

AppendixB: DeepwaterDrilling

1

Deepwater drilling has been commonly known historically as the process of

conducting oil & gas exploration and production operations in seawater

depths of more than 500 feet (ft). Using this definition, there have been

approximately 600 Deepwater wells drilled in the GoM.

2

Oil production in water depths exceeding 6,000 ft is currently taking place in

different parts of the world.

3

New explorations in ultra-Deepwater drilling

operations are being performed in water depths exceeding 9,000 ft.

4

Deepwater drilling presents unique technical and safety challenges, especially

for the BOP. At these depths, the BOP equipment, hoses, and connections

cannot be reached, except by Remote Operated Vehicle (ROV). ROV

operations are difficult due to water pressure, lack of visibility, depth

perception and color (everything is monochromatic), lack of appropriate tools

and the limitations of remote control. In addition, the BOP cannot easily be

brought to the surface even when the well is shut in, especially when the well

is flowing. When the BOP malfunctions, repair or replacement becomes

difficult, if not impossible. Accordingly, planning for Deepwater drilling BOP

strategies must be undertaken with the utmost care and prudence.

SINTEF published a reliability study on behalf of the MMS, to review subsea

BOP performance, entitled Deepwater Kicks and BOP Performance dated July

24, 2001.

5

The study reported a total of 117 BOP failures and 48 well kicks

were recorded in the 83 wells observed between 1997 and 1998.

6

Of the 83

wells, 58 wells were deemed exploratory drilling, defined as drilling in less

well known formations. Macondo was an exploratory well.

7

The report indicated that many of the GoM Deepwater wells were high

pressure/high temperature wells.

8

The frequency of Deepwater kicks where

a BOP was necessary to control the event was high when there was a low

limit between the pore pressure and fracture pressure, such as on the

Macondo.

9

During the kick control operations, BOP failures were observed

that were probably caused by the kick killing operations.

10

Macondo experienced numerous lost circulation events, and three kicks

between February and April 2010, including one which resulted in reducing

the total depth of the well.

11

The kicks were circulated out while the annular

was engaged. Refer to Figure B.1 on the following page.

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

7 AppendixB: DeepwaterDrilling|

Figure B.1. Macondos History of Lost Returns or Lost Circulation Source:

Skripnikova

12

In BP's risk assessment for the Macondo well, it was identified that offset

wells (wells drilled in the vicinity to access the same reservoir) had

experienced multiple kicks and lost circulation events which presented a risk

to time and costs.

13

Risk to safety was never mentioned.

The SINTEF report concluded that BOP configuration should include two (2)

BSRs to increase safety availability in Deepwater drilling.

14

Replacing the

upper pipe ram with a BSR would improve the ability to shear and seal the

well during an emergency well control situation.

15

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

8 AppendixC: WellControl|

AppendixC: WellControl

Well Control or blowout prevention is a critical part of drilling,

completing, and working over wells. Blowout equipment is the final

line of defense against a catastrophic event which may include

fatalities, uncontrollable release of oil and gas, and evacuation of

entire communities.

Blowout prevention is much more than blowout preventers. It is an

integral system that not only includes equipment but training and

stringent policies adhered to by the entire team. BPs publication BP-

Wells Engineer OJT Module #7

16

For deepwater drilling operations, well control efforts must be competently

performed and all reasonable preventative measures taken to avoid an

offshore blowout catastrophe. These measures entail the prevention of

fluids, i.e., formation liquids and gases, from entering the wellbore. The

entrance of formation fluids and gases into the wellbore are referred to as a

kick.

17

Kicks must first be recognized and then controlled.

There are multiple barriers, or layers of prevention, which are relied upon to

maintain the control of fluids, both produced and injected. The design,

installation and/or use of these barriers is critical. Good well control

procedures normally consist of installing barriers to uncontrolled flow. Kicks

occur because a barrier has failed to control fluid pressure in the formation.

For example, some barriers are:

Hydrostatic Fluid Pressure;

Downhole Casing;

Annular Cement and;

Mechanical Barriers.

The primary barrier is the fluid column, which BP recognized.

18

Hydrostatic fluid pressure is the pressure exerted against the formation by a

fluid at equilibrium due to the force of gravity.

19

In oil and gas well drilling

operations, the engineered fluids used in the Rotary Drilling Rigs Circulating

System are commonly referred to as drilling mud (Mud). Refer to Figure

C.1 on the following page.

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

9 AppendixC: WellControl|

Figure C.1. Hydrostatic Pressure exerted by a Column of Fluid. Shape is

insignificant.

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

10 AppendixC: WellControl|

Pressure is defined as the force distributed over an area.

P = F/A where:

P is pressure in pounds per square inch (psi)

F is the force normal or perpendicular to the area in pounds (lbs)

A is the area in square inches (in)

The pressure gradient can be used to calculate the pressure exerted by a

column of fluid vs. depth. Referring to Figure 6.1, the pressure gradient of

fresh water is 0.433 psi per foot of depth. Therefore, at a depth of 1 foot,

the hydrostatic pressure is equal to 0.433 x 1 ft = 0.433 psi. At a depth of

50 ft, the hydrostatic pressure is equal to 0.433 x 50 ft = 21.65 psi

20

Refer to Figure C.2 below with regard to calculating the pressure gradient of

water.

Figure C.2. Pressure Gradient of Fresh Water

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

11 AppendixC: WellControl|

If a heavier or denser fluid is used, such as salt water or an engineered fluid

such as mud, the calculation of the pressure gradient is determined by

dividing the weight of 1 cubic foot of the fluid by 144.

Drilling mud weights in the English system can be expressed in pounds per

cubic foot (lbs/ft) or pounds per gallon (lbs/gal). There are 7.48 gallons

per cubic foot. Dividing 7.48 gallons by 1 square foot equals 0.052 gallons

per foot (gal/ft). If the muds weight (MW) is known in lbs/gal and the

true vertical depth of the well is known in feet, then the hydrostatic pressure

in the wellbore at its true vertical depth (TVD) is equal to the MW (lbs/gal)

x 0.052 x TVD (ft) = hydrostatic pressure (psi). For example, at a TVD of

10,500 ft and drilling with a 14.1 lbs/gal drilling mud, the hydrostatic

pressure of the column of fluid at the bottom of the well would be calculated

as 10,500 ft x 0.052 x 14.1 = 7,698.6 psi.

When drilling an oil & gas well, the hydrostatic pressure of the fluid column in

the well should hold back formation fluids and gases.

21

If formation pressure

exceeds the hydrostatic pressure, the well could kick. A kick may be a

combination of water, gas, and/or oil, alone and/or in combination. Refer to

Figure C.3 below.

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

12 AppendixC: WellControl|

Figure C.3. Well Control

Because gas is compressible and liquid is generally considered not to be

compressible, if a well kick is believed to have occurred, it should be treated

as a gas kick.

22

Formation pressure can become greater than hydrostatic pressure under

certain circumstances. For example:

1. Insufficient mud weight;

23

2. Lost circulation from the wellbore;

24

3. Cementing operations;

25

4. Drilling operations where:

Excessive rates of penetration are employed;

Pressure charged formations are encountered;

Underbalanced drilling operations are underway or;

Shallow gas is encountered.

All competent Operators regard the management of hydrostatic pressure as

the primary means of well control.

26

Engineering, controlling, managing and

monitoring the mud used in the wellbore is the Operators primary means of

preventing a blowout.

27

Well control equipment, including BOPs, is

considered a secondary means of well control.

28

At the first sign of a kick, the wells operator and the drilling rigs crew must

first detect it, then stop it from progressing through the use of one or more

of the barriers.

29

The influx is then circulated out of the wellbore. BP's well

control policies dictated which well control equipment (such as an annular or

ram-type BOP) was used to prevent the influx from escalating and flowing to

the surface in an uncontrolled manner, or a blowout.

30

The BP well site leader ("WSL") had the responsibility for overseeing all

operations on the well. That responsibility included the delegation and

oversight of the minute-to-minute monitoring of data, and the review and

approval of the drilling contractor's well control procedures.

31

BPs Macondo well was an example of a blowout which should have been

avoided, and, after occurring, managed and controlled.

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

13 AppendixD: BlowoutPreventers&Systems|

AppendixD: BlowoutPreventers&Systems

A BOP is basically a pressure vessel. It can have multiple configurations

based upon the drilling and completion operations being conducted.

A BOP is also a valve. When actuated, a BOP is intended to seal-off (1) the

annular space or (2) the wellbore from below in order to contain formation

pressures, i.e., the kick, downhole. The annulus or annular space is the area

which surrounds a cylindrical object within a larger cylinder. In the oilfield, it

is the donut-shaped space between the outside diameter (OD) of the pipe

in the wellbore and the inside diameter (ID) of either the wellbore or

casing. Refer to Figure D.1.

The BOP provides a means of containing wellbore flows and pressures during

a kick. The design of the BOP permits drilling mud to be circulated into and

out of the wellbore so that the kick can be circulated out and the well can be

returned to its controlled, i.e., non-flowing condition.The BOP is also capable

of suspending the drill string.

Figure D.1. The Wellbore Annulus

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

14 AppendixD: BlowoutPreventers&Systems|

Once a BOP is actuated and seals, it contains the wellbore fluids and the

wellbore pressures beneath it.

BOP original equipment manufacturers (OEM) provide their BOPs with

maximum allowable working pressure (MAWP) ratings such as 2,000 psi,

3,000 psi, 5,000 psi, 10,000 psi and 15,000 psi. MAWP is provided for static

and not dynamic flow conditions. Regardless of the BOP stacks overall

pressure rating, the MAWP of the downhole casing which lines the wellbore

(Casing) limits the wells MAWP.

There are 2 types of BOPs; annular and ram-type. Refer to Figures D.2 and

D.3 below.

Figure D.2. Exemplar: Hydril Annular BOP

Figure D.3. Exemplar: Cameron Ram-Type BOP

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

15 AppendixD: BlowoutPreventers&Systems|

When the drill string is in the wellbore, a subsea BOP must have the

capability of shearing the drill string, shutting-in the wellbore and sealing it

off from the surface. Shearing the drill string is accomplished by installing

Shear rams into the body of a ram-type BOP.

All subsea BOPs are required to have a shearing/sealing ram (a BSR). A

blind ram seals, a shearing ram shears, a blind-shear ram does both. When

the BSR was developed, it was the first time there was the ability to shear

and seal simultaneously with one (1) movement of the rams through the

opening of the wellbore. Prior, all rams had to seal around the pipe and then

attempt to shear with another stroke. Because of dynamic flow conditions,

this was often a failure.

After the drill string is severed by the Shear rams, the LMRP should be

capable of being disconnected from the lower BOP stack.

Refer to Figure D.4 on the following page of a subsea BOP connected to its

MODU.

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

16 AppendixD: BlowoutPreventers&Systems|

(1) Conductor Pipe and

Subsurface Casing

(2) Wellhead and Casing

Hanger Systems

(3) BOP

Connector

(4) BOP (LMRP and Lower BOP

Stack) & Flex Joint

(5) Marine Riser

System

(6) Telescopic Joint

Assembly

Motion Compensation

System to include:

Drill String Motion

Compensator

Riser and Guideline

Tension Systems

Upper Marine Riser

Package(UMRP)

Waterlevel

SeaFloor

Figure D.4. Subsea BOPs hooked-up to a

Mobile Offshore Drilling Unit (MODU)

(from the 1896-1987 Oilfield Composite

Catalogue, Vetco Gray)

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

17 AppendixD: BlowoutPreventers&Systems|

Because the BOP is placed on the oceans floor, it must be operated from the

surface. Electrical and hydraulic lines, control pods, hydraulic accumulators,

valves, choke and kill lines, a riser connector, a wellhead connector and a

support frame are connected to, and are part of, a BOP. Acoustic devices

were available that would allow for the remote actuation of subsea BOPs.

The BOP on the HORIZON was a five (5) cavity stack which attached to the

wellhead. The lower BOP stack sits on the wellhead. The Lower BOP Stack is

connected to the Lower Marine Riser Package (LMRP). The LMRP contained

the annular BOPs. The LMRP had two (2) control pods, designated blue and

yellow. A Multiplex Electronic Control (MUX) cable connected the pods to

the HORIZON. Electronic signals were transmitted from the rig through the

MUX cables to the electronic packages within the pods. Then the signals

were decoded to deliver certain commands to solenoid valves using battery

power.

Figure D.7. MUX Cables & Hydraulic Conduits connected to the Blue & Yellow Pods

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

18 AppendixD: BlowoutPreventers&Systems|

Solenoid valves are flow control devices in each pod. When energized by an

electronic signal, a solenoid valve generates a hydraulic signal to operate a

hydraulic component on the BOP.

At the bottom of the HORIZON LMRP was

a hydraulically actuated connector. This

connector attached the LMRP to the top of

the lower BOP stack. This connector was

similar to the wellhead connector which

locked the lower BOP stack onto the

wellhead.

The LMRP could be disconnected from the

lower BOP stack, remotely by operator

controls on the rig. Then, the HORIZON

could move-off, if necessary, while the

Lower BOP stack remained on the subsea

wellhead. Refer to Figure D.6.

Auxiliary lines include (a) choke and kill lines (b) mud booster lines and (c)

hydraulic conduit lines. They are normally spaced asymmetrically around the

Riser.

(a) choke and kill lines extend from the wellbore at the seafloor up to

the MODU when the BOP has been shut-in and the wellbore sealed.

Mud can be pumped down the kill line into the wellbore. Mud and

wellbore fluids are circulated out of the wellbore through the choke

Line. A Drilling choke, i.e., variable opening valve, is connected at

the end of the choke Line in order to control the flow and pressure

of the displaced wellbore fluids and mud.

Figure D.6. Example of Disconnect LMRP

from Lower BOP Stack with HORIZON

moving-off

(from the cover of Camerons

Emergency, Back-up and Deepwater

Safety Systems)

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

19 AppendixD: BlowoutPreventers&Systems|

The BOP and its control systems (CS) must also have emergency closure

systems available to the MODU on the surface.

Failures of BOPs have been well documented throughout the industry.

Several reports studying BOP failures and several reviews show a long

history of BOP failure upon emergency activation. Well control policies that

rely solely on the BOP as the only barrier are reckless and below the

minimum standard of care. BPs own policy requires a minimum of two (2)

barriers and the BOP is not considered one of those barriers.

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

20 AppendixE: BOPRegulatoryCompliance|

AppendixE: BOPRegulatoryCompliance

The regulatory requirements for the BOP are detailed and thorough.

In 1938, the United States Federal Government, through the Office of

Federal Register, established a written Code of Federal Regulations (CFR).

In 2010, the MMS was the Federal Governments agency that governed Title

30 Part 250 Oil and Gas and Sulphur Operations in the Outer

Continental Shelf. Included in 30 CFR 250:440, 442, 443 and 445 are the

regulations which mandate the use of a subsea BOP and set forth minimum

requirements.

The regulations mandate, among other things, that: 1) a description of the

BOP to be used on the well be given to MMS [CFR 250:415], 2) the BOP be

maintained and inspected [30 CFR 250:446], and tested [30 CFR 250:447-

449], and 3) personnel be trained in its use [30 CFR 250:1500-1506].

BP did not comply with many of the regulations and violated more than one

of them.

Some of the regulations that the MMS requires an Operator such as BP to

comply with include: (Emphasis Added)

250.107 Protect health, safety, property, and the environment

by:

(c) Us[ing] the best available and safest technology ("BAST")

whenever practical on all exploration, development, and production

operations;

(d)(1) Avoiding the failure of equipment that would have a significant

effect on safety, health, or environment;

250.213 Provide general information with the Exploration

Plan including:

(g) Blowout scenario. A scenario for the potential blowout of the

proposed well in your EP that you expect will have the highest volume

of liquid hydrocarbons. Include the estimated flow rate, total volume,

and maximum duration of the potential blowout. Also, discuss the

potential for the well to bridge over, the likelihood for surface

intervention to stop the blowout, the availability of a rig to drill a relief

well, and rig package constraints. Estimate the time it would take to

drill a relief well.

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

21 AppendixE: BOPRegulatoryCompliance|

250.401 Keep wells under control at all times by:

(a) Us[ing] the best available and safest (BAST) drilling

technology to monitor and evaluate well conditions and to minimize

the potential for the well to flow or kick;

(c) Ensur[ing] that the Toolpusher, Operator's representative, or a

member of the drilling crew maintains continuous surveillance on

the rig floor from the beginning of drilling operations until the well is

completed or abandoned, unless you have secured the well with

blowout preventers (BOPs), bridge plugs, cement plugs, or packers;

(d) Use personnel trained according to the provisions of subpart O;

(e) Us[ing] and maintain[ing] equipment and materials

necessary to ensure the safety and protection of personnel,

equipment, natural resources, and the environment.

250.407 Conduct tests to determine reservoir characteristics

to:

determine the presence, quantity, quality, and reservoir

characteristics of oil, gas, sulphur, and water in the formations

penetrated by logging, formation sampling, or well testing.

250.413 What must my description of well drilling design

criteria address:

(f) Maximum anticipated surface pressures. For this section,

maximum anticipated surface pressures are the pressures that you

reasonably expect to be exerted upon a casing string and its related

wellhead equipment. In calculating maximum anticipated surface

pressures, you must consider: drilling, completion, and producing

conditions; casing setting depths; total well depth; formation fluid

types; safety margins; and other pertinent conditions. You must

include the calculations used to determine the pressures for the

drilling and the completion phases, including the anticipated surface

pressure used for designing the production string;

250.416 Describe the diverter and BOP Systems to:

(e) Show the blind-shear rams installed in the BOP stack (both

surface and subsea stacks) are capable of shearing the DP in

the hole under maximum anticipated surface pressures

("MASP").

250.440 Provide general requirements for BOP systems

components:

GreggS.Perkin,P.E.

EngineeringPartners

International

August26,2011 BLOWOUTPREVENTERMACONDO

22 AppendixE: BOPRegulatoryCompliance|

You must design, install, maintain, test, and use the BOP

system and system components to ensure well control. The

working-pressure rating of each BOP component must exceed

maximum anticipated surface pressures. The BOP system

includes the BOP stack and associated BOP systems and

equipment.

250.442 What are the requirements for a subsea BOP system:

When drilling with a subsea BOP system you must:

(b) Have an operable dual-pod control system to ensure proper and

independent operation of the BOP system.

(k) Before removing the marine riser, displace the fluid in the riser

with seawater. Additionally, you must maintain sufficient hydrostatic

pressure or take other suitable precautions to compensate for the

reduction in pressure and to maintain a safe and controlled well

condition.

250.443 What associated systems and related equipment must

all BOP systems include:

All BOP systems must include the following associated systems and

related equipment:

(a) An automatic backup to the primary accumulator-charging

system.

(g) A wellhead assembly with a rated working pressure that exceeds

the maximum anticipated surface pressure.