Академический Документы

Профессиональный Документы

Культура Документы

Solenoid Valve With Isolating Diaphragm: Type 0780

Загружено:

Oren WeinsteinИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Solenoid Valve With Isolating Diaphragm: Type 0780

Загружено:

Oren WeinsteinАвторское право:

Доступные форматы

Solenoid Valve with Isolating Diaphragm

Type 0780

3/2 way; universal function; DN 2 and 3; G 1/4 and sub-base version; flow rate: up to 175 l/min

Advantages / Benefits

EEx-ed-IIC T6 approved Universal function Separating diaphragm isolates solenoid system from operating fluid Operational reliability Long service life, even in non-lube conditions Insensitive to contaminated fluids Lockable manual override standard

Design

Applications

Fluids Neutral gases and liquids Technical vacuum Lubricated and unlubricated compressed air

The direct acting 3/2 way solenoid valve has a pivoted armature as the switching method. This unique valve design hermetically isolates the actuator from the fluid. It provides a long service life, even in unlubricated applications. The solenoid epoxy encapsulation efficiently dissipates the heat generated by the fluid.

- Direct-acting - Body materials: brass or stainless steel - Fast-acting - Sub-base connection for manifold mounting

Applications Direct acting single valve or pilot valve for process, chemical and petro-chemical industry Actuator control Manifolded assembly

Fluid Control Systems

Solenoid Valve with Isolating Diaphragm

Type 0780

Technical data

Circuit Function T 3/2-way valve, Universal function

Symbol

2

1 3

Valve specification

Solenoid specification

Body Materials

Body and seat brass or stainless steel 1.4401

Operating voltages 24, 110, 230 V/UC Voltage tolerance 10 %

Seal materials NBR

FPM

Neutral fluids, e.g. compressed air, town gas, water, hydraulic oil, oils and fats without additives Hot air, oxygen, per-solutions, hot oils with additives +55C

Power consumption Inrush UC 40 W Hold UC 3 W Duty cycle 100% continuously rated Use reduced switch-on time for manifold installation, depending on operating conditions. approx. 30 c.p.m. IP 65 EEx-ed-IIC T5 (e = increased safety) (d = pressure-proof housing)

Max. ambient temperature

Fluid temperatures with NBR seal 0 up to +70C with FPM seal -10 up to +70C Max. viscosity Response times opening closing 37 mm 2/s

Cycling rate Rating Type of protection

30 ms 40 ms

Times measured at outlet A, from switching on until pressure rise to 90 % / pressure drops to 10 % at a max. working pressure of 6 bar.

Installation / Accessories Installation as required, but preferably with solenoid system upright

Electr. connection Moulded cable (3000 mm length) Terminal box without fuse

Solenoid Valve with Isolating Diaphragm

Type 0780

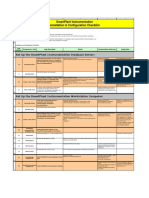

Ordering chart (other versions on request) Type 0780 with brass body

Circuit Port Orifice [mm] with cable (3000 mm length) T T T Sub base Sub base G 1/4 2.0 2.0 2.0 3.0 2.0 2.0 0 - 10 0 - 10 0 - 10 0 - 10 0 - 10 0 - 10 0.10 0.10 0.11 0.16 0.10 0.10 108 108 120 175 108 108 NBR FPM NBR NBR NBR FPM EEx-ed-IIC T5 EEx-ed-IIC T5 EEx-ed-IIC T5 EEx-ed-IIC T5 EEx-ed-IIC T5 EEx-ed-IIC T5 0.6 0.6 0.6 0.6 0.6 0.6 138 246 A 138 252 G 139 384 W 139 387 Z 138 249 M 138 255 B 138 247 B 138 253 H 139 385 X 139 388 A 138 250 J 138 256 C 138 248 L 138 254 A 139 386 Y 139 389 B 138 251 F 138 257 D Pressure range [bar] Kv-value Q Nn -value Seal (water) [m 3 /h] (air) [l/min] material [kg] 024/UC Ex-approval Weight Item-No. Voltage 110/UC 230/UC function connection

T G 1/4 with terminal box T T Sub base Sub base

Type 0780 with stainless steel body

Circuit Port Orifice [mm] with cable (3000 mm length) T T T Sub base Sub base G 1/4 2.0 2.0 2.0 3.0 2.0 2.0 0 - 10 0 - 10 0 - 10 0 - 10 0 - 10 0 - 10 0.10 0.10 0.11 0.16 0.10 0.10 108 108 120 175 108 108 NBR FPM FPM FPM NBR FPM EEx-ed-IIC T5 EEx-ed-IIC T5 EEx-ed-IIC T5 EEx-ed-IIC T5 EEx-ed-IIC T5 EEx-ed-IIC T5 0.6 0.6 0.6 0.6 0.6 0.6 138 258 N 138 264 C 139 390 G 139 393 X 138 261 H 138 266 E 138 259 P 138 265 D 139 391 V 139 394 Y 138 262 A 138 267 F 138 260 L 137 899 R 139 392 W 139 395 Z 138 263 B 138 268 Q Pressure range [bar] Kv-value Q Nn -value Seal (water) [m 3 /h] (air) [l/min] material [kg] 024/UC Ex-approval Weight Item-No. Voltage 110/UC 230/UC function connection

T G 1/4 with terminal box T T Sub base Sub base

Solenoid Valve with Isolating Diaphragm

Type 0780

Dimensions [mm] type 0780 multiple manifold Single Manifold

or plug-in connector

valve manifold

G 1/4

20

13

G 1/4 58

Manifold for Overall length A Hole spacing B

2 valves 69

3 valves 106 37

4 valves 143 74

5 valves 180 111

6 valves 217 148

7 valves 254 185

8 valves 291 222

Ordering chart for manifolds and accessories

Ordering Code for multiple Light Alloy Manifolds

Manifolds Item-No.

Accessories

Specification

Item-No.

1valve 2valves 3valves 4valves 5valves 6valves 7valves 8valves

005 043 Z 005 045 T 005 366 H 005 294 S 005 295 T 005 296 U 005 403 Y 006 074 Z

O-ring connector nipple O-ring connector nipple without drill hole Blanking plug with seal G 1/4 Lock for manual override, through Blanking plate

005 049 F 006 049 G 005 050 C 013 372 W 005 625 V

Solenoid Valve with Isolating Diaphragm

Type 0780

Dimensions [mm] type 0780 with moulded-in cable (3000 mm length)

cable connection

58

53 73 3000

flanged version

M4 31

4,5

11 10.7 24 6 100 38 locked screws 75 53 73 3000

36.5

100

51

32

Solenoid Valve with Isolating Diaphragm

Type 0780

Dimensions [mm] type 0780 with terminal box

terminal box version

131

19

G 1/4 NPT 1/4

9 46 threaded version

flanged version

M4 31

4,5

11

10.7

60

18

24

74

38 locked screws

37 123

75

In case of special requirements, please consult for advice.

We reserve the right to make technical changes without notice. 805-GB/ 1-0158

32

Вам также может понравиться

- DS 0330 Data Sheet Solenoide ValveДокумент5 страницDS 0330 Data Sheet Solenoide ValvetueresuecoОценок пока нет

- Ds0780 Eexed Eu enДокумент4 страницыDs0780 Eexed Eu enosto72Оценок пока нет

- TITANIA 1138enДокумент4 страницыTITANIA 1138enalexprgОценок пока нет

- 2/2-way valves DN 20 to 50 for air solenoid actuated diaphragm valvesДокумент4 страницы2/2-way valves DN 20 to 50 for air solenoid actuated diaphragm valvesOscar CurimanyaОценок пока нет

- 445e TDS Varitube EДокумент4 страницы445e TDS Varitube EKhánh NgânОценок пока нет

- Burkett 5281 Standard EU enДокумент4 страницыBurkett 5281 Standard EU enYing Kei ChanОценок пока нет

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Документ12 страницIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Lê Duy MinhОценок пока нет

- Catalogue Pages TC15Документ21 страницаCatalogue Pages TC15Truong ThuatОценок пока нет

- Temperature Sensors Types MBT 5250, 5260 and 5252: Data SheetДокумент8 страницTemperature Sensors Types MBT 5250, 5260 and 5252: Data SheetPetar HosticОценок пока нет

- Ebs PuДокумент2 страницыEbs PuZoran DanilovОценок пока нет

- Diaphragm Valve Metal Construction GuideДокумент12 страницDiaphragm Valve Metal Construction GuidealbetoОценок пока нет

- Wilo Drain TC 40Документ8 страницWilo Drain TC 40PrateekОценок пока нет

- DS6213 Standard EU enДокумент5 страницDS6213 Standard EU enwinwin2302Оценок пока нет

- 2Документ14 страниц2WormInchОценок пока нет

- Irrigation Solenoid ValveДокумент1 страницаIrrigation Solenoid ValveAtul KalaskarОценок пока нет

- SONDA cONDUTIVÍMETRO PDFДокумент8 страницSONDA cONDUTIVÍMETRO PDFAngeloОценок пока нет

- Amarex N: Submersible Motor Pumps DN 50 To 100Документ44 страницыAmarex N: Submersible Motor Pumps DN 50 To 100Ben RahierОценок пока нет

- KSB Valvula Diafragma SISTO10Документ4 страницыKSB Valvula Diafragma SISTO10Sarah PerezОценок пока нет

- Spirax Sarco BTM-7Документ3 страницыSpirax Sarco BTM-7Bambang Agung LaxmonoОценок пока нет

- 0420 PV 201 Globe Valve Data SheetДокумент12 страниц0420 PV 201 Globe Valve Data SheetMohamed Farag MostafaОценок пока нет

- Automatic Valve Gemue DB - 512 - GBДокумент6 страницAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- Pune Techtrol FGTДокумент2 страницыPune Techtrol FGTBenjamin StricklandОценок пока нет

- N en en 5 8 120 82090Документ2 страницыN en en 5 8 120 82090refaeОценок пока нет

- Electro Válvula Del CompresorДокумент4 страницыElectro Válvula Del CompresorneumaticoОценок пока нет

- GEA CAIRplus unit technical documentationДокумент11 страницGEA CAIRplus unit technical documentationVlad BalanОценок пока нет

- 30GXДокумент12 страниц30GXAdolfo Riquelme Novoa0% (1)

- Brochure TG enДокумент8 страницBrochure TG enpascal_chinОценок пока нет

- Wall-mounted cooling units 300/500WДокумент1 страницаWall-mounted cooling units 300/500WTruc LeОценок пока нет

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationДокумент5 страницSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroОценок пока нет

- 2 Way Valves BurkertДокумент4 страницы2 Way Valves BurkertParinpa KetarОценок пока нет

- 38CKC Product DataДокумент26 страниц38CKC Product DataCarlos Enrique Godoy Sifontes0% (1)

- Pulse Valves - Turbocontrols - It PDFДокумент40 страницPulse Valves - Turbocontrols - It PDFRicardo Ferrari TrevisanОценок пока нет

- WPI-KE-1104-SP141-QM5433 (Datasheet)Документ4 страницыWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémОценок пока нет

- Particulate Filter/Regulator: Performance DataДокумент3 страницыParticulate Filter/Regulator: Performance DataDedu IonutОценок пока нет

- Trane XB13 SC ProductДокумент72 страницыTrane XB13 SC ProductPhilip D AguirreОценок пока нет

- Solenoid Valve Data SheetДокумент14 страницSolenoid Valve Data SheetGuido Moreno PeredoОценок пока нет

- Jung Pumpen Multicut Sewage Pumps GuideДокумент6 страницJung Pumpen Multicut Sewage Pumps GuideAnghelescu-Topliceanu Georgiana AndreeaОценок пока нет

- Breather/Drain Plugs: SeriesДокумент1 страницаBreather/Drain Plugs: SeriesGolfkung PairojОценок пока нет

- Technical Data TP1: SAVE THE ENVIRONMENT: Before Printing, Think About The Environment. Thanks!Документ9 страницTechnical Data TP1: SAVE THE ENVIRONMENT: Before Printing, Think About The Environment. Thanks!Lucian AnghelОценок пока нет

- XR15 Performance DataДокумент16 страницXR15 Performance Databarber bobОценок пока нет

- Carrrier Manual 38ckc-c5pdДокумент20 страницCarrrier Manual 38ckc-c5pdAaron LeveyОценок пока нет

- Ilmed TT PDFДокумент6 страницIlmed TT PDFKNIGHTHAGENОценок пока нет

- ARI-Strainer technical specificationsДокумент6 страницARI-Strainer technical specificationsEmnОценок пока нет

- Rittal FansДокумент8 страницRittal FansSreekanth RaveendranОценок пока нет

- Valvula ASCO Falcon SB2500Документ2 страницыValvula ASCO Falcon SB2500Elmer HuashuayoОценок пока нет

- Endress+Hauser: RTD Thermometer Omnigrad TST11Документ4 страницыEndress+Hauser: RTD Thermometer Omnigrad TST11Pame CoronaОценок пока нет

- ASCO 327 Solenoid Valves ATEX IECEx Certified For Hazardous Areas2Документ4 страницыASCO 327 Solenoid Valves ATEX IECEx Certified For Hazardous Areas2harishОценок пока нет

- R 175 UkДокумент4 страницыR 175 UkAhmed EldalyОценок пока нет

- Temp Sensor ChillerДокумент3 страницыTemp Sensor Chillerpradeep_tyagi80Оценок пока нет

- PFH13232 enДокумент4 страницыPFH13232 envoodoo709Оценок пока нет

- AEGNEP Compressed AirДокумент42 страницыAEGNEP Compressed AirDavid HayesОценок пока нет

- CGAT Catalog0303Документ2 страницыCGAT Catalog0303Chinith HengОценок пока нет

- T101 Drilling MachineДокумент4 страницыT101 Drilling MachineFranklin Avendaño ArapaОценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesОт EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- 16RGHXC 1 850 10Документ1 страница16RGHXC 1 850 10Oren WeinsteinОценок пока нет

- Agami PDFДокумент4 страницыAgami PDFOren WeinsteinОценок пока нет

- 16RGHXC 1 850 10Документ1 страница16RGHXC 1 850 10Oren WeinsteinОценок пока нет

- Martensitic SS Alloy MaterialsДокумент1 страницаMartensitic SS Alloy MaterialsOren WeinsteinОценок пока нет

- DS WasteWaterTreatment PTA 0318 ENG PDFДокумент2 страницыDS WasteWaterTreatment PTA 0318 ENG PDFOren WeinsteinОценок пока нет

- Lineshaft Turbine Bowl Assembly DataДокумент3 страницыLineshaft Turbine Bowl Assembly DataOren WeinsteinОценок пока нет

- Griptight® Isolation Plug Test Plug Standard Sizes: Dc2692 11/13 Rev 3 5/17 Page 1 of 9Документ9 страницGriptight® Isolation Plug Test Plug Standard Sizes: Dc2692 11/13 Rev 3 5/17 Page 1 of 9Oren WeinsteinОценок пока нет

- Dkddpb202a502 FC200 SGДокумент68 страницDkddpb202a502 FC200 SGOren WeinsteinОценок пока нет

- Test Results RDL-800-1200Документ2 страницыTest Results RDL-800-1200Oren WeinsteinОценок пока нет

- Agami PDFДокумент4 страницыAgami PDFOren WeinsteinОценок пока нет

- Agami PDFДокумент4 страницыAgami PDFOren WeinsteinОценок пока нет

- Type "CA" Cast Discharge Head: (Effective March 15, 2013)Документ2 страницыType "CA" Cast Discharge Head: (Effective March 15, 2013)Oren WeinsteinОценок пока нет

- שבוע5הרצאהДокумент6 страницשבוע5הרצאהOren WeinsteinОценок пока нет

- Type "FF" Fabricated Discharge Head: (Effective June 1, 2006)Документ2 страницыType "FF" Fabricated Discharge Head: (Effective June 1, 2006)Oren WeinsteinОценок пока нет

- Painting & Sand Blasting Report For Trussed StructureДокумент1 страницаPainting & Sand Blasting Report For Trussed StructureAshwani Dogra33% (3)

- Xylem Flygt 2250 Datasheet 60hzДокумент2 страницыXylem Flygt 2250 Datasheet 60hzOren Weinstein0% (1)

- SchoolofLifeSciencesAdmissionOpen2021-2022Документ4 страницыSchoolofLifeSciencesAdmissionOpen2021-2022Amiruddin RafiudeenОценок пока нет

- ARK Survival 600 Player Level CapДокумент16 страницARK Survival 600 Player Level CapArcTrooper210Оценок пока нет

- L .. Eee - .: Distribution Voltage RegulatorsДокумент11 страницL .. Eee - .: Distribution Voltage RegulatorsSirajulОценок пока нет

- Camera Raw UpdateДокумент3 страницыCamera Raw UpdateHamsharfiОценок пока нет

- Engineeringexperv 00000 I 00146Документ60 страницEngineeringexperv 00000 I 00146LALEОценок пока нет

- How to Size a Fire Pump and Understand Performance CurvesДокумент12 страницHow to Size a Fire Pump and Understand Performance CurvesAmar kobitaОценок пока нет

- Nitya Parayana Slokas MalayalamДокумент3 страницыNitya Parayana Slokas MalayalamGopakumar NairОценок пока нет

- Wireless DoorbellДокумент20 страницWireless Doorbellmujahed1987Оценок пока нет

- LTE UMTS GSM Network OptimizationДокумент44 страницыLTE UMTS GSM Network OptimizationAvi Shetty100% (1)

- II B.Tech II Semester Regular Examinations, Apr/May 2007 Chemical Engineering Thermodynamics-IДокумент7 страницII B.Tech II Semester Regular Examinations, Apr/May 2007 Chemical Engineering Thermodynamics-IrajaraghuramvarmaОценок пока нет

- FinePrint pdfFactory Pro Trial Version PDF CreationДокумент40 страницFinePrint pdfFactory Pro Trial Version PDF CreationTUAN NGUYEN VANОценок пока нет

- Differences Between Routers, Switches and HubsДокумент2 страницыDifferences Between Routers, Switches and HubsPappu KhanОценок пока нет

- LCD panel and module replacement parts for saleДокумент1 страницаLCD panel and module replacement parts for saleValeria bolañosОценок пока нет

- HRIS1Документ24 страницыHRIS1UMESH VINAYAK ARVINDEKARОценок пока нет

- Eaton 9130 Rack 700-3000vaДокумент4 страницыEaton 9130 Rack 700-3000vaJose Luis PintoОценок пока нет

- To Civil Engineering: RoadsДокумент30 страницTo Civil Engineering: Roadshemant kumarОценок пока нет

- Tomtom Device ForensicsДокумент5 страницTomtom Device ForensicsSwaroop WaghadeОценок пока нет

- BNI Vision April 2023 Roster BookДокумент16 страницBNI Vision April 2023 Roster BookTushar MohiteОценок пока нет

- Blasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyДокумент3 страницыBlasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyEjike Francis ChizobaОценок пока нет

- C Programming: Charudatt KadolkarДокумент34 страницыC Programming: Charudatt KadolkarDhiliban SwaminathanОценок пока нет

- Guide to Rubber Expansion JointsДокумент7 страницGuide to Rubber Expansion JointsHu HenryОценок пока нет

- Compressive Strength, Chloride Diffusivity and Pore Structure of High Performance Metakaolin and Silica Fume ConcreteДокумент8 страницCompressive Strength, Chloride Diffusivity and Pore Structure of High Performance Metakaolin and Silica Fume ConcreteAboalmaail AlaminОценок пока нет

- SmartPlant Instrumentation installation checklistДокумент2 страницыSmartPlant Instrumentation installation checklistmnoormohamed82Оценок пока нет

- Dual-Band Band Pass Filters Using Stub-Loaded ResonatorsДокумент3 страницыDual-Band Band Pass Filters Using Stub-Loaded ResonatorsfracosoeОценок пока нет

- Communication in AfricaДокумент5 страницCommunication in AfricaJaque TornneОценок пока нет

- Sevice Manual BOBCAT S630 PDFДокумент890 страницSevice Manual BOBCAT S630 PDFArtemio Garcia Barrientos100% (11)

- Pyxis SPT HepДокумент597 страницPyxis SPT HepanithaarumallaОценок пока нет

- Complete Checklist for Manual Upgrades to Oracle Database 12c R1Документ27 страницComplete Checklist for Manual Upgrades to Oracle Database 12c R1Augustine OderoОценок пока нет

- Manual de Mantenimiento Del Piper PA-24Документ863 страницыManual de Mantenimiento Del Piper PA-24Bruno Starczewski50% (2)

- B2BДокумент31 страницаB2BAjay MaheskaОценок пока нет