Академический Документы

Профессиональный Документы

Культура Документы

Medical Cables: Often Overlooked

Загружено:

richardhammond47Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Medical Cables: Often Overlooked

Загружено:

richardhammond47Авторское право:

Доступные форматы

Medical cables are as important to a medical device as the device itself.

Medica l device designers many times focus on the device and overlook the wire and cabl es that is needed for the device to perform its function. Medical cables tend to be more specialized due to the many types of uses and environments it is subjec ted to. The wire and cable is many times not thought of until the end of the des ign process, which may be too late. Knowing your medical cable limitations and t he options available to you in the beginning is important especially when design ing housing or specifying connectors. Some things to keep in mind when specifyin g wire and cable for a medical device: Size- With the size of devices becoming smaller many times smaller gauge wire an d cable is needed. Off the shelf wire and cable usually go as small as 28AWG. Fi ne wire and custom cable designs are usually needed. Flexibility- Handheld devices and medical robots require flexible cables which c an withstand repetitive flexing. Higher stranded conductors and sometimes alloys are needed to achieve this. Sterilization- Sterilization can be done with alcohol, steam or gamma to name a few. Cable jackets need to withstand the sterilization process. Bio-compatibility- Medical grade cables are needed depending on the level of con tact with the patient. Bio-compatible and implantable grade compounds are availa ble for medical devices. Construction- Cables sending signals, power and even gas/fluid can be constructe d in on jacket. Constructions can vary from the simple wire to complex hybrid ca ble. Unique- Medical devices are all unique in regards to application, requirements a nd environment. You should not use an off the shelf mass produced cable designed for to meet the generic needs of a variety of industries for a specialized medi cal device. Considering your wire and cable needs from the early stages of your product desi gn will prevent problems down the line in regards to failures in the field, desi gn issues and time constraints. Designing custom medical cables for your applica tion ensures you have a medical device that will exceed performance and longevit y you require. Depending on the type of use a variety of medical grade insulation materials ar e available. Reusable medical cables are built to endure constant flexing and ex tended cycles of sterilization. Insulation may be Teflon, TPE or silicone rubber w ith TPR or silicone jackets. For disposable medical cables PVC and PE are the in sulation most commonly used. Discuss your application with your custom cable man ufacture in order to choose the right material for your medical device. Working with a custom wire and cable manufacture is easier than you think. Custo m wire and cable engineers work with you every step of the way to determine and suggest the best materials and construction for your medical application. It's l ike having a wire and cable expert on your team. Cable designs are usually modif ied throughout the design process to accommodate changes to the device design. M any custom wire and cable manufacturers are able to produce small quantities for prototypes and clinical trials. Labels: silicone jackets

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

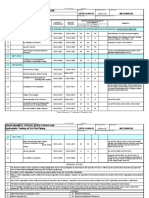

- Saudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingДокумент10 страницSaudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingAhdal NoushadОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Chennai CMBT Metro Station AIC Access Audit ReportДокумент44 страницыChennai CMBT Metro Station AIC Access Audit ReportDisability Rights AllianceОценок пока нет

- SPECAA22421Документ4 страницыSPECAA22421SURJIT SINGHОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Trosten Ahu CatalogueДокумент88 страницTrosten Ahu Cataloguehanimamoo7Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Field Development PlanДокумент11 страницField Development PlanOKORIEОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- FABRICS Manelius Afhandling Og DataДокумент328 страницFABRICS Manelius Afhandling Og DatacarlossegoviaОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Thermal Insulation Calculation at Sandwich Panels With PolyurethaneДокумент4 страницыThermal Insulation Calculation at Sandwich Panels With Polyurethanesumanth.n nОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Affa Tiles BookletДокумент41 страницаAffa Tiles BookletAnonymous iTzCnMОценок пока нет

- Geomembranas ImpermeablesДокумент20 страницGeomembranas ImpermeablesEnzo Andres Gentile PachecoОценок пока нет

- Ecospace: Hoistway Plan ViewДокумент1 страницаEcospace: Hoistway Plan ViewHoward RoarkОценок пока нет

- Layher Allround - Description and Technical SpecificationДокумент3 страницыLayher Allround - Description and Technical SpecificationYogesh WadhwaОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Stormwater: (Interlocking Joint) - SANS 677Документ1 страницаStormwater: (Interlocking Joint) - SANS 677Ephraim BarezОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Bituthene 3000-3000 HCДокумент2 страницыBituthene 3000-3000 HCRm1262Оценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 2159 2009Документ9 страниц2159 2009wolf10070% (2)

- Bulleen School - Design BriefДокумент5 страницBulleen School - Design Briefpaulineng1Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- 01-Article - Per. STR. Gedung 5 LantaiДокумент8 страниц01-Article - Per. STR. Gedung 5 Lantaimuh khalifardiОценок пока нет

- Pressure Vessel PDFДокумент8 страницPressure Vessel PDFdanielreyeshernandezОценок пока нет

- Analytical Solution For Radial Consolidation Considering SoilДокумент15 страницAnalytical Solution For Radial Consolidation Considering SoilAnonymous VJHwe0XBОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Christopher Lyon ResumeДокумент2 страницыChristopher Lyon Resumeapi-353696827Оценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Types of PumpsДокумент68 страницTypes of PumpsVicky JeganОценок пока нет

- Installation Instructions ISOnV ENGДокумент48 страницInstallation Instructions ISOnV ENGLuz BarradasОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- GroutingДокумент22 страницыGroutingfhlim20690% (2)

- Proposed Wedding Hall and Garden DesignДокумент3 страницыProposed Wedding Hall and Garden DesignMendoza, Kyle S.Оценок пока нет

- CC603 Topik 1Документ55 страницCC603 Topik 1farrita95Оценок пока нет

- 2014CC BC Chapter 33 Safeguards During Construction or DemoДокумент109 страниц2014CC BC Chapter 33 Safeguards During Construction or DemoMannyОценок пока нет

- SECP Real EstateДокумент89 страницSECP Real Estateamanatbutt100% (1)

- Audi A4 No. 41 / 1Документ23 страницыAudi A4 No. 41 / 1Martins JansonsОценок пока нет

- CDM Guidance For DesignersДокумент47 страницCDM Guidance For DesignersAlan Beech100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Road Design & ConstructionДокумент157 страницRoad Design & ConstructionSekichi Yamada80% (10)

- Correct Duct SizingДокумент3 страницыCorrect Duct Sizingnim_gourav1997100% (1)