Академический Документы

Профессиональный Документы

Культура Документы

Process Control Project Engineering Guidelines

Загружено:

Ahmad EmamИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Process Control Project Engineering Guidelines

Загружено:

Ahmad EmamАвторское право:

Доступные форматы

Page : 1 of 50

KLM Technology Group

Project Engineering Standard

Rev: 01 June 2011

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

GUIDELINES FOR PROCESS CONTROL PROJECT ENGINEERING (PROJECT STANDARDS AND SPECIFICATIONS)

TABLE OF CONTENT

SCOPE INITIALISATION PHASE User Requirements and Scope of Work Checklist of User Requirements and Scope of Work CONCEPTUAL ENGINEERING Conceptual Design Design Scope Class I Estimates and Budgets Programme Project Reports Design Estimate/Proposal/Tender FEASIBILITY ENGINEERING PHASE Feasibility Design Feasibility Design Review Class II Estimate DETAIL ENGINEERING PHASE Design Simulation Equipment Types and Definition Specifications Enquiries, Adjudication, Contracts Detail Design Class III Estimate Operability Simulation Software Development Shop Floor Testing

3 3 3 3 7 7 8 9 10 11 12 13 13 15 16 19 19 20 21 22 23 24 26 27 29

KLM Technology Group

Project Engineering Standard

GUIDELINES FOR PROCESS CONTROL PROJECT ENGINEERING (PROJECT STANDARDS AND SPECIFICATIONS)

Page 2 of 50

Rev: 01

June 2011

CONSTRUCTION PHASE Class IV Estimate Site Installation COMMISSIONING PHASE Commissioning PROJECT CLOSURE PHASE As-Built Documentation Contracts Finalisation Updating Departmental Database Internal Project Review Close Out Reports APPENDIX A

APPENDIX B

30 30 31 33 33 35 35 36 36 38 39 41

43

KLM Technology Group

Project Engineering Standard

GUIDELINES FOR PROCESS CONTROL PROJECT ENGINEERING (PROJECT STANDARDS AND SPECIFICATIONS)

Page 3 of 50

Rev: 01

June 2011

SCOPE This Project Standard and Specification provides guidelines on the engineering processes that go into completing Process Control and Instrumentation (C & I) work for clients. INITIALISATION PHASE User Requirements and Scope of Work 1. Scope Determine the client's requirements for control and instrumentation and write them up for reference during the project. 2. Input Discuss with the project leader and client the requirements in terms of the checklist detailed at the end of this procedure to ensure that all items relating to the User Requirements and Scope of Work are covered. The Project Brief must also be studied to ensure its requirements are covered. 3. Process Determine the requirements in conjunction with the client. The information should be gathered by studying the Project Brief and/or discussions with the client. It must then be analyzed to ensure that it is complete and consistent. A checklist of items to be evaluated is attached to this procedure. 4. Output Produce a document entitled User Requirements and Scope of Work. It is circulated to all interested parties in the project. They will respond with their comments which are to be incorporated into a revision of the document. 5. Approval The document must be approved by the client and the discipline Project C&I Engineer once the revisions are complete. Checklist of User Requirements and Scope of Work The following is a checklist of the factors to be considered: 1. Systems Required

KLM Technology Group

Project Engineering Standard

GUIDELINES FOR PROCESS CONTROL PROJECT ENGINEERING (PROJECT STANDARDS AND SPECIFICATIONS)

Page 4 of 50

Rev: 01

June 2011

plant control and instrumentation monitoring systems telephone systems intercom systems radio systems networking for voice and data CCTV access control fire detection and protection security systems vehicle location/tracking/condition monitoring feasibility study conceptual design estimating simulation design software specification enquiries orders installation site supervision commissioning project program type of plant: material (gold, coal, etc.); process (CIP, rail loading etc.); scale (pilot, sample, test, production) description of process operation flow sheets cost sensitivity of the project special process requirements e.g. hazardous processes, explosive and/or toxic and/or corrosive. level of automation required level of instrumentation required new, extended, modified, upgraded or refurbished production factors, e.g. productivity index, plant availability/utilisation, allowable downtime

2. Services Required

3. Timescales 4. Process Control Requirements

KLM Technology Group

Project Engineering Standard

GUIDELINES FOR PROCESS CONTROL PROJECT ENGINEERING (PROJECT STANDARDS AND SPECIFICATIONS)

Page 5 of 50

Rev: 01

June 2011

description of control facilities (i.e. degree of functionality in terms of logging, reporting, diagnostics, optimisation, maintenance, simulation capabilities, etc.) to be catered for now or in the future. number and quality of plant operators to be catered for (i.t.o. level of understanding of the process, equipment and control systems) plant infrastructure requirements for air, water supplies. type of control system required: e.g. hardwired, PLC, distributed control system, supervisory system degree of centralisation/de-centralisation plant geographical layout and control nodes control system architecture connection to management level systems local/remote control of machines or processes connection to other plants, areas or systems system response times reliability intellectual property rights standardisation/conformity with existing systems/equipment equipment preferences non-preferences compatibility with existing equipment fire retardancy of cables client preferences for specifications preferred design standards, drawing symbols and numbering systems possibility of future extensions (plant areas and/or streams) and to what extent it must be allowed for in the design supervisory system expansion plc expansion tags, database control cubicle expansion additional instrumentation spare space requirements (i.e. instrument rooms, cable racks, etc.) spares policy, commissioning and maintenance (project, client supply) hazardous areas and classification personnel and equipment protection circuitry

5. Plant Control Philosophy

6. Equipment and Design Requirements

7. Spare Capacity Requirements

8. Safety Requirements

KLM Technology Group

Project Engineering Standard

GUIDELINES FOR PROCESS CONTROL PROJECT ENGINEERING (PROJECT STANDARDS AND SPECIFICATIONS)

Page 6 of 50

Rev: 01

June 2011

earth fault/leakage limitation requirements security/entry restriction requirements fire protection requirements (cables, seals) environmental sensitivity of project altitude ambient temperature range humidity corrosion, in air/water/ground lightning activity pollution, dust reliability of power supply stability or quality of power supply (voltage, frequency, harmonics) interruptions to raw mains supply - frequency and duration provision of clean, secure supplies, e.g. UPS, CVT required duration of back-up supplies for instrumentation and computer systems lightning/surge protection practice earthing requirements availability of skilled manpower availability of locally manufactured equipment availability of spare parts availability of communication infrastructure availability of suppliers and contractors need for special work permits, security clearances - central, regional and local government requirements applicable standards and authorities number of occupants and facilities temperature requirements humidity ventilation and air filtering requireme vibration static control cable management e.g. ducts, raised floor lighting

9. Environmental Considerations

10. Power Source (Liaise with Electrical Engineer)

11. Local Infrastructure

12. Control and Instrumentation Room Requirements

KLM Technology Group

Project Engineering Standard

GUIDELINES FOR PROCESS CONTROL PROJECT ENGINEERING (PROJECT STANDARDS AND SPECIFICATIONS)

Page 7 of 50

Rev: 01

June 2011

13. Quality Assurance Requirements QA philosophy identification of critical equipment plant life expectancy obtain copies of above diagrams, if available

14. Site Layout and General Arrangement Drawings 15. Training and System Development Requirements for Operating and Maintenance Staff services required nature of facilities required simulation needs

CONCEPTUAL ENGINEERING Conceptual Design 1. Scope The Conceptual Design gathers sufficient information on the job to allow it to be cost and planned. Develop alternative designs. 2. Input The User Requirements and Scope of Work, Block plan and Flow sheets are used to do the conceptual design. 3. Process The input documents are analyzed to yield information on the following: - control system configuration - number and size of the control nodes - types and number of instruments - instrumentation and control equipment geographical layout. 4. Outputs In order to provide estimates for the project the following documents are to be produced: - preliminary instrument schedule - preliminary I/O schedule - preliminary Control System Architecture Block Plan 5. Approval

KLM Technology Group

Project Engineering Standard

GUIDELINES FOR PROCESS CONTROL PROJECT ENGINEERING (PROJECT STANDARDS AND SPECIFICATIONS)

Page 8 of 50

Rev: 01

June 2011

The Project C&I Engineer is to approve the documents. Design Scope 1. Scope The design scope defines the work to be done by the C & I Department for the client and the documents that will be produced. 2. Inputs The inputs are the User Requirements and Scope of Work, and the Conceptual Design. Hold meetings with the client and Project leader to discuss the requirements. 3. Process Once the scope of work is known, the C & I engineer can make proposals on what services are to be included and how the work is to be done. Where the client prefers to do portions of the work or wants to be involved in, or approve, certain portions of the work it is advisable to draw up a responsibility schedule. The responsibility schedule defines which deliverables are to be produced by the various parties. 4. Outputs The Design Scope will define the specific services to be provided and a list of the output documents (or deliverables) that will be produced. Services to be provided may include: - Plant Simulation - Engineering - Enquiries, Adjudication and Orders - Design - Software - Operator Training - Site Supervision - Commissioning Output Documents may include: User Requirements and Scope of Work Preliminary Design Design Scope Class I Capital Budget and Reimbursable Estimate Basic Project Requirements for C & I Design, comprising a compilation of the above documents Conceptual Design

KLM Technology Group

Project Engineering Standard

GUIDELINES FOR PROCESS CONTROL PROJECT ENGINEERING (PROJECT STANDARDS AND SPECIFICATIONS)

Page 9 of 50

Rev: 01

June 2011

Class II Budget Specifications Detail Design Drawings Functional Specification Software Documentation Enquiries and Adjudications Class III Budget Progress Reports Class IV Budget As Built Documents Close Out Report

5. Approvals The Design Scope needs the approval of the Project CIE Engineer, who will discuss the document with the CIE Manager before it is submitted for client approval. Class I Estimates and Budgets 1. Scope Approximate costs for the proposed C & I work are required early in the project. Class I estimates are the lowest level of accuracy produced for projects. They are "Order of Magnitude" estimates where the target accuracy is dependent on the data available. The range of accuracy is to be indicated on the estimate. Refer to the Project procedures for the detailed definition of Class I estimates. 2. Inputs The Conceptual Design gives the capital items to be purchased. The Design Scope document details the work to be done. 3. Process Capital Equipment costs are estimated by obtaining current budgetary quotes and comparing with actual costs, suitably escalated from past projects. The C & I costs must be checked against the total capital value of the project. Standard rates for design drawings multiplied by the number of drawings required allows the design reimbursable budget to be calculated. Similarly the engineering and software work needs to be estimated and hours put to the work. Once this is done it must be compared with actual hours used on similar past projects. The cost of the reimbursable hours needs to be checked as a percentage of the capital value of the C & I costs.

KLM Technology Group

Project Engineering Standard

GUIDELINES FOR PROCESS CONTROL PROJECT ENGINEERING (PROJECT STANDARDS AND SPECIFICATIONS)

Page 10 of 50

Rev: 01

June 2011

4. Outputs Standard estimate sheets are available for reimbursable man-hours and capital costs. These are completed, showing the work to be done, the level of accuracy and the associated costs. 5. Approvals It is essential that the reimbursable estimates for all large projects are signed by the Manager in addition to the Project C&I Engineer. Capital cost estimates will be discussed by the Project C&I Engineer with the CIE Manager. Program 1. Scope A provisional program of work is drawn up to ensure that the C & I work can be scheduled within the time-scales required by the client. 2. Inputs The number of reimbursable hours has been determined in the Class I estimate. The project plan will give the approximate time-scales available to do the work and the list of required deliverables. 3. Process Discussions with the planner around the above documents allow the C & I work to be scheduled. The C & I Engineer will then estimate how many people will be required and when they will be needed. This will allow a program of work to be defined in conjunction with the project planner. The impact on the department must be considered. The program must show all the project phases including capital equipment phasing to ensure that the work can be done within the required time-scales. The work breakdown should be shown in terms of the deliverables to be produced. Different levels of detail are normally needed (Level 1, 2, 3) to suit the requirements of the overall project program. 4. Output This work is done in conjunction with the Project Planner and the final output is generated by him. It remains the responsibility of the discipline engineer to ensure the accuracy of his portion of the work.

Вам также может понравиться

- Basic & Detail Engineering ServicesДокумент9 страницBasic & Detail Engineering ServicesbondreОценок пока нет

- Process Plant Eng Activity ModelДокумент43 страницыProcess Plant Eng Activity Modelمحمد يازيد هوساينОценок пока нет

- Concept and Basic, Details Engg InfoДокумент2 страницыConcept and Basic, Details Engg InfomgkvprОценок пока нет

- PROJECT STANDARDS and SPECIFICATIONS Instrumentation Project Engineering Rev01Документ20 страницPROJECT STANDARDS and SPECIFICATIONS Instrumentation Project Engineering Rev01Laurence Malanum50% (2)

- Process DesignДокумент2 страницыProcess DesignmuthakaniОценок пока нет

- Nuts and Bolts of Project Management: Right Timing + Right Decision = SuccessОт EverandNuts and Bolts of Project Management: Right Timing + Right Decision = SuccessРейтинг: 5 из 5 звезд5/5 (1)

- Interface Management PhilosophyДокумент10 страницInterface Management Philosophykarthikugan66Оценок пока нет

- 06 - Project Schedule Management-2019!06!13 13-20-52Документ105 страниц06 - Project Schedule Management-2019!06!13 13-20-52Sherif MansourОценок пока нет

- 118 PlanningДокумент41 страница118 PlanningSoumitra GuptaОценок пока нет

- Project Cost Estimation (CEST)Документ13 страницProject Cost Estimation (CEST)LuciaОценок пока нет

- Engineering Execution PlanДокумент23 страницыEngineering Execution Planari zeinОценок пока нет

- Design Document CHCKLSTДокумент41 страницаDesign Document CHCKLSTAndile CeleОценок пока нет

- Fertilizer Project DeliverablesДокумент28 страницFertilizer Project DeliverablesClément50% (2)

- Process Piping Design & EngineeringДокумент4 страницыProcess Piping Design & Engineeringtibi1000Оценок пока нет

- Engineering ProcedureДокумент34 страницыEngineering ProcedureAnthony YunОценок пока нет

- Control Accounts, Work Packages, Planning PackagesДокумент11 страницControl Accounts, Work Packages, Planning PackageskbaltimoreОценок пока нет

- Dokumen - Tips - Epcprojectinterdepency and Work Flow 1pdfДокумент103 страницыDokumen - Tips - Epcprojectinterdepency and Work Flow 1pdfAhmed AggourОценок пока нет

- Project Communications ManagementДокумент8 страницProject Communications ManagementilleziaОценок пока нет

- Schedule Management Plan: Project Name: Project NumberДокумент10 страницSchedule Management Plan: Project Name: Project Numberanon_565581976Оценок пока нет

- Pistep Act ModДокумент13 страницPistep Act ModkamlОценок пока нет

- 001-Pro Document and Data ControlДокумент25 страниц001-Pro Document and Data ControlKöksal PatanОценок пока нет

- P&ID LegendДокумент29 страницP&ID LegendEmmanuel Cervantes VelázquezОценок пока нет

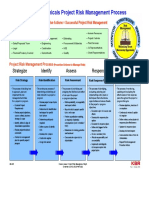

- Energy & Chemicals Project Risk Management ProcessДокумент2 страницыEnergy & Chemicals Project Risk Management ProcessnbnbОценок пока нет

- Project <PROJECT NAME> CharterДокумент6 страницProject <PROJECT NAME> CharterUkasha MalikОценок пока нет

- Engineering CVP RACI Feb 2013Документ1 страницаEngineering CVP RACI Feb 2013Taufik SantosoОценок пока нет

- Essons Earned K WWTP U W: Eadue Pgrade OrksДокумент6 страницEssons Earned K WWTP U W: Eadue Pgrade Orksgroup2sd1314Оценок пока нет

- KBR Infrastructure Controls Planning & SchedulingДокумент4 страницыKBR Infrastructure Controls Planning & SchedulingkamlОценок пока нет

- Project (Time) Control For An EPC ProjectДокумент12 страницProject (Time) Control For An EPC ProjectcelalettinilhanОценок пока нет

- Plant Layout DesignДокумент7 страницPlant Layout Designnani cherryОценок пока нет

- Project planning and scheduling procedure documentДокумент65 страницProject planning and scheduling procedure documentNorgjieОценок пока нет

- 4 Phases of the Engineering Design ProcessДокумент8 страниц4 Phases of the Engineering Design ProcessFelipe ValleОценок пока нет

- Change Control Management Plan Template With InstructionsДокумент10 страницChange Control Management Plan Template With InstructionsMeghna CmОценок пока нет

- Engineering document delivery stagesДокумент1 страницаEngineering document delivery stagessyafiqОценок пока нет

- 202 Procedure 0-Project Execution PlanДокумент8 страниц202 Procedure 0-Project Execution PlanagaricusОценок пока нет

- Project Execution Plan GuidelinesДокумент21 страницаProject Execution Plan GuidelineslampardbkОценок пока нет

- PT Borneo Mitra Sinergi: Project Close Out PlanДокумент4 страницыPT Borneo Mitra Sinergi: Project Close Out PlanaswarОценок пока нет

- Saep 305Документ5 страницSaep 305brecht1980Оценок пока нет

- Project Execution ModelДокумент99 страницProject Execution ModelEdha Ali100% (3)

- FEED Deliverable List (Sample) - The Project DefinitionДокумент8 страницFEED Deliverable List (Sample) - The Project DefinitionKerleauОценок пока нет

- Project Execution Plan WoodsideДокумент3 страницыProject Execution Plan WoodsideDebashish Das100% (1)

- 02 Project Life CycleДокумент6 страниц02 Project Life Cyclebagus sujatmikoОценок пока нет

- Final report format templateДокумент3 страницыFinal report format templateYuvaraj GovindОценок пока нет

- Work Execution PlanДокумент48 страницWork Execution PlanVladimir DovalОценок пока нет

- Systems Completion - Area Plan: Banyu Urip ProjectДокумент13 страницSystems Completion - Area Plan: Banyu Urip Projectsayafrands6252Оценок пока нет

- Engineering Documents in EPCДокумент9 страницEngineering Documents in EPCEditan IwedОценок пока нет

- Controlsoft Engineering ProfileДокумент37 страницControlsoft Engineering ProfileDuraisamy PanchatcharamОценок пока нет

- Project Controls Coding StructureДокумент7 страницProject Controls Coding Structurejehd21350Оценок пока нет

- 3DP-G04-00034 - Off Project Design ReviewДокумент22 страницы3DP-G04-00034 - Off Project Design ReviewtavenegasОценок пока нет

- PVU Chapter 5 Costs in Petroleum E&PДокумент26 страницPVU Chapter 5 Costs in Petroleum E&Psmile100% (1)

- Process Engineering Deliverables OverviewДокумент7 страницProcess Engineering Deliverables Overviewsohambandyopadhyay1677Оценок пока нет

- Project Control Handbook: Guidance for EM Baseline ManagementДокумент69 страницProject Control Handbook: Guidance for EM Baseline ManagementRochdi BahiriОценок пока нет

- Cost Management Plan TemplateДокумент8 страницCost Management Plan TemplateSyed Faraz RazaОценок пока нет

- Tracking Project Performance PART-1 Schedule Updating-Fall18 PDFДокумент77 страницTracking Project Performance PART-1 Schedule Updating-Fall18 PDFPablo AlarconОценок пока нет

- Sample of Feed CTRДокумент83 страницыSample of Feed CTRAsyraf Nordin100% (2)

- 6engineer ActivityДокумент43 страницы6engineer ActivitymkrasanОценок пока нет

- Basic DesignДокумент18 страницBasic DesignM AhmadОценок пока нет

- Project Engineering in Oil & Gas Industry SharedДокумент24 страницыProject Engineering in Oil & Gas Industry SharedKojiro Hadate100% (3)

- 11 Steps of Automation ProjectДокумент12 страниц11 Steps of Automation ProjectKok MunОценок пока нет

- CE10 (QS) LP1 MergedДокумент10 страницCE10 (QS) LP1 Mergedrosary originalОценок пока нет

- CV - Edson C Ayuste - Senior Instrument Engineer - March2018Документ8 страницCV - Edson C Ayuste - Senior Instrument Engineer - March2018Edson AyusteОценок пока нет

- Instruction Manual Series 854 XTG Level GaugeДокумент60 страницInstruction Manual Series 854 XTG Level GaugeJandri JacobОценок пока нет

- Ucc 900 Sor em Wpi 0001 - B01Документ73 страницыUcc 900 Sor em Wpi 0001 - B01JonesОценок пока нет

- Smarter Washing Solutions: Modular Wash RangeДокумент5 страницSmarter Washing Solutions: Modular Wash RangeSujesh AnОценок пока нет

- Flap System RiginДокумент12 страницFlap System RiginHarold Reyes100% (1)

- DLP IN ICT 9 1st MeetingДокумент2 страницыDLP IN ICT 9 1st MeetingHEDDA FULOОценок пока нет

- Section V - Contract Adminstration Procedures Major BuildingsДокумент13 страницSection V - Contract Adminstration Procedures Major BuildingsAyodele Oluwaseyi DinaОценок пока нет

- Designing of 3 Phase Induction Motor Blackbook DoneДокумент30 страницDesigning of 3 Phase Induction Motor Blackbook Donetryd0% (1)

- Graffiti Model Lesson PlanДокумент9 страницGraffiti Model Lesson Planapi-286619177100% (1)

- Section 3.4 The Conditional and Related StatementsДокумент11 страницSection 3.4 The Conditional and Related Statementsmister sparklesОценок пока нет

- NCP 1014Документ24 страницыNCP 1014rodricaldasОценок пока нет

- Kompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminДокумент9 страницKompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminHendrayana RamdanОценок пока нет

- Grupo Stoncor Description - Stonhard Carboline Fibergrate PDFДокумент22 страницыGrupo Stoncor Description - Stonhard Carboline Fibergrate PDFAndres OsorioОценок пока нет

- GbiДокумент14 страницGbimaurice86Оценок пока нет

- 1 Clock Domain CrossingДокумент35 страниц1 Clock Domain CrossingRamakrishnaRao SoogooriОценок пока нет

- A. evolve B. protect C. argue D. resist: Thời gian làm bài: 45 phút, không kể thời gian phát đềДокумент5 страницA. evolve B. protect C. argue D. resist: Thời gian làm bài: 45 phút, không kể thời gian phát đềPham Thuy HuyenОценок пока нет

- Adiabatic Production of Acetic AnhydrideДокумент7 страницAdiabatic Production of Acetic AnhydrideSunilParjapatiОценок пока нет

- CDM 856 WheelloaderweichaiengineДокумент1 страницаCDM 856 WheelloaderweichaiengineRusmiyanto YantoОценок пока нет

- Risk and Risk ManagementДокумент8 страницRisk and Risk ManagementMARY JUSTINE PAQUIBOTОценок пока нет

- Eccsa Five Year (2014 15 - 2018 19) Strategic PlanДокумент95 страницEccsa Five Year (2014 15 - 2018 19) Strategic Planyayehyirad100% (1)

- Explosive Ordnance DisposalДокумент13 страницExplosive Ordnance DisposalZelwisОценок пока нет

- Mental AspectДокумент29 страницMental AspectBenjii CarlosОценок пока нет

- CM Group Marketing To Gen Z ReportДокумент20 страницCM Group Marketing To Gen Z Reportroni21Оценок пока нет

- Academic Transition To Senior High SchoolДокумент30 страницAcademic Transition To Senior High SchoolGabriel ExalaОценок пока нет

- Formal Analysis of Timeliness in Electronic Commerce ProtocolsДокумент5 страницFormal Analysis of Timeliness in Electronic Commerce Protocolsjuan david arteagaОценок пока нет

- CA 1 - Đề thi AV5 - CLC - Made - efДокумент5 страницCA 1 - Đề thi AV5 - CLC - Made - efQuang NguyenОценок пока нет

- Dayal Bagh: Spircon 2013: Book of AbstractsДокумент202 страницыDayal Bagh: Spircon 2013: Book of AbstractsSant Mat100% (2)

- MCCB SchneiderДокумент2 страницыMCCB SchneiderkumontholОценок пока нет

- Marginal Field Development Concepts (Compatibility Mode)Документ17 страницMarginal Field Development Concepts (Compatibility Mode)nallay1705100% (1)

- The historical evolution of organizational behavior and how it shaped modern managementДокумент3 страницыThe historical evolution of organizational behavior and how it shaped modern managementSaravanan Swagger100% (1)

- Kevin Chiu - Solving Procrastination v1.1Документ2 страницыKevin Chiu - Solving Procrastination v1.1TêteHauteОценок пока нет