Академический Документы

Профессиональный Документы

Культура Документы

Stores and Store Management

Загружено:

Siddhartha KamatИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Stores and Store Management

Загружено:

Siddhartha KamatАвторское право:

Доступные форматы

NICMAR

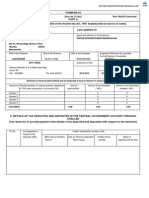

MCM 311: CONSTRUCTION MATERIALS MANAGEMENT ASSIGNMENT STORES AND STORES MANAGEMENT

FACULTY: Dr. A. K. GARG

Submitted By:

Aditya Kale-251073 Nishant Kamal-251074 Siddhartha Kamat-251075 Gourav Kapoor-251076 Vaibhav Kapoor-251077 Narendra Kashikar-251078

NATIONAL INSTITUTE OF CONSTRUCTION MANAGEMENT AND RESEARCH

Introduction Stores management is part of the overall function of materials management. In order, therefore, to understand the function of the former it is desirable to have a clear

understanding of what materials management stands for. Beginning with the term management is important to examine its definition and objectives. Management is the specific purpose of planning, controlling and implementing. Material s management" is one of the recent additions to the growing glossary on management. Materials management is the process if planning, implementing and controlling the flow or storage of input, facilities, service and information efficiently and effectively from the point of supply to the point of consumption in the conformity of the companies' objective. Stores organization may be defined as a systematic coordination and combination of efforts in manner, which would result in optimum efficiency with a minimum of expenditure. The term Store, Storehouse, or Warehouse refer to a building or room or place where materials are kept. The function of stores is to receive, store and issue materials. Stores are normally divided into various sections such as Receiving section Tool stores General stores Raw materials stores Finished parts stores

Stores plays a vital role in the operations of a company.Stores networks are incredibly complex and therein lies the opportunity of improvement. Stores function as an element of materials department and has an interface with many user departments in its daily operations. The basic purpose served by stores is the provision of uninterrupted service to manufacturing divisions. Stores act as a cushion between purchase and manufacturing on one hand and manufacturing and marketing on the other. The inherent limitations of forecasts make the stores function a necessity. Stores function is an inseparable part of all business and non business

concerns, whether they are industrial or service oriented, public or private, small or large. The task of store keeping relates to safe custody and stocking of materials, their receipts, issues, and accounting with the objective of efficiently and economically providing the right material at the right time whenever required in the right condition to all user departments. Necessity of Stores One must always remember that even though store keeping doesnt add any value to the product in the normal sense, it is an essential function and just cannot be wished away. At times stores may add time utility or value by preserving scarce material that may be required in future. By proper preservation and storage, the store department avoids any depreciation in the value of inventory. The financial view considers stores as an overhead i.e. cost with no return. This all the more highlights the need for economic operation and efficient stores management. The cost of stores can be categorized into a capital cost component and revenue expenditure component. The capital cost consist of the sunk cost in land building, roads, yards, material handling equipment and related facilities. Because of the very irreversible nature of this cost, proper planning of stores can go long way in reducing this capital expenditure that may also have a bearing on the revenue expenditure in the stores. The revenue component of stores expenditure consists of salaries and wages of store personnel, maintenance cost, stationary cost, communication expenses, and inventory carrying cost. One must always remember that efficiency in stores operations cannot be built overnight but has to be thought of right from the initial planning stage. Stores must be visualized as an integral part of the purchasing manufacturing marketing link. Unfortunately, stores management is looked down upon by many as an operational clerical function and fails to attract appropriate talent because of its underdog nature. One has to bear in mind that the stores manager heads the single largest group of current assets and his performance is the key to smooth production and subsequent

marketing. Many decisions related to stores have a dramatic impact on the operational efficiency of the production department and profitability of the entire organization. Even seemingly routine decisions such as selection of racks, shells, bins, material handling equipment, safety practices, inspection procedures etc. are reflected in the operational efficiency. One must appreciate the role of stores in maintaining optimum inventory and highlighting exception cases through building up of proper MIS by maintaining accurate records. Functions of Stores The following are the principal functions of a store; 1. To receive raw materials, components, tools, spares, supplies, equipment and other items and account for them. 2. To provide adequate, proper and efficient storage and preservation for all the items. 3. Physical checking of all incoming materials as per the delivery challan / invoice and proper maintenance of daily goods receipt register or records. 4. Arrange for inspection of incoming materials. 5. Ensure that goods inward notes (GIN) are raised and distributed without delay. 6. Issue materials to the consuming departments against authorised requisitions and account for the same. 7. Maintain accurate and up to date records of material received, issued, rejected, disposed, and quantity on hand of all the items. 8. Ensure that all documents relating to receipts and issue are sent to stock control, accounts and other concerned departments. 9. Undertake stock verification as per approved procedure. 10. To highlight stock accumulation, discrepancies and abnormal consumption and initiate appropriate control action, wherever necessary.

11. To minimise obsolescence, surplus and scrap through proper codification, standardization, preservation and handling. 12. To ensure good housekeeping so as to minimise the need for material handling. 13. To make available a balanced flow of materials so as to economise on capital tied up in inventory. 14. To accept and store scrap and other discarded materials. Location of Stores: The first question that arises is with regard to the location of the stores. Will there be one store or many? Should it be very close to actual construction site or away from it? What transport facilities should be made available? These questions stem from one primary concern who is being served and what are the services provided. It must be remembered that economy and efficiency are the vital factors. Some of the principles to be observed in this regard are as follows: In choosing the location, observe the principle of minimum movement. Plan for future. A storehouse should not merely take care of present needs but also those of the future. All storehouses should be sited with expansion in mind. There should be a considerable degree of flexibility. Accessibility for road, rail or river transport should be an important consideration. Planning should concern itself with loading and unloading facilities. Sufficient precautions should be taken to maintain security from fire, theft, explosion, toxic substances, etc. A variety of services must be provided for water, light, drainage and telephone, etc.

Stores Building & Stores Layout The primary importance is given to the inward & outward flows of raw materials & vehicles in an orderly fashion. Working areas, including raw materials inward & outward , maintenance areas & packing areas should be grouped as closely together ,that would reduce the costs. The height of the building from floor to ceiling must be enough to permit maximum loading & tacking level of materials Main gangways should run the length of buildings & across in short ones Gangways must be wide enough for two large vehicles or mechanical equipments likely to pass each other without collision Subsidiary gangways should run of the main gangways but not necessarily at right angles Proper lightning must be provided. Door should be wide & high enough. Floor thick ness & strength must be specified & checked. Fire precautions need to be carefully considered & provide fire exits. Stores Organization: Organization is a vehicle to achieve the predetermined objectives. It is a framework of tasks, responsibilities, authorities, and associated personnel. The type of organization must be geared to achieve the desired objectives efficiently and economically. Organization is based on commonality of certain tasks and specialization of work. It is an indispensible means to good management. A faulty organization structure can seriously hamper its performance. Steps in organization: 1. Identify the entire gamut of tasks to be performed 2. Group and re group the tasks according to certain well defined common characteristics.

3. Define and delegate responsibility and commensurate authority. 4. Establish reporting and structural relationships between all positions. Stores organization must comprise of the following: 1. Outline and communicate to all concerned, the primary and other objectives of the store functions. 2. Define clear-cut responsibilities. 3. Bestow appropriate authority and practice delegation of power to enable fulfilling the given responsibilities. 4. Establish proper communication channels 5. Allocate tasks to qualified personnel. In short, stores organization can be defined as the systematic coordination and combination of efforts in a fashion that results in an optimum efficiency and minimum expenditure. Traditionally stores function has been visualised as a part of production department and was never given the attention and importance it rightfully deserved. The conventional practice is to locate the stores near user departments so as to minimize material handling cost and ensure timely supplies so as to allow smooth production. The materials department is seldom consulted in aspects such as stores location and layout. The receipt stores usually part of the Stores set -up and is under the Stores-in-Charge of stores. Depending on its size and complexity, it will have a few clerks and a supervisor can be at a fairly junior level in most cases, but for a very large Receipt Store, there can be senior officer also. The receipt store can be of three types: Centralized: Where all the goods are received at one place. Semi-centralized: Here the paperwork can be done at one place and the actual deliveries at the shop floor or yards, etc.

Decentralized: In this case there is a separate receipt section attached to each store or group of stores. This might be because of the specialized nature of the articles or because of the distances between production shops. Good storage procedures have several benefits: They enable smooth running of storage and aid in the reduction of delays and bottlenecks in office work. They assist in speedy execution of work because what is to be done is clearly laid down. No one is in doubt and trained clerks need merely follow instructions. They assist a better control on what is done and act as a check on how it is done. A good procedure will have sufficient internal in -built checks at work this can aid in prevention of fraud and establish a better control over the work done. They can lead to economies in expenditure because of savings in terms of indirect labour & overheads. There will be a greater coordination between stores and purchase, Inventory Control, Receipts etc. and also between stores and production, accounts and other departments. Procedures well laid down, facilitate training of staff because it is easy to make people understand and practice set procedures and methods for carrying out work. They reduce chances of error and thereby add to overall efficiency. Proper accounting and better stock control will result. Proper storage and improved preservation of materials are the outcome of the practice of goods storage procedure. Speedy issue will take place. Quick identification of material is enabled. They result in less damage to material during handling. Reduce inventory will result.

Centralised and Decentralised Stores The structure of store is a major factor in its organization. A very big factory having a large number of product lines may have a main stores which can serve as base, with decentralized stores for each unit of production, preferably located as near the unit as possible. Another possibility is that the main store can be completely eliminated and supplies effected directly to the suit stores. In a small company, one store would be adequate to serve all units. A large company marketing a variety of goods may have a central warehouse of finished goods at its factory location, besides large number of stock points in the various cities. A small company on the other hand can have just one simple warehouse from which the entire distribution can take place. Centralization or Decentralization then is a matter of convenience. However, one basic organizational feature must be observed. The entire Stores setup should be under the unified control of one department with Senior Controller of Stores in charge, in order to efficiently achieve the objectives of the function, of stores. Stock Verification: The stores manager holds the physical custody of the materials and is responsible for safe upkeep as well as for any major discrepancy. He must constantly review the stocks and reconcile the physical and book stocks, which differ in almost all organizations. The magnitude of this problem will increase as the number of transactions increase, because mistakes may be committed in transactions and this can accumulate to major discrepancies. For example, if the weighing scale indicates 1 kg less every time they weigh, and there are 100 weighing in a period, the store keeper would have issued 100 kg without any records and will find himself short when the physical check is made using the same weigh bridge. Issues without indents, improper check of receipts, pilferage, obsolescence, deterioration and damage due to different causes of improper storage, Shrinkage, evaporation, spoilage, etc. Are other factors that have to be considered in this context. In order to exercise strict control on the above, the store manager must verify the stocks periodically.

Experience indicates that many discrepancies in practice are due to improper documentation, like -

a) Complying with urgent issues without vouchers, b) Delays in posting the receipts and issues and c) Issue by numbers, receipt by weight and accounting by numbers, etc. Stock verification can be defined as the process of physical counting, weighing or measuring the stock of materials that is held and making a record of these figures. Normally personnel from the accounts department are given this responsibility. Sometimes the auditors ( or bankers to whom the stock is hypothecated) also undertake the verification of stocks on a sample basis ; in order to check the reality of the performance statements. A well-defined verification process, can also pinpoint any drawbacks or shortcomings in the methods of storage, movement of materials, handling of materials, obsolescence, etc. A regular verification process ensures that the system and procedures laid in the manual are adhered to. Physical verification of stocks started off as a periodic exercise, usually coinciding with the annual account closing, under the direction of accounts department. This procedure acting as a postmortem exercise, can stop the normal function of the plant towards the year end, if the number of items are large. Since there is an urgency for quick completion, this may lead to an ineffective verification process. To overcome this difficulty, materials are checked throughout the year and verifications are so staggered, that all materials are covered in a year. It will be advantageous to cover the high consumption value a items more than the other items in this perpetual continuous system. The verification process, whether periodic or perpetual should be thorough, or well organized weighing and the unit of measurements must be consistent and the measuring instruments must be properly calibrated, so that measuring errors are minimal. Care should be taken to avoid double counting, overlooking items kept at old places, with ancillaries and in transit, etc.

The process of physical verification can be complete only if necessary follow up action is planned. After tabulation of physical stock, attempts should be made to reconcile with book balance, indicating operating stock plus receipt minus issues. It is very common that the two sets of figures for each item may not tally and hence the problem arises in stores management. A detailed investigation is called for, if there are major differences particularly in high value items, to avoid recurrence of the same in future. Usually, organizations fix up limits for discrepancies and discrepancy vouchers are signed by the appropriate authorities. However, stock verification should not be perceived as a witch hunting process and store personnel must be involved in the exercise. The organizations will gain, if the stores personnel are motivated by a proper development of the atmosphere, culture and value systems. Inventory Management and Control Need for Inventory Control: Inventory is maintained basically to ensure operational smoothness. It is the materials departments responsibility to ensure that this operational smoothness is carried out at the minimum cost commensurate with efficiency. This is done through inventory control. Inventory control may be defined as a set of policies and procedures by which an organisation determines what materials it should hold in stock and the quantities of each that it should carry. Inventory consists of: Stores inventory: raw materials, spares, components, etc. Work in Process: semi-finished goods on the factory floor. Finished goods lying in the warehouse, prior to dispatch for sale. Large inventories tie up large amounts of money. On the other hand, too little inventory might end up in work stoppages, extra machine set ups, lost saes and loss of customer goodwill because of inability to deliver the product. It is of prime importance that a business organization determines and maintains an adequate inventory for a given of business. Inventory is created for two general-protection and economy. Protection refers to the provision of the provision of the necessary raw material with minimum delay. Whereas economy refers to effect lower product cost by realizing the economies resulting from

quantities per order. There are two fundamental questions which normally arise in inventory control: How much to buy at one time? When to buy this quantity?

Four fundamental factors that govern this are: Requirements: this is based on the information Quantity in stock or on order Procurement time or lead time Obsolescence.

Economic Order Quantity One of the most effective techniques for determination of quality is called economic order quantity. There are two major cost involved in it: 1.purchasing cost and 2.invenotry cost The EOQ is that quantity at which the cost of procuring the annual requirement of an item and the inventory carrying cost are equal, that is where the total of the two cost are low. Selective inventory control: there are variations in the inventory control from item to item and this should be done on selective basis. Following are the classifications: 1. ABC classification 2. VED Classification 3. HML Classification 4. XYZ Classification Stores Accounting and Records Various records are used in the stores. Bin cards: these cards are very simple, giving the description of the item including the code no., the unit of issues, and the quantity of the item. etc. Stock Cards: these are kept in the stores office. There are various kinds of stock cardsshowing the quantity only, showing the quantities and unit price. Showing the quantities, init price, value of stock, value of the balance in stock.

Stores Transfer note Material return note Goods inward note/ goods receipt no. Materials reject no. Scrap note Gate pass Inventory form Temporary loan form Techniques of stocktaking: Annual stocktaking Perpetual inventory method Daily stocktaking Checking by stores-in-charge Periodic checking

Stock Valuation: there are various methods of valuing material issues. FIFO: First In First Out LIFO: Last in First out HIFO: Highest in first out NIFO: Next in first out Base Stock Simple average Weighted average Standard average Replacement Price

Вам также может понравиться

- Job Description:: 4) Inventories Supplies and Equipment at End of Each VoyageДокумент3 страницыJob Description:: 4) Inventories Supplies and Equipment at End of Each VoyageMukesh PadwalОценок пока нет

- Chapter 5 & 6 Editted StorageДокумент12 страницChapter 5 & 6 Editted StorageMOHAMMED KEDIRОценок пока нет

- Inventory Management in General Stores of A TertiaryДокумент35 страницInventory Management in General Stores of A TertiaryMahnaz AnsariОценок пока нет

- Amit Kumar Dubey: Supply Chain Management/ ProcurementДокумент2 страницыAmit Kumar Dubey: Supply Chain Management/ ProcurementAnkit DubeyОценок пока нет

- Stores ManagementДокумент28 страницStores ManagementDilip YadavОценок пока нет

- 11.0 Material HandlingДокумент4 страницы11.0 Material HandlingNol BarandonОценок пока нет

- Book of Office Mana Gement: Written By: M Nawaz Birhamani Roll No: 2k17/PAE/72Документ167 страницBook of Office Mana Gement: Written By: M Nawaz Birhamani Roll No: 2k17/PAE/72ameeque khaskheliОценок пока нет

- Periodic Inventory SystemДокумент16 страницPeriodic Inventory SystemSohel Bangi100% (1)

- PMR14-BSP Cy2014Документ80 страницPMR14-BSP Cy2014JJ AsonyerОценок пока нет

- Material Handling: Jomon Joseph Roll No: 029Документ17 страницMaterial Handling: Jomon Joseph Roll No: 029Jomon JosephОценок пока нет

- PGPM 33 - NICMAR AssignmentsДокумент18 страницPGPM 33 - NICMAR AssignmentsVinod Vasan100% (2)

- StorekeeperДокумент2 страницыStorekeeperAbdirisaq MohamudОценок пока нет

- Men - Machines - Methods - Money - MaterialsДокумент42 страницыMen - Machines - Methods - Money - MaterialsAbhirup MukherjeeОценок пока нет

- Material HandlingДокумент99 страницMaterial HandlingsalunkensОценок пока нет

- Construction of New Road Phase 3Документ10 страницConstruction of New Road Phase 3mustafeОценок пока нет

- Topic 9 - Tendering ProcedureДокумент36 страницTopic 9 - Tendering ProcedureKen MutuiОценок пока нет

- Effects of Material Management Techniques On Construction Project Success Perspective of Material Managers in Northern Region of GhanaДокумент6 страницEffects of Material Management Techniques On Construction Project Success Perspective of Material Managers in Northern Region of GhanaMohamed WayrahОценок пока нет

- 1 Lecture Let's Write An Impactful Business Plan!Документ41 страница1 Lecture Let's Write An Impactful Business Plan!Billyrefanto JpgОценок пока нет

- Organization For Materials ManagementДокумент60 страницOrganization For Materials ManagementNaushad PulikkandyОценок пока нет

- On ShutdownДокумент26 страницOn ShutdownRatna Tiwary100% (1)

- Construction Material Management Through Inventory CONTROL TECHNIQUESДокумент5 страницConstruction Material Management Through Inventory CONTROL TECHNIQUESMohamed WayrahОценок пока нет

- Business Development ConstructionДокумент2 страницыBusiness Development Constructionapi-1213523070% (1)

- Maintenance Culture: Mama Cass Restaurants LimitedДокумент22 страницыMaintenance Culture: Mama Cass Restaurants LimitedOsagie AlfredОценок пока нет

- Activity Based CostingДокумент50 страницActivity Based CostingDebrina A. WidyasariОценок пока нет

- 7-Principles of Material Handling-170811Документ5 страниц7-Principles of Material Handling-170811pammy313Оценок пока нет

- Purchase & Store ManagementДокумент42 страницыPurchase & Store ManagementChintan Anadkat82% (11)

- Stores Management Objective & Service: Objective - To Provide The Service To Production or Operating Functions. ServicesДокумент72 страницыStores Management Objective & Service: Objective - To Provide The Service To Production or Operating Functions. ServicesShashikant Kari100% (1)

- Towards World Class In-Plant Logistics: Hindustan Industries LimitedДокумент2 страницыTowards World Class In-Plant Logistics: Hindustan Industries LimitedAravind Maddireddy100% (1)

- Material HandelingДокумент14 страницMaterial HandelingAakanshaОценок пока нет

- Facilities Planning (SLP)Документ14 страницFacilities Planning (SLP)pavanidhawanОценок пока нет

- MaintenanceДокумент18 страницMaintenancemohammad baniissaОценок пока нет

- SM City Cebu WP SignedДокумент2 страницыSM City Cebu WP SignedCris EnerioОценок пока нет

- Material ManagementДокумент38 страницMaterial ManagementanushavergheseОценок пока нет

- Making Hotel Maintenance ChangesДокумент3 страницыMaking Hotel Maintenance Changesmintek2009Оценок пока нет

- Store ManagementДокумент40 страницStore ManagementSashi RajОценок пока нет

- Stock VerificationДокумент26 страницStock VerificationRishi MaliОценок пока нет

- Assignment Nicmar / Code Office: Site Organization & Management Reg. No. - 217-09-11-51049-2194Документ15 страницAssignment Nicmar / Code Office: Site Organization & Management Reg. No. - 217-09-11-51049-2194Manvendra singhОценок пока нет

- Stock Functions& DiscrepancyДокумент30 страницStock Functions& DiscrepancyManish Kumar100% (1)

- 1 Planning Housekeeping OperationsДокумент4 страницы1 Planning Housekeeping OperationsAbhishek ChowdhuryОценок пока нет

- 1.planning and Organising The Housekeeping DepartmentДокумент7 страниц1.planning and Organising The Housekeeping DepartmentAviral KumarОценок пока нет

- Warehouse Supervisor Cum Lesson PlannerДокумент56 страницWarehouse Supervisor Cum Lesson Plannernayra khan67% (3)

- Inventory Management PowerPoint PresentationДокумент30 страницInventory Management PowerPoint PresentationHisaan KamranОценок пока нет

- Week 4 DOIP (Inventory Management Fundamentals)Документ29 страницWeek 4 DOIP (Inventory Management Fundamentals)majid aliОценок пока нет

- Stores Management and Materials HandlingДокумент21 страницаStores Management and Materials HandlingMr. Umang PanchalОценок пока нет

- On-Site Building Construction Management Level IV: MODULE TITLE: Managing Subordinates andДокумент58 страницOn-Site Building Construction Management Level IV: MODULE TITLE: Managing Subordinates andKinfe Dufera GonfaОценок пока нет

- Principles of Warehousing and Stock ControlДокумент82 страницыPrinciples of Warehousing and Stock ControlMwanza MaliiОценок пока нет

- Maintenance Procedure PDFДокумент6 страницMaintenance Procedure PDFAya AbdoОценок пока нет

- Contract PresentationДокумент28 страницContract PresentationShreeОценок пока нет

- Material Handling & StorageДокумент41 страницаMaterial Handling & StorageAganon AristotleОценок пока нет

- Management of Stores: Prepared By:Abhinav SinghДокумент36 страницManagement of Stores: Prepared By:Abhinav SinghfikrhomeОценок пока нет

- Sample Guest HouseДокумент33 страницыSample Guest HouseSiddhartha100% (1)

- AssignmentPGPM 33Документ15 страницAssignmentPGPM 33Santosh Thakur100% (1)

- JLL-Reinventing Facilities Managemnt For The Digital WorldДокумент9 страницJLL-Reinventing Facilities Managemnt For The Digital WorldKerie ThamОценок пока нет

- 10 Stores ManagementДокумент36 страниц10 Stores ManagementSudheer SirangulaОценок пока нет

- Building Maintenance PlanДокумент4 страницыBuilding Maintenance PlanhafizahОценок пока нет

- Stores and Inventory ManagementДокумент18 страницStores and Inventory ManagementUdit Sharma0% (1)

- Nicmar: Stores and Inventory Management (Infrastructure Projects)Документ19 страницNicmar: Stores and Inventory Management (Infrastructure Projects)searchers007Оценок пока нет

- Stores and Inventory ManagementДокумент19 страницStores and Inventory Managementjagdeep_naidu92% (50)

- Materials Management: Dr. K. K. Saju Professor Division of Mechanical Engineering Soe, CusatДокумент78 страницMaterials Management: Dr. K. K. Saju Professor Division of Mechanical Engineering Soe, CusatRitwik AravindОценок пока нет

- Warehouse Operations Best 5 PracticesДокумент4 страницыWarehouse Operations Best 5 PracticesJochie Teruel100% (1)

- A Critical Review of BIM in Indian Context by (Kamat Et Al)Документ78 страницA Critical Review of BIM in Indian Context by (Kamat Et Al)Siddhartha KamatОценок пока нет

- Tunnel Boring MachineДокумент20 страницTunnel Boring MachineSiddhartha KamatОценок пока нет

- Microsoft Project Lab AssignmentДокумент14 страницMicrosoft Project Lab AssignmentSiddhartha KamatОценок пока нет

- Indian Economy V/s American Economy: A Comparative StatementДокумент9 страницIndian Economy V/s American Economy: A Comparative StatementSid KamatОценок пока нет

- Negotiation in Real EstateДокумент13 страницNegotiation in Real EstateSiddhartha KamatОценок пока нет

- Construction Equipment ManagementДокумент14 страницConstruction Equipment ManagementSiddhartha Kamat100% (1)

- Decision MakingДокумент16 страницDecision MakingSiddhartha KamatОценок пока нет

- Prospectus of Chartered Life Insurance Ltd. 29.04.2021 P 370Документ370 страницProspectus of Chartered Life Insurance Ltd. 29.04.2021 P 370Rumana SharifОценок пока нет

- EasyPAY WebДокумент25 страницEasyPAY Webnkumar_701351Оценок пока нет

- Semester - Iii (CBCS)Документ195 страницSemester - Iii (CBCS)Sakila SОценок пока нет

- Bid Letter - Micro Inks PDFДокумент18 страницBid Letter - Micro Inks PDFGaneshОценок пока нет

- CH10 Revised AДокумент16 страницCH10 Revised AMaimoona Ghani0% (1)

- Cost Draft 2Документ13 страницCost Draft 2wynellamae100% (1)

- Salaries Project Sec 15,16,17Документ47 страницSalaries Project Sec 15,16,17glorydharmarajОценок пока нет

- Brookstone Ob-Gyn Associates (A) : Tthe Crimson Press Curriculum Center Tthe Crimson Group, IncДокумент5 страницBrookstone Ob-Gyn Associates (A) : Tthe Crimson Press Curriculum Center Tthe Crimson Group, IncDr-YousefMHassan100% (1)

- NWRB Regulations: A Presentation For "Public Dialogue On Bulk Water Meter Arrangements" Quezon City, June 26, 2014Документ19 страницNWRB Regulations: A Presentation For "Public Dialogue On Bulk Water Meter Arrangements" Quezon City, June 26, 2014Catherine Kaye Belarmino AlmonteОценок пока нет

- 6018-P1-LEMBAR KERJA AKUNTANSI. Jawaban Uk 2019Документ58 страниц6018-P1-LEMBAR KERJA AKUNTANSI. Jawaban Uk 2019adiirwanto80% (5)

- Financial Management: Learning Objectives (Slides 1-1 To 1-3)Документ19 страницFinancial Management: Learning Objectives (Slides 1-1 To 1-3)Ekaterina MazyarkinaОценок пока нет

- Petrozuata Analysis WriteupДокумент5 страницPetrozuata Analysis Writeupgkfernandes0% (1)

- BMR Case StudyДокумент92 страницыBMR Case StudychamatkaribabaОценок пока нет

- CIR Vs Club FilipinoДокумент3 страницыCIR Vs Club Filipinolovekimsohyun89Оценок пока нет

- Mckinsey Case Collection Part 2Документ263 страницыMckinsey Case Collection Part 2Thiago Aires Mendes75% (4)

- f5 Smart NotesДокумент98 страницf5 Smart Notessakhiahmadyar100% (1)

- Project Report of Parle ProductДокумент29 страницProject Report of Parle ProductParth patelОценок пока нет

- AFAR 201808 1 Business Combination Statutory MergersДокумент6 страницAFAR 201808 1 Business Combination Statutory MergersAlarich Catayoc0% (1)

- Shopping For CreditДокумент8 страницShopping For CreditmooОценок пока нет

- Fund DisbursementДокумент33 страницыFund DisbursementNawal AbdulgaforОценок пока нет

- Fofa 1: Introduction To AccountingДокумент19 страницFofa 1: Introduction To AccountingRahul MittalОценок пока нет

- Bidding GuidelineДокумент5 страницBidding GuidelineBianca CezarОценок пока нет

- Financial Report (October 2017)Документ2 страницыFinancial Report (October 2017)Marija DukićОценок пока нет

- Accounting ReviewerДокумент5 страницAccounting ReviewerHershi TrishОценок пока нет

- Introduction To Quiz: Economics of Wind EnergyДокумент5 страницIntroduction To Quiz: Economics of Wind EnergyNiko100% (1)

- Form 16 by Tcs PDFДокумент5 страницForm 16 by Tcs PDFAnonymous utPqL6jA3i25% (4)

- Beaumont Budget Fy2017Документ271 страницаBeaumont Budget Fy201712NewsNowОценок пока нет

- MFP Report PDFДокумент0 страницMFP Report PDFserbac2007Оценок пока нет

- Study On Retail BankingДокумент47 страницStudy On Retail Bankingzaru1121Оценок пока нет

- Supply Chain Game Round 2Документ5 страницSupply Chain Game Round 2douding41163.com100% (1)