Академический Документы

Профессиональный Документы

Культура Документы

Battery & Charger Spec for LPG Terminal

Загружено:

smi249Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Battery & Charger Spec for LPG Terminal

Загружено:

smi249Авторское право:

Доступные форматы

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 Rev: A Page 1 of 11

SPECIFICATION FOR BATTERY & BATTERY CHARGER (D.C. SYSTEM)

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 Rev: A Page 2 of 11

List of Contents

Pages

1.0 2.0 2.1. 2.2. 2.3. 2.4. 2.5. 2.6.

Scope...............................................................................................................................3 Technical Specification...................................................................................................3 Mode of Operation: Design Criteria Battery Charger SMF (VRLA) Battery D.C. Distribution Board Component Specification 3 3 4 7 8 9

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 Rev: A Page 3 of 11

1.0

1.1

Scope

This specification intended to cover Design, Engineering, Manufacture, Assembly, Painting, Inspection, Testing at manufacturers works, Delivery to site inclusive of packing & transportation, Testing and Commissioning assistance of Battery, Battery Charger & DCDB complete with all accessories. 1 set of 110V D.C. system (Battery, Battery Charger & DCDB) in accordance with this specification, standards stated herein and Appendices enclosed herewith, shall comprise of the following: a) b) c) d) SMF (VRLA) Battery complete with racks & accessories. One No. Float charger. One No. Float cum Boost charger. DCDB

1.2 1.3 1.4

This specification shall be read in conjunction with Tender for Major Electrical Equipment. All equipment supplied shall be new and best of their respective kinds and shall be of the class most suitable for the purpose for which they are intended. Modification / changes in components, if any suggested during scrutiny / approval of drawings and execution of work shall be carried out by successful vendor at no extra cost.

2.0

2.1. 2.1.1

Technical Specification

Mode of Operation: Under the normal conditions, i.e. when A.C. supply is available at Battery Charger input terminals, the float charger shall supply the continuous D.C. load plus the float/trickle charging current of the Battery. In addition some of the impulse loads of duration less than a minute shall also be fed by charger. Therefore, charger shall be designed to meet such momentary overload conditions. In the event of failure of A.C. supply, the emergency D.C. load shall be supplied by the Battery for the duration of 2 Hrs. On restoration of A.C. supply, the Float charger shall supply the load current and Float cum boost charger shall charge the battery. During such conditions battery remains connected to load through intermediately tapped cell. Each diode shall be rated to carry the maximum discharge current of the battery. An interlock shall be provided such that when boost charger is charging the battery, the float charger gets disconnected automatically from battery, through D.C. contactor. D. C. contactor shall be rated to carry safely the various currents of the Batteries. Power supply for D.C. contactor coil shall be derived from Battery terminals. Design Criteria The battery shall be used to supply protection & control circuits of electrical Breakers, annunciators, D.C. critical lighting etc. independently of outside power sources. The Battery Backup power shall be available for 120 minutes in the event of complete power failure. The battery sizing shall account for suitable temperature correction factors, ageing factors of 1.25, depth of discharge of 80%.

2.1.2 2.1.3

2.1.4

2.2. 2.2.1

2.2.2

2.2.3

Load details for determining load cycle

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 Rev: A Page 4 of 11

Load cycle shall be decided based on the following load details: A) First minute : i) ii) 33kV breaker trip coil - 3 nos LV incomer breaker trip coil - 3 nos

B) Last minute : i) ii) 33kV breaker closing coil - 3 nos LV incomer breaker closing coil - 3 nos

C) Continuous load : i) ii) Emergency lighting load 1500watts All indicating lamp, annunciator window, multifunction meter shall be continuous and vendor to workout in detail to size the battery.

Vendor shall calculate the AH capacity of battery based on the above load details and furnish sizing calculations and backup documents/graphs, along with the offer. 2.2.4 The Float Charger shall be used to supply normal D.C. loads and float charging current of charged Battery. The Float cum Boost charger shall be designed to supply boost charging current requirement of the associated battery as well as to supply normal D.C.Load. After full discharge of battery bank, the Float Cum boost charger shall be capable of charging the battery to its full capacity in 8 hours duration while supplying normal D.C.Load. Output voltage shall not vary more than 10%; Vendor shall specify output voltage regulator or dropping diode etc. used to achieve the above requirement. The end cell voltage after discharge shall be limited to 1.75 volts/cell. The rating of battery charger shall be suitable for the battery size selected. Vendor shall size the Charger, suitable to chosen Battery AH capacity and furnish charger sizing calculations along with the offer. Complete Battery charger system including rectifier, battery, static switches etc. shall have 15% spare capacity for future load growth. DC distribution board shall be provided to feed various loads. The provision of incoming and outgoing feeders on DC distribution boards shall be as specified in the enclosed SLD in Attachment-3. The maximum temperature rise in any part of the equipment as well as that of any component and their terminals while delivering rated current shall not exceed the permissible limits stipulated in relevant standards. The Battery, Battery Charger & DCDB shall be located in substation having clean but hot, humid and tropical atmosphere. All equipment shall be designed to operate satisfactorily under the ambient and environmental conditions specified. Batteries shall not be located in separate room. Maximum noise level of charger shall be less than 80 dB. Battery Charger Constructional features: a) The charging equipment shall be housed in a free standing, floor mounted compartmentalized panels having separate compartments for float and float cum boost charging equipment, battery connection to DC bus, DC distribution equipment, including incoming feeders and outgoing feeders in different compartments. Panels shall have provision for bottom entry of cables with removable cable gland plate. (i.e. separate compartmentalised panels for each float charger, float cum boost charger and DC distribution).

2.2.5 2.2.6 2.2.7

2.2.8

2.2.9 2.3. 2.3.1

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 b) Rev: A Page 5 of 11

The panel shall be of CRCA sheet steel construction and provided with concealed hinges. Adequate ventilating grills or louvers with fine brass wire mesh shall be provided. Thickness of sheet steel shall be at least 2.0 mm. Degree of protection provided by the enclosure to the internals of charger shall be IP-42. The instruments, switches and indicating lamps shall be flush mounted on the front panel. Suitable neoprene rubber gaskets shall be provided all around doors and cover plates, between two shipping sections, two charger sections, two panel sections, for making charger construction dust and vermin proof. All PCBs used in the charger shall be made of glass epoxy material. Electronic cards shall be plug in type and shall be mounted on standard racks. Rack shall have PCB guides which shall allow the insertion of PCBs smoothly without requiring force. Racks shall be mounted on hinged pivot to enable the rack to be turned for access to back side terminals. PCBs shall include status indicating LED lights and test connections in the front to facilitate fault diagnosis. PCBs shall be identified with proper permanent labels as per approved drawings.

c) d)

e)

2.3.2

Operation a) The Battery charger shall be with static Silicon Controlled Rectifiers (SCRs), It shall be complete with filter circuits to limit the ripple within 1% (RMS) in the DC output. The rectifier transformers shall be of dry type, AN cooled, vacuum impregnated double wound with adequate number of primary taps. Transformer shall be ClassB insulation having a continuous rating at least 125 % of the rating of the charger. Reactance of transformer shall be suitable to take care of regulation and surges. Battery charger shall be designed for a maximum voltage ripple of 1 % (rms) when connected to a battery with an ampere-hour capacity equal to or greater than four times the ampere capacity of the charger. The rectifier-charger shall be of the current-limiting type set not higher than 125 % for the solid state design. Charger shall be current limited to both the float and equalize positions in order to protect the equipment from a short circuit on the load side. The rectifier-charger shall have a minimum power factor (PF) of 0.8 under the following operating conditions: -15 % of the rated input voltage -5 % of the rated frequency Full rectifier output f) g) h) A walk-in circuit shall be provided to limit in-rush current to 110 % of rectifier/charger full-load current. The RMS sum of all harmonics in the input waveform shall not exceed 10 % of the RMS value of the fundamental harmonic with the system operating at rated voltage and current. The charger output shall be filtered to eliminate any harmonics superimposed on the rectifier output voltage.

b)

c) d) e)

2.3.3

Voltage Regulation a) The float charger shall have both auto and manual voltage regulation arrangements with provision of selector switch. Output DC voltage shall not vary beyond 1% of the set value when controlled through AVR with load varying from no load to full load simultaneously with specified fluctuations in input voltage and frequency.

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 b) Rev: A Page 6 of 11

Charger output voltage shall vary no more than 10 as a result of a transient 4,000-volt peak lasting 100 microseconds with 40-ohm source impedance, the batteries, and the full load connected.

2.3.4

Controls a) The Float cum boost charger shall be complete with manually controlled motorized, variac and three phase rectifier bank. The voltage regulation shall be uniform and step less throughout the voltage variation range. For achieving this, voltage Raise/Lower push buttons shall be provided on front of float cum boost charger section. An interlock shall be provided in the float cum boost charger so that float cum boost charger can be made ON only when the autotransformer is in minimum position. The float charger controller shall have built in load limiting feature, which will limit the load on charger in the event of overload and reduce the output voltage in order to transfer the load to the battery. The current setting of load limiting device shall be uniformly adjustable between 100% and 150% of full load. Charger shall be provided with all required float and equalizer controls. Chargers shall be provided with an automatic charging control circuit to switch the rectifier output automatically from float charging to equalize charging if the charger is in current limit for more than 30 seconds. Equalize charging time shall be controlled by a timer that has an adjustable setting from 8 to 12 hours.

b)

c)

2.3.5

Protection, Indicators & Alarms a) The rectifier equipment shall be complete with heat sink and have its own protective devices. In addition, surge protection devices and fast acting HRC fuses suitable for rectifier protection shall be provided in each arm of rectifier connections. Battery charger shall be furnished with the manufacturer's standard indicating and Audio & Visual alarm devices, which shall include, but not be limited to, the following: AC circuit breaker and AC power-on light AC power-failure relay for remote alarm AC under voltage DC disconnect switch, without over current protection DC ground-detection lights with relay for remote alarm contacts DC under voltage & over voltage. DC positive to earth and D.C. negative to earth faults. Low DC-voltage relay for remote alarm DC voltmeter and ammeter with 2-percent accuracy Charger failure alarm (loss of DC current) Float & Float cum Boost charger rectifier fuse failure. Float/ Float cum Boost charger D.C. side output fuse failure. Float charger overload. Float cum Boost charger overload. Battery Fuse Failure Float and equalize potentiometer and selector switch to override automatic charge control

b)

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 Equalize pilot light Battery-disconnected relay for remote alarm Chargers-out-of-balance relay for remote alarm (for load sharing chargers) Unit of common alarm contact for remote indication c) d) e) Alarms shall have local indication on the battery charger. Indicator lamps on the charger panel shall be operated at no more than 75 of the rated voltage of the lamp for extended life. If cooling fans are approved, an alarm shall be provided to signal a loss of ventilation. A sail switch upstream of the cooling fans shall activate the alarm. The sail switch shall be mounted inside the charger enclosure. Alarm contacts shall be rated for 5 amps at 110 volts DC for connection to a remote annunciator. Isolated alarm contacts shall be provided. The contacts shall open to actuate the alarms. Rev: A Page 7 of 11

f)

2.4. 2.4.1

SMF (VRLA) Battery General Features a) The chargeable batteries shall be Lead acid maintenance free (SMF-VRLA). type of nominal voltage specified in SLD in Attachment-3. The end cell voltage after discharge shall be limited to 1.75 volts/cell. Batteries shall not require any water topping up and shall emit no corrosive fumes or gases under normal operating conditions. The batteries shall be supplied along with the necessary mounting racks or sheet steel enclosure complete with the provision for clamping the cables. Battery racks shall be of steel frame with epoxy painted/ PVC lined. Vendor shall indicate the ventilation requirements if any, for the battery.

b)

c) 2.4.2

Constructional features a) Electrolyte The Electrolyte shall be of battery grade sulphuric acid. b) Plates The Positive & Negative plates shall be constructed of heavy duty lead alloy grids type .The plates shall be corrosion resistant & shall have low self discharge properties. The plates shall be designed for maximum durability during all service, conditions including high rate of discharge and rapid fluctuation of load. c) Containers & Covers Each cell shall be assembled in high grade, flame retardant polymer or moulded hard rubber container. The container shall be leak proof, non-absorbent, shock absorbing not liable to deformation within the range of working temperature and not affected by the acid. Electrolyte high-level and low-level lines shall be marked on at least two of the four sides of a cell and visible from the front of the completed assembly. A permanent airtight seal shall be provided between the cover & container to stop electrolyte & air leakage. The container shall be designed to withstand the pressure caused by charging & discharging characteristics of the battery.

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 d) Cell lids Cells lids shall be of glass, plastic or ebonite complete with either suitable rubber gasket for closed type or bituminous sealing compound for sealed type of containers. e) Safety Vents Flame arresting vent plug housing the safety valve shall be provided. The vent plugs shall be explosion proof, self resealing, resisting acid overflow and pressure regulating types. The valve shall be automatically sealed to prevent diffusion of air. f) Separators Separator between plates shall permit free flow of electrolyte and shall maintain the electrical insulation between the plates. Separators shall be of wood or high density absorbent Glass MAT non woven with excellent porosity. g) Connectors Lead coated copper connectors shall be furnished to use as inter cell, interior, inter tier and inter row connectors. The lead plating shall be adequate to ensure proper protection against corrosion during the entire life of the battery. Nuts, bolts and washers shall be of lead coated copper. h) Terminal Posts The cell terminal posts shall be provided with connector bolts and nuts, effectively coated with lead to prevent corrosion. Positive and negative terminal posts shall be clearly and indelibly marked for easy identification. Lead plated plate, tubular tinned copper lugs, bolts, nuts, washers etc. shall be furnished for connection of outgoing purchasers aluminium conductor cables. Intermediate posts for easy termination of purchasers cable shall be provided. i) Cell Insulators The cells shall be supported on hard rubber/PVC pads, fixed on the rack with adequate clearance between the adjacent cells. j) k) 2.5. 2.5.1 All hardware necessary for complete assembly of system shall be provided. A disconnect switch shall be provided near battery bank for isolation of batteries. Rev: A Page 8 of 11

D.C. Distribution Board Constructional Features a) b) D.C. Distribution Board shall be a separate panel, but shall form an integral part of a panel board, when placed by the side of the charger panels. Cubicle door shall have rolled edges with suitable neoprene gasket to make it dust proof. The door shall be provided with lock and key arrangement to prevent unauthorised opening of the door. Outgoing MCB/Fuse mounting plates shall be adequately braced to avoid wobbling during pulling or insertion of fuses. DCDB shall comprise of double pole MCBs as specified in SLD attached in Attachment-3.

c) d) 2.5.2

Bus bars a) b) Busbars in the battery charger and DCDB shall be Aluminium liberally sized for the specified current rating (both short circuit and continuous currents.) The main horizontal busbars of distribution boards shall be located in a separate chamber extending over entire length. Bus bar chamber shall have separately screwed covers. All bus bars, links, etc. shall be provided with heat-shrinkable insulating sleeves to prevent accidental contacts.

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 c) d) e) Rev: A Page 9 of 11

Power shall be distributed to each circuit in each section by flexible copper conductor cables. Buses shall be spaced with adequate clearances between positive and negative and between positive/negative and ground. Minimum clearance shall not be less than 25 mm. Bus supports shall be of arc resistant, non tracking low moisture absorption type moulded insulators of high impact strength and high Creepage surface. Material of bus supports shall be cast epoxy resin/DMC/SMC. Supports for each bus shall be independent from support for other phase/pole busbar. All bus works shall be braced to withstand stresses due to short circuit current without damage. Colour code shall be used to identify the busbars as per relevant standards. Suitable sleeving shall be provided over busbars for insulating the same as secondary insulation.

f) g) 2.5.3

Low Voltage Disconnect DC Power System shall be supplied with a low voltage disconnect which will automatically disconnect the load from the battery upon low voltage to prevent the battery from becoming completely discharged on charger malfunction or failure. The low voltage disconnect shall have an adjustable trip point and shall be capable of breaking full DC load current.

2.6. 2.6.1

Component Specification Switches/ MCCBs/MCBs a) Switches or 4 pole MCCBs as per SLD shall be provided for incomer. MCCBs/A.C. Switches shall be four pole, air break and heavy duty type, capable of safely breaking the full load current of associated feeder. A.C. incoming MCCB/Switch shall have a quick-make, quick-break mechanism operated by a suitable external handle complete with position indicator. b) MCBs for outgoing feeders shall be double pole type, and shall be suitably rated to make and break and carry the rated D.C. current.

2.6.2

Fuses a) Fuse shall be HRC, link type, with a maximum rupturing capacity suited for rated voltage. Rewirable fuses shall not be acceptable. Fuses provided for protection of rectifier shall be of the type suitable for the intended duty. b) Fuses shall be furnished complete with fuse bases and carriers of such design as to permit easy replacement of fuse elements. Visible indication shall be provided on blowing of the fuse. c) The incomer fuse rating shall be so chosen as to provide discrimination with feeder fuses.

2.6.3

Contactors Contactors shall be air break type with 2 NO + 2NC auxiliary contacts. Utilisation category shall be AC-1 or DC-1. Continuous current rating of contactors shall be at least 15% higher than full load current of connected equipment.

2.6.4

CTs and PTs CTs and PTs shall be of epoxy resin cast type. Accuracy class of the metering CTs and PTs shall be 1.0.

2.6.5

Relays Relays shall be microprocessor/static type. Further, relays shall be draw out plug in type and shall be provided with hand reset type flag indicator. Thermal overload relays shall be ambient temperature compensated and shall be hand reset type.

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 2.6.6 Meters a) Meters shall be square type, flush mounting. b) Each meter shall be provided with zero adjuster on the front. c) Accuracy of the meters shall be 3%. d) Minimum size of the meters shall be 96 mm x 96 mm and meters shall be of taut band type. e) Meters shall be operated from outputs of CTs/PTs/DC shunts as required. Rev: A Page 10 of 11

2.6.7

Following control switches/ pushbuttons to be provided as a minimum. a) ON /OFF control switch for AC supply to charger. b) Auto / Manual selector switch to select mode of operation. c) Potential meters for voltage & current adjustment in float mode. d) Potential meters for voltage & current adjustment in Float cum Boost mode.

2.6.8

Push Buttons and Indicating Lamps a) Push Buttons and Indicating Lamps shall be panel mounting type. b) Lamps shall be clustered LED type with low watt consumption. c) Push Button actuator shall be shrouded with dust tight rubber grommet cover. Associated springs and contacts shall be of robust construction. Push Button shall be provided with integral escutcheon plates with 2NO + 2NC contacts rated to make, break and carry 5A DC at 110V, 30V or 220V DC.

2.6.9

Space Heaters & Panel a) Each vertical section of panel shall be provided with thermostat controlled space heaters rated 240 volts, single phase, 50 Hz. The heaters shall have individual ON-OFF MCB. b) Wiring of space heaters in each board shall be grouped and brought out to easily accessible terminals. c) Cubicle illumination lamp along with MCB operating on 240V, 1 phase supply shall be provided. Lamp operation shall be controlled through door limit switch. d) 240V supply shall be suitably tapped by vendor from incoming supply.

2.6.10

Wiring a) The wiring shall be complete in all respects so as to ensure proper functioning of control, protection, interlocking and measurement schemes. b) Control wiring shall be done with flexible, heat resistant, switchboard wires; 650/1100V grade, multi-stranded copper conductor. Each wire shall be identified at both ends using engraved ferrules designation in accordance with the approved wiring diagram. Interlocking type plastic ferrules shall be used for identification. Minimum size of the wires used for plug cord for electronic cards shall be 0.5mm2 copper. Wires shall not be spliced or tapped between terminal points. Wherever wires cross sheet steel barriers rubber grommets shall be provided around holes in sheet steel barrier. All internal wires shall be terminated with tinned copper crimping type lugs.

2.6.11 Cable Termination a) Distribution boards shall be designed to facilitate cable entry from bottom. Removable undrilled plates shall be furnished for this purpose. Sufficient space shall be provided to avoid sharp bending and for ease of connection, a minimum space of 300mm from the gland plate to the nearest terminal shall be provided.

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

VISAKH MARKETING INSTALLATION RESITEMENT PROJECT LPG TERMINAL Doc No: 256324-500-SP-ELE-006 Rev: A Page 11 of 11

b) Multiway, clip on type terminal blocks complete with screws, nuts, washers, and marking strips shall be furnished for terminating the internal wiring and outgoing control cables. Stud type terminals shall be provided for power cables. c) Each control terminal shall be capable of connecting 2 nos. 2.5 sq. mm copper wire at one end without any damage to the conductor or any looseness of connection.. 2.6.12 Ground Bus a) Copper ground bus of size 25mm x 6mm shall be furnished along the entire length of each section of Battery Charger and DCDB. b) Each equipment of board shall be connected directly to the ground bus by two separate and distinct connections. Doors of charger shall be effectively earthed through flexible copper wires of adequate size. c) Grounding terminals on the ground bus shall be provided at two points of the Battery Charger. Connectors shall be provided at either ends for connection to Purchasers ground conductor. d) DC Power shall be Ungrounded.

P:\Andheri\IndiaProject\256324 HPCL- LPG\10 Procurement\TENDER\15 Major Electrical Equipment Package\Final Tender 24-Aug09\Editable\Annexure- 6\Specification for Battery & Battery Charger.doc

Вам также может понравиться

- 44ac2700-00-E.05-0005-A4 - DC Ups SizingДокумент14 страниц44ac2700-00-E.05-0005-A4 - DC Ups SizingSatrajit BanerjeeОценок пока нет

- Technical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationДокумент30 страницTechnical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationS.M.Touhidur RahmanОценок пока нет

- Build Your Own EMP GeneratorДокумент22 страницыBuild Your Own EMP GeneratorMark Reichfeld100% (1)

- Uhp SCT E00 XJ C 0001 x0 Calculation For BedgДокумент116 страницUhp SCT E00 XJ C 0001 x0 Calculation For Bedgwaqqar shaikhОценок пока нет

- 110V Battery Sizing - Ni-Cad-Dhunge Shangu SS - Rev-02Документ21 страница110V Battery Sizing - Ni-Cad-Dhunge Shangu SS - Rev-02Janmejey BarikОценок пока нет

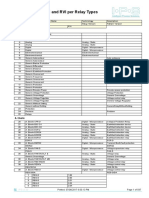

- IPS-ENERGY - Available Relay ModelsДокумент597 страницIPS-ENERGY - Available Relay Modelsbrahim100% (2)

- Parts ListДокумент7 страницParts Listnguyencongthanh2011Оценок пока нет

- BUSHING CT SIZINGДокумент9 страницBUSHING CT SIZINGNageswar MakalaОценок пока нет

- 11kv VT Sizing CalДокумент16 страниц11kv VT Sizing CalChilukuri Jithendra100% (2)

- Acdb Relay Setting - 21.04.16Документ6 страницAcdb Relay Setting - 21.04.16Mohideen SikanderОценок пока нет

- Civil Design and Construction of 132kv 66kV and 33kV SubstationДокумент31 страницаCivil Design and Construction of 132kv 66kV and 33kV SubstationJohn John Pechjhon100% (7)

- REF & MetrosilДокумент1 страницаREF & MetrosilNeeraj SinghОценок пока нет

- Power Factor CorrectionДокумент5 страницPower Factor CorrectionAsif SajwaniОценок пока нет

- UPS SpecificationДокумент15 страницUPS Specificationpreetam100% (1)

- Marcel - Dekker.protective - Relaying.theory - And.applications.2nd - Ebook TLFeBOOKДокумент426 страницMarcel - Dekker.protective - Relaying.theory - And.applications.2nd - Ebook TLFeBOOKMahesh Singh94% (17)

- 1600kVA EBG 33kV GIS DTT REF Settings PDFДокумент2 страницы1600kVA EBG 33kV GIS DTT REF Settings PDFManu ManojОценок пока нет

- 110V Battery SizingДокумент13 страниц110V Battery SizingsofianeОценок пока нет

- Ni-CD Battery Charger SpecificationДокумент18 страницNi-CD Battery Charger SpecificationAdrianne DouglasОценок пока нет

- Introduction To Batteries & UPS StandardsДокумент6 страницIntroduction To Batteries & UPS StandardsMohamed EldinОценок пока нет

- LV Relay SettingДокумент12 страницLV Relay SettingRatheesh KumarОценок пока нет

- Coil Winder Instructions.: Parts ListДокумент10 страницCoil Winder Instructions.: Parts Listsmi249Оценок пока нет

- 50/75/100 MVA, 220/132 KV & 50/75/100 MVA, 22/33 KV Outdoor SubstationДокумент16 страниц50/75/100 MVA, 220/132 KV & 50/75/100 MVA, 22/33 KV Outdoor Substationdeepthik27Оценок пока нет

- Short Circuit ABC Learn It in An Hour, Use It Anywhere, Memorize No Formula (1974) PDFДокумент12 страницShort Circuit ABC Learn It in An Hour, Use It Anywhere, Memorize No Formula (1974) PDFDanielAlejandroRamosQueroОценок пока нет

- Battery Sizing SS 06Документ6 страницBattery Sizing SS 06aanouar77Оценок пока нет

- Protection Coordination Report: Camerich Paper Private LTDДокумент42 страницыProtection Coordination Report: Camerich Paper Private LTDramesh cuppuОценок пока нет

- 6Документ23 страницы6api-3854942100% (1)

- Earthing Cal - Rev-01 - As Per Mecon Comnt.Документ9 страницEarthing Cal - Rev-01 - As Per Mecon Comnt.Prateek SinghОценок пока нет

- Battery Charger SpecsДокумент15 страницBattery Charger Specstenk_manОценок пока нет

- Earthing Transformer PDFДокумент13 страницEarthing Transformer PDFNelson SarriasОценок пока нет

- Chapter 4 Differential ProtectionДокумент27 страницChapter 4 Differential ProtectionJames100% (1)

- A Standard Dictionary of Muslim Names For BabiesДокумент191 страницаA Standard Dictionary of Muslim Names For BabiesSultan MohideenОценок пока нет

- VCB PanelsДокумент17 страницVCB PanelsSenthil Prasadh100% (1)

- Paper 2Документ34 страницыPaper 2Bhavik PrajapatiОценок пока нет

- 216kV Surge Arrester Technical SpecificationДокумент16 страниц216kV Surge Arrester Technical SpecificationSolar PowerОценок пока нет

- UPS System Data Sheet SpecificationДокумент15 страницUPS System Data Sheet SpecificationbilalОценок пока нет

- Fault Level Calculations Cal.Документ6 страницFault Level Calculations Cal.sureshnfclОценок пока нет

- Fewa SpecificationsДокумент28 страницFewa SpecificationsAnonymous GdZqtY88ZRОценок пока нет

- Training Report in 220 KV Sub Station of DTLДокумент59 страницTraining Report in 220 KV Sub Station of DTLishank_bounthiyal0% (1)

- Technical Specification 420kV Shunt reactorДокумент59 страницTechnical Specification 420kV Shunt reactordeepak2628Оценок пока нет

- Battery Charger Sizing SS 1, Rev 03Документ15 страницBattery Charger Sizing SS 1, Rev 03Pramod B.Wankhade100% (1)

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsОт EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsОценок пока нет

- VT Sizing Calculation for 132kV Cable Feeder and Bus VTДокумент8 страницVT Sizing Calculation for 132kV Cable Feeder and Bus VTChilukuri Jithendra100% (1)

- Battery Charger Formula IEEE 946Документ2 страницыBattery Charger Formula IEEE 946Lordwin JacksonОценок пока нет

- D.C. Supplies Technical Specification for Battery, Charger InstallationДокумент14 страницD.C. Supplies Technical Specification for Battery, Charger InstallationMohammed Zubair100% (1)

- Required Inputs For Relay Setting CalculationДокумент6 страницRequired Inputs For Relay Setting CalculationIsuru WijewardeneОценок пока нет

- SM10 E0 CA 1109 03 Relay CoordinationДокумент536 страницSM10 E0 CA 1109 03 Relay CoordinationAsif SajwaniОценок пока нет

- Gujarat Energy Transmission Corporation LTD.: 400 KV / 220 KV / 132 KV / 66 KV Gas Insulated Switchgear (Gis)Документ64 страницыGujarat Energy Transmission Corporation LTD.: 400 KV / 220 KV / 132 KV / 66 KV Gas Insulated Switchgear (Gis)Ashwin SevariaОценок пока нет

- Al-Dahiya Grounding 240607 PDFДокумент7 страницAl-Dahiya Grounding 240607 PDFSomnath DasОценок пока нет

- Technical Data 33kV GIS GV3Документ5 страницTechnical Data 33kV GIS GV3muthusamyeeeОценок пока нет

- LT Power Cable Sizing Criteria As Per NTPCДокумент13 страницLT Power Cable Sizing Criteria As Per NTPCAwnish KumarОценок пока нет

- 220kV GIS Tech Spec - TrackДокумент42 страницы220kV GIS Tech Spec - Trackaravind_k104100% (1)

- Package SubstationДокумент9 страницPackage SubstationuddinnadeemОценок пока нет

- Design Basis for 65/81MVA Generator TransformerДокумент9 страницDesign Basis for 65/81MVA Generator Transformersrigirisetty208Оценок пока нет

- DC System SpecsДокумент19 страницDC System SpecsAboudouleОценок пока нет

- Electrical SORДокумент74 страницыElectrical SORkokuei60% (5)

- Relay Setting Calculation-NPC-Yas152Документ15 страницRelay Setting Calculation-NPC-Yas152মোঃ মহসিনОценок пока нет

- DESIGN OF 500kVA 11 0.415kV SUBSTATION O PDFДокумент100 страницDESIGN OF 500kVA 11 0.415kV SUBSTATION O PDFAshok TomarОценок пока нет

- Delta Electronics solar inverter FRT functionsДокумент2 страницыDelta Electronics solar inverter FRT functionsSAEL SOLARОценок пока нет

- Relay Coordination PDFДокумент125 страницRelay Coordination PDFAnonymous kjvaeVJNОценок пока нет

- Catalog SM6Документ81 страницаCatalog SM6adi_neluОценок пока нет

- TS 110V 150AH Batterry Charger Battery DCDBДокумент24 страницыTS 110V 150AH Batterry Charger Battery DCDBkajale.shrikantОценок пока нет

- Motor StartingДокумент16 страницMotor StartingBabar SaleemОценок пока нет

- Is - 1651 - 1991Документ15 страницIs - 1651 - 1991sangitaghaisas100% (1)

- Indian Standard: Application Guide For Electrical Relays For Ac SystemsДокумент16 страницIndian Standard: Application Guide For Electrical Relays For Ac SystemsvenkateshbitraОценок пока нет

- TANTRANSCO TENDER Supply of 11kV & 33kV Outdoor Vacuum Circuit BreakersДокумент71 страницаTANTRANSCO TENDER Supply of 11kV & 33kV Outdoor Vacuum Circuit BreakersKrishnaFBОценок пока нет

- Indian Standard: Specification For Interconnecting Bus-Bars For Ac Voltage Above 1 KV Up To and Including 36 KVДокумент25 страницIndian Standard: Specification For Interconnecting Bus-Bars For Ac Voltage Above 1 KV Up To and Including 36 KVrobinknit2009Оценок пока нет

- Iocl City Gas Distribution Project For GAДокумент4 страницыIocl City Gas Distribution Project For GAsubudhiprasannaОценок пока нет

- Training Programme For Assistant Engineers (2009-10) : Topic: DC Batteries and Battery ChargersДокумент3 страницыTraining Programme For Assistant Engineers (2009-10) : Topic: DC Batteries and Battery ChargersashokОценок пока нет

- Battery Charger Technical SpecificationДокумент24 страницыBattery Charger Technical Specificationkajale.shrikantОценок пока нет

- SizeofDOL StarDeltaStarterPartsДокумент15 страницSizeofDOL StarDeltaStarterPartsHeri IrawanОценок пока нет

- 2750 514-23 en Rev 2Документ10 страниц2750 514-23 en Rev 2smi249Оценок пока нет

- Islamic Baby NamesДокумент72 страницыIslamic Baby NamesAkhlaq HussainОценок пока нет

- 001434Документ44 страницы001434smi249Оценок пока нет

- Fundamental Principles of Transformer Thermal Loading and Protection ERLPhase TexasAM2010Документ14 страницFundamental Principles of Transformer Thermal Loading and Protection ERLPhase TexasAM2010Nani JОценок пока нет

- Cancel All RedirectionsДокумент20 страницCancel All Redirectionssmi249Оценок пока нет

- Lesson 3Документ30 страницLesson 3MohamedОценок пока нет

- 2005 FattahcvДокумент8 страниц2005 Fattahcvsmi249Оценок пока нет

- KsksДокумент1 страницаKskssmi249Оценок пока нет

- KsksДокумент1 страницаKskssmi249Оценок пока нет

- Decimal Worksheet SolutionsДокумент5 страницDecimal Worksheet Solutionssmi249Оценок пока нет

- Decimal Worksheet SolutionsДокумент5 страницDecimal Worksheet Solutionssmi249Оценок пока нет

- Open Neturals OctFAI2013Документ6 страницOpen Neturals OctFAI2013david23281dОценок пока нет

- Dia 6545 001Документ14 страницDia 6545 001SointronicОценок пока нет

- Isc 2SC4834: Silicon NPN Power TransistorsДокумент3 страницыIsc 2SC4834: Silicon NPN Power TransistorsErwin Rolando EscobarОценок пока нет

- Belmont Phot-X II Dental X-Ray - Service Manual PDFДокумент28 страницBelmont Phot-X II Dental X-Ray - Service Manual PDFNayyar MahmoodОценок пока нет

- BD135 BD137 BD139: Silicon NPN Power TransistorsДокумент3 страницыBD135 BD137 BD139: Silicon NPN Power Transistorsjoedoe43Оценок пока нет

- Ampact Line DisconnectДокумент1 страницаAmpact Line DisconnectAmit BhatiaОценок пока нет

- 2615B CT Shorting Using ME Series Test DisconnectДокумент5 страниц2615B CT Shorting Using ME Series Test DisconnectdienlangchuОценок пока нет

- XLPE Cu Three Core 3.3kV DS+EN PDFДокумент4 страницыXLPE Cu Three Core 3.3kV DS+EN PDFGalang WicaksonoОценок пока нет

- Micom E10: Indications and ControlsДокумент2 страницыMicom E10: Indications and ControlsTomuta StefanОценок пока нет

- 220V Homemade Portable Power InverterДокумент7 страниц220V Homemade Portable Power InverterMuqheed ShaikОценок пока нет

- Electrical Site Office Outdoor Lighting ProjectДокумент2 страницыElectrical Site Office Outdoor Lighting ProjectShahed HussainОценок пока нет

- 1 What Is Semiconductor? Semiconductor .Документ12 страниц1 What Is Semiconductor? Semiconductor .cyric wongОценок пока нет

- Test Switch PDFДокумент10 страницTest Switch PDFJohan VargasОценок пока нет

- ZYTD-38S: Dimension (MM)Документ1 страницаZYTD-38S: Dimension (MM)ahmadmn_scribdОценок пока нет

- Lab Report IV Characteristics of DiodeДокумент5 страницLab Report IV Characteristics of DiodeAamir AliОценок пока нет

- 245 Wiring Diagram For Electronic Ignition Switch (EIS) Control UnitДокумент5 страниц245 Wiring Diagram For Electronic Ignition Switch (EIS) Control UnitRosli YaacobОценок пока нет

- Umidificator PDFДокумент3 страницыUmidificator PDFPC MediaPointОценок пока нет

- stps30l45cw 282527Документ8 страницstps30l45cw 282527Zuprecqk Trance Martinez VidalОценок пока нет

- MDS3653URH Datasheet ReemplazoДокумент9 страницMDS3653URH Datasheet ReemplazoHubert RodriguezОценок пока нет

- Design of A Generator Excitation System PDFДокумент79 страницDesign of A Generator Excitation System PDFvictor hidroОценок пока нет

- Fusing Equipment: Elf™ Current-Limiting Dropout FuseДокумент12 страницFusing Equipment: Elf™ Current-Limiting Dropout FuseAhmed SabriОценок пока нет

- 3 Phase Forward ReverseДокумент6 страниц3 Phase Forward ReverseLiyana NasarudinОценок пока нет

- MOSFET Course Notes - MMA HAKIMДокумент22 страницыMOSFET Course Notes - MMA HAKIMAdnan HossainОценок пока нет

- Tuto 7 Synch GeneratorДокумент1 страницаTuto 7 Synch GeneratorVievie Le BluewberrietrufflesОценок пока нет

- Introduction of Electrical MachinesДокумент21 страницаIntroduction of Electrical MachinesUmair MansoorОценок пока нет