Академический Документы

Профессиональный Документы

Культура Документы

Ancon Channel & Bolt Fixings

Загружено:

atiattiИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ancon Channel & Bolt Fixings

Загружено:

atiattiАвторское право:

Доступные форматы

CI/SfB

(21.9)

Xt6

August 2007

Channel and Bolt Fixings

for the Construction Industry

Ancon designs and manufactures high integrity steel products for the construction industry. Through continuous programmes of new product development, inward investment and employee advancement, the company is committed to maintaining the highest level of customer service within a dynamic and challenging industry. Masonry Support Systems Windposts and Lintels Wall Ties and Restraint Fixings Channel and Bolt Fixings Tension Systems Special Fabrications Flooring & Formed Sections Shear Load Connectors Reinforcing Bar Couplers Reinforcement Continuity Systems Punching Shear Reinforcement Insulated Balcony Connectors Refractory Fixings

There are various methods of fixing stainless steel masonry supports, restraints and windposts to either concrete or steel frames. The selection of the most appropriate method will depend on many factors including fixing centres, edge distances, type of fixture, loading and the site adjustment required.

Range of Fixings Channel Profiles Cast-in Channels Surface-Fixed Channels Installation Guidance Single Expansion Bolts High Performance Bolts Bonded Anchors Steelgrip Set Screws Self-Drilling Screws Plug and Screw Fixings Hollow Slab Anchors Cast-in Sockets Applications Other Ancon Products

4-5 6 7-8 9 10 12 13 14-15 16 17 17 18 18 18 19 19

Designing with Bolts and Bonded Anchors 11

ISO 9001: 2000 FM 12226

ISO 14001: 2004 EMS 505377

Channel and Bolt Fixings

CAST-IN CHANNELS Cast-in Channels range from simple selfanchoring slots for accepting restraint fixings to large capacity channels with integral anchors (pages 6-8). They provide the necessary adjustment required when fixing to concrete and can eliminate site drilling. Nail holes aid the fixing of channels to timber formwork and an infill prevents the ingress of concrete during casting. Cast-in fixings do not generate expansive forces in the concrete and can be used at close centres and closer to the edges than expansion fixings. Omega

Patent No: 2249110

AnconLock AnconLock has teeth cut into the returned lips of the channel. The T head bolts used to fix to this channel have a matching serrated surface on the underside of the head which provides a high resistance to slip under shear load along the line of the channel.

15

11.3 kN 100 70

Ancon SD21 Channel Tie Fixed to Omega 21/18 Slot and MDC Support System Bolted to 30/20 Channel

15 27

6.8 kN

The Omega 21/18 Channel is a self-anchoring channel for use with Ancon wall ties referenced _ _21. The shallow depth of 18mm allows the channel to be used where there is reduced cover to the reinforcement. Nail holes aid the fixing of the channel to timber formwork. If steel formwork is to be used, or the formwork is to be surface-vibrated, please seek advice from Ancons Technical Services Team. 30/20

Patent No: EP0882164B

CombiDeck

Patent No: 2256211

Ancon 30/20 is a high performance channel. Its unique shape allows the applied load to be fed directly from the channel lips to the anchors and the more compact section size improves its fit between reinforcement. Specially designed T-head bolts ride up the sloping sides of the channel and securely lock behind the front lips. This channel also accepts standard 20mm wide wall ties. 30/20 is filled with continuously extruded closed-cell PE-LD foam. This material is removed easily in long sections and is 100% recyclable. Ancon 30/20 should be used in preference to 38/17 channel. 30/20 is a high performance channel and its lower material content offers considerable cost benefits.

Ancon CombiDeck has been developed for use with the permanent metal deck shuttering of steel frame structures. CombiDeck edge support is supplied with an integral channel section, usually 30/20 channel, built into the side to accept Ancon T head bolts. More information on this product can be found in the Ancon Masonry Support Systems literature.

MDC Support System Fixed to CombiDeck Featuring 30/20 Channel

AnconLock 41/27

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk

SURFACE-FIXED CHANNELS Plain-backed channels can be surface-fixed to steel, concrete and in some instances, masonry (page 9). 25/14 Ancon 25/14 accepts Ancon _ _ 25 wall ties and has been designed to tie masonry cladding to steel frames, including light section steel studwork. It is fixed to the steel at 450mm vertical centres with self-drilling screws (page 17). The channel is supplied with pre-punched holes at close centres to allow cutting on site and has a 16mm opening to accommodate a drive socket for the fixing screws. More information on this system, including wall tie spacing, is available in the Ancon Wall Ties and Restraint Fixings brochure. BOLT FIXINGS Expansion Bolts The range consists of Single Expansion Bolts and High Performance Bolts. The latter have double expansion clips that reduce axial and edge spacings and will achieve high performance even in cracked concrete (pages 12-13). Bonded Anchors These fixings create a strong chemical bond between the anchor and the host material. Resin is supplied in either ready-mixed capsules or mixed on application from a cartridge (pages 14-15). Fixings for Steelwork The Ancon Steelgrip simplifies the fixing of support systems to hollow steel sections where access is only available from one side (page 16). Stainless steel set screws and selfdrilling screws are also available (page 17). Cast-in Sockets Sockets enable fixing to concrete where adjustment is either unnecessary or can be provided elsewhere (page 18). Plug and screw fixings, and anchors for fixing to hollow core concrete slabs, complete the range (page 18).

Ancon MDC System Fixed to Concrete with Single Expansion Bolts

Ancon 25/14 Channel, SD25 Wall Tie and Self-Drilling Screw

Channel and Bolt Fixings

ANCON CHANNEL Ancon Channels are produced in a range of profiles, as illustrated.

21/18 - Omega

18mm

13mm

36/8

8mm

12mm

25/14

14mm 16mm 25mm

28/15

15mm

12mm

36mm

21mm

28mm

38/17*

17mm 18mm 38mm

30/20*

19mm 17mm 29mm

41/27 - AnconLock

27mm 21mm 41mm

40/25

25mm 18mm 40mm

49/30

54/33

30mm

72/49

33mm 49mm

22mm 49mm

22mm 54mm 33mm 72mm

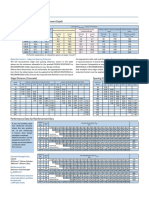

The table below shows channel lengths, availability and, where appropriate, the T bolt required.

Channel Reference 21/18 36/8 25/14 28/15 38/17* 30/20* 40/25 41/27 49/30 54/33 72/49 Standard Bolts M10 M12 M12 M16 M16 M16 M20 M24 Preferred T Bolt Length (mm) 50, 100 50, 100 50, 90 50 50, 80 50 50 50, 100 Tightening Torque (Nm) 20 30 50 70 70 70 120 200 Other Size Bolts M16 x 50 M12 x 50, M20 x 55 M12 x 50, M16 x 50 Preferred Lengths (mm) 100, 3000 100, 2400, 3400 800, 1200, 2700, 3000 100, 150, 3000 100, 150, 3000 100, 150, 3000 1000, 3000 100, 150, 200, 3000 3000 3000 3000 Stainless Steel 304 316/320 Carbon Steel Hot-dipped Galvanised

Notes: The recommended tightening torque is for the standard bolts. Hot-dip galvanised channels can be supplied in lengths up to 6000mm. *Ancon 30/20 should be used in preference to 38/17 channel. 30/20 is a high performance channel and its lower material content offers considerable cost benefits.

Fixing to Channels Fixing to channels is by T head bolts. These are inserted into the channel and turned through 90. The bolt must then be tightened to the correct torque. Tapped plate washers can be used as an alternative to T bolts where non-standard bolt lengths or diameters are required. Restraint Fixings Ancon wall ties can be used with 25/14, 28/15, 30/20, 38/17 and 36/8 channels in order to provide the necessary restraint to an outer leaf of masonry.

T-Head Bolts Inserted into Channel and Turned Through 90

90

Stainless steel, electro-plated and hot-dip galvanised T-Head Bolts are available.

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk

CAST-IN CHANNELS Allowable Channel Loads The allowable loads are based on channels with standard anchors (page 8), cast into concrete with a strength of 30N/mm2. The allowable loads will ensure a minimum factor of safety of 3 against failure.

Longitudinal loads are achieved by friction using fully-tightened stainless steel or grade 4.6 bolts. Higher longitudinal loads can be achieved by using higher strength bolts at an increased torque. AnconLock toothed channel should be used for most applications involving longitudinal loads. Allowable Loads at Standard Edge Distances

Channel Reference 21/18 - Omega 28/15 38/17* 30/20* 40/25 41/27 - AnconLock 49/30 54/33 72/49 Edge Distance (mm) 50 50 75 75 100 100 150 160 250 Tension (kN) 1.9 4.3 7 7.5 8 11.3 12 23 27

Shear 15 Tension

15 Shear

Tension

Shear (kN) 1.5 4.3 8 8 10 6 14 23 27

Longitudinal (kN) 1 2 2 2 6.8 2 3 8

200 200 200 Standard Edge Distance 50

Allowable Loads at Reduced Edge Distances

Channel Reference 21/18 - Omega 28/15 38/17* 30/20* 40/25 41/27 - AnconLock 49/30 54/33 72/49 Edge Distance (mm) 50 40 60 60 80 100 120 160 250 Tension (kN) 1.9 4 5 6 7.5 11.3 10 23 27 Shear (kN) 1.5 4 6 6 9 6 10 23 27 Longitudinal (kN) 1 2 2 2 6.8 2 3 8

200 200 200 Reduced Edge Distance 50

Allowable Bolt Pair Loads

Channel Reference 21/18 - Omega 28/15 38/17* 30/20* 40/25 41/27 - AnconLock 49/30 54/33 72/49 * Longitudinal Load Edge Distance (mm) 50 50 75 75 100 100 150 160 250 Tension (kN) 7 9 10 12 16 15 25 27 Shear (kN) 7 9 12 12 13.6* 15 25 27

100 200 Edge Distance 100 50

Minimum Channel Position Dimensions

Channel Reference 21/18 - Omega 28/15 38/17* 30/20* 40/25 41/27 - AnconLock 49/30 54/33 72/49 End Distance Notes: The allowable loads shown in the tables above are for channels using the standard bolts. *Ancon 30/20 should be used in preference to 38/17 channel. 30/20 is a high performance channel and its lower material content offers considerable cost benefits. End Distance (mm) 50 50 50 50 80 50 130 175 225 Spacing (mm) 100 100 150 150 200 200 300 320 500 Concrete Depth (mm) 75 95 95 95 100 100 105 165 185

Channel Spacing

Concrete Depth

Channel and Bolt Fixings

Double Crimped Lugs

Bull Horn Lugs

Channel Lugs Channels are supplied with either integral double crimped lugs or single welded L lugs, depending on the size of the channel. Bull Horn lugs are welded at 90 to the line of the channel and can be specified as an alternative to the standard double crimped lugs.

Single 'L' Lugs

Double Crimped Lugs

Dimensions

Channel Ref Length (mm) Centres (mm) Width (mm) Thickness (mm) Spacings (mm) 28/15 65 70 11 2.5 235 38/17 65 70 15 2.5 235 30/20 65 70 11 2.5 220 40/25 65 70 15 2.5 235 41/27 65 70 20 3.0 235 49/30 65 70 20 3.0 235

Thickness

Width

Centres Length Spacing

Spacing

Single L Lugs

Dimensions

Channel Ref Length (mm) Return (mm) Width (mm) Thickness (mm) Spacings (mm) Length 54/33 120 35 30 6 235 72/49 125 35 50 6 235

Ancon 30/20 Channel

Thickness Width Spacing Return Spacing

Channel Infill All Ancon channels are supplied filled to help stop the ingress of concrete during casting. Expanded polystyrene is supplied in most channels. Ancon 30/20 is filled with continuously extruded closed-cell PE-LD foam. This material is removed easily in long sections and is 100% recyclable.

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk

SURFACE-FIXED CHANNELS In addition to the plain-backed 36/8 and 25/14, most Ancon channels can be supplied without the anchor lugs for surface fixing to concrete, steelwork and other materials. The allowable load will depend on the fixing centres, the type of fixing and the base material.

Surface-Fixed Channel with Welded Plate Bolted to Concrete

Surface-Fixed Channel Bolted to Concrete

Surface-Fixed Channel Fixed with a T-Head Bolt to Cast-in Channel

Y

Surface-Fixed Channel Fixed to Steelwork with Self-Drilling Screw

Allowable Loads The allowable loads for surface-fixed channels in the table below assume partial fixity (M=WL/6) and are limited by either a maximum stress of 160N/mm2 or a deflection of span/325. Allowable loads for other spans and/or different end fixity can be calculated using the section properties shown below.

Y Surface-Fixed Channel References Allowable Load (kN) Fixing Centres (mm) 150 200 300 450 600 36/8 0.50 0.50 0.50 0.23 0.13 25/14 0.50 0.50 0.50 0.37 0.28 28/15 2.75 2.06 1.38 0.92 0.69 38/17 4.74 3.55 2.37 1.58 1.18 40/25 8.0 6.62 4.42 2.94 2.21 41/27 AnconLock 11.07 8.3 5.54 3.69 2.77 49/30 12.0 11.57 7.71 5.14 3.86 54/33 23.0 18.96 12.64 8.43 6.32

Note: Fixing into 36/8 and 25/14 will be with wall ties, not T bolts, and the maximum allowable load is limited to 0.5kN; this maximum should be applied to all channels where the fixing is a wall tie. Channel References Mass (Kg/m) Area (cm2) Ixx (cm4) Iyy (cm4) Zxx (cm3) Zyy (cm3) 36/8 0.63 0.79 0.09 1.13 0.16 0.63 25/14 0.51 0.64 0.16 0.60 0.17 0.48 28/15 1.08 1.36 0.38 1.37 0.43 0.98 38/17 1.73 2.19 0.74 3.93 0.74 2.07 40/25 2.11 2.67 2.03 6.09 1.38 3.04 41/27 AnconLock 2.48 3.14 2.68 7.31 1.73 3.56 49/30 3.03 3.84 4.26 13.15 2.41 5.37 54/33 4.98 6.30 7.53 22.75 3.95 8.42

Channel and Bolt Fixings

Correct Installation Showing Channel Butted Together

INSTALLATION GUIDANCE CAST-IN CHANNELS Fixing to Timber Formwork Ancon Cast-in Channels are normally supplied in 3000mm lengths with welded anchors, nail holes, and infill. Incorrect installation is likely to result in expensive remedial work. All nail holes need to be utilised (except with Omega Channel), to prevent excessive ingress of concrete fines between the formwork and the channel during casting. Both nail holes should be utilised when fixing 21/18 Omega Channel 100mm long to timber formwork. Longer lengths of this channel should be nailed at each end and then fixed at 300mm centres. Nails with a plain shank should be installed perpendicular to the channel to ensure the easy removal of the formwork and the retention of the channel in the concrete. Welded Fabrications Where channels with welded anchors are cut on site, it is important to ensure that there is a whole anchor within 50mm from the end of the channel. Where horizontal cast-in channel is used in conjunction with brickwork support systems, all external corners must incorporate a Welded Corner Fabrication. Release oil must not be applied to either the channel or the anchor. Minimum Edge Distance Care should be taken to ensure that the dimensions from the centre of the channel to the edges of the concrete are not less than the minimum edge distance shown on page 7. The channel must be lined and levelled correctly. In every situation, care must be taken to ensure a good fit is obtained between the face of the channel and the formwork. SURFACE-FIXED CHANNELS Channels are supplied plain-backed for surface fixing to either concrete or steelwork. When bolting channel to concrete or steelwork it is important to utilise all fixing holes (except with 25/14 channels), incorporating the square washer provided and ensuring its correct orientation to achieve the allowable loads. Bolt and washer specifications are shown and bolts should be installed following the guides on page 12 and 13. 25/14 Channel should be fixed to steelwork at 450mm vertical centres with self-drilling screws. Bolt and Washer Specifications

Channel 28/15 38/17 40/25 41/27 49/30 54/33 Bolt Diameter M8 M10 M12 M16 M16 M20 Washer 25 x 25 x 3 30 x 30 x 3 40 x 40 x 4 40 x 40 x 4 50 x 50 x 5 50 x 50 x 5

Minimum Edge Distance Channel Nailed to Formwork

Fixing to Steel Formwork Channels can be secured to steel formwork by using standard T head bolts in pre-drilled holes. Where metal deck floors are being used, Ancon CombiDeck has a built-in channel and will replace the standard edge trim.

10

Removal of Formwork When the concrete is poured, care should be taken to ensure that it is fully compacted around the back of the channel and especially adjacent to anchors. After the concrete has cured and the formwork is removed, the nails should either be cut off or bent away from any tie or T head bolt.

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk

EXPANSION BOLTS AND BONDED ANCHORS Design Considerations There are several factors which will affect the performance of these fixings. The following areas should be considered to ensure that the expected performance is achieved. Embedment The minimum embedment of anchors which are used to support stone cladding should be at least 75mm. To achieve this, the maximum fixing thickness will reduce with some of the smaller diameter bolts. Edge Distances and Spacings Anchors fixed into concrete must be positioned to ensure that the specified minimum edge distances and spacings are not exceeded. Where reduced edge distances and spacings are unavoidable, the appropriate reduction factors must be applied. For instances where multiple close edges and spacings occur, the reduction factor is applied for every case. Fixing Thickness and Shims The maximum fixing thickness for bolts shown is the maximum thickness which can be accommodated without reducing embedment. This maximum thickness cannot be achieved in every situation. Fixings which are subject to shear, or a combination of shear and tension, may have restrictions on the maximum thickness of shims. In particular, where shims are incorporated behind masonry support angles, their thickness should be restricted to 16mm, or the outside diameter of the fixing, whichever is less. Combined Loads The recommended maximum loads in the tables on pages 12 to 18 are static loads in either tension or shear. In many applications however, the anchor will be subject to a combination of shear and tension. The combined loads must satisfy the following equation:Applied Tensile Load Safe Tensile Load + Applied Shear Load Safe Shear Load < 1.2 _

Outside diameter of fixing (16mm maximum)

Maximum Shimming Thickness

Fixings into Concrete The recommended static safe working loads in this brochure are based on concrete with a compressive strength of 30N/mm2. A different value may be appropriate if fixings are used in concrete with a different strength. The tensile load can be calculated using the following empirical formula if the compressive strength is in the range of 20 - 50 N/mm2 and expansion or chemical / resin bolts are used.

Bolt Spacings

Tensile Load = Tensile Load in 30N/mm2 Concrete

Concrete Strength 30

These factors only apply to static tensile loads and are intended for guidance only. Site testing may be required to establish the true capacity of particular anchors.

11

Channel and Bolt Fixings

EXPANSION BOLTS Single Expansion Through Bolts Single Expansion bolts fix into a hole which is similar to the diameter of the bolt. This allows the hole to be drilled through the hole in the item to be fixed. The Single Expansion bolt is a cost-effective anchor, available in grade 1.4401 (316) stainless steel in a wide range of sizes.

Performance Data

Bolt Reference Thread Size Overall Length (mm) SWL Tension (kN) SWL Shear (kN) Hole Dia. in Concrete (mm) Hole Dia. in Fixture (mm) Min. Embedment (mm) Normal Edge Distance (mm) Normal Spacing (mm) Tightening Torque (Nm) Max. Fixing Thickness (mm) FBN6/10 A4-68 M6 68 3.3 4.3 6 6.5 40 60 120 7.5 10 FBN8/50 A4-115 M8 115 4.4 5.3 8 9 48 75 144 15 50 FBN10/15 A4-90 M10 90 5.8 7.5 10 11 50 75 150 30 15 FBN10/50 A4-125 M10 125 5.8 7.5 10 11 50 75 150 30 50 FBN12/15 A4-115 M12 115 10.9 12.9 12 13 70 105 210 50 15 FBN12/45 A4-145 M12 145 10.9 12.9 12 13 70 105 210 50 45 FBN16/25 A4-145 M16 145 13.4 16.9 16 17 84 125 250 100 25 FBN16/50 A4-169 M16 169 13.4 16.9 16 17 84 125 250 100 50

Note: Working loads are based on a concrete of minimum class C25/30, to BS EN 206-1.

Reduction Factors

Edge (mm) 50 55 60 65 70 75 90 100 105 115 125 M6 0.83 0.92 1.00 Tension: Reduction Factors M8 M10 M12 0.70 0.76 0.82 0.88 0.94 1.00 0.87 0.94 1.00 0.86 0.95 1.00 M16 0.83 0.91 1.00 M6 0.83 0.92 1.00 Shear: Reduction Factors M8 M10 M12 0.70 0.76 0.82 0.88 0.94 1.00 0.87 0.94 1.00 0.86 0.95 1.00 M16 0.83 0.91 1.00 Spacing (mm) 40 50 55 75 90 100 120 145 150 210 250 Tension and Shear: Reduction Factors M6 M8 M10 M12 M16 0.67 0.71 0.73 0.81 0.88 0.92 1.00 0.67 0.69 0.76 0.81 0.84 0.91 1.00 0.68 0.75 0.80 0.83 0.90 0.98 1.00 0.67 0.71 0.73 0.78 0.84 0.85 1.00 0.67 0.69 0.73 0.78 0.79 0.91 1.00

Before Installation The following checks must be carried out prior to the installation of Single Expansion Bolts.

1 The appropriate length and diameter drill bit is used. 2 The correct edge distance and spacing are used in accordance with either the information in the table or that specified on drawings produced by Ancon Building Products. 3 The anchor/fixing is the correct size. 4 The correct setting tools are used.

Installation

5 6

Drill the hole, through the pre-drilled hole in the fixture, into the concrete. This hole should be drilled perpendicular to the substrate surface, and to the correct diameter and depth. All dust and loose material should be removed from the hole using a wire brush or blow pump.

Lightly tap the throughbolt with a hammer through the fixture and into the hole, until the fixing depth is reached.

7

Tighten bolt to the recommended torque.

12

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk

High Performance Bolts These are high performance through bolts manufactured in grade 1.4401 (316) stainless steel. They have double expansion clips that reduce axial and edge spacing and achieve high performance even in cracked concrete. They fix into a hole which is similar to the diameter of the bolt. This allows the hole to be drilled through the hole in the item to be fixed.

Performance Data

Bolt Reference Thread Size Overall Length (mm) SWL Tension (kN) SWL Shear (kN) Hole Dia. in Concrete (mm) Hole Dia. in Fixture (mm) Min. Embedment (mm) Normal Edge Distance (mm) Normal Spacing (mm) Tightening Torque (Nm) Max. Fixing Thickness (mm) FAZ10/10 A4-93 M10 93 11.5 10.3 10 10.5 60 90 180 45 10 FAZ10/30 A4-113 M10 113 11.5 10.3 10 10.5 60 90 180 45 30 FAZ12/10 A4-108 M12 108 14.6 14.9 12 13 70 105 210 60 10 FAZ12/30 A4-128 M12 128 14.6 14.9 12 13 70 105 210 60 30 FAZ12/50 A4-148 M12 148 14.6 14.9 12 13 70 105 210 60 50 FAZ16/25 A4-146 M16 146 20.9 25.7 16 18 85 130 260 110 25 FAZ16/50 A4-171 M16 171 20.9 25.7 16 18 85 130 260 110 50

Note: Working loads are based on a concrete of minimum class C25/30, non-cracked, to BS EN 206-1. For cracked concrete please contact Ancon.

Reduction Factors

Edge (mm) 55 65 75 80 85 90 100 105 110 120 130 M10 0.71 0.79 0.88 0.92 0.96 1.00 Tension: Reduction Factors M12 M16 0.72 0.79 0.83 0.86 0.90 0.97 1.00 0.64 0.68 0.76 0.80 0.84 0.92 1.00 M10 0.61 0.72 0.83 0.89 0.94 1.00 Shear: Reduction Factors M12 M16 0.62 0.72 0.76 0.81 0.86 0.95 1.00 0.50 0.56 0.67 0.72 0.78 0.89 1.00 Spacing (mm) 55 65 75 80 90 100 125 150 180 210 260 Tension & Shear: Reduction Factors M10 M12 M16 0.65 0.68 0.71 0.72 0.75 0.78 0.85 0.92 1.00 0.65 0.67 0.69 0.71 0.73 0.79 0.86 0.93 1.00 0.64 0.65 0.67 0.69 0.74 0.79 0.84 0.90 1.00

Before Installation The following checks must be carried out prior to the installation of High Performance Bolts.

1 The appropriate length and diameter drill bit is used. 2 The correct edge distance and spacing are used in accordance with either the information in the table or that specified on drawings produced by Ancon Building Products. 3 The anchor/fixing is the correct size. 4 The correct setting tools are used.

Installation

5 6

Drill the hole, through the pre-drilled hole in the fixture, into the concrete. This hole should be drilled perpendicular to the substrate surface, and to the correct diameter and depth. All dust and loose material should be removed from the hole using a wire brush or blow pump.

Insert the bolt through the component to be fixed and into the concrete. Add any packing shims that may be required.

7

Tighten bolt to the recommended torque.

13

Channel and Bolt Fixings

BONDED ANCHORS Capsule Anchors The capsule contains epoxy resin, quartz granules and a hardener, and provides an expansion-free anchorage for the stainless steel studs. These can be used in a variety of solid materials including concrete, stone and masonry.

Performance Data

Anchor Reference Thread Size Overall Length (mm) SWL Tension (kN) SWL Shear (kN) Hole Dia. in Concrete (mm) Hole Dia. in Fixture (mm) Min. Embedment (mm) Normal Edge Distance (mm) Normal Spacing (mm) Tightening Torque (Nm) Max. Fixing Thickness (mm) CA08/13-110 M8 110 5.1 5.9 10 9 80 80 160 10 13 CA10/20-130 M10 130 7.6 9.3 12 11 90 90 180 20 20 CA12/25-160 M12 160 11.3 13.6 14 13 110 110 220 40 25 CA16/35-190 M16 190 15.4 25.2 18 17 125 125 250 80 35 CA20/65-260 M20 260 28.6 39.4 25 22 170 170 340 150 65

Note: Working loads are based on a concrete of minimum class C25/30, to BS EN 206-1.

Reduction Factors

Edge (mm) 40 50 60 65 80 85 90 100 110 125 170 M8 0.50 0.63 0.75 0.81 1.00 Tension: Reduction Factors M10 M12 M16 0.55 0.66 0.72 0.89 0.94 1.00 0.54 0.59 0.72 0.77 0.82 0.91 1.00 0.52 0.64 0.68 0.72 0.80 0.88 1.00 M20 0.50 0.53 0.59 0.65 0.74 1.00 M8 0.50 0.63 0.75 0.81 1.00 Shear: Reduction Factors M10 M12 M16 0.55 0.66 0.72 0.89 0.94 1.00 0.54 0.59 0.72 0.77 0.82 0.91 1.00 0.52 0.64 0.68 0.72 0.80 0.88 1.00 M20 0.50 0.53 0.59 0.65 0.74 1.00 Spacing (mm) 80 90 110 125 160 170 180 220 250 300 340 Tension and Shear: Reduction Factors M8 M10 M12 M16 M20 0.75 0.78 0.84 0.89 1.00 0.75 0.81 0.85 0.94 0.97 1.00 0.75 0.78 0.86 0.89 0.91 1.00 0.75 0.82 0.84 0.86 0.94 1.00 0.75 0.76 0.82 0.87 0.94 1.00

Before Installation The following checks must be carried out prior to the installation of Capsule Anchors.

1 The appropriate length and diameter drill bit is used. 2 The correct edge distance and spacing are used in accordance with either the information in the table or that specified on drawings produced by Ancon Building Products. 3 The anchor/fixing is the correct size. 4 The correct setting tools are used.

Installation

5 7

Drill correct diameter and depth of hole for the stud or socket. Clean the hole using brush and pump.

Offer bolt up to capsule and switch on machine. Drive bolt into capsule. To prevent over mixing, stop as soon as bottom of hole is reached. Leave undisturbed until resin has set.

8

14

Insert CA capsule into the hole. Connect bolt to drilling machine using the appropriate driver system.

Position fixture and tighten to recommended torque.

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk

Resin Anchors The cartridge contains a two-part system of polyester resin and hardener which mixes in the nozzle during pumping. The general purpose resin can be used with most materials including concrete, blockwork and brickwork.

Performance Data

Anchor Reference Thread Size Overall Length (mm) SWL Tension (kN) SWL Shear (kN) SWL 20.5N/mm2 Brickwork (kN) SWL 7N/mm2 Blockwork (kN) Hole Dia. in Concrete (mm) Hole Dia. in Fixture (mm) Min. Embedment (mm) Normal Edge Distance (mm) Normal Spacing (mm) Tightening Torque (Nm) Max. Fixing Thickness (mm) RA06/10-85 M6 90 2.2 2 1 0.7 8 6.5 60 75 130 5 10 RA08/13-110 M8 110 4.2 3.6 1.8 1.2 10-12 9 80 85 170 10 13 RA10/20-130 M10 130 6.3 5.2 2.6 1.7 12-14 11 90 110 220 20 20 RA12/25-160 M12 160 8.6 7.2 3.6 2.4 14-16 13 110 130 260 40 25 RA16/35-190 M16 190 12 10.6 5.3 3.5 18-20 17 125 165 330 80 35 RA20/65-260 M20 260 18.8 16.9 24 22 170 210 420 150 65

Note: Working loads are based on a concrete of minimum class C25/30, to BS EN 206-1 unless stated otherwise.

Reduction Factors for use in Concrete

Edge (mm) 40 45 55 65 75 85 110 130 150 165 180 210 M6 0.53 0.60 0.73 0.87 1.00 Tension: Reduction Factors M8 M10 M12 M16 0.47 0.53 0.65 0.76 0.88 1.00 0.41 0.50 0.59 0.68 0.77 1.00 0.42 0.50 0.57 0.65 0.85 1.00 0.39 0.45 0.51 0.66 0.79 0.91 1.00 M20 0.40 0.52 0.62 0.71 0.78 0.86 1.00 M6 0.53 0.60 0.73 0.87 1.00 Shear: Reduction Factors M8 M10 M12 M16 0.47 0.53 0.65 0.76 0.88 1.00 0.41 0.50 0.59 0.68 0.77 1.00 0.42 0.50 0.57 0.65 0.85 1.00 0.39 0.45 0.51 0.66 0.79 0.91 1.00 M20 0.40 0.52 0.62 0.71 0.78 0.86 1.00 Spacing (mm) 40 45 55 65 85 100 130 170 220 260 330 420 Tension and Shear: Reduction Factors M6 M8 M10 M12 M16 M20 0.73 0.75 0.78 0.81 0.87 0.91 1.00 0.62 0.63 0.66 0.69 0.75 0.80 0.88 1.00 0.60 0.62 0.65 0.67 0.73 0.79 0.89 1.00 0.61 0.63 0.67 0.70 0.75 0.83 0.92 1.00 0.60 0.63 0.65 0.70 0.76 0.83 0.85 1.00 0.60 0.62 0.65 0.70 0.76 0.81 0.89 1.00

Before Installation The following checks must be carried out prior to the installation of Resin Anchors.

1 The appropriate length and diameter drill bit is used. 2 The correct edge distance and spacing are used in accordance with either the information in the table or that specified on drawings produced by Ancon Building Products. 3 The anchor/fixing is the correct size. 4 The correct setting tools are used.

Installation

5 7

Drill hole to correct diameter and depth for stud size being used. Thoroughly clean hole using brush and air.

6

Insert bolt with a twisting action and leave the anchor undisturbed until the resin has cured.

Insert cartridge into cartridge gun and attach nozzle. Dispense to waste until an even colour. Pump into hole.

Position fixture and tighten to recommended torque.

15

Channel and Bolt Fixings

FIXINGS FOR STEEL FRAMES Ancon Steelgrip Ancon Steelgrip simplifies the fixing of masonry support systems to hollow steel sections, or other applications where access is only available from one side. It is a high performance fixing, available in two sizes. This bolt is only available for use with Ancon systems. It features a serrated washer that corresponds with the serrations on all Ancon brackets. The serrated surfaces interlock, and as the head is tightened to the correct torque the sleeve expands. The Steelgrip consists of a zinc plated sleeve and cone, and a stainless steel screw and serrated washer.

Hole Dia Thickness

Minimum Edge Distance

Minimum Edge Distance (mm)

Thickness (mm) Ancon Steelgrip 10 Ancon Steelgrip 12 6 21 24 8 23 26 10 25 28

Note: Minimum spacing 50mm

UK Patent No: 2410307

Performance Data

Thread Size (mm) Ancon Steelgrip 10 Ancon Steelgrip 12 M10 M12 Max. Shims (mm) 16 16 Overall Length (mm) 70 70 Fixing Thickness (mm) 28 28 SWL Tension (kN) 10.0 15.0 SWL Shear (kN) 6.0 10.0 Steelwork Hole Dia. (mm) 19 20 Fixture Hole Dia. (mm) 19 20 Bolt Torque (Nm) 45 80

Note: Steelgrip is only for use with Ancon Systems.

Before Installation The following checks must be carried out prior to the installation of Ancon Steelgrip.

1 The appropriate diameter drill bit is used. 2 The correct edge distance is used in accordance with either the information in the table or that specified on drawings produced by Ancon Building Products. 3 The correct setting tool is used.

Installation

4 6

Drill hole to correct size as stated.

5

Begin to tighten with torque wrench. Adjustments to the line and level of the fixture can be made before the bolt has been fully tightened. Fully tighten to the recommended torque.

Insert the fixing through the fixture and into the pre-drilled hole ensuring the serrations are the correct orientation to interlock.

16

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk

Set Screws Stainless steel set screws, nuts and washers are available in a range of diameters and lengths in grades A2(304) and A4(316). Set screws can be shrink-wrapped and supplied complete with nylon washer to prevent bi-metallic corrosion when fixing to steel.

Set Screws Area of Shank (mm2) Area of Root of Thread (mm2) Property Class SWL Tension (kN) SWL Shear (kN) Tightening Torque (Nm) M6 28 20 70 6.0 4.1 6 M8 50 36 70 10.9 7.5 14 M10 78 58 70 17.4 12.0 27 M12 113 84 70 25.2 17.4 48 M16 201 157 70 47.1 32.5 120 M20 314 245 70 73.5 50.8 230

Self-Drilling Screws These screws feature a shaped drill tip of hardened steel that allows installation without pre-drilling. Hi-thread screws accommodate insulation between a surface-fixed channel and the steel frame. In addition to those products identified in the table, Ancon can supply hi-thread screws to suit an insulation thickness above 70mm thick and a steel thickness above 4mm. More information is available on request.

Self-Drilling Screws Material Diameter (mm) Length (mm) SWL Tension (kN) 1.6mm 2.0mm 2.5mm 3.0mm 3.5mm 4.0-12mm Insulation Thickness Steel Thickness (mm)

Self-drilling screws should be fixed using a driver with a speed of around 1800rpm. Drive sockets are available.

HTCS-65-2PT Coated Steel 5.5 65 1.0 1.5 2.0 2.5 2.5 35-50mm

HTCS-85-2PT Coated Steel 5.5 85 1.0 1.5 2.0 2.5 2.5 50-70mm

HTSS-65-2PT Stainless Steel 5.5 65 1.0 1.5 2.0 2.5 2.5 35-50mm

HTSS-85-2PT Stainless Steel 5.5 85 1.0 1.5 2.0 2.5 2.5 50-70mm

SDTCS-38-5PT SDTSS-38-5PT SDTSS-35-5PT Coated Steel 5.5 38 2.5 Stainless Steel 5.5 38 2.5 Stainless Steel 5.5 35 2.5 -

Note: The working loads are based on tests and include a minimum factor of safety of 3.0.

17

Channel and Bolt Fixings

PLUG AND SCREW FIXINGS The SX8 and SX8L plugs are manufactured from high quality nylon and are resistant to weathering, ageing and rotting. They require an 8mm diameter hole and are suitable for use in various types of block as well as concrete. The fixing into the SX and SXL plugs is a stainless steel No 12 woodscrew.

SX8 Hole Depth (mm) Hole Diameter (mm) Woodscrew SWL Concrete (N) SWL Solid Brick (N) SWL 7N Dense Concrete Block (N) SWL 4N Aircrete (N) Note: SWLs have a minimum factor of 6 against ultimate failure 40 8 No 12 800 500 250 150 SX8L 75

HOLLOW SLAB ANCHORS FHY anchors are manufactured from A4 stainless steel and are used for fixing to hollow core concrete slabs. They require a 16mm diameter hole and are supplied with an M10 stainless steel bolt. The anchor is installed flush with the concrete surface and if it is positioned at a core, the sleeve forms a Y shape.

FHY M10 Thread Size Overall Length (mm) SWL Tension (kN) SWL Shear (kN) Hole Dia. in Concrete (mm) Hole Dia. in Fixture (mm) Normal Edge Distance (mm) Normal Spacing (mm) Tightening Torque (Nm) M10 52 4 4 16 10.5 100 200 20 Reduction Factors Edge (mm) M10 50 60 70 80 90 100 0.5 0.6 0.7 0.8 0.9 1.0 Spacing (mm) 100 120 140 160 180 200 M10 0.5 0.6 0.7 0.8 0.9 1.0

CAST-IN SOCKETS These sockets offer a simple solution to fixing into concrete for locations where adjustment is either unnecessary or can be provided elsewhere. Other sizes and lengths can be supplied in addition to the standard range. Ancon Cast-in Sockets should not be used as part of a lifting system.

Cast-in Sockets Thread Size Overall Length (mm) SWL Tension (kN) SWL Shear (kN) Outside Diameter (mm) Cross Pin Length (mm) Cross Pin Diameter (mm) Centre of Cross Pin to End of Socket (mm) Minimum Edge Distance (mm) Minimum Spacing (mm) 10/75 M10 75 6.2 3.9 16 50 6 10 75 150 12/75 M12 75 9 5.7 20 75 10 12 75 150 16/75 M16 75 16.9 10.8 22 75 10 15 75 150 20/75 M20 75 23 17 26 88 12 16 75 150 24/100 M24 100 30 23.8 35 100 16 20 100 200

Note: The published working loads are based on tests using unreinforced concrete with a strength of 30N/mm2, incorporating a dense gravel aggregate. However crushing strength is no guide to concrete strength in either shear or tension, and concrete with a similar compressive strength but with a different aggregate may not achieve the same performance. Providing suitable reinforcement is incorporated around the sockets, the published values will provide a sufficient factor of safety for concrete with different characteristics.

18

Tel: +44 (0) 114 275 5224 Web: www.ancon.co.uk

APPLICATIONS

OTHER ANCON PRODUCTS Wall Ties and Restraint Fixings Ancon manufactures ties in a variety of lengths and types for restraining brickwork, blockwork and stonework. These ties can be fixed to concrete and structural steelwork, as well as any type of masonry. Masonry Support Systems Masonry cladding on concrete or steel framed buildings is normally supported by stainless steel masonry support systems. Ancon has developed the most comprehensive range of stainless steel support systems and restraints. Products include AnconOptima, a standard system available from stock. A full design and drawing service accompanies our bespoke support systems. Tension Systems The use of tie bars in structures and buildings as an architectural as well as a structural element is increasing. Ancon Tension Systems comprise a range of components which can be supplied in carbon steel or stainless steel in a variety of sizes and finishes. The system looks particularly impressive when used with large areas of glazing or timber trusses. Shear Load Connectors Ancon DSD and ESD Shear Load Connectors are used to transfer shear across expansion and contraction joints in concrete. They are more effective than standard dowels at transferring load and allowing movement to take place, and can be used to eliminate double columns at structural movement joints in buildings. Reinforcing Bar Couplers The use of reinforcing bar couplers can provide significant advantages over lapped joints. Design and construction of the concrete can be simplified and the amount of reinforcement required can be reduced. The Ancon range includes threaded and mechanically bolted couplers. Punching Shear Reinforcement Used within a slab to provide additional reinforcement around columns, Ancon Shearfix is the ideal solution to the design and construction problems associated with punching shear. The system consists of double-headed studs welded to flat rails, positioned in a symmetrical pattern around the column head. The shear load from the slab is transferred through the studs into the column.

Retail Development Buchanon Galleries, Glasgow, UK

Deutsche Bank Sydney NSW, Australia

Magistrates Court Mansfield, UK

Mixed-Use Development Tottenham Court Road, London, UK

19

Ancon Building Products President Way, President Park Sheffield S4 7UR United Kingdom Tel: +44 (0) 114 275 5224 Fax: +44 (0) 114 276 8543 Email: info@ancon.co.uk Visit: www.ancon.co.uk Ancon (Middle East) FZE PO Box 17225 Jebel Ali Dubai United Arab Emirates Tel: +971 (0) 4 883 4346 Fax: +971 (0) 4 883 4347 Email: anconccl@emirates.net.ae Ancon Building Products 114 Kurrajong Avenue Mount Druitt Sydney NSW 2770 Australia Tel: +61 (0) 2 9675 1000 Fax: +61 (0) 2 9675 3390 Email: pac.ancon@anconbp.com.au Visit: www.anconbp.com.au

Ancon (Schweiz) AG Gewerbezone Widalmi 10 3216 Ried bei Kerzers Switzerland Tel: +41 (0) 31 750 3030 Fax: +41 (0) 31 750 3033 Email: info@ancon.ch Visit: www.ancon.ch Ancon Building Products GesmbH Gerspergasse 9/3 Top 1 A-1210 Vienna Austria Tel: +43 (0) 1 259 58 62-0 Fax: +43 (0) 1 259 58 62-40 Email: info@ancon.at Visit: www.ancon.at Ancon GmbH Bartholomusstrasse 26 90489 Nuremberg Germany Tel: +49 (0) 911 955 1234 0 Fax: +49 (0) 911 955 1234 9 Email: info@anconbp.de Visit: www.anconbp.de

These products are available from:

The construction applications and details provided in this literature are indicative only. In every case, project working details should be entrusted to appropriately qualified and experienced persons. Whilst every care has been exercised in the preparation of this document to ensure that any advice, recommendations or information is accurate, no liability or responsibility of any kind is accepted in respect of Ancon Building Products. With a policy of continuous product development Ancon Building Products reserves the right to modify product design and specification without due notice.

Ancon Building Products 2007

ISO 9001: 2000 FM 12226

ISO 14001: 2004 EMS 505377

Вам также может понравиться

- Specification Data: Performance Data at Standard Embedment DepthДокумент1 страницаSpecification Data: Performance Data at Standard Embedment DepthatiattiОценок пока нет

- Rapid Steel Decking BrochureДокумент16 страницRapid Steel Decking BrochureatiattiОценок пока нет

- Design of Steel Beam in Torsion PDFДокумент148 страницDesign of Steel Beam in Torsion PDFdaeealiОценок пока нет

- 04 Acciaio Connection DesignДокумент62 страницы04 Acciaio Connection DesignSultano78Оценок пока нет

- Roof Systems: Eaves BeamsДокумент75 страницRoof Systems: Eaves BeamsatiattiОценок пока нет

- Terrace Railing HeightsДокумент2 страницыTerrace Railing HeightsatiattiОценок пока нет

- Halfen Detan BrochureДокумент12 страницHalfen Detan BrochureatiattiОценок пока нет

- Complete Rawl Product CatalogueДокумент154 страницыComplete Rawl Product CatalogueatiattiОценок пока нет

- G1398 STA 01 RevA All en Build Station Lane WindPostДокумент5 страницG1398 STA 01 RevA All en Build Station Lane WindPostatiattiОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Table 7-3 UPC DFUДокумент4 страницыTable 7-3 UPC DFUAhmed OsmanОценок пока нет

- PNGF Rooftop 048 350 R410aДокумент32 страницыPNGF Rooftop 048 350 R410aRayhan Sayeed100% (1)

- Material Finish GuideДокумент7 страницMaterial Finish GuideRomie CubalОценок пока нет

- Internship Report on Peck Chew Piling (M) Sdn BhdДокумент38 страницInternship Report on Peck Chew Piling (M) Sdn BhdMardi Mude100% (1)

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Документ1 страницаMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (2)

- Para ProductsДокумент12 страницPara ProductsKyle MoolmanОценок пока нет

- Sprinkler 2 01 2021Документ2 страницыSprinkler 2 01 2021rajaОценок пока нет

- Testing and Quality Control of Welds WFC 206-1Документ35 страницTesting and Quality Control of Welds WFC 206-1ibrahim mustaphaОценок пока нет

- Mechanical - Vendor ListДокумент1 страницаMechanical - Vendor ListImythОценок пока нет

- Technical Specification For Auxiliary Cooling TowerДокумент7 страницTechnical Specification For Auxiliary Cooling TowerAnonymous vwbLPTpj100% (2)

- AISC Design Guides: A Resource For Practicing EngineersДокумент40 страницAISC Design Guides: A Resource For Practicing EngineersSergio Manuel Céh ChaleОценок пока нет

- Contraction JointsДокумент5 страницContraction JointsbiniamОценок пока нет

- Physics of Low Dimensional MaterialsДокумент61 страницаPhysics of Low Dimensional MaterialsRavi GehwaniОценок пока нет

- Cube TestДокумент15 страницCube TestFAHIEMAH ZAHRA YAAKUBОценок пока нет

- Electrical Layout Design and Load Calculation GuideДокумент75 страницElectrical Layout Design and Load Calculation Guide2GI20AT021 Devki HanamshetОценок пока нет

- MATERIALSДокумент44 страницыMATERIALSnadyaОценок пока нет

- Input:: Depth of Failure Surface or Tunnel Below SlopeДокумент1 страницаInput:: Depth of Failure Surface or Tunnel Below SlopemartinmuguruzaОценок пока нет

- Introduction To Rolling ProcessДокумент2 страницыIntroduction To Rolling ProcessdevtorОценок пока нет

- Coal Fly Ash and Raw or Calcined Natural Pozzolan For Use in ConcreteДокумент3 страницыCoal Fly Ash and Raw or Calcined Natural Pozzolan For Use in ConcreteJose Francisco Villarreal CanalesОценок пока нет

- BoQ-Beam Retrofitting Works LandTДокумент2 страницыBoQ-Beam Retrofitting Works LandTAbhijit KarpeОценок пока нет

- Materials System SpecificationДокумент21 страницаMaterials System SpecificationPrasanna UmapathyОценок пока нет

- Miscellaneous Accessories: Submittal A-338GДокумент2 страницыMiscellaneous Accessories: Submittal A-338Gfernandoperdomo20-1Оценок пока нет

- Fatigue FailureДокумент22 страницыFatigue FailureHimanshu YadavОценок пока нет

- Flash Cards Questions Fire Code of The PhilippinesДокумент150 страницFlash Cards Questions Fire Code of The PhilippinesJan WickОценок пока нет

- 2-Daily Concrete Gradation RegisterДокумент1 страница2-Daily Concrete Gradation Registershinde rushiОценок пока нет

- QuoteДокумент35 страницQuoteFaheem KhanОценок пока нет

- Method of PlasteringДокумент3 страницыMethod of PlasteringTAHER AMMAR100% (2)

- G+2 Villa First Floor Roof Structural DrawingДокумент4 страницыG+2 Villa First Floor Roof Structural DrawingsmallhouseconstructionsОценок пока нет

- Cálculo Sin ModificacionesДокумент26 страницCálculo Sin ModificacionesAngel MingaОценок пока нет

- Assignment 1Документ3 страницыAssignment 1Ansuman SahooОценок пока нет