Академический Документы

Профессиональный Документы

Культура Документы

Structural Characterization and Surface Modification of Sulfonated Polystyrene - (Ethylene-Butylene) - Styrene Triblock Proton Exchange Membranes

Загружено:

Nayilis Pahola Mendez MerlanoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Structural Characterization and Surface Modification of Sulfonated Polystyrene - (Ethylene-Butylene) - Styrene Triblock Proton Exchange Membranes

Загружено:

Nayilis Pahola Mendez MerlanoАвторское право:

Доступные форматы

Journal of Membrane Science 214 (2003) 245257

Structural characterization and surface modication of sulfonated polystyrene(ethylenebutylene)styrene triblock proton exchange membranes

Jongok Won a, , Sang Wook Choi b , Yong Soo Kang b , Heung Yong Ha c , In-Hwan Oh c , Hoon Sik Kim d , Kyoung Tae Kim e , Won Ho Jo e

Department of Applied Chemistry, Sejong University, 98 Gunja, Gwangjin, Seoul 143-747, South Korea Center for Facilitated Transport Membranes, Korea Institute of Science and Technology, 39-1 Hawolgok, Sungbuk, Seoul 139-791, South Korea c Center for Fuel Cells, Korea Institute of Science and Technology, 39-1 Hawolgok, Sungbuk, Seoul 139-791, South Korea d CFC Alternatives Research Center, Korea Institute of Technology, 39-1 Hawolgok, Sungbuk, Seoul 139-791, South Korea e Department of Material Science, Seoul National University, Seoul 151-742, South Korea

b a

Received 8 January 2002; received in revised form 12 November 2002; accepted 13 November 2002

Abstract Structural characteristics and membrane performance of polystyrene-block-poly(ethylene-ran-butylene)-block-polystyrene (sSEBS) copolymer proton exchange membranes in water-swollen and different ratio of water/methanol-swollen are studied by small angle X-ray scattering (SAXS), ATR FT-IR, AFM. SAXS prole of sSEBS membrane showed that microstructure was a hexagonally cylindrical structure and it was maintained in the existence of methanol in water until 30 wt.%. As the main interest was on the development of proton exchange membranes for fuel cells operating at lower temperature with liquid methanol feed, a selective thin layer was introduced on the top of sSEBS membrane by simple plasma treatment in the presence of maleic anhydride in order to prevent methanol crossover. Both methanol permeability and proton conductivity gradually decreased with increasing loading amounts of maleic anhydride. Hydrophobic anhydride properties on the top of sSEBS membrane act as a barrier for methanol but also for proton, resulting in decreasing methanol permeability and proton conductivity. The hydrolysis of anhydride groups to carboxylic acid provides a facilitated transport site for the proton. After hydrolysis, the proton conductivity was recovered and the recovery rate of proton conductivity by hydrolysis was higher than that of methanol permeability. 2002 Elsevier Science B.V. All rights reserved.

Keywords: Proton exchange membrane; Methanol crossover; Sulfonated polystyrene-block-poly(ethylene-ran-butylene)-block-polystyrene; Plasma surface modication

1. Introduction Fuel cells are an attractive power-generation technology that converts chemical energy directly [1].

Corresponding author. Tel.: +82-2-3408-3230; fax: +82-2-462-9954. E-mail address: jwon@sejong.ac.kr (J. Won).

Among them, direct methanol fuel cells (DMFCs) using polymer electrolyte membranes are candidates for the application of portable power source, electric vehicle and transport application because they do not require any fuel processing equipment (reformer, catalytic burner) and can be operated at low temperature [2,3]. Most DMFC research has concentrated on polymer electrolyte membrane fuel cells (PEMFC) fed

0376-7388/02/$ see front matter 2002 Elsevier Science B.V. All rights reserved. doi:10.1016/S0376-7388(02)00555-0

246

J. Won et al. / Journal of Membrane Science 214 (2003) 245257

directly with methanol [4,5]. The membrane used in DMFCs was developed for PEMFC applications for optimizing the proton conductivity; these membranes are not optimal with regard to methanol blocking. The proton diffusion across the membrane is associated with water transport in the membrane and methanol is also transported to the cathode by electro-osmotic drag, that is, methanol crossover, due to the similar properties of methanol (such as its dipole moment), and consequently, a decrease in cell performance [6,7]. Therefore, the membrane is a strong determining factor, which has to be optimized for DMFC. Moreover, the membrane has become thinner in order to lower cell resistance, and thin membranes tend to provide higher permeability for liquid methanol. Therefore, in DMFCs, a thicker membrane, such as Naon 120, has been used [8]; use of Naon membrane in DMFCs is associated with disadvantages including very high cost and a high rate of methanol permeation [9,10]. Thus, interests in the development of a low-cost membrane and a methanol blocking membrane that include good chemical stability and proton conductivity for DMFC have increased distinctly. The membrane prepared by DAIS-Analytical Corp., which is based on commercially available styrene ethylenebutylenestyrene (SEBS) triblock polymers, contain styrenenic blocks, which are subsequently sulfonated [1114]. DAIS membranes are reported to be much less expensive to produce than Naon. However, the main drawback in employing hydrocarbon-based materials is their poor chemical stability compared to peruorinated or partially peruorinated membranes due to the lower CH bond dissociation enthalpy [15]. For this reason, DAIS membranes are suitable for portable fuel cell power sources of 1 kW or less [11], for which operating temperatures are <60 C. Another drawback of sulfonated SEBS (sSEBS) membranes is their high methanol transport. Considerable effort has been devoted to the development of membrane having reduced methanol crossover. Membranes containing metallic blocking layers were proposed [6]. Organicinorganic composite membranes containing zeolites [16], silica [17] or tin doped mordenites [18] were investigated. It is also reported that to reduce the afnity for water of the Naon membrane by Cs+ impregnation, decreases the methanol crossover by 2 orders of magnitude [19]. Other promising composite membranes are

containing polybenzimidazole and phosphoric acid [20]. Other alternative are membranes made from blends of acidic and basic polymers [21]. These membranes are made by blending acidic polymers such as sulfonated polysulfones, sulfonated polyetherketones, or sulfornated polyetheretherketones with basic polymers such as poly(4-vinylpyridine), polybenzimidazole. Surface modication of membranes is an attractive approach since it changes the surface properties of a polymer membrane [2225]. Plasma techniques have been used to modify various types of membranes [26] as well as to induce graft polymerization [27]. In our previous work [24,25], modication of the surface of the polymer membrane by plasma in the presence of maleic anhydride (MAH) produces hydrophobic properties on the top of the polymer substrate, which may act as a barrier layer for methanol. In this research, we have prepared a composite membrane by introducing a selective layer on the surface of proton exchange membranes with the aim of blocking methanol. Non-uorinated proton exchange membranes, sSEBS, were chosen as a model system, and plasma technique has been used. The structure of the sSEBS membrane has been characterized by small angle X-ray scattering (SAXS). The surface of the sSEBS substrate was modied by plasma treatment with MAH, and then anhydride groups were hydrolyzed to form carboxylic acid as shown in Scheme 1. Thin layers of carboxylic acid were prepared on the surface of sSEBS substrates. The structure of the membrane and layer is characterized by ATR FT-IR, AFM and the performance of the membrane is determined by proton conductivity and methanol permeability.

2. Experimental 2.1. Materials Sulfonated polystyrene-block-poly(ethylene-ranbutylene)-block-polystyrene (sSEBS) solution in 1-propanol and dichloroethane (molecular weight 80000, 28 wt.% styrene and 45% of sulfonation; Aldrich), maleic anhydride (MAH; Junsei) and methanol (Merck, RPA) were purchased and used as received.

Scheme 1.

248

J. Won et al. / Journal of Membrane Science 214 (2003) 245257

2.2. Preparation of membrane sSEBS solution is poured into a Teon dish and dried at room temperature until complete evaporation of the solvent has taken place. The membranes were washed with deionized water before being placed in a vacuum oven for further drying at 25 C. The nal thickness of the membrane thus obtained was in the range of 60200 m. 2.3. Plasma surface treatments and hydrolysis Fifty milliliter of MAH were placed in a plasma reactor with sSEBS lms in order to introduce succinic anhydride groups on the sSEBS lms [28]. Plasma treatment was carried out using a R300A radio frequency generator (Autoelectric, Seoul), operating at 13.56 MHz and setting at 50 W. The membrane was glow-discharged for 20 s under the pressure of 0.1 Torr [17] in a bell jar type reactor (6 cm radius 11 cm deep). Inductively coupled plasma was generated by a circular coil connected to a radio frequency generator. After the plasma reaction on sSEBS membranes, each sample was placed in a round-bottom ask containing 125 ml of a 1 M NaOHHaHCO3 solution. The surface succinic anhydride groups were hydrolyzed to carboxylic acid salt groups. The samples were reuxed for 30 min, rinsed twice with distilled water, and vacuum dried for 24 h. A conversion of carboxylic acid salt to surface carboxylic acid groups was accomplished by placing the sample in 3 M HCl solution for 2 h, rinsing twice with distilled water, and vacuum dried for 24 h. 2.4. Characterization of the membranes The thickness of the succinic anhydride layer was estimated by the following methods; sSEBS were spin coated on the top of clean glass and the glass sample was plasma treated in the presence of MAH at the same condition. Then the thickness was measured by Rudoph RE350 2.4D Ellipsometer before and after plasma treatment. The values assumed are those of succinic layers on the surface of sSEBS membranes (estimated limitation of detection). Synchrotron small angle X-ray scattering measurements were performed at 4C1 SAXS beam line in Pohang Accelerator Laboratory, Korea. The raw data

were corrected for scattering from the empty cell, air scattering, dark current from detector and sample transmission at room temperature. Following these corrections, the data were circularly averaged to produce I(q) versus q plots where I(q) is the scattered intensity and q the scattering vector which is related to the scattering angle 2 (q = 4 sin /). The typical beam size was smaller than 1 mm 1 mm and the q range was from 0.005 to 0.122 1 [29]. The samples are in dried, in water-swollen, and in different ratio of methanol/water mixtures swollen state. All samples were kept in sealed polyimide envelopes during the measurement. AFM imaging was performed in air using a Digital Instruments Nanoscope V (Santa Barbara, CA) in tapping mode. 2.5. Membrane performance study The amount of methanol/water absorbed in sSEBS membrane was measured as a function of methanolwater uptake and temperature. The weight of a dried membrane was measured after drying the sample in a vacuum oven. The dried samples were equilibrated in each different ratio of methanol/water solution and weighed after the surface was dried with absorbent paper [30]. The methanolwater uptake amount of absorbed methanol/water was calculated by the following relationship: methanolwater uptake(%) = Mwet Mdry 100 Mdry (1)

where Mwet and Mdry are weights of wet and dried samples, respectively. A homemade two-point probe method was used to measure the proton conductivity of the membranes. As pointed out by Pivovar et al. [31], the interest conductivity for fuel cell application, is in the transverse rather than the longitudinal direction, so we used a two-point probe technique. It was found that a decrease in conduction of 70% for Naon tested in the transverse rather than the longitudinal direction [32]. Before the measurement of proton conductivity, the prepared membranes were equilibrated with deionized water and then surface dried with an absorbent paper to avoid any possible contribution to the impedance response from water lming between the probe and the membrane. Membranes were then

J. Won et al. / Journal of Membrane Science 214 (2003) 245257

249

quickly inserted into the stainless steel electrode of 12.756 cm2 and forced the current to pass through the membrane. A spring linked to one of the electrodes kept the membrane under a slight but constant pressure, thereby providing good contact between the electrodes and the membrane. Complex impedance measurements were carried out in the frequency range of 1 Hz to 8 MHz at 25 C, using ZAHNER IM-6 impedance analyzer [33]. Impedance spectra of membranes gave Nyquist plots [34,35] and the proton conductivity, K, was calculated from the plots: the resistance, R, was obtained from the intercept of either curve (high frequencies semicircle or low frequencies tail, whichever is more appropriate) with the real axis (Zreal), and using the formula K = l/RA, where l is the thickness and A the contact area of the sample [33]. The average conductivity of sSEBS membrane and Naon 117 are 1.74102 and 2.93102 s/cm, respectively. Methanol permeability of the membranes was determined using the diaphragm diffusion cell shown in Fig. 1 [36,37]. This cell consisted of two reservoirs each approximately 48 ml, separated by a vertical membrane. The membrane was clamped between the

two reservoirs and they were stirred during the experiment. Prior to the test, the membranes were equilibrated in deionized water for at least 5 h. Initially, one reservoir contained a methanolwater mixture (5 wt.% methanol; Cell A) and the other reservoir contained only water (Cell B). Increases over time in the concentration of methanol in the reservoir Cell B were detected by gas chromatography (Gow-mac Instrument Co.) and differential refractometer (RI750F by Young Inc. Co.). Each reservoir has a capillary tube for sampling l l for gas chromatography [31]. For chosen samples, the reservoir Cell B was connected directly to a differential refractometer and the concentration variation was measured continuously with detection time. Methanol concentration in the receiving reservoir detected as a function of time has the following relationship: CB (t) = A DK CA (t t0 ) VB L (2)

where CA and CB are the concentration of methanol in Cells A and B, VA and VB are the volumes of Cells A and B, A and L are the area and thickness of membrane, and D and K are the methanol diffusivity

Fig. 1. Diffusion cell.

250

J. Won et al. / Journal of Membrane Science 214 (2003) 245257

and partition coefcient, respectively. The product DK is the membrane permeability [37]. The average permeability values of sSEBS and Naon 117 at room temperature are 1.69 106 and 2.86 106 cm2 /s, respectively. The permeability of the sSEBS membrane is slightly lower than that of Naon 117. FT-IR measurements were performed on a 6030 Galaxy Series FT-IR spectrometer (Mattson Instruments); 256 scans were signal-averaged at a resolution

of 4 cm1 . The ATR spectra were obtained using a KRS-5 prism with an incident angle of 45 . 3. Results and discussion 3.1. Structural characterization of sSEBS SAXS has been used to study the size and the spatial arrangement of the micro domains of triblock

Fig. 2. SAXS proles of sSEBS membranes in dried and water-swollen state at room temperature.

Fig. 3. SAXS proles of sSEBS membranes at different concentration of methanol solution.

J. Won et al. / Journal of Membrane Science 214 (2003) 245257

251

copolymers. The structure of the sSEBS membrane was reported as a heterogeneous microstructure with polar (hydrophilic) ion-rich domains separated from a non-polar (hydrophobic) dielectric matrix [13,38]. Fig. 2 shows the circularly integrated SAXS curves from a dried and a water-swollen state of sSEBS membranes. The micro domain morphology of a dried triblock copolymer can be determined from the scattering vector (q) values of higher order peaks relative to the rst order peak for inter-particle scattering since they exhibit different arrays depending on the

shapes of micro-domain structure such as spheres in cubic lattice, cylinders in hexagonal lattice, and lamellar [3941]. Cylinders arranged in a hexagonal lattice result in relative q values of 1, 31/2 , 41/2 , 71/2 , 91/2 , 121/2 , . . . [3941]. The sequence of reections in the dried sSEBS membrane is in accordance with the assumption of a hexagonal packing of cylinders. The inter-cylinder distance, a, is given by [39,40] a= 2 q 4 3 (3)

Fig. 4. Absorption for the methanolwater solutions as a function of (a) methanol concentration at 25 C, (b) temperature at 20 wt.% of methanol solution.

252

J. Won et al. / Journal of Membrane Science 214 (2003) 245257

where q is the q position of the rst maximum. Then the cylinder diameter, d, can be estimated using Eq. (4). d=a 2 3PS (4)

where PS is the volume fraction of the micro domain. The inter-cylinder distance and cylinder diameter for dry triblock copolymer were calculated using q = 0.0167 1 and PS = 0.25 given by the manufacturer, and found to be 430 and 230 , respectively. It can be seen that the value of q moved to lower scattering angle to 0.0106 1 for the water-swollen state while maintaining ordered q values. This means that the cylindrical structure is maintained but the inter-domain spacing increases to, ca. 680 , and so does the cylindrical diameter. Fig. 3 shows the structural behavior of sSEBS membranes at different concentrations of methanol in water. It can be seen that the value of q moved to higher scattering angles and shapes is smoothing with increasing amounts of methanol. It means that inter-domain spacing decreased and the structure is being destroyed. Methanol was known to permeate mainly through the cylindrical hydrophilic ion-rich domain [35]. However, it is also possible for methanol to solvate the hydrophobic ethylenebuthylene (EB)

matrix domain because of the favorable solubility parameter of EB block to methanol rather than to water. The solubility parameters of EB, methanol and water are 16.2, 29.7 and 47.9 (J/cm3 )1/2 , respectively. Therefore the clear borderline between hydrophobic and hydrophilic regimes destroyed due to the different preferential adsorption between the solvents and sSEBS lms. Therefore, the volume of cylindrical part is decreased. However, the cylindrical morphologies are still sustained in this experimental condition. The amount of the methanolwater uptake with increasing amounts of methanol in water, and temperature, are plotted in Fig. 4a and b, respectively. The methanolwater uptake rate was also measured and the value of methanolwater uptake levels off in 3 h, which provided for all samples to be equilibrated in 3 h. The methanolwater uptake generally increases with increasing methanol content and temperature. From the results of SAXS and methanol/water absorption of sSEBS membranes in different concentrations of methanol, to understand equilibrium or further the transport mechanism of methanol in sSEBS proton exchange membrane is not expected to be a simple process. Since methanol can be transported both in hydrophilic and hydrophobic regimes, blocking the methanol transport through the hydrophilic ion-rich channel [35] may not be sufcient to solve the methanol crossover problem. Therefore, the surface

Fig. 5. FT-IR spectra of succinic anhydride plasma-treated sSEBS membranes (a) before hydrolysis and (b) after hydrolysis.

J. Won et al. / Journal of Membrane Science 214 (2003) 245257

253

modication with methanol blocking materials would help to solve the methanol crossover phenomena. 3.2. Surface modication of sSEBS Succinic anhydride can be chemically bound to the surface of polymer substrate by plasma treatment with MAH [4244]. ATR FT-IR spectroscopy provides information on the surface of the anhydride-modied sSEBS lm, which is shown in Fig. 5. The spectrum of the succinic anhydride layer on the plasma-treated sSEBS membrane has three bands at 1844, 1778 and 1730 cm1 , which can be attributed to the asymmetric

and symmetric anhydride C=O stretching modes of succinic anhydride and the C=O stretching modes of the carboxyl group resulting most likely from the ring-opening reaction of anhydride on the surface, respectively. The intensity of the 1778 cm1 is much stronger than that of the 1730 cm1 band, meaning that the majority of the anhydride functionality is maintained during plasma treatment. Surface succinic anhydride layer having hydrophobic properties on the surface of sSEBS membrane will operate as a barrier for methanol as well as for proton. Therefore, it is necessary to provide the facilitated channel for proton transport by providing ion exchange sites such as

Fig. 6. Changes of (a) permeability and (b) conductivity of surface-modied sSEBS membranes before and after hydrolysis.

254

J. Won et al. / Journal of Membrane Science 214 (2003) 245257

carboxylic acid. With this idea in mind, the succinic anhydride layer on the surface was hydrolyzed to carboxylic acids groups (Scheme 1). After hydrolysis, the intensity of the 1778 cm1 band is drastically reduced, and a new band at 1583 cm1 is detected. The 1583 cm1 band is assigned to the asymmetric stretching modes of COO of the carboxylic acid salt. This assignment was conrmed by subsequent surface washing with 1 M HCl which showed the formation of a carboxylic acid C=O stretching mode. At the same time, a loss of the carboxylic acid salt band was detected [17]. However, incomplete conversion of the surface anhydride to carboxylic acid salt is apparent, indicating that there are anhydride groups which may reside below the surface due to polymerization and thus are unavailable for further reactions, and these may act as a hydrophobic layer. The deposited amount was detected by the thickness measurement of the loading amount of MAH in the plasma reactor. Although we have tried to measure the thickness dependence of the loading amount of MAH at lower concentration ranges, it was not detected, being below the practical lower limit of the ellipsometry. The thickness of the anhydride layer was 440 10 when the sample was plasma treated with 100 mg of MAH, and our previous result showed that the deposited amount increases and then levels off [24], so the thickness must be <440 when the sample is plasma treated with 50 mg of MAH. In Fig. 6a and b, the membrane conductivity and permeability at room temperature before and after hydrolysis are plotted as a function of the MAH content in the reactor, respectively. Clearly, the surface modication of the sSEBS membrane reduced both the methanol permeability and the conductivity with the loading amount of MAH (open circle in Fig. 6a and b). After hydrolysis, decreased proton conductivity was recovered and also permeability (lled circle). The rate of recovery, Rr , due to the hydrolysis was estimated by the following equation: Rr = Va V b 100 Vb (5)

Fig. 7. The recovering rate of conductivity and permeability.

where Vb and Va are the values of conductivity or permeability before and after hydrolysis, respectively. Fig. 7 shows the recovering rate of conductivity and permeability of each sample of loading amount of MAH. It can be seen that the recovering rate of

conductivity was higher than that of the permeability, as shown in the gure. The surface modication by plasma treatment in this research provides the possibility of improved performance in the conductivitypermeability relationship, but the values are not that promising as yet. We have found the reason for those unsatisfactory results is the high swelling of sSEBS membrane measured by SAXS and signicant swelling hysteresis. Fig. 8a and b show the surface AFM images of the sSEBS membranes before and after plasma treatment, respectively. The area of the image is 5 m 5 m in the x,y-plane with an expended z-axis. The plasma treatment slightly increased the surface roughness from 1.994 to 3.352 nm. However, the surface was dramatically changed after swelling. Both samples were equilibrated in 5 wt.% of methanol solution and then dried slowly at room temperature. Fig. 8c and d show images of dried samples of Fig. 8a and 8b after swollen in 5 wt.% methanol solution, and the surface roughness were 5.151 and 8.971, respectively. The surface of sample Fig. 8c is different from the one of the pristine sample, and the difference is serious for the plasma-treated sample. In section analysis, the plasma-modied sample shows very different depth prole from that of the unmodied sample, implying a different swelling behavior between succinic anhydride on the top layer and that of the bulk layer in methanol solution. Therefore, stress builds in the surface of the succinic anhydride layer during the

J. Won et al. / Journal of Membrane Science 214 (2003) 245257 Fig. 8. AFM images of (a) pristine and (b) surface-modied sSEBS membranes; (c) and (d) are dried samples of (a) and (b) after they were equilibrated in 5 wt.% of methanol solution, respectively. 255

256

J. Won et al. / Journal of Membrane Science 214 (2003) 245257

swelling process, which affects the surface morphology as well as the methanol permeability and proton conductivity. 4. Summary and conclusions Structural properties of commercially available non-uorinated proton exchange membranes have been characterized by SAXS. Water and different ratio of methanol/water-swollen sSEBS proton exchange membranes has been studied. SAXS prole of sSEBS membrane showed that microstructure of sSEBS lm was a hexagonally cylindrical structure. It was found that inter domain spacing and cylinder diameter increase at water-swollen state from the q lowering scattering angles. The value of q moved to higher scattering angles as the methanol concentration increased in water, presumably due to the transport of methanol both in the hydrophobic matrix and hydrophilic ion-rich domain. The surface of the sSEBS membrane was modied by simple plasma treatment in the presence of MAH in order to provide a barrier for methanol. A hydrophobic succinic anhydride thin layer was chemically attached on the surface of the sSEBS membrane and acted as a barrier for the methanol and proton transport. The proton conductivity and methanol permeability gradually decreased with increasing loading amounts of MAH. Hydrolysis of anhydride groups provides carboxylic acid, which can provide facilitated transport sites for the proton. After the hydrolysis process, decreasing proton conductivity was recovered along with methanol permeability. The recovery rate of proton conductivity by hydrolysis was higher than that of methanol permeability. Acknowledgements Supports for this work were provided by the Korea Research Council of Fundamental Science and Technology and the Ministry of Science and Technology of Korea (Creative Research Initiatives Program). This work has beneted from the use of Synchrotron source 4C1 SAXS beam line in Pohang Accelerator Laboratory (PAL), Korea and SAXS instrument with Cu K radiation at the National Instrumentation Center for Environment Management (NICEM).

References

[1] E. Perry Murray, T. Tsai, S.A. Barnett, A direct methane fuel cell with a ceria-based anode, Nature 400 (1999) 649. [2] X. Ren, M.S. Wilson, S. Gottesfel, High performance direct methanol polymer electrolyte fuel cells, J. Electrochem. Soc. 143 (1996) 12. [3] N.A. Hampson, M.J. Wilars, B.D. McNicol, The methanolair fuel cell: a selective review of methanol oxidation mechanisms at platinum electrodes in acid electrolytes, J. Power Sources 4 (1979) 191. [4] M.K. Ravikumar, A.K. Shukla, Effect of methanol crossover in a liquid-feed polymer-electrolyte direct methanol fuel cell, J. Electrochem. Soc. 143 (1996) 2601. [5] A. Kver, W. Vielstich, Investigation of methanol crossover and single electrode performance during PEMFC operation: a study using a solid polymer electrolyte membrane fuel system, J. Power Sources 74 (1998) 211. [6] C. Pu, W. Huang, K.L. Ley, E.S. Smotkin, A methanol impermeable proton conducting composite electrolyte system, J. Electrochem. Soc. 142 (1995) 119. [7] G.T. Burstein, C.J. Barnett, A.R. Kucernak, K.R. Williams, Aspects of the anodic oxidation of methanol, Catal. Today 38 (1998) 425. [8] X. Ren, T.E. Springer, S. Gottesfeld, Water and methanol uptakes in Naon membranes and membrane effects on direct methanol cell performance, J. Electrochem. Soc. 147 (2000) 92. [9] F. Babir, T. Gomez, Efciency and economics of proton exchange membrane (PEM) fuel cells, Int. J. Hydrogen Ener. 21 (1996) 891. [10] M.W. Verbrugge, Methanol diffusion in peruorinated ionconducting membranes, J. Electrochem. Soc. 136 (1989) 417. [11] S.G. Ehrenberg, J.M. Serpico, B.M. Sheikh-Ali, T.N. Tangredi, E. Zador, G.E. Wnek, in: O. Savadogo, P.R. Roberge (Eds.), Proceedings of the Second International Symposium on New Materials for Fuel Cell and Modern Battery Systems, Montreal, Canada, 610 July 1997, p. 828. [12] S.G. Ehrenberg, J.K. Serpico, G.E. Wnek, J.N. Rider, Fuel cell incorporating novel ion-conducting membrane, US Patent, 5,468,574 (1995). [13] G.E. Wnek, J.N. Rider, J.M. Serpico, A.G. Einset, Proceedings of the First International Symposium on Proton Conducting Membrane Fuel Cells, Electrochemical Society, 1995, p. 247. [14] W. Grot, Use of Naon peruorosulfonic acid products as separators in electrolytic cells, Chem. Ing. Technol. 50 (1978) 299. [15] R.B. Hodgdon Jr., Polyelectrolytes prepared from peruoroalkylaryl macromolecules, J. Polym. Sci. 6 (1968) 171. [16] Z. Poltarzewskii, W. Wieczorek, J. Przyluski, V. Antonucci, Novel proton conducting composite electrolytes for application in methanol fuel cells, Solid State Ionics 119 (1999) 301. [17] P.L. Antonucci, A.S. Aroc, P. Cret`, E. Ramunni, V. Antonucci, Investigation of direct methanol fuel cell based on a composite Naonsilica electrolyte for high temperature operation, Solid State Ionics 125 (1999) 431.

J. Won et al. / Journal of Membrane Science 214 (2003) 245257 [18] N. Rao, T.P. Andersen, P. Ge, Tin mordenite membrane for direct methanol fuel cell, Solid State Ionics 72 (1994) 334. [19] V. Tricoli, in: S. Gottesfeld, T.F. Fuller (Eds.), Proceedings of the Second International Symposium on Proton Conducting Membrane Fuel Cells II, Boston, MA, 1998, p. 358. [20] T.J. Wang, S. Wasmus, R.F. Savinell, Real-time mass spectrometric study of methanol crossover in a direct methanol fuel cell, J. Electrochem. Soc. 143 (1996) 1233. [21] J. Kerres, A. Ullrich, F. Meier, T. Hring, Synthesis and characterization of novel acidbase polymer blends for application in membrane fuel cells, Solid State Ionics 125 (1999) 243. [22] J. Won, M.H. Kim, Y.S. Kang, H.C. Park, U.Y. Kim, S.C. Choi, S.K. Koh, Surface modication of polyimide and polysulfone membranes by ion beam for gas separation, J. Appl. Polym. Sci. 75 (2000) 1554. [23] Y.S. Park, Y.S. Kang, J. Won, Surface immobilization of starshaped poly(ethylene oxide) on poly(dimethylsiloxane), J. Appl. Polym. Sci. 83 (2002) 2369. [24] B.J. Cha, Y.S. Kang, J. Won, Preparation and characterization of dendrimer layers on poly(dimethylsiloxane) lms, Macromolecules 34 (2001) 6631. [25] J. Won, K.J. Ihn, Y.S. Kang, Gold nano-particle patterns on polymer lms in the presence of poly(amidoamine) dendrimers, Langmuir 18 (2002) 8246. [26] P.W. Kramer, Y.S. Yeh, H. Yasuda, Low temperature plasma for the preparation of separation membranes, J. Membr. Sci. 46 (1989) 1. [27] M. Ulbricht, G. Belfort, Surface modication of ultraltration membranes by low temperature plasma. II. Graft polymerization onto polyacrylonitrile and polysulfone, J. Membr. Sci. 111 (1996) 193. [28] S.R. Caboury, M.W. Urban, Microwave plasma reactions of solid monomers with silicone elastomer surfaces, Langmuir 9 (1993) 3225. [29] H.-G. Haubold, Th. Vad, H. Jungbluth, P. Hiller, Nano structure of Naon: a SAXS study, Electochim. Acta 46 (2001) 1559. [30] S.M.J. Zaidi, S.D. Mikhailenko, G.P. Roberton, M.D. Guiver, S. Kaliaguine, Proton conducting composite membranes from polyether ether ketone and heteropolyacids for fuel cell applications, J. Membr. Sci. 173 (2000) 17. [31] B.S. Pivovar, Y. Wang, E.L. Cussler, Pervaporation membranes in direct methanol fuel cells, J. Membr. Sci. 154 (1999) 155.

257

[32] C.L. Gardner, A.V. Anantaraman, Measurement of membrane conductivities using an open-ended coaxial probe, J. Electroanal. Chem. 395 (1995) 67. [33] M.A. Vargas, R.A. Vargas, B.-E. Mellander, New proton conducting membranes-based PVAL/H3 PO2 /H2 O, Electochim. Acta 44 (1999) 4227. [34] R.A. Vargas, A. Garca, M.A. Vargas, Phase behavior of complexes of PVA and acid salts, Electochim. Acta 43 (1998) 1271. [35] J.J. Fontanella, M.C. Wintersgill, J.S. Wainrght, R.F. Savinell, M. Litt, High pressure electrical conductivity studies of acid doped polybenzimidazol, Electochim. Acta 43 (1998) 1289. [36] V. Tricoli, Proton and methanol transport in poly(peruorosulfonate) membranes containing Cs+ and H+ cations, J. Electrochem. Soc. 145 (1998) 3798. [37] N. Carretta, V. Tricoli, F. Picchioni, Ionomeric membranes based on partially sulfonated poly(styrene): synthesis, proton conduction and methanol permeation, J. Membr. Sci. 166 (2000) 189. [38] X. Lu, W.P. Steckle, R.A. Weiss, Morphological studies of a triblock-copolymer ionomer by small-angle X-ray scattering, Macromolecules 26 (1993) 6525. [39] R.F. Storey, D.W. Baugh III., Poly(styrene-b-isobutyleneb-styrene) block copolymers and ionomers therefrom: morphology as determined by small-angle X-ray scattering and transmission electron microscopy, Polymer 41 (2000) 3205. [40] B. Heck, P. Arends, M. Ganter, J. Kressler, B. Sthn, SAXS and TEM Studies on poly(styrene)-block-poly(ethene-co-but1-ene)-block-poly(styrene) in bulk and at various interfaces, Macromolecules 30 (1997) 4559. [41] S. Sakurai, H. Kawada, T. Hashimoto, L.J. Fetters, Thermoreversible morphology transition between spherical and cylindrical microdomains of block copolymers, Macromolecules 26 (1993) 5796. [42] M.E. Ryan, A.M. Hynes, J.P.S. Badyal, Pulsed plasma polymerization of maleic anhydride, Chem. Mater. 8 (1996) 37. [43] S.R. Gaboury, M.W. Urban, Microwave plasma reactions of solid monomers with silicone elastomer surfaces: a spectroscopic study, Langmuir 9 (1993) 3225. [44] S.R. Gaboury, M.W. Urban, Quantitative attenuated total reectance Fourier transform infrared analysis of microwave plasma reacted silicone elastomer surfaces, Langmuir 10 (1994) 2289.

Вам также может понравиться

- Nafion/Analcime and Nafion/Faujasite Composite Membranes For Polymer Electrolyte Membrane Fuel CellsДокумент5 страницNafion/Analcime and Nafion/Faujasite Composite Membranes For Polymer Electrolyte Membrane Fuel Cellsshoemakerlevy9Оценок пока нет

- Improving properties by inorganic nano-additives _2019Документ8 страницImproving properties by inorganic nano-additives _2019SureshBharadwajОценок пока нет

- TFC Polyamide Membranes Modified by Grafting of Hydrophilic Polymers - An FT-IR AFM TEM StudyДокумент10 страницTFC Polyamide Membranes Modified by Grafting of Hydrophilic Polymers - An FT-IR AFM TEM StudyAlisya AlyaОценок пока нет

- 1 s2.0 S0376738818302163 MainДокумент8 страниц1 s2.0 S0376738818302163 MainLeyla UОценок пока нет

- 10 1016@j Memsci 2018 07Документ32 страницы10 1016@j Memsci 2018 07Elizabeth ZamoraОценок пока нет

- Tiraferri A Et Al DX - Doi.org:10.1021:am200536p - ACS Appl. Mater. Interfaces 2011, 3, 2869-2877Документ9 страницTiraferri A Et Al DX - Doi.org:10.1021:am200536p - ACS Appl. Mater. Interfaces 2011, 3, 2869-2877parnaz88Оценок пока нет

- Desalination by Ammonia-Carbon Dioxide Forward Osmosis: Influence of Draw and Feed Solution Concentrations On..Документ11 страницDesalination by Ammonia-Carbon Dioxide Forward Osmosis: Influence of Draw and Feed Solution Concentrations On..Javier Rodrigo Nahuat SansoresОценок пока нет

- Fouling-Resistant Coatings For Reverse Osmosis Membranes: Gas and Liquid Permeation Studies On Morphology and Mass Transport EffectsДокумент9 страницFouling-Resistant Coatings For Reverse Osmosis Membranes: Gas and Liquid Permeation Studies On Morphology and Mass Transport Effectssyed_ahmed_71Оценок пока нет

- Solid State Ionics: Jilin Wang, Lulu WangДокумент8 страницSolid State Ionics: Jilin Wang, Lulu WangCharanraj MohanОценок пока нет

- Effects of Coagulation Conditions On The Properties of Regenerated Cellulose Films Prepared in NaOH in Urea Aqueous SolutionДокумент8 страницEffects of Coagulation Conditions On The Properties of Regenerated Cellulose Films Prepared in NaOH in Urea Aqueous Solutionsurached thongboonОценок пока нет

- Nano-Silica Layered Composite Membranes Prepared by PECVD For Direct Methanol Fuel CellsДокумент6 страницNano-Silica Layered Composite Membranes Prepared by PECVD For Direct Methanol Fuel CellssggdgdОценок пока нет

- Modification of Chitosan Membranes With Nanosilica Particles As Polymer Electrolyte MembranesДокумент10 страницModification of Chitosan Membranes With Nanosilica Particles As Polymer Electrolyte MembranesGiacomo AccomandoОценок пока нет

- Enhancing Stability and Efficiency of Perovskite Solar Cells With Crosslinkable Silane-Functionalized and Doped FullereneДокумент9 страницEnhancing Stability and Efficiency of Perovskite Solar Cells With Crosslinkable Silane-Functionalized and Doped FullerenepeterОценок пока нет

- Separation and Purification Technology: F. Arndt, F. Ehlen, S. Schütz, H. Anlauf, H. NirschlДокумент8 страницSeparation and Purification Technology: F. Arndt, F. Ehlen, S. Schütz, H. Anlauf, H. Nirschlnermeen ahmedОценок пока нет

- Advances in Polymeric Nanofiltration Membrane - A ReviewДокумент56 страницAdvances in Polymeric Nanofiltration Membrane - A ReviewPolanqОценок пока нет

- Dispersion of Alumina Suspension Using Comb-Like and Diblock Copolymers Produced by RAFT Polymerization of AMPS and MPEGДокумент13 страницDispersion of Alumina Suspension Using Comb-Like and Diblock Copolymers Produced by RAFT Polymerization of AMPS and MPEGKelvin XuОценок пока нет

- Preparation of PDMS - Al O Composite Hollow Fibre Membranes For VOC Recovery From Waste Gas StreamsДокумент8 страницPreparation of PDMS - Al O Composite Hollow Fibre Membranes For VOC Recovery From Waste Gas Streamsrelristein2719Оценок пока нет

- Increasing The Ion Conductivity by Modification of Anion Exchange Membranes For Alkaline Fuel CellsДокумент14 страницIncreasing The Ion Conductivity by Modification of Anion Exchange Membranes For Alkaline Fuel CellsBsoul SajaОценок пока нет

- Perovskite Solar Cell - WikipediaДокумент14 страницPerovskite Solar Cell - WikipediaShreeyesh BiswalОценок пока нет

- 1607 04627 PDFДокумент30 страниц1607 04627 PDFshubhamОценок пока нет

- JMaterChem2010 20 7788 PDFДокумент12 страницJMaterChem2010 20 7788 PDFecully03Оценок пока нет

- Composite Proton Exchange Membranes Based On ChitoДокумент15 страницComposite Proton Exchange Membranes Based On ChitoNafillah AbdurrahmanОценок пока нет

- Journal of Membrane Science: SciencedirectДокумент7 страницJournal of Membrane Science: SciencedirectmОценок пока нет

- 2008 Karakoulia Micr - Mesop.Mater. ODP+V-silicatesДокумент10 страниц2008 Karakoulia Micr - Mesop.Mater. ODP+V-silicatesmatoula karaОценок пока нет

- A New Nanosensor Composed of Laminated Samarium Borate and Immobilized Laccase For Phenol DeterminationДокумент7 страницA New Nanosensor Composed of Laminated Samarium Borate and Immobilized Laccase For Phenol DeterminationpollolocolocolocoОценок пока нет

- A Novel Polyester Amide Loose Composite Nanofiltration Membr - 2022 - Journal ofДокумент10 страницA Novel Polyester Amide Loose Composite Nanofiltration Membr - 2022 - Journal ofFelipe Leyva HaroОценок пока нет

- Microporous and Mesoporous Materials: Wei Shan, Lei Chen, Yang Chu, Feipeng Zhao, Guozheng Liang, Aijuan Gu, Li YuanДокумент10 страницMicroporous and Mesoporous Materials: Wei Shan, Lei Chen, Yang Chu, Feipeng Zhao, Guozheng Liang, Aijuan Gu, Li YuancansuОценок пока нет

- Comb Shaped SEBS Based Anion Exchange Membranes With Obviou - 2022 - ElectrochimДокумент12 страницComb Shaped SEBS Based Anion Exchange Membranes With Obviou - 2022 - ElectrochimLeyla UОценок пока нет

- Tan 2010Документ7 страницTan 2010Mandal RupeshОценок пока нет

- Characterizing Salt Permeability in Polyamide Desalination Membranes Using Electrochemical Impedance SpectrosДокумент40 страницCharacterizing Salt Permeability in Polyamide Desalination Membranes Using Electrochemical Impedance SpectrosshubhamОценок пока нет

- Journal of Membrane Science: Bo Zhang, Zhen HeДокумент7 страницJournal of Membrane Science: Bo Zhang, Zhen HeAditya KumarОценок пока нет

- MiMeMat100 (2007) 173Документ10 страницMiMeMat100 (2007) 173alimakbarОценок пока нет

- Engineered Complex Emulsion System: Toward Modulating The Pore Length and Morphological Architecture of Mesoporous SilicasДокумент8 страницEngineered Complex Emulsion System: Toward Modulating The Pore Length and Morphological Architecture of Mesoporous SilicasRafael Ricardo Celin ManceraОценок пока нет

- 聚合物和陶瓷形态对锂离子电池隔膜电纺PAN,聚合物陶瓷复合纳米纤维膜材料和电化学性能的影响Документ8 страниц聚合物和陶瓷形态对锂离子电池隔膜电纺PAN,聚合物陶瓷复合纳米纤维膜材料和电化学性能的影响yinghuanchen123Оценок пока нет

- MP Review PaperДокумент10 страницMP Review PaperMUHAMMAD USMAN Mechanical Pesh.-Batch 20Оценок пока нет

- A Modified Two-Step Sequential Spin-Coating Method For Perovskite Solar Cells Using CsI Containing Organic Salts in Mixed Ethanol Methanol SolventДокумент7 страницA Modified Two-Step Sequential Spin-Coating Method For Perovskite Solar Cells Using CsI Containing Organic Salts in Mixed Ethanol Methanol Solvent北科大-洪珮倫Оценок пока нет

- Influence of Nanoscale Nio On Magnetic and Electrochemical Behavior of Pvdf-Based Polymer NanocompositesДокумент9 страницInfluence of Nanoscale Nio On Magnetic and Electrochemical Behavior of Pvdf-Based Polymer NanocompositesBharathi PonrajОценок пока нет

- tmpB031 TMPДокумент6 страницtmpB031 TMPFrontiersОценок пока нет

- Surface & Coatings Technology: Young-Yeon Ji, Yong-Cheol Hong, Suck-Hyun Lee, Sung-Dae Kim, Sang-Sik KimДокумент5 страницSurface & Coatings Technology: Young-Yeon Ji, Yong-Cheol Hong, Suck-Hyun Lee, Sung-Dae Kim, Sang-Sik KimDjo BrainОценок пока нет

- Enhanced Performance of The Solid Alkaline Fuel Cell Using PVA-KOH MembraneДокумент9 страницEnhanced Performance of The Solid Alkaline Fuel Cell Using PVA-KOH MembraneDgek LondonОценок пока нет

- Synthesis and Characterization of Carbon Nanotubes/poly Vinyl Alcohol Nanocomposite Membranes For Dehydration of IsopropanolДокумент11 страницSynthesis and Characterization of Carbon Nanotubes/poly Vinyl Alcohol Nanocomposite Membranes For Dehydration of IsopropanolConicov IuliaОценок пока нет

- Dmso MembraneДокумент21 страницаDmso MembraneKers CelestialОценок пока нет

- Study On Nano-Multi-Walled Carbon Nanotubes and Nano-TiO2 Modified Composite Reverse Osmosis Membrane in Water TreatmentДокумент12 страницStudy On Nano-Multi-Walled Carbon Nanotubes and Nano-TiO2 Modified Composite Reverse Osmosis Membrane in Water Treatmentyingxiao maОценок пока нет

- Separation and Puri Fication Technology: SciencedirectДокумент11 страницSeparation and Puri Fication Technology: SciencedirectMaite Roque CastroОценок пока нет

- Jurnal 2 Membran Fuell From Chitosan & ABSДокумент8 страницJurnal 2 Membran Fuell From Chitosan & ABSMochammad Rendra PascariansyahОценок пока нет

- Enhancement of Pervaporation Performance of Composite Membranes Through in Situ Generation of Silver Nanoparticles in Poly (Vinyl Alcohol) MatrixДокумент11 страницEnhancement of Pervaporation Performance of Composite Membranes Through in Situ Generation of Silver Nanoparticles in Poly (Vinyl Alcohol) MatrixSiddhartha MoulikОценок пока нет

- Surface Treatment of Aramid Fiber by Air Dielectric Barrier Discharge Plasma at Atmospheric PressureДокумент6 страницSurface Treatment of Aramid Fiber by Air Dielectric Barrier Discharge Plasma at Atmospheric PressureZe MariОценок пока нет

- Sulfonated Poly (Ether Ether Ketone) Membranes For Direct Methanol Fuel CellДокумент9 страницSulfonated Poly (Ether Ether Ketone) Membranes For Direct Methanol Fuel CellAxel RodríguezОценок пока нет

- Ref Nata P1 - No 5Документ8 страницRef Nata P1 - No 5yanniputriОценок пока нет

- Membranes 13 00654Документ27 страницMembranes 13 00654Dr.Ghada MohammedОценок пока нет

- Abd Jalil Et Al - 2017 - Vacuum-Assisted Tailoring of Pore Structures of Phenolic Resin Derived CarbonДокумент9 страницAbd Jalil Et Al - 2017 - Vacuum-Assisted Tailoring of Pore Structures of Phenolic Resin Derived Carbon周世奇Оценок пока нет

- PVA / Montmorillonite Nanocomposites: Development and PropertiesДокумент23 страницыPVA / Montmorillonite Nanocomposites: Development and PropertiesDgek LondonОценок пока нет

- The Ability of A Nanofiltration Membrane To Remove Hardness and Ions From SeawaterДокумент12 страницThe Ability of A Nanofiltration Membrane To Remove Hardness and Ions From SeawaterRahul Gogia100% (1)

- Journal of Colloid and Interface ScienceДокумент9 страницJournal of Colloid and Interface SciencenimzaiОценок пока нет

- Optimizing Scalability, Stability, and Performance of Perovskite Solar CellsДокумент16 страницOptimizing Scalability, Stability, and Performance of Perovskite Solar CellsSimonSwifterОценок пока нет

- Preparation of Plasma-Polymerized SiOx-like Thin Films From A MixtureДокумент6 страницPreparation of Plasma-Polymerized SiOx-like Thin Films From A MixturekgvtgОценок пока нет

- 1 s2.0 S0304389417303357 MainДокумент15 страниц1 s2.0 S0304389417303357 MainIkram ADNANEОценок пока нет

- Recent Development of Novel Membranes For Desalination 2018 DesalinationДокумент23 страницыRecent Development of Novel Membranes For Desalination 2018 DesalinationWendyОценок пока нет

- Evaluating The Performance of Hybrid ProtonДокумент16 страницEvaluating The Performance of Hybrid ProtonMizanur RahmanОценок пока нет

- Ordered Porous Solids: Recent Advances and ProspectsОт EverandOrdered Porous Solids: Recent Advances and ProspectsValentin ValtchevОценок пока нет

- Design Calculation of Single-Stage Radial Type Centrifugal Blower For Rice MillДокумент5 страницDesign Calculation of Single-Stage Radial Type Centrifugal Blower For Rice MillMuhammadTayyabОценок пока нет

- Internal Combustion Engine Cooling MethodsДокумент52 страницыInternal Combustion Engine Cooling MethodsShiva KumarОценок пока нет

- Ntcle 100Документ17 страницNtcle 100Roberto RicardoneОценок пока нет

- Light and ReflectionДокумент34 страницыLight and ReflectionAmina AlmarzooqiОценок пока нет

- Cyclic Loading Behavior of An Inovative Semi Rigid Connection For Engineered Bamboo-Steel Hybrid FrameДокумент8 страницCyclic Loading Behavior of An Inovative Semi Rigid Connection For Engineered Bamboo-Steel Hybrid FrameAhmad YaniОценок пока нет

- Ce511 S1 Cay Sim1.1Документ8 страницCe511 S1 Cay Sim1.1Thony CayОценок пока нет

- Specification PURAD PVDF 2020Документ6 страницSpecification PURAD PVDF 2020Josue EstradaОценок пока нет

- Determination of wavelength of light using a telescopeДокумент10 страницDetermination of wavelength of light using a telescopeSneha NairОценок пока нет

- Seismic Design of Steel ConnectionsДокумент8 страницSeismic Design of Steel Connectionsgutian259Оценок пока нет

- Classification in Mineral ProcessingДокумент3 страницыClassification in Mineral ProcessingNyasha Makwarimba0% (1)

- PDF 5000 Series Vertical Pumps Elastomer Lined or All Metal Abrasion Corrosion Resistant - CompressДокумент4 страницыPDF 5000 Series Vertical Pumps Elastomer Lined or All Metal Abrasion Corrosion Resistant - CompressPepe CarrОценок пока нет

- Solutions and Their Properties: CHM 112 M. PrushanДокумент36 страницSolutions and Their Properties: CHM 112 M. PrushanLouie Jay LidoОценок пока нет

- Aceite Royal Purple - Synfilm - 46Документ2 страницыAceite Royal Purple - Synfilm - 46micmarley2012Оценок пока нет

- Warping in Open SectionsДокумент6 страницWarping in Open SectionsPramin PradeepОценок пока нет

- Biomechanics: A PrimerДокумент3 страницыBiomechanics: A PrimerjournalОценок пока нет

- ZN SДокумент5 страницZN SDikshitJain100% (2)

- Chemical Engineering Science: Ishara Dedunu Kamalanathan, Peter James MartinДокумент11 страницChemical Engineering Science: Ishara Dedunu Kamalanathan, Peter James MartinarulrajasiОценок пока нет

- W/C RATIO AND ITS EFFECT ON CONCRETE STRENGTHДокумент12 страницW/C RATIO AND ITS EFFECT ON CONCRETE STRENGTHVijay BhanОценок пока нет

- Topic 15 (1) - Spectacle Lenses and Their Subsidiary EffectsДокумент11 страницTopic 15 (1) - Spectacle Lenses and Their Subsidiary EffectsshadowosОценок пока нет

- Sea Water Intake & Outfall System For Coastal Power ProjectsДокумент3 страницыSea Water Intake & Outfall System For Coastal Power ProjectsAldy NovaldyОценок пока нет

- Midterm and HomeworksДокумент10 страницMidterm and HomeworksSeila MolinaОценок пока нет

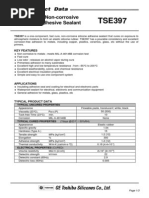

- Pdata Tse397Документ3 страницыPdata Tse397zakariiОценок пока нет

- 102 Weld EconomicsДокумент5 страниц102 Weld EconomicsdayalramОценок пока нет

- Blast Load Analysis and Effect On High Rise Structures: Boyina Sita Rama KrishnaДокумент8 страницBlast Load Analysis and Effect On High Rise Structures: Boyina Sita Rama KrishnaMadhav PurohitОценок пока нет

- BME21 FinalДокумент230 страницBME21 FinalsreeshpsОценок пока нет

- ElectricityДокумент11 страницElectricityi919647Оценок пока нет

- 224C2 2-2006Документ8 страниц224C2 2-2006Anh PhongОценок пока нет

- Crystallization EquipmentДокумент37 страницCrystallization EquipmentMadeline Ngo100% (10)

- Chapter 24 Bridge SubstructureДокумент7 страницChapter 24 Bridge SubstructureSteverich2k6Оценок пока нет

- Hydrogel Coatings Prevent Marine Fouling at Low SpeedsДокумент21 страницаHydrogel Coatings Prevent Marine Fouling at Low Speedss_brizzolaraОценок пока нет