Академический Документы

Профессиональный Документы

Культура Документы

USB to RS232 Converter Using Atmel Microcontrollers

Загружено:

Nugraha IndrawanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

USB to RS232 Converter Using Atmel Microcontrollers

Загружено:

Nugraha IndrawanАвторское право:

Доступные форматы

USB to RS232 Using Atmel ATtiny2313 or ATmega8

The Universal Serial Bus (USB) interface has become extremely popular, due to its simplicity for end user applications (Plug and Play without restart). For developers, however, USB implementation into end systems has been more complicated compared to e.g. RS232. In addition there is a need for device drivers as software support on the PC side. Because of this, RS232 based communication is still very popular among end systems manufacturers. This interface is well established and has good operating system support, but recently the physical RS232 port has been removed from the standard PC interface, giving ground to USB ports. Implementation of USB into external devices can be done in two ways: 1. By using a microcontroller with hardware implemented USB interface. It is necessary to know how USB works and write firmware into the microcontroller accordingly. Additionally, it is necessary to create a driver on the computer side, unless if the operating system includes standard USB classes. The main disadvantage is the lack of availability of this kind of microcontrollers and their high price compared to simple RS232 microcontrollers. 2. The second option is to use some universal converter between USB and another interface. This other interface will usually be RS232, 8-bit data bus, or TWI bus. In this case there is no need for special firmware, it isnt even necessary to know how USB works, and no driver writing is required, as the converter vendor will offer one driver for the whole solution. The disadvantage is the higher price of the complete system, and the greater dimensions of the complete product. The solution presented in this document is a USB implementation into a low-cost microcontroller through emulation of the USB protocol in the microcontroller firmware. The main challenge for this design was obtaining sufficient speed. The USB bus is quite fast: LowSpeed 1.5Mbit/s, FullSpeed 12Mbit/s, HighSpeed 480Mbit/s. The AVR microcontrollers are fully capable of meeting the hard speed requirements of LowSpeed USB. The solution is however not recommended for higher USB speeds.

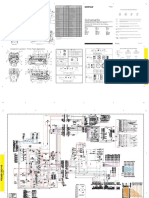

Extensive details regarding physical USB communication can be found at the website www.usb.org. This documentation is very complex and difficult for beginners. A very good and simple explanation for beginners can be found in the document USB in a Nutshell. Making Sense of the USB Standard written by Craig Peacock [2]. In this application note the explanation is limited in scope to understanding the device firmware. The USB physical interface consists of 4 wires: 2 for powering the external device (VCC and GND), and 2 signal wires (DATA+ and DATA-). The power wires give approximately 5 volts and max. 500mA. The AVR can be supplied from the Vcc and GND. The signal wires named DATA+ and DATA- handle the communication between host (computer) and device. Signals on these wires are bi-directional. Voltage levels are differential: when DATA+ is at high level, DATA- is at low level, but there are some cases in which DATA+ and DATA- are at the same level, like EOP (end of packet). Therefore, in the firmware driven USB implementation it is necessary to be able to sense or drive both these signals. According to the USB standard the signal wires must be driven high between 3.0-3.6V, while the Vcc supported by the USB host is 4.4 5.25V. So if the microcontroller is powered directly from the USB lines, then the data lines must pass through a level converter to compensate for the different voltage levels. Another solution is to regulate the Vcc supported by the host down to 3.3V, and run the microcontroller at that voltage level. A schematic diagram of the microcontroller connection to the USB bus is shown in Figure 8. This schematic was made for the specific purpose of a USB to RS232 converter. There were also implemented specific functions as direct pin control and EEPROM read/write. The USB data lines, DATA- and DATA+, are connected to pins PB0 and PB1 on the AVR. This connection cannot be changed because the firmware makes use of an AVR finesse for fast signal reception: The bit signal captured from the data lines is right shifted from LSB (PB0) to carry and then to the reception register, which collects the bits from the data lines. PB1 is used as input signal because on 8-pin ATtiny2313. This pin can be used as external interrupt INT0. No additional connection to INT0 is necessary the 8-pin version of the AVR is the smallest pin count available. On other AVRs, an external connection from DATA+ to the INT0 pin is necessary to ensure no firmware changes between different AVR microcontrollers. For proper USB device connection and signaling, the AVR running as low speed USB device must have a 1.5k? pull-up resistor on DATA-. The Vcc supplied by the USB host may vary from 4.4V to 5.25V. This supply has to be regulated to 3.0 3.6V before connecting the 1.5k? pull-up resistor and sourcing the AVR. Dimension a voltage regulator depending on the power load of the target system. The voltage regulator must be a low drop-out regulator. The schematic in Figure 8 use a LE35 regulator with a nominal output voltage of 3.5V. But one can use any similar solution as long as the required properties are held. Even a very simple regulator based on a Zener diode could in some cases be used. The other components provide functions for proper operation of the microcontroller only: Crystal as clock source, and capacitors for power supply filtering. This small component count is sufficient to obtain a functional USB device, which can communicate with a computer through the USB interface. This is a very simple and inexpensive solution. Some additional components can be added to extend the device functions. A TSOP1738 infrared sensor can be used to receive an IR signal. A MAX232 TTL to RS232 level converter should be added to make a USB to RS232 converter. To control LED diodes or display, they can be connect to I/O pins directly or through resistors.

Вам также может понравиться

- USB to RS232 Converter Using Atmel MicrocontrollersДокумент4 страницыUSB to RS232 Converter Using Atmel Microcontrollersmikcomi100% (1)

- MicrocontrollersДокумент14 страницMicrocontrollersanshu4u06100% (1)

- Basics of SPI Communication ProtocolДокумент19 страницBasics of SPI Communication ProtocolNEETHU PRAKASH100% (1)

- Volume52 Number4Документ64 страницыVolume52 Number4torinomg100% (1)

- SIMPLE DIGITAL SECURITY SYSTEMДокумент47 страницSIMPLE DIGITAL SECURITY SYSTEMAnkita Tiwari100% (1)

- Datasheet Sen23292pДокумент15 страницDatasheet Sen23292pjessie100% (1)

- Ubm Edn 201207Документ64 страницыUbm Edn 201207qtdragon100% (2)

- I2c CommunicationДокумент9 страницI2c CommunicationSanjay Sharma100% (2)

- Chapter 4 PIC IO ProgrammingДокумент28 страницChapter 4 PIC IO ProgrammingAndy Wo100% (1)

- Networking Tutorial - TCPIP Over EthernetДокумент8 страницNetworking Tutorial - TCPIP Over EthernetAbhilash V Pillai100% (24)

- U 0712076Документ3 страницыU 0712076peter100% (1)

- RS 232Документ1 страницаRS 232Aneela Pathan100% (1)

- 16FUSB Project - 1.2Документ16 страниц16FUSB Project - 1.2Emanuel Paz100% (1)

- PS2® To Usb Mouse Translator Hardware DiagramДокумент10 страницPS2® To Usb Mouse Translator Hardware Diagramjhenriqueh100% (1)

- Gems Pressure Transducer PDFДокумент5 страницGems Pressure Transducer PDFFelix Alex de Vera100% (1)

- AIS SchematicДокумент6 страницAIS SchematicKyai Sumirat Gludug Sinawang100% (4)

- Read Modify WriteДокумент2 страницыRead Modify WriteMisbah UrRehman100% (1)

- Serial WinДокумент4 страницыSerial WinFrancisco Ochoa Bueno100% (1)

- Sound Sensor Module PDFДокумент5 страницSound Sensor Module PDFTrần Thảo Nguyên100% (1)

- PIC+l293d DocumentДокумент5 страницPIC+l293d Documentmadduanil100% (1)

- Details of ARP and PPPДокумент40 страницDetails of ARP and PPPYogesh Palkar100% (1)

- LCD 2 X 8Документ4 страницыLCD 2 X 8dek_war100% (1)

- Lecture 7 - LCDДокумент25 страницLecture 7 - LCDSuhaib Abugdera100% (1)

- 20x4 LCD Brief DataДокумент7 страниц20x4 LCD Brief Datavigneshwaranj87100% (1)

- Masters 2012 - Introduction To Microchip USB SolutionsДокумент79 страницMasters 2012 - Introduction To Microchip USB SolutionsTech[BR]100% (2)

- Ieee 802.11Документ13 страницIeee 802.11jeffy100% (1)

- ICD2 Poster 51265hДокумент1 страницаICD2 Poster 51265hngt881100% (1)

- PDF Edne Nov 2013Документ48 страницPDF Edne Nov 2013torinomg100% (1)

- 4.6.2 Universal Serial Bus (USB)Документ18 страниц4.6.2 Universal Serial Bus (USB)kollavivek_534195858100% (2)

- TempДокумент3 страницыTempParth Joshi100% (1)

- H-Bridge: 4.1 DefinitionДокумент11 страницH-Bridge: 4.1 DefinitionJunaid Iftikhar100% (1)

- Ucn 5821 AДокумент7 страницUcn 5821 ACelso Conceição100% (1)

- Easypic v7 Manual v104Документ38 страницEasypic v7 Manual v104Rodolfo Víctor Hilario Poma100% (1)

- USB Chip - Choices Jul2000Документ5 страницUSB Chip - Choices Jul2000Jameskrazy100% (1)

- User'S Manual: PIC-P26J50 Proto Development BoardДокумент19 страницUser'S Manual: PIC-P26J50 Proto Development Boardgiapy0000100% (1)

- A 2.4 GHZ Gaas-Hbt Class-E Mmic Amplifier With 65% PaeДокумент4 страницыA 2.4 GHZ Gaas-Hbt Class-E Mmic Amplifier With 65% PaeKevin Dany100% (1)

- What Is The Difference Between Microcontrollers and 8051Документ6 страницWhat Is The Difference Between Microcontrollers and 8051Erandi Brito100% (1)

- x64 AsmДокумент4 страницыx64 Asmasdmin100% (1)

- LCD Basics McaДокумент13 страницLCD Basics Mcaharshad lokhande100% (1)

- AVR Hardware Design ConsiderationsДокумент14 страницAVR Hardware Design ConsiderationsAmarnath M Damodaran100% (1)

- CommchkДокумент4 страницыCommchkjamesyu100% (1)

- Bascom and AVR, RS-232Документ10 страницBascom and AVR, RS-232akbar100% (1)

- DYP-ME007TX Ultrasonic Sensor Arduino Library Compatible Serial Output ModuleДокумент2 страницыDYP-ME007TX Ultrasonic Sensor Arduino Library Compatible Serial Output Modulevenikiran100% (1)

- Plecs Tl431Документ11 страницPlecs Tl431khsniper100% (1)

- 10 Helpful Hints For ADS - 06 - 10Документ2 страницы10 Helpful Hints For ADS - 06 - 10yazorcan100% (1)

- About Usb InterfaceДокумент6 страницAbout Usb InterfaceSantosh Kumar100% (1)

- Default Switch/Jumper SettingsДокумент16 страницDefault Switch/Jumper SettingsRafael Avella100% (1)

- I2C Protocol in Fpga Using VHDL: Main Project Interim Report As A Partial Fullment of The CurriculumДокумент18 страницI2C Protocol in Fpga Using VHDL: Main Project Interim Report As A Partial Fullment of The CurriculumShuvra Saha100% (1)

- XL MaxSonar WR - Datasheet PDFДокумент26 страницXL MaxSonar WR - Datasheet PDFfernandoviolante8551100% (1)

- Names of student: -Nguyễn Tiến Đức -Trần Hoàng Đăng Khoa Class: 16DTCLC1 Subject: Computer NetworkingДокумент17 страницNames of student: -Nguyễn Tiến Đức -Trần Hoàng Đăng Khoa Class: 16DTCLC1 Subject: Computer NetworkingAnonymous EAPWaVHfYp100% (1)

- Instructions Assembler DirectivespptДокумент22 страницыInstructions Assembler DirectivespptAntra Gurain100% (1)

- Send arbitrary Ethernet frame using libpcap in CДокумент9 страницSend arbitrary Ethernet frame using libpcap in CAl Gambardella100% (1)

- An2178 01Документ5 страницAn2178 01slyrye100% (1)

- Design and Functional Verification of I2C Master Core Using OVMДокумент6 страницDesign and Functional Verification of I2C Master Core Using OVMPraveen Kumar100% (1)

- A Note On Character LCD DisplaysДокумент11 страницA Note On Character LCD DisplaysLishan Jayanath100% (2)

- Bidirectional Current Source-TIДокумент9 страницBidirectional Current Source-TIestraj1954100% (1)

- USB Overview: This Course Serves As An Introduction To USBДокумент68 страницUSB Overview: This Course Serves As An Introduction To USBDien Nguyen100% (1)

- Lecture 9 USB To PIC Microcontroller InterfaceДокумент8 страницLecture 9 USB To PIC Microcontroller Interfaceaaaa100% (1)

- Ubs ModДокумент14 страницUbs ModPatricio Andres100% (2)

- Beagle AnalyzerДокумент205 страницBeagle AnalyzerbelzurkurОценок пока нет

- Valtra T-Series-Classic-Hitech Manual Sec WatДокумент233 страницыValtra T-Series-Classic-Hitech Manual Sec WatBogusław BonczekОценок пока нет

- Instalaciones Eléctricas Industriales: Estudio del cortocircuitoДокумент26 страницInstalaciones Eléctricas Industriales: Estudio del cortocircuitoMikhaelA.RodriguezОценок пока нет

- Operating Manual: LKHSP Self-Priming Centrifugal PumpДокумент15 страницOperating Manual: LKHSP Self-Priming Centrifugal Pumppablo ortizОценок пока нет

- Atril Director - Wenger - Flex Conductors Stand-Basket Acc - Assembly - 236C128Документ2 страницыAtril Director - Wenger - Flex Conductors Stand-Basket Acc - Assembly - 236C128Produccion ProartesОценок пока нет

- Merkur Non-Heated Spray Packages: Instructions/PartsДокумент58 страницMerkur Non-Heated Spray Packages: Instructions/PartsFranklin LewisОценок пока нет

- Service Manual: 17" LCD Monitor IBM L170Документ54 страницыService Manual: 17" LCD Monitor IBM L170Yonny MunozОценок пока нет

- Term Paper On Embedded SystemДокумент11 страницTerm Paper On Embedded Systemsupreetsingh1960% (1)

- RE 2558 Manual V1.0 01Документ68 страницRE 2558 Manual V1.0 01Hamilton GutierrezОценок пока нет

- SL0005 Hydronix RangeДокумент6 страницSL0005 Hydronix RangeP.S.J.SarmaОценок пока нет

- NoteДокумент264 страницыNoteBelayneh TadesseОценок пока нет

- Final Draft - Specification - ISEJ65 - 22 - 02 - 2021Документ2 страницыFinal Draft - Specification - ISEJ65 - 22 - 02 - 2021Uday KumarОценок пока нет

- Antenna Isolator BuildДокумент6 страницAntenna Isolator BuildpegabendОценок пока нет

- Schematic - 131675901 3512 Electronico PDFДокумент2 страницыSchematic - 131675901 3512 Electronico PDFkhanghanh2017 a0% (1)

- HVDC Transmission Systems Textbook Chapter SummaryДокумент24 страницыHVDC Transmission Systems Textbook Chapter SummaryWillam MetzОценок пока нет

- Workshop Manual Octavia Engine Mechanics 1Документ72 страницыWorkshop Manual Octavia Engine Mechanics 1Shriram Iyer100% (2)

- Hho ManualДокумент23 страницыHho ManualtononoinkОценок пока нет

- 320C excavator swivel systemДокумент3 страницы320C excavator swivel systemMepita MecânicaОценок пока нет

- Digital Planet: Tomorrow's Technology and You: Hardware BasicsДокумент28 страницDigital Planet: Tomorrow's Technology and You: Hardware BasicsYazanОценок пока нет

- Cse-1100 1Документ25 страницCse-1100 1Showmik AhmedОценок пока нет

- Leader LBO 516Документ31 страницаLeader LBO 516raan4Оценок пока нет

- Simple Transformer-Less Inverter Circuit - 1000 WattДокумент9 страницSimple Transformer-Less Inverter Circuit - 1000 WattPramillaОценок пока нет

- CB SCV NovДокумент2 страницыCB SCV NovAhmed Abd ElkaderОценок пока нет

- SRT8KRMXLI DATASHEET WW en-WWДокумент4 страницыSRT8KRMXLI DATASHEET WW en-WWOscar VazquesОценок пока нет

- AEAT 9000 1GSH0 Full Option Ultra Precision 17 Bit Absolute Single Turn Encoder PDFДокумент8 страницAEAT 9000 1GSH0 Full Option Ultra Precision 17 Bit Absolute Single Turn Encoder PDFNguyen Quang VinhОценок пока нет

- Affordable High-End AudioДокумент120 страницAffordable High-End Audiozambila100% (2)

- Fuel and maintenance checkДокумент1 страницаFuel and maintenance checkDPОценок пока нет

- Ficha Tecnica - Bomba Hidraulica Sauer Danfoss PDFДокумент220 страницFicha Tecnica - Bomba Hidraulica Sauer Danfoss PDFpokebalomanОценок пока нет

- 966g XMSN GearsДокумент6 страниц966g XMSN Gearsrao abdul bariОценок пока нет

- Jacking A319/A320/A321 Aircraft (40Документ8 страницJacking A319/A320/A321 Aircraft (40cheemeng79Оценок пока нет

- Actuators & Valves Position Monitoring SwitchboxДокумент8 страницActuators & Valves Position Monitoring SwitchboxCall For JusticeОценок пока нет