Академический Документы

Профессиональный Документы

Культура Документы

Trex 06169

Загружено:

OSDocs2012Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Trex 06169

Загружено:

OSDocs2012Авторское право:

Доступные форматы

s250.

438

lf you want a departuroto:

30 CFRCh. ll (7-t{X

fhn you mct..

Edition)

(d) Us a gingle divertef line for flting driltng Mainbin an apprcNiate vasse, heading to prcvide tor downwind diE6ion. oprations on a dynamically positioned drillshio.

[68 FR 8423,Feb. 20,Z0A3l

$250.433 ation

What are and testing

the diverter reqrrirenents?

actu-

and actuations at the facilitv duration ofdrilling the well. [68 FR 8423,Feb. 20, 2003]

for the

When you install the diverter svs, tem, you must actuate the diverier sealing element, diverter valves, and diverter-control systems and control stations. You must also flow-test the vent lines. (a) For drilling operations with a surt'ace wellhead configuration, you must actuate the diverter system at least once every 24-hour period after the initial test. After you have nippled up on conductor,casing, you must pressuretest the dlverter-sealing element and diverter valves to a minimum of 200 psi. While the diverter is lnstalled. vou must conduct subsequent presjure tests within 7 days after the previous test. {b) For floating driiling operations with a subsea BOP stack, iou'm.r"t a.tuate the diverter system ivithin Z days after the previous a;tuation. (c) You must alternate actuations and tests between control stations. [68 FR 8423,Feb. 20, 2003] g25O.4U What are the recordkeepins requirements for diverter alctul ations and tests? You must record the time, date. and results of all diverter actuations and tests in the drlller's report. In addition, you must: (a) Record the diverter pressure test on a pressure chart; (b) Require your onsite representa. tive to sign and date the pressure test chart; (c) Identify the control station used during the test or actuation; (d) Identify problems or irregularities observed during the testing or actuations and record actions taken to remedy the problems or irregularities; and (e) Retain all pressure charts and reports pertaining to the diverter tests

BLOWOUT PREVENTER (BOP) SYSTEM REQUIREMENTS 6260;140 lYhat are the general neauir:ements for BOP eysteme and syetem componente? You must design, install, maintain, test, and use the BOP system and syscem components to ensure well control. The working-pressure rating of each BOP component must exceed maximum anticipated surface pressures. The BOp system includes the BOP stack and associated BOP systems and equipment. [68 FR 8423,Feb. Z(),z00gj 92ffi.441 Srhat are the reouirements for a surface BOP atack? (a) When you drill with a surface BOP stack, you must install the BOp system before drilling below surface casing. The surface BOP stack must include at least four remote-controlled. hydraulically operated BOps, consisting of an annular BOP, two BOps equipped with pipe rams, and one BOp equipped with blind or blind-shear rams, (b) No later than February 21, 20ffi, your surface BOP stack must lnclude at least four remote-controlled, hv-of draulically operated BOPs consisting an annular BOP, two BOps equipped with pipe rams, and one BOP equipped with blind-shear rams. The blind-sh-ear rams must be capable of shearing the drill pipe that is in the hole. (c) You must install an accumulator system that provides 1.5 times the volume of fluid capacity necessary to close and hold cl6sed att gOp co-mponents. The system must perform with a minimum pressure of 200 psi above the precharge pressure without assistance . charging system. If you supply tothe accumulator regulators by rig air

316

Q ,I b ' l

Exhibit No. Worldwide Court

Вам также может понравиться

- T) Nited States Department of The Interior Minerals Management ServiceДокумент6 страницT) Nited States Department of The Interior Minerals Management ServiceOSDocs2012Оценок пока нет

- OTC-23473-MS - New Generation Control System For 20ksi Subsea BOP - Shanks - 2012Документ12 страницOTC-23473-MS - New Generation Control System For 20ksi Subsea BOP - Shanks - 2012Anonymous TYj74uwОценок пока нет

- Chiller Testing Procedure Rev 1Документ15 страницChiller Testing Procedure Rev 1Ali AimranОценок пока нет

- Bop - Inspection and TestingДокумент53 страницыBop - Inspection and TestingAustin AsuquoОценок пока нет

- Well Control Requirements For Wireline OperationsДокумент2 страницыWell Control Requirements For Wireline OperationsFlor MarchitaОценок пока нет

- Bladder Surge Tank Protects PumpsДокумент7 страницBladder Surge Tank Protects PumpsMunish BansalОценок пока нет

- T&C Procedure For Air Conditioning Chiller SystemДокумент11 страницT&C Procedure For Air Conditioning Chiller SystemAli AimranОценок пока нет

- Downwhole Deployment Valve Specification - (CNPC) Option1Документ13 страницDownwhole Deployment Valve Specification - (CNPC) Option1RobertОценок пока нет

- DOP 203 - Rev 2Документ54 страницыDOP 203 - Rev 2Fernando AybarОценок пока нет

- C3W Distributor Valve Test DataДокумент10 страницC3W Distributor Valve Test DataChandra Mohan Rawat0% (1)

- Deployment of The Reelwell Drilling MethodДокумент9 страницDeployment of The Reelwell Drilling Methodraj kumarОценок пока нет

- Piping Flushing Procedure Ensures Clean SystemsДокумент4 страницыPiping Flushing Procedure Ensures Clean SystemsAhmed Gomaa100% (1)

- Technical Specification MRSДокумент14 страницTechnical Specification MRSPrasanna kumar subudhiОценок пока нет

- Assignment 6.Документ3 страницыAssignment 6.Justin ButlerОценок пока нет

- Bladder Surge Tank SystemДокумент5 страницBladder Surge Tank SystemihllhmОценок пока нет

- A4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFДокумент4 страницыA4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFJose BijoyОценок пока нет

- Technical Service Bulletin: Commissioning Procedure For HydracapДокумент10 страницTechnical Service Bulletin: Commissioning Procedure For HydracapValesh MonisОценок пока нет

- EM 385-1-1 Chapters 20-26Документ179 страницEM 385-1-1 Chapters 20-26MusabОценок пока нет

- Oil Tender Part 3Документ40 страницOil Tender Part 3Dhrubajyoti SonowalОценок пока нет

- 9/27/01 AC 43.13-1B CHG 1: Figure 12-5. Pitot/static System For A Small AircraftДокумент5 страниц9/27/01 AC 43.13-1B CHG 1: Figure 12-5. Pitot/static System For A Small Aircraftaerogem618Оценок пока нет

- NORSOK D-SR-005 On Coiled TubingДокумент17 страницNORSOK D-SR-005 On Coiled TubingJozsef MagyariОценок пока нет

- Deepwater Discovery: Top Drive Varco Tds4Документ5 страницDeepwater Discovery: Top Drive Varco Tds4philip williamsОценок пока нет

- BOP Accumulator UnitsДокумент18 страницBOP Accumulator Unitsjosegutierrez88201050% (2)

- Technical Specification - PumpДокумент7 страницTechnical Specification - PumpBalasundaramSrinivasaRajkumarОценок пока нет

- TP201.3A Determination of 5 Inch WC Static Pressure Performance of Vapor Recovery Systems of Dispensing FacilitiesДокумент10 страницTP201.3A Determination of 5 Inch WC Static Pressure Performance of Vapor Recovery Systems of Dispensing FacilitiesCésar Oswaldo Aguilera OjedaОценок пока нет

- SECTION 22 14 29 Sump Pumps Part 1 - General 1.1 DescriptionДокумент353 страницыSECTION 22 14 29 Sump Pumps Part 1 - General 1.1 DescriptionMi doremiОценок пока нет

- ML C 650 c65mm763Документ11 страницML C 650 c65mm763operacionesОценок пока нет

- Choke Maintnance PDFДокумент42 страницыChoke Maintnance PDFbtrasla9023Оценок пока нет

- NTL 2011-n11Документ9 страницNTL 2011-n11ger80Оценок пока нет

- QA-WIS Well Intervention Syllabus V3.2Документ24 страницыQA-WIS Well Intervention Syllabus V3.2Ramanamurthy Palli0% (1)

- A4 SPEC Surge Control Dynamics FIV AIV Station2014Документ4 страницыA4 SPEC Surge Control Dynamics FIV AIV Station2014Kroya HunОценок пока нет

- Detergent Flushing of Pre Boiler System-Procedure 250Документ11 страницDetergent Flushing of Pre Boiler System-Procedure 250Sara LopezОценок пока нет

- Coiled Tubing EquipmentДокумент17 страницCoiled Tubing EquipmentRombo RootОценок пока нет

- Schlumberger Coiled TubingДокумент29 страницSchlumberger Coiled Tubingmashangh100% (7)

- ANNEX VIII BOP Testing, Inspection, Training and MaintenanceДокумент5 страницANNEX VIII BOP Testing, Inspection, Training and MaintenanceMohsen Shk100% (1)

- Turbine Flowmeter Design: (MUSM)Документ8 страницTurbine Flowmeter Design: (MUSM)jose mirandaОценок пока нет

- Specs of Hydraulic BrakesДокумент2 страницыSpecs of Hydraulic Brakesbijlwanr1Оценок пока нет

- Wet ScrubberДокумент5 страницWet ScrubberBia AkramОценок пока нет

- Guidelines & Recommended Practices For Selection of Artificial Lift SystemsДокумент19 страницGuidelines & Recommended Practices For Selection of Artificial Lift SystemsHesham SamyОценок пока нет

- Well PreparationДокумент16 страницWell PreparationfarajОценок пока нет

- Especificacion TACO AC (F) - CBXДокумент5 страницEspecificacion TACO AC (F) - CBXpca97Оценок пока нет

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyДокумент16 страницGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddydioneslealОценок пока нет

- Rotary Displacement Flowmeter Design: GeneralДокумент7 страницRotary Displacement Flowmeter Design: Generaljose mirandaОценок пока нет

- Instruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaДокумент14 страницInstruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaAlexandre EmmerickОценок пока нет

- Scope of Work For High Pressure Rotomol Cleaning of Underground Cooling Water PipelinesДокумент4 страницыScope of Work For High Pressure Rotomol Cleaning of Underground Cooling Water PipelinesSumeet PanwarОценок пока нет

- Maintenance and Operation Manual Hydraulic Choke and Control ConsoleДокумент42 страницыMaintenance and Operation Manual Hydraulic Choke and Control ConsoleMehdi Hajd KacemОценок пока нет

- 01 ExxonMobil Surface Equipment Policy & Procedures - 5Документ10 страниц01 ExxonMobil Surface Equipment Policy & Procedures - 5sitemaster60Оценок пока нет

- Bhel LP-HP Bypass OrderДокумент32 страницыBhel LP-HP Bypass OrderGiriDharanОценок пока нет

- Technical Standards PNGRBДокумент44 страницыTechnical Standards PNGRBRashid HussainОценок пока нет

- AES Vol 2 P15007 Split AC UnitsДокумент5 страницAES Vol 2 P15007 Split AC UnitsShreejith PanickerОценок пока нет

- Pressure Testing StandardsДокумент3 страницыPressure Testing StandardsAntonio DiabanzaОценок пока нет

- Well Iadc 27Документ4 страницыWell Iadc 27cyrel carl moloОценок пока нет

- BFP TDДокумент22 страницыBFP TDJackSparrow8650% (2)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingОт EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingРейтинг: 5 из 5 звезд5/5 (9)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Components for Pneumatic Control Instruments: The Static and Dynamic Characteristics of Pneumatic Resistances, Capacitances and Transmission LinesОт EverandComponents for Pneumatic Control Instruments: The Static and Dynamic Characteristics of Pneumatic Resistances, Capacitances and Transmission LinesОценок пока нет

- Reciprocating Compressors:: Operation and MaintenanceОт EverandReciprocating Compressors:: Operation and MaintenanceРейтинг: 4 из 5 звезд4/5 (7)

- DOJ Pre-Trial Statement On QuantificationДокумент14 страницDOJ Pre-Trial Statement On QuantificationwhitremerОценок пока нет

- 2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411Документ41 страница2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411OSDocs2012Оценок пока нет

- 2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349Документ13 страниц2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349OSDocs2012Оценок пока нет

- HESI's Post-Trial BriefДокумент52 страницыHESI's Post-Trial BriefOSDocs2012Оценок пока нет

- State of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)Документ23 страницыState of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)OSDocs2012Оценок пока нет

- BP Pre-Trial Statement On QuantificationДокумент13 страницBP Pre-Trial Statement On Quantificationwhitremer100% (1)

- 2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlДокумент13 страниц2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlOSDocs2012Оценок пока нет

- BP's Post-Trial BriefДокумент72 страницыBP's Post-Trial BriefOSDocs2012Оценок пока нет

- To's Post-Trial BriefДокумент57 страницTo's Post-Trial BriefOSDocs2012Оценок пока нет

- To's Proposed FOF and COLДокумент326 страницTo's Proposed FOF and COLOSDocs2012Оценок пока нет

- BP's Proposed Findings - Combined FileДокумент1 303 страницыBP's Proposed Findings - Combined FileOSDocs2012Оценок пока нет

- HESI's Proposed FOF and COLДокумент335 страницHESI's Proposed FOF and COLOSDocs2012Оценок пока нет

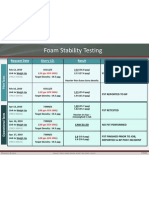

- Foam Stability Testing: Request Date Slurry I.D. Result CommentsДокумент1 страницаFoam Stability Testing: Request Date Slurry I.D. Result CommentsOSDocs2012Оценок пока нет

- State of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)Документ22 страницыState of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)OSDocs2012Оценок пока нет

- USAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)Документ121 страницаUSAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)OSDocs2012Оценок пока нет

- April 20, BLOWOUT: BP Misreads Logs Does Not IdentifyДокумент22 страницыApril 20, BLOWOUT: BP Misreads Logs Does Not IdentifyOSDocs2012Оценок пока нет

- USAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)Документ49 страницUSAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)OSDocs2012Оценок пока нет

- PSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013Документ72 страницыPSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013OSDocs2012100% (1)

- Arnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"Документ5 страницArnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"OSDocs2012Оценок пока нет

- Macondo Bod (Basis of Design)Документ23 страницыMacondo Bod (Basis of Design)OSDocs2012Оценок пока нет

- Exterior: Circa 2003Документ1 страницаExterior: Circa 2003OSDocs2012Оценок пока нет

- Plaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013Документ199 страницPlaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013OSDocs2012Оценок пока нет

- Driller HITEC Display CCTV Camera System: Source: TREX 4248 8153Документ1 страницаDriller HITEC Display CCTV Camera System: Source: TREX 4248 8153OSDocs2012Оценок пока нет

- DR Gene: CloggedДокумент1 страницаDR Gene: CloggedOSDocs2012Оценок пока нет

- Circa 2003Документ1 страницаCirca 2003OSDocs2012Оценок пока нет

- Laboratory Results Cement Program Material Transfer TicketДокумент13 страницLaboratory Results Cement Program Material Transfer TicketOSDocs2012Оценок пока нет

- Circa 2003Документ1 страницаCirca 2003OSDocs2012Оценок пока нет

- End of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateДокумент1 страницаEnd of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateOSDocs2012Оценок пока нет

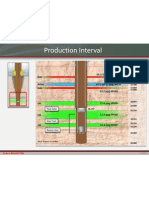

- Production Interval: 14.1-14.2 PPG M57B Gas Brine GasДокумент1 страницаProduction Interval: 14.1-14.2 PPG M57B Gas Brine GasOSDocs2012Оценок пока нет

- Webster:: Trial Transcript at 3975:2-4Документ1 страницаWebster:: Trial Transcript at 3975:2-4OSDocs2012Оценок пока нет

- Hypothetical Process PathsДокумент9 страницHypothetical Process Pathsifiok100% (1)

- FANS AT WORK IN BOILERS: CASE STUDIES ON FAN AND DRAFT SYSTEM DESIGNДокумент23 страницыFANS AT WORK IN BOILERS: CASE STUDIES ON FAN AND DRAFT SYSTEM DESIGNAli BariОценок пока нет

- Fluid Mechanics Lab Experiments UET LahoreДокумент13 страницFluid Mechanics Lab Experiments UET LahoreLim Andrew0% (1)

- EngineДокумент21 страницаEngineCHERRY ANN OLAJAYОценок пока нет

- CRP Sampling LiteratureДокумент24 страницыCRP Sampling LiteratureSDP02Оценок пока нет

- Safety Valve SizingДокумент11 страницSafety Valve Sizingvũ hiềnОценок пока нет

- Separation Using Membrane - Water&oilДокумент4 страницыSeparation Using Membrane - Water&oilsasiОценок пока нет

- Tasnee 1925ASДокумент1 страницаTasnee 1925ASpolymeianОценок пока нет

- Pipe Alcorcon1Документ86 страницPipe Alcorcon1Nelson Naval Cabingas100% (11)

- The Calculation of Fixed Tubesheet Exchangers According To ASME Section VIII Division1Документ15 страницThe Calculation of Fixed Tubesheet Exchangers According To ASME Section VIII Division1AKSHAY BHATKAR100% (1)

- Catalogo Denison Serie PV PDFДокумент36 страницCatalogo Denison Serie PV PDFEdison YesidОценок пока нет

- KIL3012 - WEEK 3 - 24.9.19 (Student Copy)Документ84 страницыKIL3012 - WEEK 3 - 24.9.19 (Student Copy)EdОценок пока нет

- Column Flotation Systems With Cavitation TubeДокумент8 страницColumn Flotation Systems With Cavitation TubeRogério Leonardo OliveiraОценок пока нет

- Operating Instructions Automatic Air Inlet ValveДокумент4 страницыOperating Instructions Automatic Air Inlet ValveelecbaОценок пока нет

- ME080 Section 8 - Other Hydraulic ComponentsДокумент101 страницаME080 Section 8 - Other Hydraulic ComponentsAhmed FaragОценок пока нет

- Engineering Interview Questions and MCQs on Fluid MechanicsДокумент20 страницEngineering Interview Questions and MCQs on Fluid MechanicspiluОценок пока нет

- Pressure Vessels Design and Practics by Somnath ChattopadhyayДокумент11 страницPressure Vessels Design and Practics by Somnath ChattopadhyaydewianzaniОценок пока нет

- Experiment 2 CHM207 Intermediate Organic Chemistry Distillation Technique and To Determine The Boiling Point of A LiquidДокумент3 страницыExperiment 2 CHM207 Intermediate Organic Chemistry Distillation Technique and To Determine The Boiling Point of A LiquidMUADZ ARОценок пока нет

- Boiler DraughtДокумент4 страницыBoiler Draughtshivrant shivrant0% (1)

- VaporizatorДокумент3 страницыVaporizatorBbogdan.eОценок пока нет

- White Paper Flowmeter AccuracyДокумент2 страницыWhite Paper Flowmeter Accuracyธนาชัย เต็งจิรธนาภาОценок пока нет

- Rectangular Sharp Crested Weirs - Francis FormulaДокумент8 страницRectangular Sharp Crested Weirs - Francis FormulaRenvil PedernalОценок пока нет

- Fundamentals of Thermodynamics Solutions ch11Документ173 страницыFundamentals of Thermodynamics Solutions ch11Cierré No'Middlename Jones88% (8)

- Sci 6 Lesson 1Документ30 страницSci 6 Lesson 1Jean Jean NasayaoОценок пока нет

- CR, Cri, CRN, CRT ATEX-approved Pumps: Installation and Operating InstructionsДокумент18 страницCR, Cri, CRN, CRT ATEX-approved Pumps: Installation and Operating InstructionsXuan Man NguyenОценок пока нет

- News - Free Cooling Using Water Economizers PDFДокумент8 страницNews - Free Cooling Using Water Economizers PDFlipi8Оценок пока нет

- Wick DrainsДокумент1 страницаWick Drainsaecom2009Оценок пока нет

- NASA Presentation CFD HistoryДокумент78 страницNASA Presentation CFD Historyjamesmoro0408Оценок пока нет

- Boiler safety valves and controlsДокумент2 страницыBoiler safety valves and controlsripalОценок пока нет