Академический Документы

Профессиональный Документы

Культура Документы

Engineering Standards

Загружено:

Abu SaemИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Engineering Standards

Загружено:

Abu SaemАвторское право:

Доступные форматы

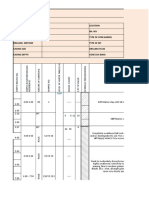

ENBRIDGE TECHNOLOGY

ENGINEERING STANDARDS DETAILS

This reference table is provided to outline the details of each Engineering Standard.

Number D01-101

Standard Name Use of Engineering Standards

Description This standard provides specific requirements and general guidance for Engineering Standards. Included in this standard is a summary of the Project Engineers responsibilities. This standard provides style, format, and content requirements for the preparation of an Engineering Standard. This standard provides a general procedure for the review and approval of new or revised Engineering Standards. This standard provides requirements, guidelines, and an overview of all related Company Engineering Standards used in the design of electric power supply and distribution systems, wiring and grounding systems, equipment and personnel safety systems, control systems, and measurement and control instruments used to power and control pipeline facilities. This standard presents requirements for the basic conceptual design approach for new or looped pipeline facilities for the transportation of crude oils, refined products, and natural gas liquids in the Companys pipeline system. This standard addresses conceptual design considerations and will serve to establish parameters and criteria on which detail designs and procedures will be based.

D01-102

Policy & Style for Engineering Standards

D01-103

Approval & Updating Procedures

D02-101

Design Basis, Electrical

D02-102

Design Basis, Main Line

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number D02-103

Standard Name Design Basis, Station & Terminal

Description This standard provides the recommendations and design basis for conceptual and detail design of pipeline and support facilities specific to the pumping, metering, and storage of crude oil and petroleum products. This standard directs the Project Engineer to the specific detailed engineering standards associated with the design of stations and terminals.

D02-104

Hazardous Area Classification

This standard provides design requirements for the classification of areas for the installation of electrical equipment at pipeline facilities, where flammable and combustible liquids are handled or stored. This standard provides the design and installation requirements for the application of fire protection systems to the transportation, metering, and storage of crude oil, natural gas liquids, and petroleum products. It includes the requirements for materials, design, procurement, manufacture, inspection, and testing. The fire protection systems presented in this standard include only the system design and installation parameters of the equipment required for fire extinguishment. Fire, vapor detection, and alarms are presented in separate standards.

D02-105

Fire Protection, Extinguishment

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number D02-106

Standard Name Noise & Acoustic Dampening

Description This standard provides technical parameters for noise measurement and the design requirements of new and retrofit acoustic dampening systems. In addition, reference is made to regulations for acceptable noise levels intended to maintain the health and safety for worker exposure and/or the impact on public dwellings or public lands surrounding pipeline facilities. Included are discussions pertaining to noise level predictions relating to equipment selection.

D02-107

Station Manual, Preparation

This standard provides requirements for the compilation of or additions to station manuals, as a result of the addition of new plant, equipment, or facilities. This standard provides assessment procedures and acceptance criteria for both external and internal pipeline corrosion, which exceed the tolerable limits specified in the Company's Operating and Maintenance Procedures Manual. External and internal pipeline corrosion shall be determined by either on-site inspection or by high resolution magnetic flux leakage internal inspection instruments.

D03-101

Pipeline Corrosion Assessment

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number D03-102

Standard Name Integrity Assessment, Oil Storage Tank

Description This standard provides criteria for the assessment and repair of crude oil storage tanks designed and constructed to API Std 650. The standard is intended to supplement API Std 653: Tank Inspection, Repair, Alteration, and Reconstruction, only in the areas of integrity assessment. Matters relating to tank modifications are outside the scope of this document and are covered in the Company's Operating and Maintenance Procedures Manual. Further, the scope of this standard is essentially restricted to the assessment of pressure retaining and structural elements, when failure of such could result in leakage or rupture. This standard establishes criteria to coordinate and conduct the assessment of pipelines, using various types of internal inspection tools (pigs). It covers the reasons for internal inspection and outlines the use of these tools in an inspection program. Operational conditions for planning and preparing a line for pigging and requirements for running various types of tools are presented.

D03-103

Internal Inspection, Main Line

D03-104

Weld Inspection

This standard provides procedures for quality control of welded construction. Welding quality control applies in the construction of pipelines, pipeline stations and terminals, tanks, and support structures. This standard provides guidelines for the Project Engineer and the Purchasing Department to inspect and expedite manufactured products and components, primarily at the manufacturer's facilities. The guidelines in this standard shall be used in conjunction with Company equipment

D03-105

Shop Inspection

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number

Standard Name

Description specifications, industry codes and standards, and jurisdictional regulations, as applicable. This standard does not attempt to cover mandatory compliance requirements for the various commodities with industry codes and standards or jurisdictional regulations.

D04-101

Cathodic Protection

This standard provides design requirements for the cathodic protection of the Companys metallic underground structures, which include station and terminal piping systems, tank bottoms, main line pipe, and associated appurtenances. This standard provides direction and insight to the Project Engineer regarding the selection and application of paints, coatings, and linings, for the planning and execution of projects. This standard provides design requirements for the construction of earthen containment berms used in either oil storage tank lots or station and terminal environmental security/drainage control applications. This standard establishes the minimum design requirements for site preparation, earthwork, grading, roads, and pavement. This standard establishes the minimum design requirements for the construction of trenches and installation of underground lines, including sewers, water lines, and pipelines. This standard provides design requirements for the construction of earth foundations placed on native, undisturbed soil to support vertical, cylindrical, above ground oil storage tanks.

D04-102

Painting, Coating, Lining

D05-101

Berm, Containment

D05-102

Site Preparation, Earthwork, Grading, Roads, & Pavement

D05-103

Trenches, Underground Lines

D05-201

Foundation, Oil Storage Tank

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number D05-202

Standard Name Foundation, Station & Terminal

Description This standard establishes the minimum design requirements for the construction of both shallow and deep reinforced concrete foundations, including foundations for pipes, valves, platforms, buildings, and equipment. This standard provides design requirements for pre-engineered metal buildings for installation at the Company station and terminal facilities. This standard provides design requirements for the specification and design of laboratory, sample, and sample storage rooms or buildings. It is intended to meet or exceed the minimum requirements of the standards listed below. It includes guidelines for product sample storage and is applicable for all facilities where product samples are stored, analyzed, tested, or otherwise handled, such that hydrocarbon vapor may be released in the course of routine activity. This standard provides the design requirements for the fabrication of structural steel members, including platforms, stairs, and ladders. This standard presents the minimum technical design requirements for new construction of and repairs to main line piping. This document covers the purely technical aspects of main line design projects and should be used in conjunction with Engineering Standard No. D02102: Design Basis, Main Line, for a comprehensive presentation of main line project requirements and considerations. This standard provides minimum design requirements for all above and below grade piping systems within stations and terminals, including crude oil, natural gas liquid, and refined petroleum products service. Station and terminal piping is defined as piping located

D05-301

Building, Station & Terminal

D05-302

Laboratory, Sample, Sample Storage Buildings

D05-401

Platforms, Stairs, Ladders

D06-101

Piping Design & Construction, Main Line

D06-102

Piping Design, Station & Terminal

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number

Standard Name

Description within the boundary of station isolation valves. This standard is intended for design of piping systems for new facilities or modifications and repairs to existing stations and terminals.

D06-103

Crossing Design, Main Line

This standard establishes the criteria for administration, environmental assessment and design of crossings of foreign facilities by the Company, and the crossing of the Company by foreign owners. This standard provides parameters for the selection and use of steel line pipe, fittings, and flanges larger than 168.3 mm (NPS 6), in nonsour crude oil, natural gas liquids, and petroleum product pipeline systems. It presents the Company's requirements for material, design, procurement, manufacture, inspection, and testing, and shall be used in conjunction with the manufacturing standards and other industry standards listed in Clause 2. This standard provides design requirements for flanged, butt weld end, and wafer type steel valves for use in crude oil, natural gas liquid, and petroleum product pipeline systems. It includes the requirements for materials, design, procurement, manufacture, inspection, and testing. This standard provides design requirements for horizontal, centrifugal, single, and multistage main line pumps in crude oil, natural gas liquids, and petroleum product services. Also included are the requirements for materials, design, procurement, manufacture, inspection, and testing. This standard provides design requirements for centrifugal, single, and multistage booster pumps and associated driver for use in crude

D06-104

Pipe & Fittings, Steel

D06-105

Valves, Steel

D07-101

Pumps, Main Line

D07-102

Pumps, Booster

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number

Standard Name

Description oil, natural gas liquids, and petroleum product services. Also included are the requirements for materials, design, procurement, manufacture, inspection, and testing.

D07-201

HVAC, Building, Station & Terminal

This standard provides the design and installation requirements on new construction for the heating, ventilating, and air-conditioning (HVAC) systems for buildings, stations, and terminals. This standard provides design requirements for electric heat tracing of main line pump seal oil drain lines and associated instruments, mechanical, float type level instruments mounted on underground oil collection sump tanks, and all other instruments which may require heat tracing cables for proper operation. This standard provides the design and installation requirements for the maintenance building heating, ventilation, and air-conditioning (HVAC) system. The HVAC system shall be designed and installed to satisfy the requirements of the following facilities: building heating and general ventilation; welding shop ventilation and makeup air system; office and lunch room HVAC system; storage room ventilation; vehicle local exhaust system and carbon monoxide detection system; and washroom and locker room exhaust system.

D07-202

Heat Tracing

D07-203

HVAC, Pipeline Maintenance Building

D07-301

Sump System Design

This standard provides design requirements for crude oil and product sump systems, incorporating horizontal, cylindrical, underground, atmospheric sump tanks, and

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number

Standard Name

Description associated equipment and piping. The standard includes requirements for materials, design, fabrication, inspection, and testing.

D07-302

Flare Stacks & Pits

This standard provides design requirements for HVP and natural gas liquids flare stacks and flare pits, including horizontal and vertical flare tips, ignition systems, flashback prevention devices, flare knockout separators, and all associated accessories and controls. This standard includes requirements for materials, design, fabrication, inspection, and testing. This standard provides design requirements for vertical, cylindrical, above ground, closed top, and open top welded steel oil storage tanks operating at atmospheric pressure, and includes the requirements for materials, design, procurement, fabrication, erection, inspection, and testing. This standard provides design requirements for all external and internal roofs as applied to vertical, cylindrical, above ground, and welded steel oil storage tanks operating at atmospheric pressure, and includes the requirements for materials, design, procurement, fabrication, erection, inspection, and testing. This standard provides design requirements for the following oil storage tank accessories: tank gauging system; tank high level alarm switch; tank mixer; and tank temperature measurement system.

D08-101

Oil Storage Tanks

D08-102

Oil Storage Tanks, Roofs

D08-103

Oil Storage Tanks, Accessories

D09-101

Oil Measurement, Mechanical

This standard provides minimum design requirements for all custody transfer metering facilities. This standard meets and, in some cases, exceeds all the minimum requirements of

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number

Standard Name

Description the standards listed below. In all cases, the Project Engineer must be familiar with the standards listed below and must comply with their provisions.

D09-102

Oil Measurement, Electrical

This standard provides the requirements and guidelines for the design of the oil measurement flow computer and associated instrumentation. This standard meets or exceeds the minimum requirements of the related standards listed below. This standard provides engineering design requirements for the specification and installation of pipeline content samplers. This standard provides an overview of all electrical power systems at Company facilities. It provides general design guidelines and requirements for estimating and preliminary design of Company power systems. In addition to providing an overview of all aspects of power system design, this standard provides design requirements for the following subjects that are not covered in related standards: system voltage selection; power system configuration and layout; transformer sizing and specification overview; power factor correction; motor starting methods; and interlocking.

D09-103

Sampler

D10-101

Power System Design

D10-102

Substation Design

This standard provides design requirements for Company substations, including general design requirements for the substation grounding system. Refer to Engineering Standard No.

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number

Standard Name

Description the standards listed below. In all cases, the Project Engineer must be familiar with the standards listed below and must comply with their provisions.

D09-102

Oil Measurement, Electrical

This standard provides the requirements and guidelines for the design of the oil measurement flow computer and associated instrumentation. This standard meets or exceeds the minimum requirements of the related standards listed below. This standard provides engineering design requirements for the specification and installation of pipeline content samplers. This standard provides an overview of all electrical power systems at Company facilities. It provides general design guidelines and requirements for estimating and preliminary design of Company power systems. In addition to providing an overview of all aspects of power system design, this standard provides design requirements for the following subjects that are not covered in related standards: system voltage selection; power system configuration and layout; transformer sizing and specification overview; power factor correction; motor starting methods; and interlocking.

D09-103

Sampler

D10-101

Power System Design

D10-102

Substation Design

This standard provides design requirements for Company substations, including general design requirements for the substation grounding system. Refer to Engineering Standard No.

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number D10-106

Standard Name Substation Grounding

Description This standard covers design of grounding systems at Company substations. The criteria outlined here ensures grounding safety with respect to personnel and equipment and is specifically formulated to fit Company installations. This standard provides design requirements for the surge protection of Company substations, switchgear, capacitor banks, cable, and 4 kV motors. This standard provides requirements and guidelines for the design of wiring systems for pipeline electrical facilities. This standard is limited to cable type wiring systems for use at a supply voltage of 4160V or less. This standard provides guidance and mandatory requirements for the design of electrical and nonelectrical grounding systems for use at Company pipeline stations, terminals, metering stations, and other related facilities. This standard provides design requirements for squirrel cage induction motors for driving main line centrifugal pumps in crude oil, natural gas liquids, and petroleum product services. Also included are the requirements for materials, design, procurement, manufacture, inspection, and testing. This standard provides design requirements and guidelines for the installation of large variable frequency drives for use with medium voltage (4 kV) induction motors on main line pumps in new and retrofit applications.

D10-107

Surge Protection, Insulation Coordination

D10-201

Wiring Methods

D10-202

Grounding Methods

D11-101

Motor, Main Line Pump

D11-102

Variable Frequency Drive

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number D11-103

Standard Name Motor Protection

Description This standard covers electrical protection requirements of main line induction motors. Motors in this category are rated 4000V and vary in size from 500 to 5000 hp. This standard provides design requirements for industrial building lighting as used in the Company's stations, terminals, and other facilities. This standard provides design requirements for industrial outdoor lighting used in the Companys stations, terminals, and easements. This standard provides design requirements and guidelines for the installation and specification of electric and electrohydraulic types of valve actuators used in pipeline service for crude oil and refined products. This standard documents the pump station control system operation and philosophy. It also outlines the general procedures to follow if a change in operation of the system is necessary. This standard provides requirements and guidelines for designing the control system for Company receipt, injection, and delivery facilities. This standard provides design requirements governing the sizing, selection, and installation of steel valves used for throttling and pressure control applications. Design criteria for control valve actuators is also covered within the scope of the standard. This standard presents policy and design requirements for pressure relief for main line and station.

D11-201

Lighting, Indoor

D11-202

Lighting, Outdoor

D11-301

Valve Actuation & Control

D12-101

Control, Pump Station

D12-102

Control, Injection, & Delivery Facilities

D12-103

Pressure Control Valves

D12-104

Pressure Relief

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Number D12-201

Standard Name Instrumentation, General

Description This standard, along with other Company and industry standards and recommended practices referenced herein, provides the basis for the selection and design of instrumentation necessary for the safe and efficient operation of the Companys pipeline systems. This standard provides design requirements for the selection and installation of gas detection instrumentation at Company field facilities. This standard provides design requirements for fire detection as used in the Companys stations, terminals, and easements. This standard provides design requirements and guidelines for: the selection and installation of vibration monitoring equipment; the specification of maximum vibration levels for factory acceptance and commissioning tests; and the analysis of vibration signature records during factory acceptance tests.

D12-202

Gas Detection

D12-203

Fire Detection

D12-204

Vibration Monitoring

D12-205 Programmable Logic Controllers

This standard provides application and design requirements for the use of programmable logic controllers in the control and monitoring of the Companys facilities, such as pumping stations, terminals, and delivery and receipt sites.

Enbridge Techno log y

ENBRIDGE

2011 Enbridge Inc. All rights reserved.

Mechanical Maintenance Manual

Вам также может понравиться

- ETI - Standards and SpecificationsДокумент31 страницаETI - Standards and SpecificationsLaurence MalanumОценок пока нет

- Module1 Stress ObjectiveДокумент48 страницModule1 Stress ObjectivepalluraviОценок пока нет

- Standards & Its Description OverviewДокумент8 страницStandards & Its Description OverviewBalakumarОценок пока нет

- Chapter 1 of ASME B31Документ4 страницыChapter 1 of ASME B31JUAN ESTEBAN GOMEZ ROJASОценок пока нет

- Codes and Standards: What Is A CodeДокумент7 страницCodes and Standards: What Is A CodeRushikesh TawareОценок пока нет

- Pipeline Manual Provides Design GuidelinesДокумент5 страницPipeline Manual Provides Design GuidelinesAnonymous PkeI8e84RsОценок пока нет

- Asme B31Документ4 страницыAsme B31torojuce1978100% (2)

- Piping CourseДокумент46 страницPiping Coursemr_heeraОценок пока нет

- AnsiДокумент4 страницыAnsiHendrie NMcОценок пока нет

- Piping Codes & StandardsДокумент12 страницPiping Codes & StandardsAhmed Mansour100% (1)

- Asme B31 - Pressure PipingДокумент3 страницыAsme B31 - Pressure PipingAndhyka Cakrabuana AdhitamaОценок пока нет

- Codes and Standards:: The Welding InstituteДокумент0 страницCodes and Standards:: The Welding InstituteBhavani PrasadОценок пока нет

- CODES and STANDARDS PDFДокумент10 страницCODES and STANDARDS PDFemnptn2667Оценок пока нет

- ASME B31 Code Guide for Pressure Piping StandardsДокумент3 страницыASME B31 Code Guide for Pressure Piping StandardsSubash NagaОценок пока нет

- Piping CodesДокумент3 страницыPiping Codesmexx4u2nvОценок пока нет

- M 398 ContentДокумент55 страницM 398 Contentbu_rockОценок пока нет

- ASME B31 - Standards of Pressure PipingДокумент3 страницыASME B31 - Standards of Pressure PipingRachit OzaОценок пока нет

- 07 Codes and Standards 30-03-07 PDFДокумент6 страниц07 Codes and Standards 30-03-07 PDFvineet chandra khanduriОценок пока нет

- ASME B31 - Standards of Pressure PipingДокумент1 страницаASME B31 - Standards of Pressure Pipingengg_mech77Оценок пока нет

- Piping PDFДокумент46 страницPiping PDFGORO43100% (1)

- Guide to Specifying and Selecting Custom Process SkidsДокумент4 страницыGuide to Specifying and Selecting Custom Process SkidsFJJMОценок пока нет

- Asme Code StandardsДокумент34 страницыAsme Code StandardsPandu Pratama YudhaОценок пока нет

- Piping Chevron OffДокумент44 страницыPiping Chevron OffdfdflkОценок пока нет

- ASME B31 codes guide pressure piping standardsДокумент3 страницыASME B31 codes guide pressure piping standardsMilind GaikwadОценок пока нет

- Facilitiy StandardДокумент83 страницыFacilitiy StandardRahul DubeyОценок пока нет

- Code and Standard Definitions OnlyДокумент4 страницыCode and Standard Definitions OnlyAnonymous 7CnrWpzZf1Оценок пока нет

- Piping Design Codes and StandardДокумент30 страницPiping Design Codes and StandardHashim Ali100% (1)

- Guidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFДокумент89 страницGuidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFSwaroop Biswas100% (1)

- Safety Instruction Sheets For Plant Piping and Cross-Country PipelinesДокумент35 страницSafety Instruction Sheets For Plant Piping and Cross-Country PipelinesRaj Bindas50% (2)

- Fab 01 QA of Welds, ISO 3834, RWC Etc.Документ17 страницFab 01 QA of Welds, ISO 3834, RWC Etc.Raghu vamshiОценок пока нет

- AsmeДокумент53 страницыAsmeSHAHAN NAFEES100% (16)

- Well Testing Project Management: Onshore and Offshore OperationsОт EverandWell Testing Project Management: Onshore and Offshore OperationsОценок пока нет

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsОт EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsРейтинг: 4 из 5 звезд4/5 (6)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AОт EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AОценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОценок пока нет

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresОт EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresРейтинг: 5 из 5 звезд5/5 (1)

- Energy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamОт EverandEnergy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamОценок пока нет

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsОт EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsОценок пока нет

- Chemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningОт EverandChemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningОценок пока нет

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsОт EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsРейтинг: 3.5 из 5 звезд3.5/5 (14)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- Plumbing and Piping Systems Inspection Notes: Up to CodeОт EverandPlumbing and Piping Systems Inspection Notes: Up to CodeРейтинг: 3 из 5 звезд3/5 (2)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationОт EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationОценок пока нет

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesОт EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesРейтинг: 5 из 5 звезд5/5 (2)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1От EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Рейтинг: 3.5 из 5 звезд3.5/5 (3)

- Mission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsОт EverandMission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsРейтинг: 5 из 5 звезд5/5 (1)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionОт EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionРейтинг: 4.5 из 5 звезд4.5/5 (16)

- Strength of Materials-II 2-2 Set-3 (A)Документ18 страницStrength of Materials-II 2-2 Set-3 (A)Sri DОценок пока нет

- Glazing Supporting Structure Design Calculation, College Building, AIIMS Nagpur (03.02.2020)Документ8 страницGlazing Supporting Structure Design Calculation, College Building, AIIMS Nagpur (03.02.2020)abdul samadОценок пока нет

- ASTT Horizontal Directional DrillingДокумент14 страницASTT Horizontal Directional DrillingSen HuОценок пока нет

- 1.03 - High-Rise Buildings PDFДокумент19 страниц1.03 - High-Rise Buildings PDFNicolas De NadaiОценок пока нет

- Review of Maximum Punching Capacity of Slabs Reinforced With ShearailДокумент23 страницыReview of Maximum Punching Capacity of Slabs Reinforced With ShearailMatthew WoodОценок пока нет

- Kisi-Kisi & Kartu Soal Usbn-A1Документ8 страницKisi-Kisi & Kartu Soal Usbn-A1yc574haОценок пока нет

- Diversion Head WorksДокумент8 страницDiversion Head WorksMrinmoy SahaОценок пока нет

- Renovation and Expansion of Arthouse at the Jones CenterДокумент7 страницRenovation and Expansion of Arthouse at the Jones Centergpreston11Оценок пока нет

- Single Line Diagram-Layout1Документ1 страницаSingle Line Diagram-Layout1Lesther SosaОценок пока нет

- UntitledДокумент19 страницUntitledRene Constantine AvilaОценок пока нет

- VbeДокумент2 страницыVbeAniket PatilОценок пока нет

- Designing A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Документ15 страницDesigning A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Jigar100% (1)

- Schedule Q (Quality Requirements)Документ86 страницSchedule Q (Quality Requirements)jeswinОценок пока нет

- Intro Well FoundationДокумент23 страницыIntro Well FoundationgoutammandОценок пока нет

- HDPE Tender DocumentДокумент4 страницыHDPE Tender Documentabhijithaval100% (1)

- Time Saver Standards For Housing and Residential Development - TextДокумент1 110 страницTime Saver Standards For Housing and Residential Development - TextPsr Krishna100% (3)

- SAP 2000 Manual Water Tank DesignДокумент20 страницSAP 2000 Manual Water Tank DesignSyner Qxz100% (1)

- Conjugate Beam Method SLUДокумент41 страницаConjugate Beam Method SLULydia D. GalinganОценок пока нет

- Bore LogДокумент4 страницыBore LogVardhanОценок пока нет

- Prueba y Ajuste Sistema HidraulicoДокумент55 страницPrueba y Ajuste Sistema HidraulicoIginio Malaver VargasОценок пока нет

- 15570Документ6 страниц15570JhoОценок пока нет

- (1981) Soil Improvement. State-Of-The-Art ReportДокумент24 страницы(1981) Soil Improvement. State-Of-The-Art ReportAndrea David RodriguesОценок пока нет

- DXB SHJ Freezone ListДокумент444 страницыDXB SHJ Freezone ListFaiza KhalidОценок пока нет

- SCentre Infra - The Leading Steel Construction Company in IndiaДокумент54 страницыSCentre Infra - The Leading Steel Construction Company in Indiaseo2.artistonkОценок пока нет

- Puddle Flanges - FlexsealДокумент6 страницPuddle Flanges - FlexsealApoorvaОценок пока нет

- Construction Progress ReportДокумент11 страницConstruction Progress ReportAnthny Alfrt GsprОценок пока нет

- Joseph Allen SteinДокумент43 страницыJoseph Allen Steinashna bansalОценок пока нет

- PMBI WorkflowДокумент3 страницыPMBI WorkflowBrian MigueОценок пока нет

- Sprinkler Head Spacing and Location GuideДокумент7 страницSprinkler Head Spacing and Location GuideWarry SolivenОценок пока нет

- Fsec & FsicДокумент36 страницFsec & FsicGeraldine Araneta Galing100% (5)