Академический Документы

Профессиональный Документы

Культура Документы

Beer Production

Загружено:

Purushottam ChateИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Beer Production

Загружено:

Purushottam ChateАвторское право:

Доступные форматы

1

INTRODUCTION Beer is the world's most widely consumed alcoholic beverage; it is the third most popular drink overall, after water and tea. It is thought by some to be the oldest fermented beverage. Beer is produced by the saccharification of starch and fermentation of the resulting sugar. The starch and saccharification enzymes are often derived from malted cereal grains, most commonly malted barley and malted wheat.[7] Unmalted maize (US: corn) and rice are widely used adjuncts to lighten the flavor and because of their lower cost. The preparation of beer is called brewing. Most beer is flavoured with hops, which add bitterness and act as a natural preservative, though other flavourings such as herbs or fruit may occasionally be included. Today, the brewing industry is a global business, consisting of several dominant multinational companies and many thousands of smaller producers ranging from brewpubs to regional breweries. The strength of beer is usually around 4% to 6% alcohol by volume (abv) though may range from less than 1% abv, to over 20% abv in rare cases. Beer forms part of the culture of beer-drinking nations and is associated with social traditions such as beer festivals, as well as a rich pub culture involving activities like pub crawling and pub games such as bar billiards. Brewing Brewing is the production of beer through steeping a starch source (commonly cereal grains) in water and then fermenting with yeast. Brewing has taken place since around the 6th millennium BC, and archaeological evidence suggests that this technique was used in ancient Egypt. Brewing takes place in a brewery by a brewer, and the brewing industry is part of most western economies. The basic ingredients of beer are water; a starch source, such as malted barley, which is able to be fermented (converted into alcohol); a brewer's yeast to produce the fermentation; and a flavouring, such as hops.[4] A secondary starch source (an adjunct) may be used, such as

maize (corn), rice or sugar.[5] Less widely used starch sources include millet, sorghum and cassava root in Africa, potato in Brazil, and agave in Mexico, among others. The amount of each starch source in a beer recipe is collectively called the grain bill. There are several steps in the brewing process, which include malting, milling, mashing, lautering, boiling, fermenting, conditioning, filtering, and packaging. There are three main fermentation methods, warm, cool and wild or spontaneous. Fermentation may take place in open or closed vessels. There may be a secondary fermentation that can take place in the brewery, in the cask, or in the bottle. Ingredients The basic ingredients of beer are water; a starch source, such as malted barley, able to be fermented (converted into alcohol); a brewer's yeast to produce the fermentation; and a flavouring such as hops. A mixture of starch sources may be used, with a secondary starch source, such as maize (corn), rice, or sugar, often being termed an adjunct, especially when used as a lower-cost substitute for malted barley. Less widely used starch sources include millet, sorghum, and cassava root in Africa, potato in Brazil, and agave in Mexico, among others. The amount of each starch source in a beer recipe is collectively called the grain bill. Water Beer is composed mostly of water. It is also required for processes like malting, boiling, fermentation, etc. Starch source The starch source in a beer provides the fermentable material and is a key determinant of the strength and flavour of the beer. The most common starch source used in beer is malted grain. Grain is malted by soaking it in water, allowing it to begin germination, and then drying the partially germinated grain in a kiln. Malting grain produces enzymes that convert starches in the grain into fermentable sugars.[9] Different roasting

times and temperatures are used to produce different colours of malt from the same grain. Darker malts will produce darker beers. Nearly all beer includes barley malt as the majority of the starch. This is because of its fibrous husk, which is important not only in the sparging stage of brewing (in which water is washed over the mashed barley grains to form the wort) but also as a rich source of amylase, a digestive enzyme that facilitates conversion of starch into sugars. Other malted and unmalted grains (including wheat, rice, oats, and rye, and, less frequently, corn and sorghum) may be used. Hops

Flavouring beer is the sole major commercial use of hops. The flower of the hop vine is used as a flavouring and preservative agent in nearly all beer made today. The flowers themselves are often called "hops". Hops are the female flower clusters (commonly called seed cones or strobiles), of a hop species, Humulus lupulus. They are used primarily as a flavoring and stability agent in beer, to which they impart a bitter, tangy flavor, though hops are also used for various purposes in other beverages and herbal medicine. Hops are used extensively in brewing for their many purported benefits, including balancing the sweetness of the malt with bitterness, contributing a variety of desirable flavors and aromas, and having an antibiotic effect that favors the activity of brewer's yeast over less desirable microorganisms. The acidity of hops is a preservative. The hop plant is a vigorous, climbing, herbaceous perennial, usually trained to grow up strings in a field called a hopfield, hop garden, or hop yard when grown commercially. Many different types of hops are

grown by farmers around the world, with different types being used for particular styles of beer. Hops are usually dried in an oast house before they are used in the brewing process, but are sometimes used to make "wet-hop" beer immediately after a harvest. Hop resins are composed of two main acids: alpha and beta acids.[23] Alpha acids have a mild antibiotic/bacteriostatic effect against Gram-positive bacteria, and favor the exclusive activity of brewing yeast in the fermentation of beer. Alpha acids are responsible for the bitter flavor in the beer.

Cross-section drawing of a hop Beta acids do not isomerize during the boil of wort, and have a negligible effect on beer taste. Instead, they contribute to beer's bitter aroma, and high beta acid hop varieties are often added at the end of the wort boil for aroma. Beta acids may oxidize into compounds that can give beer off-flavors of rotten vegetables or cooked corn. The effect of hops on the finished beer varies by type and use, though there are two main hop types: bittering and aroma. Bittering hops have higher concentrations of alpha acids, and are responsible for the

large majority of the bitter flavor of a beer. European (so-called "noble") hops typically average 59% alpha acids by weight (AABW), and the newer American species typically range from 819% AABW. Aroma hops usually have a lower concentration of alpha acids (~5%) and are the primary contributors of hop aroma and (nonbitter) flavor. The degree of bitterness imparted by hops depends on the degree to which otherwise insoluble alpha acids (AAs) are isomerized during the boil, and the impact of a given amount of hops is specified in International Bitterness Units (IBUs). Unboiled hops are only mildly bitter. On the other hand, the nonbitter flavor and aroma of hops come from the essential oils, which evaporate during the boil. Aroma hops are typically added to the wort later to prevent the evaporation of the essential oils, to impart "hop taste" (if during the final 30 minutes of boil) or "hop aroma" (if during the final 10 minutes, or less, of boil). Aroma hops are often added after the wort has cooled and while the beer ferments, a technique known as "dry hopping", which contributes to the hop aroma. The four major components of the essential oil of hops are myrcene, humulene, caryophyllene, and farnesene, which comprise about 6080% of the oil for most hop varieties. Today, a substantial amount of "dual-use" hops are used, as well. These have high concentrations of alpha acids and good aromatic properties. These can be added to the boil at any time, depending on the desired effect.

Yeast Yeast is the microorganism that is responsible for fermentation in beer. Yeast metabolises the sugars extracted from grains, which produces alcohol and carbon dioxide, and thereby turns wort into beer. In addition to fermenting the beer, yeast influences the character and flavour. The dominant types of yeast used to make beer are Saccharomyces cerevisiae, known as ale yeast, and Saccharomyces uvarum, known as lager yeast; their use distinguishes ale and lager. Brettanomyces ferments lambics, and Torulaspora delbrueckii ferments Bavarian weissbier. ("Saccharomyces" derives from Latinized Greek and means "sugar mold" or

"sugar fungus", saccharo- being the combining form "sugar-" and myces being "fungus". Cerevisiae comes from Latin and means "of beer".) Brewing yeasts may be classed as "top cropping" (or "topfermenting") and "bottom-cropping" (or "bottom-fermenting"). Top cropping yeasts are so called because they form a foam at the top of the wort during fermentation. An example of a top-cropping yeast is Saccharomyces cerevisiae, sometimes called an "ale yeast". Bottom-cropping yeasts are typically used to produce lager-type beers, though they can also produce ale-type beers. These yeasts ferment well at low temperatures. An example of bottom-cropping yeast is Saccharomyces pastorianus, formerly known as S. carlsbergensis. Decades ago, taxonomists reclassified S. carlsbergensis (uvarum) as a member of S. cerevisae, noting that the only distinct difference between the two is metabolic. Lager strains of S. cerevisae secrete an enzyme called melibiase, allowing it to hydrolyse melibiose, a disaccharide, into more fermentable monosaccharides. Top-cropping and bottom-cropping, cold-fermenting and warm-fermenting distinctions are largely generalizations used by the laypersons to communicate to the general public. The most common top cropping brewer's yeast, S. cerevisiae, is the same species as the common baking yeast. Brewer's yeast is also very rich in essential minerals and the B vitamins (except B12). However, baking and brewing yeasts typically belong to different strains, cultivated to favour different characteristics: baking yeast strains are more aggressive, to carbonate dough in the shortest amount of time possible; brewing yeast strains act slower, but tend to produce fewer off-flavours and tolerate higher alcohol concentrations (with some strains, up to 22%). Clarifying agent Some brewers add one or more clarifying agents to beer, which typically precipitate (collect as a solid) out of the beer along with protein solids and are found only in trace amounts in the finished product. This process makes the beer appear bright and clean, rather than the cloudy appearance of ethnic and older styles of beer such as wheat beers.

Examples of clarifying agents include isinglass, obtained from swimbladders of fish; Irish moss, a seaweed; kappa carrageenan, from the seaweed Kappaphycus cottonii; Polyclar (artificial); and gelatin.[28] If a beer is marked "suitable for Vegans", it was generally clarified either with seaweed or with artificial agents. Brewing process There are several steps in the brewing process, which include malting, milling, mashing, lautering, boiling, fermenting, conditioning, filtering, and packaging. 1) Malting

Malting is the process where the barley grain is made ready for brewing. Malting is broken down into three steps in order to help to release the starches in the barley. First, during steeping, the grain is added to a vat with water and allowed to soak for approximately 40 hours. During germination, the grain is spread out on the floor of the germination room for around 5 days. The goal of germination is to allow the starches in the barley grain to break down into shorter lengths. The germination process creates a number of enzymes, notably -amylase and -amylase, which convert the starch in the grain into sugar. When this step is complete, the grain is referred to as green malt. The final part of malting is kilning. Here, the green malt goes through a very high temperature drying in a kiln. The temperature change is gradual so as not to disturb or damage the enzymes in the grain. Depending on the amount of roasting, the malt will take on a dark colour and strongly influence the colour and flavour of the beer. When kilning is complete, there is a finished malt as a product.[31] 2) Milling

The next step in the brewing process is milling. This is when the grains that are going to be used in a batch of beer are cracked. Milling the grains makes it easier for them to absorb the water that they are mixed with and which extracts sugars from the malt.[32] The malt is crushed to break apart the grain kernels, expose the cotyledon, which contains the majority of the carbohydrates and sugars, increase their surface area, and separate the smaller pieces from the husks. Milling can also influence the general characteristics of a beer. 3) Mashing In brewing and distilling, mashing is the process of combining a mix of milled grain (typically malted barley with supplementary grains such as corn, sorghum, rye or wheat), known as the "grain bill", and water, known as "liquor", and heating this mixture. Mashing allows the enzymes in the malt to break down the starch in the grain into sugars, typically maltose to create a malty liquid called wort.[1] There are two main methods - infusion mashing, in which the grains are heated in one vessel; and decoction mashing, in which a proportion of the grains are boiled and then returned to the mash, raising the temperature. Mashing involves pauses at certain temperatures (notably 45 C, 62 C and 73 C) [113F, 144F, and 163F], and takes place in a "mash tun" - an insulated brewing vessel with a false bottom.[3][4][5] The end product of mashing is called a "mash". a) Mashing-in Mixing of the strike water, water used for mashing in, and milled grist must be done in a such a way as to minimize clumping and oxygen uptake. Mashing in is typically done between 35C and 45C (95F and 113F). The weight-to-weight ratio of strike water and grain varies from 1:2 for dark beers in single-step infusions to 1:4 or even 1:5, ratios more suitable for light-colored beers and decoction mashing, where much mash water is boiled off. b) Enzymatic rests

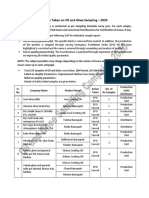

Optimal rest temperatures for major mashing enzymes

Temp C Temp F

Enzyme

Breaks down Protein Starch Starch

40-45 C 104.0-113.0 F -Glucanase -Glucan 50-54 C 122.0-129.2 F Protease 62-67 C 143.6-152.6 F -Amylase 71-72 C 159.8-161.6 F -Amylase

-Glucanase rest -glucan is a general term for polysaccharides, such as cellulose, made up of chains of glucose molecules connected by beta glycosidic bonds, as opposed to alpha glycosidic bonds in starch. These are a major constituent of the cell wall of plants, and make up a large part of the bran in grains. A -glucanase rest done at 40C (104F) is practiced in order to break down cell walls and make starches more available, thus raising the extraction efficiency. Should the brewer let this rest go on too long, it is possible that a large amount of -glucan will dissolve into the mash, which can lead to a stuck mash on brew day, and cause filtration problems later in beer production. Protease rest Protein degradation via a proteolytic rest plays many roles: production of free-amino nitrogen (FAN) for yeast nutrition, freeing of small proteins from larger proteins for foam stability in the finished product, and reduction of haze-causing proteins for easier filtration and increased beer clarity. In all-malt beers, the malt already provides enough protein for good head retention, and the brewer needs to worry more about more FAN being produced than the yeast can metabolize, leading to off flavors. The haze causing proteins are also more prevalent in all-malt beers, and the brewer must strike a balance between breaking down these proteins, and limiting FAN production. Amylase rests

10

The amylase rests are responsible for the production of free fermentable and nonfermentable sugar from starch in a mash. Starch is an enormous molecule made up of branching chains of glucose molecules. -amylase breaks down these chains from the end molecules forming links of two glucose molecules, i.e. maltose. -amylase cannot break down the branch points, although some help is found here through low -amylase activity and enzymes such as limit dextrinase. The maltose will be the yeast's main food source during fermentation. During this rest starches also cluster together forming visible bodies in the mash. This clustering eases the lautering process. The -amylase rest is also known as the saccharification rest, because during this rest the -amylase breaks down the starches from the inside, and starts cutting off links of glucose one to four glucose molecules in length. The longer glucose chains, sometimes called dextrins or maltodextrins, along with the remaining branched chains, give body and fullness to the beer. Because of the closeness in temperatures of peak activity of amylase and -amylase, the two rests are often performed at once, with the time and temperature of the rest determining the ratio of fermentable to nonfermentable sugars in the wort and hence the final sweetness of the fermented drink; a hotter rest also a fuller-bodied, sweeter beer as amylase produces more unfermentable sugars. 66C (151F) is a typical rest temperature for a pale ale or German pilsener, while Bohemian pilsener and mild ale are rested more typically at 67-68C (153 - 154F). c) Mash-out

After the enzyme rests, the mash is raised to its mash-out temperature. This frees up about 2% more starch, and makes the mash less viscous, allowing the lauter to process faster. Although mash temperature and viscosity are roughly inversely proportional, the ability of brewers and distillers to use this relationship is constrained by the fact that -Amylase quickly denatures above 78C (172.4F). Any starches extracted once the mash is brought above this temperature cannot be broken down, and will cause a starch haze in the finished product, or in

11

larger quantities an unpleasantly harsh flavor can develop. Therefore, the mash-out temperature rarely exceeds 78C (172.4F). 4) Lautering Lautering is the separation of the wort (the liquid containing the sugar extracted during mashing) from the grains [43] and separated into the clear liquid wort and the residual grain. Lautering usually consists of 3 steps: mashout, recirculation, and sparging.

a) Mashout Mashout is the term for raising the temperature of the mash to 170 F (77 C). This both stops the enzymatic conversion of starches to fermentable sugars, and makes the mash and wort more fluid. Mashout is considered especially necessary if there is less than 1.5 quarts of water per pound of grain (3 liters of water per kilogram of grain), or if the grain is more than 25% wheat or oats. The mashout step can be done by using external heat, or simply by adding hot water.[1] b) Recirculation Recirculation consists of drawing off wort from the bottom of the mash, and adding it to the top. Lauter tuns typically have slotted bottoms to assist in the filtration process. The mash itself functions much as a sand filter to capture mash debris and proteins. This step is monitored by use of a turbidimeter to measure solids in the wort liquid by their opacity.[1] c) Sparging Sparging is trickling water through the grain to extract sugars. This is a delicate step, as the wrong temperature or pH will extract tannins from the chaff (grain husks) as well, resulting in a bitter brew. Typically, 50% more water is used for sparging than was originally used for mashing. Sparging is typically conducted in a lauter tun.[1] Lauter tun

12

A lauter tun is the traditional vessel used for separation of the extracted wort. While the basic principle of its operation has remained the same since its first use, technological advances have led to better designed lauter tuns capable of quicker and more complete extraction of the sugars from the grain. The false bottom in a lauter tun has thin (0.7 to 1.1 mm) slits to hold back the solids and allow liquids to pass through. The solids, not the false bottom, form a filtration medium and hold back small solids, allowing the otherwise cloudy mash to run out of the lauter tun as a clear liquid. The false bottom of a lauter tun is today made of wedge wire, which can provide a free-flow surface of up to 12% of the bottom of the tun. Wort Wort is the liquid extracted from the mashing process during the brewing of beer or whisky. Wort contains the sugars that will be fermented by the brewing yeast to produce alcohol. 5) Boiling Boiling the malt extracts, called wort, ensures its sterility, and thus prevents a lot of infections. During the boil hops are added, which contribute bitterness, flavour, and aroma compounds to the beer, and, along with the heat of the boil, causes proteins in the wort to coagulate and the pH of the wort to fall. Finally, the vapours produced during the boil volatilise off flavours, including dimethyl sulfide precursors. The boil must be conducted so that it is even and intense. The boil lasts between 15 and 120 minutes, depending on its intensity, the hop addition schedule, and volume of water the brewer expects to evaporate. Whirlpooling At the end of the boil, the wort is set into a whirlpool. In most large breweries, there is a separate tank for whirl pooling. These tanks have a large diameter to encourage settling, and is flat bottomed or with a slope of 1 or 2 towards the outlet, a tangential inlet near the bottom of the whirlpool, and an outlet on the bottom near the outer edge of the

13

whirlpool. A whirlpool should have no internal protrusions that might slow down the rotation of the liquid. The bottom of the whirlpool is often slightly sloped towards the outlet. Newer whirlpools often have "Denk rings" suspended in the middle of the whirlpool. These rings are aligned horizontally and have about 75% of the diameter of the whirlpool. The Deck rings prevent the formation of secondary eddies in the whirlpool, encouraging the formation of a cohesive trub cone in the middle of the whirlpool. Smaller breweries often use the brew kettle as a whirlpool Hopback A hopback is a sealed chamber that is inserted in between the brewing kettle and counter-flow wort chiller. Hops are added to the chamber, the hot wort from the kettle is run through it, and then immediately cooled in the wort chiller before entering the fermentation chamber. It facilitates maximum retention of volatile hop aroma compounds that would normally be driven off when the hops contact the hot wort. Because it is a sealed chamber, the volatile hop compounds are trapped in the hot wort, and then the wort is immediately cooled, which keeps the volatile compounds in solution. Wort cooling After the whirlpool, the wort must be brought down to fermentation temperatures (2026Celsius)[39] before yeast is added. In modern breweries this is achieved through a plate heat exchanger. A plate heat exchanger has many ridged plates, which form two separate paths. The wort is pumped into the heat exchanger, and goes through every other gap between the plates. The cooling medium, usually water, goes through the other gaps. The ridges in the plates ensure turbulent flow. A good heat exchanger can drop 95 C wort to 20 C while warming the cooling medium from about 10 C to 80 C. The last few plates often use a cooling medium which can be cooled to below the freezing point, which allows a finer control over the wort-out temperature, and also enables cooling to around 10 C. After cooling, oxygen is often dissolved into the wort to revitalize the yeast and aid its reproduction. While boiling, it is useful to recover some of the energy used to boil the wort. On its way out of the brewery, the steam created during the

14

boil is passed over a coil through which unheated water flows. By adjusting the rate of flow, the output temperature of the water can be controlled. This is also often done using a plate heat exchanger. The water is then stored for later use in the next mash, in equipment cleaning, or wherever necessary. Another common method of energy recovery takes place during the wort cooling. When cold water is used to cool the wort in a heat exchanger, the water is significantly warmed. In an efficient brewery, cold water is passed through the heat exchanger at a rate set to maximize the water's temperature upon exiting. This now-hot water is then stored in a hot water tank.[48] 6) Fermenting Fermentation in brewing is the conversion of carbohydrates to alcohols and carbon dioxide or organic acids using yeasts, bacteria, or a combination thereof, under anaerobic conditions. A more restricted definition of fermentation is the chemical conversion of sugars into ethanol. The science of fermentation is known as zymurgy. After the wort is cooled and aerated usually with sterile air yeast is added to it, and it begins to ferment. It is during this stage that sugars won from the malt are metabolized into alcohol and carbon dioxide, and the product can be called beer for the first time. Fermentation happens in tanks which come in all sorts of forms, from enormous cylindro-conical vessels, through open stone vessels, to wooden vats. Most breweries today use cylindro-conical vessels, or CCVs, which have a conical bottom and a cylindrical top. The cone's aperture is typically around 60, an angle that will allow the yeast to flow towards the cone's apex, but is not so steep as to take up too much vertical space. CCVs can handle both fermenting and conditioning in the same tank. At the end of fermentation, the yeast and other solids which have fallen to the cone's apex can be simply flushed out of a port at the apex. Open fermentation vessels are also used, often for show in brewpubs, and in Europe in wheat beer fermentation. These vessels have no tops, which makes harvesting top-fermenting yeasts very easy. The

15

open tops of the vessels make the risk of infection greater, but with proper cleaning procedures and careful protocol about who enters fermentation chambers, the risk can be well controlled. Fermentation tanks are typically made of stainless steel. If they are simple cylindrical tanks with beveled ends, they are arranged vertically, as opposed to conditioning tanks which are usually laid out horizontally. Only a very few breweries still use wooden vats for fermentation as wood is difficult to keep clean and infection-free and must be repitched more or less yearly. After high krausen occurs, a bung device (German: Spundapparat) is often put on the tanks to allow the C O2 produced by the yeast to naturally carbonate the beer. This bung device can be set to a given pressure to match the type of beer being produced. The more pressure the bung holds back, the more carbonated the beer becomes. Fermentation methods There are three main fermentation methods, warm, cool and wild or spontaneous. Fermentation may take place in open or closed vessels. There may be a secondary fermentation which can take place in the brewery, in the cask or in the bottle. Brewing yeasts may be classed as "top-cropping" (or "topfermenting") and "bottom-cropping" (or "bottom-fermenting"). Top-cropping yeasts are so called because they form a foam at the top of the wort during fermentation. They can produce higher alcohol concentrations and in higher temperatures, typically 16 to 24 C (61 to 75 F), produce fruitier, sweeter beers. An example of a top-cropping yeast is Saccharomyces cerevisiae. Bottom-cropping yeasts are typically used to produce cool fermented, lager-type beers, though they can also ferment at higher temperatures if kept under 34C. These yeasts ferment more sugars, creating a dryer beer, and grow well at low temperatures. An example of bottom-cropping yeast is Saccharomyces pastorianus, formerly known as Saccharomyces carlsbergensis. To ensure purity of strain, a "clean" sample of brewing yeast is sometimes stored, either dried or refrigerated in a laboratory.[54][55] After a

16

certain number of fermentation cycles, a full scale propagation is produced from this laboratory sample. Typically, it is grown up in about three or four stages using sterile brewing wort and oxygen. i) Warm-fermenting

In general, yeasts such as Saccharomyces cerevisiae are fermented at warm temperatures between 15 and 20 C (59 and 68 F), occasionally as high as 24 C (75 F),[56] while the yeast used by Brasserie Dupont for saison ferments even higher at 29 C (84 F) to 35 C (95 F).[57] They in general form a foam on the surface of the fermenting beer, as during the fermentation process its hydrophobic surface causes the flocs to adhere to CO2 and rise; because of this, they are often referred to as "top-cropping" or "top-fermenting" though this distinction is less clear in modern brewing with the use of cylindro-conical tanks. In general, warmfermented beers are ready to drink within three weeks after the beginning of fermentation, although some brewers will condition them for several months. ii) Cool fermenting Lager is beer that has been cool fermented at around 10 C (50 F), compared to typical warm fermentation temperatures of 18 C (64 F). It is then stored for 30 days or longer close to the freezing point, and during this storage sulphur components developed during fermentation dissipate. Though it is the cool fermenting that defines lager, the main technical difference with lager yeast is its ability to process raffinose (a trisaccharide composed of the sugars galactose, fructose, and glucose), which means that all sugars are fermented, resulting in a well attentuated beer; warm fermenting yeast only cleaves and ferments the fructose portion of raffinose, leaving melibiose, which it cannot further cleave into two monosaccharides due to its lack of melibiase, so ale remains sweeter with a lower conversion of sugar into alcohol. Raffinose is a minor dry component of Carlsberg barley, but once malted is practically nonexistent. iii) Spontaneous fermentation

17

These beers are brewed primarily around Brussels, Belgium. They are fermented in oak barrels after being inoculated with wild yeast and bacteria while cooling in a Koelship. Wild yeast and bacteria ferment the wort in the oak barrels. The beers fermented from yeast and bacteria in the Brussels area are called Lambic beers. These bacteria add a sour flavour to the beer. iv) Bottle fermentation Some beers undergo a fermentation in the bottle, giving natural carbonation. This may be a second or third fermentation. They are bottled with a viable yeast population in suspension. If there is no residual fermentable sugar left, sugar may be added. The resulting fermentation generates CO2 that is trapped in the bottle, remaining in solution and providing natural carbonation. v) Cask conditioning Cask ale or cask-conditioned beer is the term for unfiltered and unpasteurised beer that is conditioned (including secondary fermentation) and served from a cask without additional nitrogen or carbon dioxide pressure. 7) Conditioning When the sugars in the fermenting beer have been almost completely digested, the fermentation slows down and the yeast starts to settle to the bottom of the tank. At this stage, the beer is cooled to around freezing, which encourages settling of the yeast, and causes proteins to coagulate and settle out with the yeast. If a separate conditioning tank is to be used, it is at this stage that the beer will be transferred into one. Unpleasant flavours such as phenolic compounds become insoluble in the cold beer, and the beer's flavour becomes smoother. During this time pressure is maintained on the tanks to prevent the beer from going flat. Conditioning can take from 2 to 4 weeks, sometimes longer, depending on the type of beer. In addition, lagers, at this point, are aged at near freezing temperatures for 16 months depending on style. This cold aging serves to reduce sulphur compounds produced by the bottom-

18

fermenting yeast and to produce a cleaner tasting final product with fewer esters. If the fermentation tanks have cooling jackets on them, as opposed to the whole fermentation cellar being cooled, conditioning can take place in the same tank as fermentation. Otherwise separate tanks (in a separate cellar) must be employed. This is where aging occurs. 8) Filtering Filtering the beer stabilizes the flavour, and gives beer its polished shine and brilliance. Filters come in many types. Many use premade filtration media such as sheets or candles, while others use a fine powder made of, for example, diatomaceous earth, also called kieselguhr, which is introduced into the beer and recirculated past screens to form a filtration bed. Filters range from rough filters that remove much of the yeast and any solids (e.g., hops, grain particles) left in the beer, to filters tight enough to strain colour and body from the beer. Used filtration ratings are normally divided into rough, fine, and sterile. Rough filtration leaves some cloudiness in the beer, but it is noticeably clearer than unfiltered beer. Fine filtration gives a glass of beer that you could read a newspaper through, with no noticeable cloudiness. Finally, as its name implies, sterile filtration is fine enough that almost all microorganisms in the beer are removed during the filtration process. Sheet (pad) filters These filters use pre-made media and are relatively straightforward. The sheets are manufactured to allow only particles smaller than a given size through, and the brewer is free to choose how finely to filter the beer. The sheets are placed into the filtering frame, sterilized (with hot water, for example) and then used to filter the beer. The sheets can be flushed if the filter becomes blocked, and usually the sheets are disposable and are replaced between filtration sessions. It should be kept in mind that pre-made filters have two sides. One with loose holes, and the other with tight holes. Flow goes from the

19

side with loose holes to the side with the tight holes, with the intent that large particles get stuck in the large holes while leaving enough room around the particles and filter medium for smaller particles to go through and get stuck in tighter holes. Sheets are sold in nominal ratings, and typically 90% of particles larger than the nominal rating are caught by the sheet. Kieselguhr filters Filters that use a powder medium are considerably more complicated to operate, but can filter much more beer before needing to be regenerated. Common media include diatomaceous earth, or kieselguhr, and perlite. 9) Packaging Packaging is putting the beer into the containers in which it will leave the brewery. Typically, this means putting the beer into bottles, aluminium cans and kegs, but it may include putting the beer into bulk tanks for high-volume customers. References

Вам также может понравиться

- Beer: Guidance in Mixology, Pairing & Enjoying Life’s Finer ThingsОт EverandBeer: Guidance in Mixology, Pairing & Enjoying Life’s Finer ThingsОценок пока нет

- Alcoholic Beverage: C H O Yeast 2C H OH 2COДокумент13 страницAlcoholic Beverage: C H O Yeast 2C H OH 2COYash ChhabraОценок пока нет

- 3rd QUARTER WEEK 1 MODULE BEERДокумент26 страниц3rd QUARTER WEEK 1 MODULE BEERJayr GiananОценок пока нет

- The Main Fermentation in the Beer Brewing Process - Selected QuestionsОт EverandThe Main Fermentation in the Beer Brewing Process - Selected QuestionsРейтинг: 5 из 5 звезд5/5 (1)

- BeerДокумент6 страницBeerMatthew PriestОценок пока нет

- Alcoholic BeveragesДокумент13 страницAlcoholic BeveragesVikas BansalОценок пока нет

- 1 - Beer Making ProcessДокумент5 страниц1 - Beer Making ProcessClarince Joyce Lao DoroyОценок пока нет

- Emerging: Brewing Is The Production ofДокумент16 страницEmerging: Brewing Is The Production ofSheerin SulthanaОценок пока нет

- Wine Fermentation - Including Winery Directions and Information on Pure YeastОт EverandWine Fermentation - Including Winery Directions and Information on Pure YeastОценок пока нет

- Types of BeerДокумент12 страницTypes of BeerFrank FernandesОценок пока нет

- PTK DraftДокумент3 страницыPTK Draftjonathantjioe123Оценок пока нет

- The Foodie's Beer Book: The Art of Pairing and Cooking with Beer for Any OccasionОт EverandThe Foodie's Beer Book: The Art of Pairing and Cooking with Beer for Any OccasionОценок пока нет

- VinegarДокумент17 страницVinegarJannusLim100% (1)

- I.H.M, Kolkata: B. SC (H & H.A) BHM 202 F&B (S) Operations 2021-2022 Fermented Beverage - Beer Page 1 of 14Документ15 страницI.H.M, Kolkata: B. SC (H & H.A) BHM 202 F&B (S) Operations 2021-2022 Fermented Beverage - Beer Page 1 of 14Souvik SenОценок пока нет

- 101 Old Time Receipts for Beer, Wine, Whiskey, other Spirits and AccoutrementsОт Everand101 Old Time Receipts for Beer, Wine, Whiskey, other Spirits and AccoutrementsОценок пока нет

- Edward, Michael - Production of Wine Beer Spirits and LiquersДокумент179 страницEdward, Michael - Production of Wine Beer Spirits and LiquersGabriel Reyes SahagúnОценок пока нет

- Rum Cocktail Recipes: Ultimate Book for Making Refreshing & Delicious Rum Based Drinks at HomeОт EverandRum Cocktail Recipes: Ultimate Book for Making Refreshing & Delicious Rum Based Drinks at HomeОценок пока нет

- Sunil Kumar: Desinged byДокумент75 страницSunil Kumar: Desinged byVipul KispattaОценок пока нет

- By, Kunjal Patel, M.sc. Microbiology .Документ30 страницBy, Kunjal Patel, M.sc. Microbiology .gaurangHpatelОценок пока нет

- 3 BeerДокумент16 страниц3 BeerJatin Kumar SinghОценок пока нет

- Chapter 7 - GlossaryДокумент12 страницChapter 7 - Glossaryandr100% (1)

- Handout BeverageДокумент34 страницыHandout BeverageNitin DurgapalОценок пока нет

- History of BeerДокумент34 страницыHistory of BeerRicky Kushalappa50% (2)

- Beer - Ingredients: Water. Beer Is Approximately 90 Percent Water. Not All Water Is IdealДокумент8 страницBeer - Ingredients: Water. Beer Is Approximately 90 Percent Water. Not All Water Is IdealFarhaan MohammedОценок пока нет

- BrewingДокумент15 страницBrewingjigneshkavybinaОценок пока нет

- How Beer Works: Main Home FoodДокумент16 страницHow Beer Works: Main Home FoodNeelajit ChandraОценок пока нет

- 2 BeerДокумент31 страница2 BeerVISHAL PATELОценок пока нет

- Sour BeersДокумент3 страницыSour Beersmauricio0327Оценок пока нет

- How To Brew Your Own BeerДокумент6 страницHow To Brew Your Own BeerJohan RiosОценок пока нет

- Beer: 3 /4 Sem Prepared by Pramod S V Page 1 of 7Документ7 страницBeer: 3 /4 Sem Prepared by Pramod S V Page 1 of 7Abhishek KumarОценок пока нет

- Brewing ProcessДокумент3 страницыBrewing ProcessjesusОценок пока нет

- Beer Glossary: Wort Primary Fermentation Fermentation Oxidation EthanolДокумент19 страницBeer Glossary: Wort Primary Fermentation Fermentation Oxidation Ethanoljean grosОценок пока нет

- Beer ProductionДокумент20 страницBeer ProductionEduardo AmezcuaОценок пока нет

- Project Report On BeerДокумент29 страницProject Report On BeerKailash JoshiОценок пока нет

- Unit 5 Lecture 6Документ11 страницUnit 5 Lecture 6Aparajita GОценок пока нет

- Notes For BeersДокумент10 страницNotes For Beersxindinzafal100% (1)

- Types of BeerДокумент5 страницTypes of BeerMicro ShamimОценок пока нет

- Vinegar Production TechДокумент4 страницыVinegar Production Techdanndiamond100% (2)

- Beer PresentationДокумент27 страницBeer PresentationRuben MarquezОценок пока нет

- Manufacturing Process of BeerДокумент43 страницыManufacturing Process of Beerabhys_raghuОценок пока нет

- BrewingДокумент43 страницыBrewingPeter FrenchОценок пока нет

- Beer Production 1Документ30 страницBeer Production 1Lingaraj Kumar100% (1)

- Rum PDFДокумент14 страницRum PDFJojie-Ann Alabarca100% (2)

- Preparation of Beer: Prepared by Namitha M Y Guest Faculty Ksrdpru GadagДокумент14 страницPreparation of Beer: Prepared by Namitha M Y Guest Faculty Ksrdpru GadagmanushaОценок пока нет

- Beer Notes 1Документ9 страницBeer Notes 1shreeya guptaОценок пока нет

- Brewing TechnologyДокумент242 страницыBrewing TechnologyShreya PokharelОценок пока нет

- The Buying Decision ProcessДокумент11 страницThe Buying Decision ProcessHazel Tryzz Ann Del MonteОценок пока нет

- Beer ProductionДокумент8 страницBeer ProductionArush SidanaОценок пока нет

- Beer Brewing PowerpointДокумент23 страницыBeer Brewing Powerpointapi-286688960100% (1)

- Food and Beverage Beer-HandoutДокумент23 страницыFood and Beverage Beer-HandoutSuruchi BhatnagarОценок пока нет

- Beer Production: Nisma Farooq (Lecturer)Документ41 страницаBeer Production: Nisma Farooq (Lecturer)Shanza LatifОценок пока нет

- Google Expeditions 1. The Ingredients of BeerДокумент1 страницаGoogle Expeditions 1. The Ingredients of BeerKhushi GargОценок пока нет

- BeerproductionДокумент57 страницBeerproductionÖmer Ferkan KemikОценок пока нет

- VinegarДокумент5 страницVinegarafridiОценок пока нет

- Aromatic Electrophilic SubstitutionДокумент71 страницаAromatic Electrophilic SubstitutionsridharancОценок пока нет

- 7 Fuel Failure in Water Reactors - Causes and MitigationДокумент165 страниц7 Fuel Failure in Water Reactors - Causes and MitigationLauri RubertiОценок пока нет

- Hospital - Data Collection & Literature StudyДокумент42 страницыHospital - Data Collection & Literature StudyNagateja MallelaОценок пока нет

- Constipation Treatment For Infants and ChildrenДокумент2 страницыConstipation Treatment For Infants and Childrenapi-559575515Оценок пока нет

- Me N Mine Science X Ist TermДокумент101 страницаMe N Mine Science X Ist Termneelanshujain68% (19)

- Geography - Development (Rural - Urban Settlement)Документ32 страницыGeography - Development (Rural - Urban Settlement)jasmine le rouxОценок пока нет

- Safety AuditДокумент9 страницSafety AuditRobena Nagum BagasОценок пока нет

- Paterno Report: Dr. Fred S. Berlin, M.D., PH.D Final Report 2-7-2013Документ45 страницPaterno Report: Dr. Fred S. Berlin, M.D., PH.D Final Report 2-7-2013The Morning CallОценок пока нет

- Biodegradable Plastic Bag Manufacturing Industry-800655 PDFДокумент68 страницBiodegradable Plastic Bag Manufacturing Industry-800655 PDFAryanОценок пока нет

- Safety Tips in Playing ArnisДокумент2 страницыSafety Tips in Playing ArnisDensyo De MensyoОценок пока нет

- Course Guide Pe1 PDFДокумент4 страницыCourse Guide Pe1 PDFrahskkОценок пока нет

- Cis MSCMДокумент15 страницCis MSCMOliver DimailigОценок пока нет

- Manual of GardeningДокумент812 страницManual of GardeningPrakash PatelОценок пока нет

- Brochure - ILLUCO Dermatoscope IDS-1100Документ2 страницыBrochure - ILLUCO Dermatoscope IDS-1100Ibnu MajahОценок пока нет

- FennelДокумент2 страницыFennelAlesam44bОценок пока нет

- Facts About Concussion and Brain Injury: Where To Get HelpДокумент20 страницFacts About Concussion and Brain Injury: Where To Get HelpJess GracaОценок пока нет

- Improving The Livelihoods of Smallholder Fruit Farmers in Soroti District, Teso Sub Region, Eastern Uganda RegionДокумент2 страницыImproving The Livelihoods of Smallholder Fruit Farmers in Soroti District, Teso Sub Region, Eastern Uganda RegionPatricia AngatoОценок пока нет

- Glycolysis Krebscycle Practice Questions SCДокумент2 страницыGlycolysis Krebscycle Practice Questions SCapi-323720899Оценок пока нет

- (Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)Документ4 страницы(Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)nguyen duong trungОценок пока нет

- B - Cracked Tooth SyndromeДокумент8 страницB - Cracked Tooth SyndromeDavid TaylorОценок пока нет

- Plumbing Breakup M 01Документ29 страницPlumbing Breakup M 01Nicholas SmithОценок пока нет

- What Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Документ5 страницWhat Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Rica machells DaydaОценок пока нет

- Datasheet MEC MPS200 v1 2018Документ4 страницыDatasheet MEC MPS200 v1 2018Cepi Sindang KamulanОценок пока нет

- Notice of Privacy Practices (Generic)Документ3 страницыNotice of Privacy Practices (Generic)cecilled_08Оценок пока нет

- Cyber Safety PP Presentation For Class 11Документ16 страницCyber Safety PP Presentation For Class 11WAZ CHANNEL100% (1)

- MCQ Homework: PeriodonticsДокумент4 страницыMCQ Homework: Periodonticsفراس الموسويОценок пока нет

- Action Taken On Oil and Ghee Sampling - 2020Документ2 страницыAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiОценок пока нет

- Nfpa 502 Critical Velocity Vs Fffs EffectsДокумент5 страницNfpa 502 Critical Velocity Vs Fffs Effectsamir shokrОценок пока нет

- Chomp Excersie 3Документ5 страницChomp Excersie 3Omahri24Оценок пока нет

- Mobrey CLT PDFДокумент18 страницMobrey CLT PDFAnonymous Oydnu9Оценок пока нет

- Process Plant Equipment: Operation, Control, and ReliabilityОт EverandProcess Plant Equipment: Operation, Control, and ReliabilityРейтинг: 5 из 5 звезд5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlОт EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlРейтинг: 4 из 5 звезд4/5 (4)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- Guidelines for Chemical Process Quantitative Risk AnalysisОт EverandGuidelines for Chemical Process Quantitative Risk AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyОт EverandSodium Bicarbonate: Nature's Unique First Aid RemedyРейтинг: 5 из 5 звезд5/5 (21)

- The Perfumed Pages of History: A Textbook on Fragrance CreationОт EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationРейтинг: 4 из 5 звезд4/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignОт EverandAn Applied Guide to Water and Effluent Treatment Plant DesignРейтинг: 5 из 5 звезд5/5 (4)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesОт EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesРейтинг: 5 из 5 звезд5/5 (1)

- Distillation Design and Control Using Aspen SimulationОт EverandDistillation Design and Control Using Aspen SimulationРейтинг: 5 из 5 звезд5/5 (2)

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksОт EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksОценок пока нет

- Chemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignОт EverandChemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignРейтинг: 4 из 5 звезд4/5 (16)

- A New Approach to HAZOP of Complex Chemical ProcessesОт EverandA New Approach to HAZOP of Complex Chemical ProcessesОценок пока нет

- The Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookОт EverandThe Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookОценок пока нет

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsОт EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottРейтинг: 4 из 5 звезд4/5 (6)

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Bioinspired Materials Science and EngineeringОт EverandBioinspired Materials Science and EngineeringGuang YangОценок пока нет

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringОт EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОт EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОценок пока нет

- Fundamentals of Risk Management for Process Industry EngineersОт EverandFundamentals of Risk Management for Process Industry EngineersОценок пока нет

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionОт EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionОценок пока нет