Академический Документы

Профессиональный Документы

Культура Документы

Manufacture of Rocket Motor Cases Using Advanced Filame

Загружено:

SumithrananthanИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Manufacture of Rocket Motor Cases Using Advanced Filame

Загружено:

SumithrananthanАвторское право:

Доступные форматы

DESIGN AND MANUFACTURING GUIDELINE FOR GUIDELINE NO.

GD-ED-2205

PAGE OF 11

AEROSPACE COMPOSITES

PREFERRED RELIABILITY PRACTICES

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

Guideline: Composites must be considered as unique materials in the design and manufacturing process because manufacturing equipment, tooling, and inspection equipment and processes have a pronounced effect on design. Since the material is formulated while the part is being built; (1) multidisciplinary, concurrent engineering design principles and (2) careful material selection and fabrication processes must be used to obtain optimum properties in aerospace composites. Benefits: Conscientious adherence to proven concurrent engineering principles and careful design and material selection guidelines in the design, manufacture, and testing of aerospace composites will result in low rejection rates and high product integrity. Successful composite designs can provide design flexibility, lightweight parts, ease of fabrication and installation (generally fewer parts), corrosion resistance, impact resistance, high fatigue strength (compared to metal structures with the same dimensions), and product simplicity when compared to conventional fabricated metal structures. Center to Contact for More Information: Marshall Space Flight Center (MSFC) Implementation: Introduction: Composites are combinations of two or more distinct materials present as separate phases and combined to form desired structures. They take advantage of the desirable properties of each component. The manufacturing technique used to fabricate a composite structure is dependent upon material performance requirements, structure configuration, and production rates. The composite design and manufacturing methods discussed in this guideline are MARSHALL primarily for structural and mechanical applications and are composed of a resin (matrix) and a fiber SPACE FLIGHT reinforcement. Typical reinforcements are shown on Figure 1. CENTER

GUIDELINE NO. GD-ED-2205 PAGE OF 11

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

Performance of composite materials in aerospace applications is superior to conventional structural materials such as steel and aluminum. Composite materials and their manu facturing processes can be tailored specifically to given design constraints. The superior physical properties of composites allow for design with minimum concern for dimensional stability, corrosion, and crack formation. While it is possible to tailor the properties of a composite structure to minimize problems in these areas, it is imperative that this be taken into consideration during the design process. Composite materials are significantly superior to conventional materials in strength-to weight ratio, one of the most important requirements of aerospace structures. Figure 1. Typical Composite Reinforcements Design: Concurrent engineering principles (i.e., the team approach to design using designers, thermal and structural analysts, manufacturing engineers, materials process engineers, tool designers, machinists, quality engineers, quality control specialists, and reliability engineers) contribute noticeably to the success of a composite materials program. Designs of composite components which are fault tolerant to known manufacturing conditions and variables should be selected. The success of a composite program is dependent upon establishing material properties early in the program. Establishing an accurate and reliable material property data base is one of the most important steps toward achieving a functional design. Experience indicates that the basic material allowables of a specific composite product should be determined utilizing the manufacturing facilities where production will take place prior to finalizing design. The preferred process should approximate the following: (1) define environmental and performance requirements; (2) review available materials against requirements to determine the family of material to be used; (3) determine materials; (4) determine materials allowables using material processed at the intended manufacturer; (5) proceed with design based on known material

GUIDELINE NO. GD-ED-2205 PAGE OF 11

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

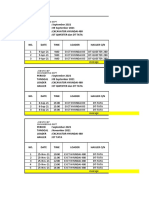

allowables; (6) test geometric configurations (i.e., special joints, specific contours, special ply layups, etc.); (7) along with nondestructive evaluation (NDE), use destructive evaluation to determine voids, ply dropoff, resin rich areas, etc., during initial manufacturing process development; (8) begin manufacturing production. Typical mechanical and impact damage properties of selected composites are shown in Tables 1 and 2. Table 1. Typical Mechanical Properties of Selected Composites

Material Type Carbon/Epoxy Nomenclature T300/934 IM7/8551-7 P75/934 AS4/3501-6 IM6/3501-6 E-glass/934 K-49/7934 IM7/APC-2 FM5055 Tensile Strength (ksi) 245 400 135 100 330 150-170 80-85 419 15-20 Modulus (Msi) 20 24 44 10 23 6-8 4 24 2.6-2.8 Strain (%) 1.0-1.2 1.62 0.2-0.5 1.0 1.5 2.75 1.85 1.6 1.0-1.2

Glass/Epoxy Kevlar/Epoxy Carbon/PEEK Carbon/Phenolic

PEEK= Polyetheretherketone Note: All samples were prepared from 16-ply quasi-isotropic layups.

Table 2. Typical Impact Damage Properties of Selected Composites

Nomenclature IM6/3501 IM7/SP500 IM7/F3900 IM7/977-2 T300/934 T650-42/1939-3 IM7/8551 IM8/8553 Max Impact Load (lb) 850 1100 1080 1170 560 1010 1240 900 Energy at Max Load (ft-lb) 9.2 9.1 9.7 10.3 3.7 8.5 12.1 7.4

(1), (4)

Compression After Impact (CAI) (ksi) (2) 23.2 36.2 39.9 47.1 (3) (3) 50 (3)

Notes: (1) All samples prepared from 16-ply quasi-isotropic layups. 2)CAI values are normalized to approximately 125 ft-lb impact energy per inch thickness. MSFC M&P Lab data unless noted otherwise. 3)MSFC M&P Lab CAI testing planned for these materials. 4)Hercules data unless otherwise noted.

GUIDELINE NO. GD-ED-2205 PAGE OF 11

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

The factors of safety shown in Table 3 should be used in the analysis and design of composites. During design and manufacturing process development, credible accept/reject criteria and acceptable repair methods should be developed. Table 3. Safety Factors for Composites

Item Ultimate Minimum Test Factor Qual Unit Nonprotoflight (1) Structure Protoflight (2) Structure 1.4 2.0 (3) 1.5 2.0 (3) 1.4 Flight Unit 1.05 Acceptance Test Flight Units

1.2

Notes: (1) Fly separate test article. 2)Fly the article tested. 3)Stress riser or discontinuity

Recommended Design and Analysis Guidelines for Composites: During the concept definition phase of the composite part design cycle, all of the critical design parameters are established. Geometric constraints and material considerations are outlined in order to establish the amount of design flexibility allowable. Maximum loads, both mechanical and thermal, are estimated. Weight, cost, and producibility concerns should be considered at this juncture. These factors should then be weighted and balanced to produce an initial design concept. For example, thermal material limitations should be balanced against cost and producibility concerns to select the appropriate composite material. Likewise, the layup of the laminate should be chosen considering not only the desired load capability, but also the thermal environment. High heat transfer areas could be cooled by using additional plies to act as a heat sink. These two factors in turn are offset by weight considerations. Several preliminary analysis and sizing tools can be used at this stage. PANDA, an elastic-plastic composite shell optimization program, is used in the analysis of stiffened panels. For flat composite panels, PASCO is sometimes used for preliminary sizing. The use of a Computer Aided Design (CAD) package is highly desirable in drawing the initial configuration. The configuration is then subjected to stress analysis. Depending on complexity, the part may be subdivided into subcomponents for separate analysis. If required, a structural computer model may be generated. For most parts, a finite element model is generated using PDA/PATRAN and the surface definitions from the CAD drawing. PATRAN is used as preprocessor and post-processor for MSC/NASTRAN, which has the capability of analyzing

GUIDELINE NO. GD-ED-2205 PAGE OF 11

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

composite plate elements. Aerodynamic, vibroacoustic and thermal loads are obtained from the appropriate discipline areas for input into the stress analysis. The vibroacoustic analysis is performed by dynamics loads engineers using MSC/NASTRAN as a processor and IDEAS as a preprocessor and post-processor. A temperature profile for the part is provided by thermal engineers using MIDAS, a finite difference thermal analyzer, and thermal material properties supplied by the composites materials engineers. For shells of revolution under axisymmetric loading, BOSOR, a finite difference structural analysis program, may be employed. A simple general shell element finite element program, STAGS, is sometimes used to obtain input loads for BOSOR models. For more detailed analysis at a particular point, SQ5, a point stress laminate analysis program, is used. Edge loads for a critical element from a finite element or finite difference model are input into this program to obtain more detailed results. Thermal effects may be approximated using this program. However, if temperature gradients become excessive, in-house developed software may be required. Although buckling coefficients may be obtained from NASTRAN, NASA-supplied buckling knockdown factors for plates with complex curvature are used to compensate for inaccuracies inherent in the finite element program. Specialized computer programs are used to analyze joints and fasteners and their interface with the composite parts. Bolt programs determine the capability of bolted joints under combined bending, tension and shear applied loads, as well as tension due to preload and differential thermal expansion. Clip analysis programs analyze metal clips using empirical data. Composite joint programs are also employed; for example, BJSFM is used for bearing loads, and JOINT is used for elastoplastic multiple bolt joints. Below is a list of representative commercial computer programs that are available for analyzing stresses and strains in composite materials under various conditions. The ones most often used by MSFC are indicated as: [MSFC]. These computer programs are available from the company or source shown in parentheses. 1.ABAQUS (Hibbitt, Carlson & Solenson, Inc.) 2.ADINA (ADINA Engineering) 3.ANSYS [MSFC] (Swanson Analysis Systems, Inc.) 4.BOSOR [MSFC] (David Bushnell) 5.NASTRAN (MacNeal-Schwendles Corp.) 6.STAGS (COSMIC) 7.CHAMPION (MSFC-used but not commercially available)

GUIDELINE NO. GD-ED-2205 PAGE OF 11

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

Critical factors affecting strength and stiffness for fiber are modulus of elasticity, strength, strain to failure, and curvature. Critical factors for the matrix are modulus of elasticity, elongation to failure, stress-strain behavior, void content, and fatigue performance. Manufacturing: Typical aerospace composite manufacturing processes consist of filament winding, fiber placement, pultrusion, tape laying, tape wrapping, press molding, hand layup and resin transfer molding. Typical fiber/matrix composite uses and processing techniques for various MSFC programs are shown in Table 4 and Table 5, respectively. A summary of composite manufacturing processes is shown in Table 6. Table 4. Typical MSFC Uses of Fiber/Matrix FIBER/MATRIX

Carbon (Graphite)/Epoxies

USAGE

1.Most used material for structural composites 2.Used in trusses, pressure vessels, optical benches, racks 3.Available in low, intermediate, and high modulus forms 4.Damage tolerance typically varies inversely with modulus 1.Used in pressure vessels and sacrificial layers 2.Used as flame barriers for carbon/epoxy structures and as galvanic corrosion barrier between carbon/epoxy, carbon/ phenolics and aluminum components 1.Used in pressure vessels and small solid rocket motors 2.Excellent damage tolerance 3.Low compressive strength 1.Excellent damage tolerance 2.Good repairability 3.Lower structural performance thermosets 1.Excellent high temperature properties 2.Used in areas of high heat flux (nozzles, fairings, nosecaps) 3.Requires higher processing temperatures

Glass/Epoxies

Kevlar/Epoxies

Fiber-Reinforced Thermoplastics

Fiber-Reinforced Bismalemides, Phenolics

There are sensitive manufacturing variables that must be closely controlled during composite fabrication. Therefore, using certified and highly skilled technicians is required. Typical manufacturing variables are heat input, cooling input, roller pressure, machine speed, tape tension, curing temperatures and curing pressures. Technicians must understand what to do when one of these variables changes. Properly controlled manufacturing processes will result in proper tensile strength, density, thermal conductivity, and interlaminar shear strength.

GUIDELINE NO. GD-ED-2205 PAGE OF 11

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

Table 5. Processing Techniques SUPPLIED FORMS

Prepreg tape of varying widths - unidirectional or fabric Prepreg tow - preimpregnation fiber bundles Dry fiber plus wet resin Fiber-reinforced bulk modulus compound

PREPARATION METHODS

Filament winding-wet winding or prepreg tool Hand layup Tape wrapping Tape laying Pultrusion Polar winding Braiding Resin transfer molding Fiber placement

CURING METHODS

Autoclave/hydroclave Oven Press Compression molding

Tooling: Major factors to be considered in the design and fabrication of tooling for structural and mechanical components are: (1) dimensional tolerance control and configuration stability, 2)location of parts in a structurally reliable assembly to give the lowest possible cost, 3)contour and size of the part, and (4) control of fiber orientation. Other significant factors which control final tool concept selection are cost, tool service life, heat up rate, total energy requirements, production rates and related facility costs. The tooling required to fabricate most composite parts can be subdivided into several major categories including ply layup tools, skin or mold forms, curing aids, handling tools, drilling and trimming tools, assembly tools, molds and mandrels. Additional tooling and equipment are shown in Table 6. Testing: Component, subcomponent, and generic structural tests are performed to verify analysis. Particular component tests may include elements of aerodynamics, vibroacoustic and thermal loading conditions, as well as significant externally applied mechanical loads. Subcomponent tests may be performed for critical areas of the component. Generic tests include flange and stiffened panel tensile tests, damage tolerance tests, and standard temperature effect tensile and compressive coupon tests.

GUIDELINE NO. GD-ED-2205 PAGE OF 11

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

Table 6. Summary of Composite Manufacturing Processes PROCESS

Filament Winding

COMPOSITE MATERIAL

Glass/Epoxy Graphite/Epoxy Kevlar/Epoxy Carbon/PEEK Carbon/Phenolic Thermosets Glass/Epoxy Graphite/Epoxy Thermosets Thermoplastics Glass/Epoxy Graphite/Epoxy Kevlar/Epoxy Carbon/PEEK Carbon/Phenolic

COMMON USES

Solid Rocket Motor cases, pressure vessels

TYPICAL TOOLING AND/OR EQUIPMENT

Removable mandrels, automated lathe, resin bath, heat source, vacuum source, curing oven, autoclave, hydroclave, handling tools, trial fixtures, drill fixtures, and assembly tools. Pultrusion machine similar to metal extrusion machine, heat source, resin bath, cut-off device.

Pultrusion

Structural shapes of constant cross-section, e.g., tees, angles, channels, rods, tubing, and squares Small to large structures of simple to complex shapes. Ply fibers placed in mold, mold closed, resin injected into mold (heated or room temp.) Small quantity production of test panels, prototype parts, or parts of complex contour

Resin Transfer Molding

Low tonnage press, contoured molds (male and female), low cost tooling using standard production steel, room temperature cure, oven or autoclave. Lay-up molds, vacuum bags, vacuum source, autoclave or hydroclave, and curing oven.

Hand Laying

Glass/Epoxy Graphite/Epoxy Kevlar/Epoxy Carbon/PEEK Carbon/Phenolic Glass/Epoxy Graphite/Epoxy Kevlar/Epoxy Carbon/PEEK Thermosets Thermoplastics Glass/Epoxy Graphite/Epoxy Kevlar/Epoxy Carbon/PEEK Carbon/Phenolic Bismalemides Thermoplastics

Mechanized Tape Laying

Small to large structures of simple or complex shapes

Molds, computer-controlled ply cutting, flat and contoured tape laying, automated ply lamination, autoclave, hydroclave, curing oven.

Fully Automatic Tape Laying

Small to large structural components of simple to complex shapes

Contoured molds, automatic tape laying equipment consists of automatic cutter, broadgood dispenser, trim table, ply transfer table, tape laying, stitching module and contour ply handling system, autoclave, hydroclave, curing oven, handling tools, trim fixture, drill fixture, and assembly tools.

GUIDELINE NO. GD-ED-2205 PAGE OF 11

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

PROCESS Press Molding COMPOSITE MATERIAL

Glass/Epoxy Graphite/Epoxy Kevlar/Epoxy Carbon/PEEK Carbon/Phenolic

COMMON USES

Flat panels, molded components for subscale solid rocket motor ablative materials

TYPICAL TOOLING AND/OR EQUIPMENT

Planten press molds (top and bottom) and heat source to mold.

Inspection: Quality assurance for composite parts centers on techniques for validating the physical and mechanical properties of a cured composite. However, quality assurance begins long before the end item is tested. A logical approach to quality control follows the fundamentals of composite reaction control: (1) raw material validation reaction control; (2) material characteristics; (3) inprocess fabrication/handling/tooling effects; (4) cure process control and documentation; (5) post cure machining. Visual inspection is used to inspect bond lines that are visible in the various bond stages and to detect any visible surface discontinuities and/or delaminations. Mechanical inspection is used to verify design dimensions, acoustics, input resistance, static loads and dynamic loads. Non destructive evaluation is perhaps the most important inspection technique for determining defects in composites, particularly the defects specified in Table 7. Technical Rationale: MSFC experience with composites includes filament winding, tape laying, fiber placement, hand layup, computerized pultrusion, and automated tape wrapping. Computer programs are available assist in the composite design process. The mechanical properties and impact damage properties that have been derived from tests of various composite materials can be used by designers to select the proper material and configuration for the job. Research is continuing to expand the available storehouse of design guidelines, leading to the production of reliable aerospace composite components. Valuable references which provide detailed design and analysis parameters for composite materials are provided in this guideline. to

GUIDELINE NO. GD-ED-2205 PAGE OF 11

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

Table 7. NDE Techniques for Detecting Defects in Composite Materials

Defect/ Composite Method* Delaminations/All 8 Density Variations/ #5 Resin Rich-Resin Poor/All 8 Voids/#1 Crazing (Microcracks)/ All 8 Wrinkles/A ll 8 Conductive Materials/ #2 X-ray Ultrasonics Computer Tomography Alcohol Wipe Thermography Eddy Current Dye Penetrant

X X

X X

X X

X X X

X X

* Composite Methods: 1.Filament winding 5. Tape wrapping 2.Fiber placement 6. Press molding 3.Pultrusion 7. Hand layout 4.Tape laying 8. Resin transfer molding Impact of Nonpractice: Failure to use state-of-the-art design techniques, tooling, manufacturing techniques, and automated manufacturing and inspection techniques for composite materials could result in the choice of inappropriate materials, costly scrappage, and potential failures in use. Failure to use composites in appropriate applications could result in noncompetitive products with greater complexity, weight, or damage susceptibility.

GUIDELINE NO. GD-ED-2205 PAGE OF 11

DESIGN AND MANUFACTURING GUIDELINE FOR AEROSPACE COMPOSITES

Related Guidelines/Practices: 1. Applications of Ablative Composites in Solid Rocket Motor Nozzles Practice No. PD-ED 1218; Marshall Space Flight Center. 2. Structural Laminate Composites for Space Applications Practice No. PD-ED-1217; Marshall Space Flight Center. References: 1. Agarwal, B.D., Broutman, L.J.: "Analysis and Performance of Fiber Composites," John Wiley and Sons, Inc., Second Edition, 1990. 2. ASM International Handbook Committee: Composite, Engineered Materials Handbook, Volume 1, Third Printing, August 1989. 3. DOD/NASA: Advanced Composites Design Guide, Volume I-IV, 1989. 4. Jones, W.K.: "Test Report Graphite/Bismalemide Allowables Data Base," Martin Marietta Composites Technology Group, August 1987. 5. Lubin: "Handbook of Composite Materials," 1982. 6. MSFC-HDBK-505A: "Structural Strength Program Requirements," January 1981. 7. MSFC-HDBK-1453: "Fracture Control Program Requirements," October 1987. 8. Morgan, Jr. L., Sigur, W.A.: "Fastening Techniques for Composite Materials," Martin Marietta Composites Technology Group, August 1985. 9. NHB 8071.1: "Fracture Control Requirements for Payloads," September 1988. 10. Sherrouse, M., Blum, C.: "Recommend Practices for Composites, Design and Analysis," Martin Marietta, Michoud, LA, March 1992. 11. Strong, Dr. A. Brent: Fundamentals of Composites Manufacturing; Materials; Methods, and Applications, Society of Manufacturing Engineers, Dearborn, MI, 1989. 12. Whitney, J.M., Daniel, I.M., Pipes, R.B.: "Experimental Methods of Fiber Reinforced Composite Materials," SESA Monograph Number 4, Prentice-Hall, Englewood Cliffs, NJ, 1982.

Вам также может понравиться

- Modeling and Analysis of Offshore Jacket PlatformДокумент9 страницModeling and Analysis of Offshore Jacket Platformgkc1977100% (1)

- VDIДокумент19 страницVDIBakkiyaraj VeluОценок пока нет

- Heritage Architecture (Ivatan House)Документ45 страницHeritage Architecture (Ivatan House)Hazel Acidre100% (1)

- Design and Manufacturing Guideline For Aerospace CompositesДокумент11 страницDesign and Manufacturing Guideline For Aerospace CompositesBrice_ParmentierОценок пока нет

- Design Requirements For Bonded and Bolted Composite StructuresДокумент50 страницDesign Requirements For Bonded and Bolted Composite Structurespest619Оценок пока нет

- Structural Laminate Composites For Space Applications: Preferred Reliability PracticesДокумент8 страницStructural Laminate Composites For Space Applications: Preferred Reliability PracticeskamjulajayОценок пока нет

- Designing Exhaust Manifolds Using Integral Engineering SolutionsДокумент11 страницDesigning Exhaust Manifolds Using Integral Engineering SolutionsAltemir Manzanete100% (2)

- Design of Pressure Vessel Using Computational TechniquesДокумент13 страницDesign of Pressure Vessel Using Computational TechniquesIJRASETPublicationsОценок пока нет

- Comparison Study Between 2D Reinforced Concrete Element Design Methodologies Using Automated Design Software For Nuclear StructuresДокумент10 страницComparison Study Between 2D Reinforced Concrete Element Design Methodologies Using Automated Design Software For Nuclear StructuresKathlene Lacosta LastimosaОценок пока нет

- Wing Design IonДокумент10 страницWing Design IonXavi VergaraОценок пока нет

- Applications Using Finite Element Methods To Reduce The Cost of Composite StructuresДокумент25 страницApplications Using Finite Element Methods To Reduce The Cost of Composite StructuresVenkata DineshОценок пока нет

- Design Requirements For Bonded and Bolted Composite StructuresДокумент52 страницыDesign Requirements For Bonded and Bolted Composite Structuresarun_justin_1Оценок пока нет

- Ufgs 07 31 26 Slate ShinglesДокумент13 страницUfgs 07 31 26 Slate ShinglessharethefilesОценок пока нет

- PIP STC01018 (Blast Resistant Building Design Criteria)Документ55 страницPIP STC01018 (Blast Resistant Building Design Criteria)Liu Leo100% (3)

- Thermal Analysis of Ic Engine Piston Usi PDFДокумент3 страницыThermal Analysis of Ic Engine Piston Usi PDFCristianОценок пока нет

- Cost - Weight Optimization of Composite Prepreg Structures For Best Draping StrategyДокумент24 страницыCost - Weight Optimization of Composite Prepreg Structures For Best Draping StrategyBeyza AlganОценок пока нет

- Spring 2020 - MD & CAD 1 - CEPДокумент2 страницыSpring 2020 - MD & CAD 1 - CEPHafiz AbdulRehman0% (1)

- VTT R 01177 17Документ27 страницVTT R 01177 17Joseph BookerОценок пока нет

- AppNote 07 FPSO and Offshore PlatformsДокумент4 страницыAppNote 07 FPSO and Offshore PlatformsRao MadepalliОценок пока нет

- SHM Paper PublishedДокумент12 страницSHM Paper Publishedravali kondaОценок пока нет

- Hyper SizerДокумент16 страницHyper SizerKamlesh Dalavadi100% (1)

- 4327 12266 1 PB PDFДокумент22 страницы4327 12266 1 PB PDFPrasad RaikarОценок пока нет

- Performance Evaluation of An Airfoil Fabricated Through Additive Manufacturing, Using Simulation and Experimental TechniquesДокумент15 страницPerformance Evaluation of An Airfoil Fabricated Through Additive Manufacturing, Using Simulation and Experimental TechniquesIJRASETPublicationsОценок пока нет

- Fatigue Life of AA7075Документ10 страницFatigue Life of AA7075Murali SiddarthОценок пока нет

- Campatelli - ComparativoДокумент11 страницCampatelli - ComparativoHenrique Cechinel CasagrandeОценок пока нет

- Design and Analysis of Wishbone For Double Wishbone Suspension SystemДокумент4 страницыDesign and Analysis of Wishbone For Double Wishbone Suspension SystemCoversTamil.MОценок пока нет

- Chemical Treatment - 90% Dimethylketone and 10% Water - ABS PartsДокумент4 страницыChemical Treatment - 90% Dimethylketone and 10% Water - ABS Partsadityakashyap.pdm22Оценок пока нет

- Aircraft Materials PDFДокумент15 страницAircraft Materials PDFza chohanОценок пока нет

- Engineering Fracture Mechanics: T. Ghidini, C. Dalle DonneДокумент15 страницEngineering Fracture Mechanics: T. Ghidini, C. Dalle DonnemnoghabiОценок пока нет

- Stress Analysis of Landing Gear of Light UnmannedДокумент7 страницStress Analysis of Landing Gear of Light Unmannedshayant nandiОценок пока нет

- Finite Element Analysis of Gasket in Pressure VesselДокумент6 страницFinite Element Analysis of Gasket in Pressure VesselIJRASETPublicationsОценок пока нет

- Core NeutronicsДокумент28 страницCore NeutronicsmayankigcarОценок пока нет

- Preliminary Design of Wellhead Spacer Spool Based On The API Acceptance CriteriaДокумент10 страницPreliminary Design of Wellhead Spacer Spool Based On The API Acceptance CriteriaEDWIN M.PОценок пока нет

- Aiaa 2003 0696 PDFДокумент11 страницAiaa 2003 0696 PDFSyed Ñąveed HąįdeŕОценок пока нет

- 1 s2.0 S2214785321032168 MainДокумент7 страниц1 s2.0 S2214785321032168 Mainsachinphalswal19Оценок пока нет

- Fire Ge Call2Документ7 страницFire Ge Call2utsav mannuОценок пока нет

- QTR Ch8 - Composite Materials and Manufacture Feb-13-2015Документ37 страницQTR Ch8 - Composite Materials and Manufacture Feb-13-2015Omar MalikОценок пока нет

- Implication of IRC 112 - 2011 On RCC Bridge DesignДокумент8 страницImplication of IRC 112 - 2011 On RCC Bridge DesignkrunalОценок пока нет

- Applsci 13 13218Документ17 страницApplsci 13 13218bareya.eztuОценок пока нет

- A1 102 HydroДокумент11 страницA1 102 HydronasrunОценок пока нет

- Chapter 5Документ24 страницыChapter 5maherkamelОценок пока нет

- Adigrat University: College of Engineering and Technology Department of Chemical EnginneringДокумент39 страницAdigrat University: College of Engineering and Technology Department of Chemical EnginneringSeid Aragaw100% (1)

- Shape Optimizatoin of Holes in Loaded PlatesДокумент131 страницаShape Optimizatoin of Holes in Loaded PlatesSaketh VandeОценок пока нет

- MMCV312 Final Exam Solutions - 2022 - ULДокумент10 страницMMCV312 Final Exam Solutions - 2022 - ULPraveet ChandОценок пока нет

- GFRP NCODE Designlife DigimatДокумент11 страницGFRP NCODE Designlife DigimatKruthika K CОценок пока нет

- Ufgs 07 41 13.16 Metal Roof PanelsДокумент12 страницUfgs 07 41 13.16 Metal Roof PanelssharethefilesОценок пока нет

- Cost Study Infusion Vs PrepregДокумент17 страницCost Study Infusion Vs PrepregAjith Krishnan100% (1)

- Aiaa Mdo TC 1998 White Paper On MdoДокумент426 страницAiaa Mdo TC 1998 White Paper On MdoFlávio CoutinhoОценок пока нет

- Approved Report For Other EpcДокумент41 страницаApproved Report For Other Epcirshad khanОценок пока нет

- Design and Stress Analysis of FRP Composite Pressure VesselДокумент8 страницDesign and Stress Analysis of FRP Composite Pressure VesselIJMTST-Online JournalОценок пока нет

- Tensile Test For Environmental Effect On Glass Fiber Composite MaterialsДокумент5 страницTensile Test For Environmental Effect On Glass Fiber Composite MaterialstheijesОценок пока нет

- Design Optimization of Stiffened Composite Panels With Buckling and Damage Tolerance ConstraintsДокумент14 страницDesign Optimization of Stiffened Composite Panels With Buckling and Damage Tolerance ConstraintslumpertОценок пока нет

- Automated Transient Thermography For The Inspection of CFRP Structures: Experimental Results and Developed ProceduresДокумент11 страницAutomated Transient Thermography For The Inspection of CFRP Structures: Experimental Results and Developed Procedurestakis1980Оценок пока нет

- Structural Analysis of Carbon Fiber 3D-Printed Ribs For Small Wind Turbine BladesДокумент14 страницStructural Analysis of Carbon Fiber 3D-Printed Ribs For Small Wind Turbine BladesGogyОценок пока нет

- 2013 Kim EffectOfTemperature-inducedLoadOnAirportConcretePBehavior 6478-English-TarjomeFaДокумент6 страниц2013 Kim EffectOfTemperature-inducedLoadOnAirportConcretePBehavior 6478-English-TarjomeFahieputcОценок пока нет

- Wind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsОт EverandWind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsОценок пока нет

- Corrosion and Corrosion Protection of Wind Power Structures in Marine Environments: Volume 2: Corrosion Protection MeasuresОт EverandCorrosion and Corrosion Protection of Wind Power Structures in Marine Environments: Volume 2: Corrosion Protection MeasuresОценок пока нет

- 04 Barriers Parapets RailingsДокумент36 страниц04 Barriers Parapets RailingsTheDark Lord100% (1)

- Table 6 1 AWS D1 1 D1 1M 2010 PDFДокумент1 страницаTable 6 1 AWS D1 1 D1 1M 2010 PDFFu AdОценок пока нет

- Development of A Device For Brazing Copper Pipes in HVAC InstallationsДокумент8 страницDevelopment of A Device For Brazing Copper Pipes in HVAC InstallationsJournal of Interdisciplinary PerspectivesОценок пока нет

- Uji Petik DT Ob 022022Документ11 страницUji Petik DT Ob 022022RaynaldiSaputraОценок пока нет

- Guideline For Quality Management of Concrete BДокумент62 страницыGuideline For Quality Management of Concrete BRam KrishnaОценок пока нет

- BrsuhcoatДокумент1 страницаBrsuhcoatpravi3434Оценок пока нет

- Fill Height TablesДокумент16 страницFill Height TablesDipendra ShresthaОценок пока нет

- St-Nerf-20 Basement Floor PlanДокумент1 страницаSt-Nerf-20 Basement Floor Planmhazarath murariОценок пока нет

- Reinforced Concrete Design (RCD - 1) Introduction and Theory III Lecture NotesДокумент26 страницReinforced Concrete Design (RCD - 1) Introduction and Theory III Lecture NotesColene GammadОценок пока нет

- Axially Loaded Compression MembersДокумент19 страницAxially Loaded Compression MembersAnjielo AusaОценок пока нет

- National Annex To EurocodeДокумент20 страницNational Annex To EurocodeYaselaОценок пока нет

- Mailing Address/Contact: Present:: S.M. Mohsi-Ul-AnisДокумент3 страницыMailing Address/Contact: Present:: S.M. Mohsi-Ul-AnisAnisОценок пока нет

- Hoa Report Muslim ArchitectureДокумент38 страницHoa Report Muslim Architecturethe dankiest mmemmОценок пока нет

- M.tech Curriculum 0Документ49 страницM.tech Curriculum 0Yash DhabaliaОценок пока нет

- Pavement Design Concepts-Flexible PavementsДокумент3 страницыPavement Design Concepts-Flexible PavementsSuryasis DasguptaОценок пока нет

- Katalog 2020 enДокумент148 страницKatalog 2020 enAlejandro BoccoОценок пока нет

- Radiator CapДокумент6 страницRadiator CapHafiz حافظ شاهОценок пока нет

- ASHARE 36 Aee - April - 2021 - Ashrae - Guideline - 36Документ42 страницыASHARE 36 Aee - April - 2021 - Ashrae - Guideline - 36Mike KennedyОценок пока нет

- Job Advert-Technical Projects CoordinatorДокумент3 страницыJob Advert-Technical Projects CoordinatorKenn MatibaОценок пока нет

- SSL AttachmentДокумент22 страницыSSL AttachmentFulkan HadiyanОценок пока нет

- AISC Properties DatabaseДокумент7 страницAISC Properties DatabaseShekh Muhsen Uddin AhmedОценок пока нет

- AGPT04J-08 Aggregate and Source RockДокумент34 страницыAGPT04J-08 Aggregate and Source RockSteveОценок пока нет

- FSA 0180 CoДокумент58 страницFSA 0180 CoNagamani ManiОценок пока нет

- Data Mesin Pendingin GMCP Kendari: NO Nama Part MesinДокумент10 страницData Mesin Pendingin GMCP Kendari: NO Nama Part Mesinrosiyady pusdika candra seОценок пока нет

- Special Repair of Biswa Dehat Link RoadДокумент15 страницSpecial Repair of Biswa Dehat Link Roadamit singhОценок пока нет

- Surrey ENGM030 Unit 1 PresentationДокумент44 страницыSurrey ENGM030 Unit 1 PresentationPhilip YapОценок пока нет

- CTBUH2020 Brochure PDFДокумент28 страницCTBUH2020 Brochure PDFgrahambrasicОценок пока нет

- DDDDДокумент185 страницDDDDJosé FernándezОценок пока нет

- Devi Heating CalculationДокумент2 страницыDevi Heating CalculationJohn AriesОценок пока нет