Академический Документы

Профессиональный Документы

Культура Документы

JarPro Jarring Analysis Software

Загружено:

eleceron7919Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

JarPro Jarring Analysis Software

Загружено:

eleceron7919Авторское право:

Доступные форматы

JarPro Drillstring Jarring Analysis to Optimize Jar Placement in BHAs

Product Description JarPro is a general-purpose 2D jarring analysis program used for performing many phases of jarring analysis ranging from jar placement optimization to detailed time histories of jarring impact. The program uses a systematic stress wave tracking approach to simulate transmission of forces and motion in the drillstring during the jarring process. This approach enables JarPro to solve complex drillstring configurations efficiently using relatively simple inputs, thus facilitating its use by drilling engineers, rig personnel, and jar manufacturers. Benefits Reduce potential of damaging or losing the BHA during jarring by proper jar selection and placement Optimize jar placement in complex bottom hole assemblies Features Simplified data input requiring only basic jarring parameter selections and drillstring data in a user-defined format All internal nodes and elements are automatically generated Output includes characteristics of jarring and stuck point movements Training and Technical Support Comprehensive one-day training seminar Complete technical support Quality Assurance Program predictions validated by users & drilling research organizations through extensive testing Extensive verification by transient dynamic finite element analysis & closedform solutions

Impulse

Ove r

all P

ull

Ha

er L mm

eng

th

In complex BHAs ,the optimum jar location depends upon number of factors, which can be analyzed by JarPro Key Capabilities: Versatile 2-dimensional drillstring modeling capabilities and ease of input Parametric analysis for jar placement, tripping force, stuck force, and stuck location Detailed time history of forces, velocities, and displacements at user-selected locations Both jarring-up and jarring-down simulations Enhanced jar placement optimization options Special sections for accelerators and shock subs with nonlinear springs Modeling the effects of mud buoyancy, side wall friction, and pump-open at jar Material changes in a drillstring Single point or differential sticking simulation Plotting the analysis results and drillstring model

JarPro proven to reduce the cost associated with freeing stuck drillstring

Kalsi Engineering, Inc. 745 Park Two Drive Sugar Land, Texas 77478 USA Phone: (281)-240-6500 Fax: (281)-240-6500 kalsi@kalsi.com www.kalsi.com

Page 1 of 4

JarPro 7 - Jarring Analysis Software

The drill string is divided into sections such as drill pipe, drill collar, and jar. Each section requires only simple data inputs

The General Jarring Analysis Data screen defines drill string environment parameters under jarring

Drill pipe

Drill collar

The Analysis Option Data screen allows inputs for a variety of optional calculations including Jarring Characteristics, Jar Placement Optimization, and Jarring Variable Study

JAR

Drill collar

Output is represented by graphs and a detailed text printout for users to obtain the optimum jar placement, and to evaluate jarring impacts to the drill string.

Page 2 of 4

JarPro Pactical Approach to Jarring Analysis

Jar Placement for Simple BHAs

In case of BHAs with uniform Drill Collars optimum jar placement depends only on the stuck force and collar lengths. Because the actual magnitude of the stuck force and location of the stuck point are not known, a family of curves can be drawn for the range of the possible values for these parameters.

Jar Placement for Complex BHAs

In case of BHAs with HWDP (Heavy Weight Drill Pipe) each curve has more then one local maximum in the available impulse. The available impulse is influenced by the movement of the larger cross-section Drill Collar below the jar and by stress-wave reflections. These plots shows that the magnitude and the location of the maximum available impulse change significantly with changes in over pull force, stuck force, and length above and below the jar.

JarPro a practical tool to predict optimum jar placement

Page 3 of 4

JarPro Extensively Validated Against FEA, Instrumented Tests and Field Results

Extensive comparisons were made between the results from the JarPro and the FEM approach to ensure that wave tracking and superposition effects were properly considered from various configurations of BHAs. The results show very good agreement between two methods. In the stress-wave tracking method, the hammer accelerations, impact times, durations, and forces can be calculated precisely.

These figures compare JarPro predictions against transient dynamic FEA results two typical BHAs. The impact forces and impulses in the primary impact duration of the two methods match closely.

JarPro a validated tool to predict optimum jar placement

Page 4 of 4

Brochure PN 534-12 Rev. 2

2010

Вам также может понравиться

- Manual Foremost DR 24 PDFДокумент108 страницManual Foremost DR 24 PDFFreddy Martínez Avendaño100% (2)

- Latch Type Drilling JAR ManualДокумент41 страницаLatch Type Drilling JAR ManualMuhammad Zikry Alfindy HazОценок пока нет

- Agitator Handbook 2005Документ22 страницыAgitator Handbook 2005casda73Оценок пока нет

- AC-0049 Well Design RulesДокумент5 страницAC-0049 Well Design RulesairlinemembershipОценок пока нет

- Drill Bits and Services PDFДокумент66 страницDrill Bits and Services PDFKonul AlizadehОценок пока нет

- EXTENDED Well Control ChecklistДокумент14 страницEXTENDED Well Control ChecklistAdam InesОценок пока нет

- 2012 10 PetroJet PresentationДокумент30 страниц2012 10 PetroJet PresentationNorfolkingОценок пока нет

- Completion SolutionsДокумент24 страницыCompletion Solutionseleceron7919100% (2)

- NOV Reamers and Wipers PDFДокумент12 страницNOV Reamers and Wipers PDFeleceron7919Оценок пока нет

- Epiroc Drill StringsДокумент16 страницEpiroc Drill StringsCarlos Regaliza100% (1)

- Pipe Recovery FpitДокумент6 страницPipe Recovery FpitMaJo MoralesОценок пока нет

- Measurement While Drilling: Signal Analysis, Optimization and DesignОт EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignОценок пока нет

- 1 - Hydra Jar - Technical DataДокумент3 страницы1 - Hydra Jar - Technical DataJoseMi Vacaflor IllanesОценок пока нет

- SLB PowerPak Handbook 2004Документ216 страницSLB PowerPak Handbook 2004casda73Оценок пока нет

- Stuck Pipe CourseДокумент4 страницыStuck Pipe CourseAdama NdiayeОценок пока нет

- Formation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsДокумент6 страницFormation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsJamalОценок пока нет

- Trackmaster CH - DesbloqueadoДокумент19 страницTrackmaster CH - DesbloqueadoPaola SamoОценок пока нет

- AEC DynamicsNewДокумент42 страницыAEC DynamicsNewMuhammad Hamdy100% (1)

- Sidetracking PrinciplesДокумент3 страницыSidetracking PrinciplesDon BraithwaiteОценок пока нет

- Monitoring Drilling Bit Parameters Parameters Allows Optimization of Drilling RatesДокумент16 страницMonitoring Drilling Bit Parameters Parameters Allows Optimization of Drilling RatesAnmol JassalОценок пока нет

- Mud/Gas Separator Sizing and Evaluation: G.R. MacdougallДокумент6 страницMud/Gas Separator Sizing and Evaluation: G.R. MacdougallDiego AraqueОценок пока нет

- Casing Running and Drilling ToolsДокумент33 страницыCasing Running and Drilling Toolsfffggg777Оценок пока нет

- MagTrak BrochureДокумент8 страницMagTrak BrochurejaloaliniskiОценок пока нет

- 03 HAL-2011 Steering Tools FДокумент10 страниц03 HAL-2011 Steering Tools FMiftahul Riski NasutionОценок пока нет

- Calculation of Forces Acting On A Rotary Steerable Liner Drilling SystemДокумент135 страницCalculation of Forces Acting On A Rotary Steerable Liner Drilling SystemNourden Al100% (1)

- 09 Icruise Best Practice v2Документ45 страниц09 Icruise Best Practice v2Nelson RamirezОценок пока нет

- An Der Gauge AgitatorДокумент22 страницыAn Der Gauge Agitatorbweimar2Оценок пока нет

- Break Out and Laying Down BhaДокумент3 страницыBreak Out and Laying Down BhakhurramОценок пока нет

- Well Integrity Course Summary in Nov-2023Документ50 страницWell Integrity Course Summary in Nov-2023Yovaraj KarunakaranОценок пока нет

- DPU Tubing Punch: Slickline Services Integrated Cased-Hole Services DPU ServicesДокумент2 страницыDPU Tubing Punch: Slickline Services Integrated Cased-Hole Services DPU ServicesOleg MalkovОценок пока нет

- Drilling Jar Manual PDFДокумент33 страницыDrilling Jar Manual PDFsmithyry2014Оценок пока нет

- CompassДокумент4 страницыCompassEnny RachelОценок пока нет

- Down HoleДокумент14 страницDown HoleGhinet Teodor-ioanОценок пока нет

- Motor PresentationДокумент23 страницыMotor PresentationVirgilioОценок пока нет

- Drilling AnalysisДокумент36 страницDrilling Analysisgplese0Оценок пока нет

- Drilltech Services (USA) Inc: Spiro-TorqДокумент10 страницDrilltech Services (USA) Inc: Spiro-TorqDante Cabrera GuzmanОценок пока нет

- Baker Hughes 43018 Axcelerate in Gom CHДокумент1 страницаBaker Hughes 43018 Axcelerate in Gom CHArumugam RajendranОценок пока нет

- 24 - HTHP WellsДокумент25 страниц24 - HTHP WellsSlim.BОценок пока нет

- IADC Vol-1 08 Directional DrillingДокумент35 страницIADC Vol-1 08 Directional Drillingballa bammouneОценок пока нет

- IADC/SPE 115283 Casing Drilling Technology As The Alternative of Drilling EfficiencyДокумент10 страницIADC/SPE 115283 Casing Drilling Technology As The Alternative of Drilling EfficiencyMicaela Flores Lanza100% (1)

- 200 Drilling Engineering PDFДокумент10 страниц200 Drilling Engineering PDFJesus De la RosaОценок пока нет

- PPE I PR 005Документ11 страницPPE I PR 005MahanderOadОценок пока нет

- Managed Pressure Drilling Modeling & Simulation (A Case Study)Документ8 страницManaged Pressure Drilling Modeling & Simulation (A Case Study)Mejbahul SarkerОценок пока нет

- Simprofile PDFДокумент14 страницSimprofile PDFDurga PrasadОценок пока нет

- Formulas y Calculos de PerforacionДокумент22 страницыFormulas y Calculos de Perforacionjairaso2950Оценок пока нет

- Pesca PDFДокумент11 страницPesca PDFrenatoОценок пока нет

- WFT 000483Документ4 страницыWFT 000483Abboud KingОценок пока нет

- SFT-709 Fishing Kit ChecklistДокумент1 страницаSFT-709 Fishing Kit ChecklistJose Antonio Acosta100% (1)

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedДокумент8 страницBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightОценок пока нет

- Logging While DrillingДокумент2 страницыLogging While DrillingFranz Gustavo Vargas MamaniОценок пока нет

- Rilling Ngineering Course (2 Ed.)Документ43 страницыRilling Ngineering Course (2 Ed.)MarcoОценок пока нет

- Tool CodesДокумент16 страницTool CodesbrowgzОценок пока нет

- Weatherford CORODДокумент6 страницWeatherford CORODclass 96Оценок пока нет

- Trackmaster Select: Modular Whipstock Sidetracking SystemДокумент9 страницTrackmaster Select: Modular Whipstock Sidetracking SystemIvan Dario Benavides BonillaОценок пока нет

- Liner Hanger Systems Data SheetДокумент1 страницаLiner Hanger Systems Data SheetJhonathan MirandaОценок пока нет

- Model "Jyq" Mechanical-Hydraulic Drilling Jar: Instruction ManualДокумент8 страницModel "Jyq" Mechanical-Hydraulic Drilling Jar: Instruction ManualMarvin William Montes Cristo100% (1)

- Section05 - Routine Drilling OperationsДокумент31 страницаSection05 - Routine Drilling OperationsMohamed ElshoraОценок пока нет

- Thiago Mikail - Apresentação IДокумент50 страницThiago Mikail - Apresentação IThiago Mikail De OliveiraОценок пока нет

- WellPlan ReportДокумент34 страницыWellPlan ReportElmar CahangirovОценок пока нет

- Successfully Drills Through Total Losses Zones, Saves 17.6 DaysДокумент2 страницыSuccessfully Drills Through Total Losses Zones, Saves 17.6 DaysAriel Della TorreОценок пока нет

- 1) Anusha A/P Nagaih 2) Melinda Mallini A/P Loudersamy 3) Sangeetha A/P Balaram 4) Vinohthinii A/P R Tamilselvan 5) Youssif SamiДокумент17 страниц1) Anusha A/P Nagaih 2) Melinda Mallini A/P Loudersamy 3) Sangeetha A/P Balaram 4) Vinohthinii A/P R Tamilselvan 5) Youssif Samitashh raoОценок пока нет

- 01-Section 02 Drilling Fluids Functions PDFДокумент11 страниц01-Section 02 Drilling Fluids Functions PDFLazharОценок пока нет

- API CasingДокумент3 страницыAPI CasinghamidОценок пока нет

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsОт EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsОценок пока нет

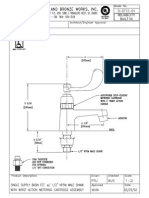

- TYS Brass and Bronze B-0712-01Документ1 страницаTYS Brass and Bronze B-0712-01eleceron7919Оценок пока нет

- LITHOLOGY Geology PDFДокумент60 страницLITHOLOGY Geology PDFeleceron7919Оценок пока нет

- BHA HomeДокумент3 страницыBHA HomeLenis CeronОценок пока нет

- Well Logs For StratigraphicДокумент249 страницWell Logs For Stratigraphiceleceron7919100% (2)

- Stratex Drilling Methods Reference GuideДокумент4 страницыStratex Drilling Methods Reference Guideeleceron7919Оценок пока нет

- T&S Brass and Bronze Works, Inc.: Travelers Rest, SC 29690 2 Saddleback Cove / P.O. Box 1088Документ2 страницыT&S Brass and Bronze Works, Inc.: Travelers Rest, SC 29690 2 Saddleback Cove / P.O. Box 1088eleceron7919Оценок пока нет

- Some Cementing Problems: HistoryДокумент6 страницSome Cementing Problems: Historyeleceron7919Оценок пока нет

- Weekly Critical RIG Equipment HSE InspectionДокумент2 страницыWeekly Critical RIG Equipment HSE Inspectioneleceron7919Оценок пока нет

- Well Control Equations DrillingformulasДокумент13 страницWell Control Equations DrillingformulastoshoyОценок пока нет

- GDO 41 Table PressДокумент1 страницаGDO 41 Table Presseleceron7919Оценок пока нет

- Drilling Assembly HandbookДокумент99 страницDrilling Assembly HandbookRodrigo Sena100% (7)

- Vam Tubular StandardsДокумент84 страницыVam Tubular StandardsMAHAN4231100% (9)

- Vam Tubular StandardsДокумент84 страницыVam Tubular StandardsMAHAN4231100% (9)

- 00 MMS Gulf of MexicoДокумент9 страниц00 MMS Gulf of Mexicoeleceron7919Оценок пока нет

- Repair Side Tracking DL LGДокумент74 страницыRepair Side Tracking DL LGeleceron7919Оценок пока нет

- Repair Side Tracking DL LGДокумент74 страницыRepair Side Tracking DL LGeleceron7919Оценок пока нет

- WEPS PDC Reamer Presentation Final5!18!12 AK Time 0425p 2Документ37 страницWEPS PDC Reamer Presentation Final5!18!12 AK Time 0425p 2eleceron7919Оценок пока нет

- Geological DescriptionДокумент3 страницыGeological Descriptioneleceron7919Оценок пока нет

- Vam Tubular StandardsДокумент84 страницыVam Tubular StandardsMAHAN4231100% (9)

- Basic Petroleum Geology BOOK by HALLIBURTON PDFДокумент87 страницBasic Petroleum Geology BOOK by HALLIBURTON PDFGOO80% (10)

- Liner 7-Casing RH3Документ48 страницLiner 7-Casing RH3eleceron7919Оценок пока нет

- Liner 7-Casing RH3Документ48 страницLiner 7-Casing RH3eleceron7919Оценок пока нет

- Rotary Drilling Rig ComponentsДокумент130 страницRotary Drilling Rig Componentsgarry_dirak100% (21)

- Managing Drilling RiskДокумент18 страницManaging Drilling RiskOtnay HaryОценок пока нет

- How To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred GrowcockДокумент16 страницHow To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred Growcockrıdvan duranОценок пока нет

- LДокумент5 страницLAditi DasОценок пока нет

- Ogpe201403 DLДокумент24 страницыOgpe201403 DLJoshua SalazarОценок пока нет

- Mechanics of Materials (CH.2) - SolutionsДокумент108 страницMechanics of Materials (CH.2) - SolutionsGary Falanga33% (3)

- SMITH CatalogДокумент86 страницSMITH CatalogGhinet Teodor-ioanОценок пока нет

- Azeez Mustafa MSC 2019Документ73 страницыAzeez Mustafa MSC 2019Bella cedricОценок пока нет

- Conduct Ultrasonic Testing and Magnetic Particle Inspection On Rig Mast and Structure As Per API RP4G CATДокумент18 страницConduct Ultrasonic Testing and Magnetic Particle Inspection On Rig Mast and Structure As Per API RP4G CATMurugananthamParamasivam100% (2)

- Well Drilling PDFДокумент23 страницыWell Drilling PDFengrcabaneroОценок пока нет

- Best Practices.Документ46 страницBest Practices.eng20072007100% (1)

- Basic of Drillpipe Tensile Capacity and Its CalculationДокумент23 страницыBasic of Drillpipe Tensile Capacity and Its CalculationAshutosh RaiОценок пока нет

- Part II Functions of A Drilling FluidДокумент47 страницPart II Functions of A Drilling FluidMoopSaidОценок пока нет

- 12 Catalogo Accesorios de Perforacion DTH para RocДокумент16 страниц12 Catalogo Accesorios de Perforacion DTH para RocAnonymous kjJfuvMM100% (2)

- Parker Drilling Company: Mud PumpsДокумент27 страницParker Drilling Company: Mud Pumpsnardo_ingОценок пока нет

- Stuck Pipe Lecture - 1 PDFДокумент9 страницStuck Pipe Lecture - 1 PDFAmar BenAmarОценок пока нет

- Drilling Tools CatalogДокумент33 страницыDrilling Tools CatalogcharanОценок пока нет

- Drillstring & BHA DesignДокумент36 страницDrillstring & BHA DesignJim BodeОценок пока нет

- United States PatentДокумент15 страницUnited States PatentJjp ParmarОценок пока нет

- Drilling Engineering Lecture DetailsДокумент6 страницDrilling Engineering Lecture Detailsdhirendra singhОценок пока нет

- Directional Drilling Program TrainingДокумент1 страницаDirectional Drilling Program TrainingElmar CahangirovОценок пока нет

- Bit Running Guidelines PDFДокумент39 страницBit Running Guidelines PDFRyan LlanetaОценок пока нет

- Bottom Hole AssemblyДокумент2 страницыBottom Hole AssemblyTabaaza Grace AmabelОценок пока нет

- Downhole Drilling Problems AnirbidДокумент45 страницDownhole Drilling Problems AnirbidMahrouz Mado0% (1)

- IADC/SPE-178776-MS Iron Roughneck Make Up Torque-Its Not What You Think!Документ21 страницаIADC/SPE-178776-MS Iron Roughneck Make Up Torque-Its Not What You Think!jasamaОценок пока нет

- Cop 4050 SeriesДокумент12 страницCop 4050 Serieskannonzk100% (4)