Академический Документы

Профессиональный Документы

Культура Документы

Synthesis and Surface Measurements of Surfactants Derived From Dehydroabietic Acid

Загружено:

Paradize NailsИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Synthesis and Surface Measurements of Surfactants Derived From Dehydroabietic Acid

Загружено:

Paradize NailsАвторское право:

Доступные форматы

Synthesis and Surface Measurements of Surfactants Derived from Dehydroabietic Acid

Peter S. Piispanena, U.R. Mikael Kjellinb, Bjrn Hedmana, and Torbjrn Norina,*

a

Department of Chemistry, Organic Chemistry, and bDepartment of Chemistry, Surface Chemistry, Royal Institute of Technology, Stockholm, Sweden

ABSTRACT: Dehydroabietates with poly(ethylene oxide) chains of average m = 12, 17, and 45 units [DeHab(E)m] were synthesized. The adsorption at the liquidvapor interface was measured, and the adsorbed amount and critical micelle concentrations (CMC) were determined. The foamability, the foam stability, wetting properties, and cloud points, with and without salt content, were studied. The results were compared with common linear alkyl ethoxylates, nonylphenol ethoxylates, and cholesterol ethoxylates. The dehydroabietic acid as hydrophobe was found to result in the same CMC as a linear dodecyl chain. DeHab(E)45 was found to be insoluble above 400 mg/L, but the surface tensions at lower concentrations were similar to those of the C1113E3840 surfactants, which exhibit CMC in aqueous media. The foaming behavior of the DeHab(E)12 and DeHab(E)17 surfactants was about the same as for common linear CnEm surfactants. The foamability as well as the foam stability increased with ethylene oxide (EO) chain length. The cloud point was depressed by increased salt concentration and increased with the number of EO units in the head group. The cloud point was significantly lower than for the corresponding surfactant with a dodecyl chain with similar EO chain length. The wetting results, obtained by measuring the contact angle at similar surface tensions, indicate that surfactants of the DeHab(E)m type are more efficient wetting agents than both disaccharide sugar surfactants and CnEm type surfactants. Paper no. S1290 in JSD 6, 125130 (April 2003). KEY WORDS: CMC, dehydroabietic acid, foaming, PEG, surface tension, surfactants, wetting.

Surfactants derived from natural products, including sugars (110) and linear alkyl polyoxyethylene-based surfactants, have been well investigated. On the other hand, there have been relatively few investigations dealing with surfactants based on large natural and rigid skeleton hydrophobes. Recently, sterols (11) and fatty acids (12) have been investigated. Polyoxyethylene-based surfactants using cholesterol (13) and phytosterol (14) have also been investigated. Biological studies of the natural surfactant class of sterolins (15) have been done, but no physicochemical properties

*To whom correspondence should be addressed at Department of Chemistry, Organic Chemistry, KTH, SE-100 44 Stockholm, Sweden. E-mail: tnorin@orgchem.kth.se Abbreviations: CMC, critical micelle concentration; DeHab(E)m, dehydroabietates with poly(ethylene oxide) chains of m = 12, 17, or 45 units; EO, ethylene oxide; IR, infrared; MS, mass spectrometry; NMR, nuclear magnetic resonance; NP-EOm (or NP-EOn), nonylphenolethoxylate of m (or n) number of EO units; PEG, polyethylene glycol. Copyright 2003 by AOCS Press

have been reported. Surface measurements of a natural saponin, gypsoside (16), and a polyoxyethylene-based rosin acid, dehydroabietic acid (17), also have been carried out. Very little is known about the properties of carbohydrate derivatives of sterols. Such derivatives were, however, recently shown to possess useful synergistic effects in reducing the critical micellar concentration (CMC) of sodium dodecyl sulfate. Furthermore, the derivatives, much like cholesterol, were able to stabilize lipid membranes in liposomes (18). There have been reports of several benecial biological properties of polyoxyethylene-based sterols. For example, oligo(ethylene oxide)-based phytosterol surfactants have been shown to be both antiprurignous and antiphlogistic, similar to cortisones (19), whereas oligo(ethylene oxide)-based cholesterol and sitosterol surfactants have been shown to lower the uptake of cholesterol when added to food (20,21). It should be noted that easily biodegradable surfactants are not necessarily less toxic to the environment. For example, for oligo(ethylene oxide)-based surfactants, the length of the alkyl chain has little effect on the biodegradability, whereas the ecotoxicity is considerably greater for the longer-chain derivatives (22). Matsumura et al. have investigated the biodegradability of a broad range of sugar surfactants (23,24) and found that alkyl glycosides are readily biodegraded compared to ethoxylated nonionic alcohols. Alkyl glucose amine derivatives are less biodegradable than the alkyl glycosides but equally as biodegradable as the ethoxylated alcohols. Despite the lower biodegradability of polyoxyethylene-based surfactants, the surfactant properties of the compounds are still of interest. In this work we have compared the physicochemical and surfactant properties of long-chain CnEm surfactants [where n denotes the number of carbon atoms in the alkyl chain and m the number of ethylene oxide (EO) units in the hydrophilic chain], as well as some alicyclic (sterol-based) and aromatic (phenol-based) surfactants, with those of corresponding surfactants with a dehydroabietic acid hydrophobe. Dehydroabietic acid is the most abundant resin acid in the by-products from the pulp and paper industry. It is therefore an interesting raw material for the production of natural product-based surfactants. To our knowledge only one previous investigation of dehydroabietic acidbased surfactants has been done (17). The surfactant head groups consisted of ethyl-terminated polyethylene glycol (PEG)-chains (11 and 22 EO units), and their phase diagrams, solubilizing capacity, and cloud points were

125

Journal of Surfactants and Detergents, Vol. 6, No. 2 (April 2003)

126

P.S. PIISPANEN ET AL.

determined (17). The aim of the present study is to draw some conclusions regarding structureproperty relationships and to compare the properties of some surfactants derived from dehydroabietic acid with related surfactants.

EXPERIMENTAL PROCEDURES

Materials. Analytical-grade reagents obtained from commercial suppliers were used unless stated otherwise. General. All melting points were measured in open glass capillaries on a Gallenkamp Melting Point Apparatus (Loughborough, United Kingdom) and are uncorrected. 1H nuclear magnetic resonance (NMR) spectra were measured at 400 MHz with a Bruker AM-400 spectrometer (Karlsruhe, Germany). The solvent CDCl3 was the reference in all measurements. Only the protons that are signicant to the derivatives are reported and the ones belonging to the dehydroabietic acid skeleton are neglected. All mass spectra were recorded on a Finnigan SSQ 7000 mass spectrometer (San Jose, CA). Infrared (IR) spectra were recorded on an ATI Mattson Innity Series Fourier transform IR spectrometer (San Jose, CA) and all samples were prepared with KBr. Only the characteristic peaks of the derivatives are presented. Surface tension and wetting was measured with a Krss K12 tensiometer (Hamburg, Germany) equipped with a sandblasted Pt plate. Synthesis. (i) Dehydroabietic acid (1). Dehydroabietic acid was purified from tall oil rosin (25). The purity of the acid was determined to be >95%. Impurities other than different rosin acids were <0.1%. (ii) Dehydroabietoyl chloride (2). Dehydroabietic acid was transformed using thionylchloride into dehydroabietoyl chloride according to previously reported methods (26,27). 1 H NMR, IR, and mass spectra are identical to those previously reported. Total yield: 72.5%. (iii) Monomethyl PEG-550 ester of dehydroabietic acid (3). Dehydroabietoyl chloride, 2 (10 g, 31.4 mmol), was mixed with 5% molar excess of monomethyl PEG-550 and triethylamine in a round bottle. A small amount of dichloromethane was added as solvent, and the mixture was reacted for 4 h at +50C. Amine hydrochloride precipitated during reaction and was ltered off at the end of the reaction. Upon cooling to room temperature, the remaining amine hydrochloride was ltered off. Evaporation of solvents under vacuum gave the product, which was fully puried by washing with diethyl ether to remove all excess acid chloride and amine, yielding a syrupy, waxy compound. By-products such as the diester cannot be formed since a monomethyl PEG is used. Small quantities (<3%; nondetectable by 1H NMR) of unreacted monomethyl PEG might remain, but such remains are not surface active and will not affect the measurements. Total yield: 26.4 g (quantitative); m.p. approximately 3540C; 1H NMR (400 MHz): 3.17 (s, 3H, CH3O), 3.503.70 (m, 44H, OCH2CH2O), 3.82 (t, J = 7Hz, 2H, CH2CH2OCO), 4.07 (t, J = 7 Hz, 2H, CH2OCO); IR (C=O ester 1725 cm1). (iv) Monomethyl PEG-750 ester of dehydroabietic acid (4). A procedure identical to the one used in the preparation of 3 was used, but with monomethyl-PEG (750) instead. Total

yield: 33.4 g (quantitative); m.p. approximately 4045C; 1H NMR (400 MHz), 3.17 (s, 3H, CH3O), 3.503.70 (m, 64H, OCH2CH2O), 3.82 (t, J = 7Hz, 2H, CH2CH2OCO), 4.07 (t, J = 7 Hz, 2H, CH2OCO); IR (C=O ester 1725 cm1). (v) Monomethyl PEG-2000 ester of dehydroabietic acid (5). A procedure identical to the one used in the preparation of 3 was used, but with monomethyl-PEG (2000) instead. Total yield: 72.1 g (quantitative); m.p. approximately 4550C; 1H NMR (400 MHz): 3.17 (s, 3H, CH3O), 3.503.70 (m, 176H, OCH2CH2O), 3.82 (t, J = 7 Hz, 2H, CH2CH2OCO), 4.07 (t, J = 7 Hz, 2H, CH2OCO); IR (C=O ester 1725 cm1). Physicochemical characterization. (i) Surface tension. Surface tension was measured with the Wilhelmy plate method using an automatic procedure with a dosimeter. The solutions were stirred for 60 s after each addition of surfactant. All solutions showed very stable surface tension values with time. The nal value was taken after 100 s of equilibration. Typically, the surface tension decreased 0.05 mN/m during the 100-s period. The experiments were repeated twice with high repeatability and the curves coincided. The temperature was set to 25C. (ii) Cloud point. The samples were immersed in a water bath, and the temperature was simultaneously measured in the water bath and inside the sample. The temperature was increased and decreased around the cloud point, at which the solution turned milky white. The accuracy of the cloud point temperature was 0.5C. The cloud point, assessed visually, was measured as a function of NaCl concentration at a constant surfactant concentration of 2 wt%. The cloud point of a 1 wt% surfactant solution was also examined. (iii) Foaming. Foamability and foam stability were investigated by the standardized RossMiles test described in detail elsewhere (28,29) (ASTM D 1173), which was performed at room temperature (~22C). An aqueous surfactant solution (200 mL) of surfactants 3 and 4 was poured into a column with 50 mL of surfactant solution in the bottom. Foaming experiments were performed with surfactant concentrations of 0.1 and 1.0 wt/vol% for both surfactants. The foam height was then measured as a function of time. (iv) Wetting. The contact angle of the surfactant solution at a concentration above the CMC was measured on a hydrophobized glass slide using the Wilhelmy plate method. The advancing contact angle is continuously measured while immersing the plate into the solution, and the receding contact angle is measured while withdrawing the plate from the solution. The plate was immersed and withdrawn from the solution at a rate of 5 mm/min, and the experiment was performed at room temperature (~22C) The details of the measuring procedure and of the glass slide hydrophobization have been described earlier (10). The contact angles with water were found to be 108 (advancing angle) and 94 (receding angle), respectively.

RESULTS AND DISCUSSION

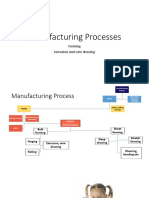

Surfactants 35 (n = 12, n = 17, and n = 45, respectively) were prepared from dehydroabietic acid (1) according to Scheme 1.

Journal of Surfactants and Detergents, Vol. 6, No. 2 (April 2003)

SURFACTANTS FROM DEHYDROABIETIC ACID

127

Surface tension. The surface tension isotherms are shown in Figure 1. The CMC, the surface tension at the CMC (CMC), the adsorbed amount at the CMC (CMC), and the area/molecule at the CMC are shown in Table 1. By increasing the number of EO groups from an average of 12 (3) to 17 (4), the surfactant became slightly more hydrophilic, but the CMC (expressed in mM) was identical within experimental error. Some surface properties of surfactants 35 are presented in Table 1 together with suitable reference surfactants. The area/molecule at the liquidvapor interface and the surface tension at the CMC were unchanged with the size of the head group in this range. When the number of EO groups was increased to 45 (5), the surfactant became even more hydrophilic and the area/molecule increased dramatically. The solubility of the surfactant decreased strongly, however, and it was estimated to be 400 mg/L. Possible reasons for the decreased solubility of 5 are discussed below. A comparison with alcohol ethoxylates with a similar degree of ethoxylation revealed that the dehydroabietic acid hydrophobe was only slightly more hydrophobic than a linear dodecyl chain with 12 carbon atoms and that the CMC was slightly lower (34). Note that the dehydroabietic acid contains 20 carbon atoms, mostly in a stiff ring structure. The surface tension at the CMC was about the same as for C12(E)15.3 (not included in Table 1). However, a large dip in the isotherm for C12(E)15.3, indicating the presence of a surface-active contaminant, made comparison difficult (34). The area/molecule was much lower than what would be expected from a linear C12E17 surfactant, which was a consequence of the stiff and compact hydrophobe and could be an indication of higher attractive forces for the dehydroabietic hydrophobes than for the dodecyl chain. This trend was also apparent by comparing the nonylphenolethoxylate (NP-EOn) series with the CnEOm series (for example, NP-EO30 to C15E40); linear alkyl ethoxylates have lower CMC values than the corresponding, or even slightly larger, aromatic or alicyclic surfactant. The polyoxyethylene dehydroabietates (35) seem to pack approximately as well as the NP-EOn series of surfactants. Thus, these two classes of surfactants both have smaller area/molecule than the linear aliphatic equivalents. Compound 5 was compared with a series of CnE40, where n is the number of linear hydrophobic carbons (with n = 11,

FIG. 1. Surface tension as a function of concentration for compounds 3 ( ), 4 ( ), and 5 (). The straight lines represent the fit from which the area/molecule is calculated.

13, 15, and 17), which were previously investigated (30). The dehydroabietic acid hydrophobe seemed to have properties similar to a linear dodecyl chain. The minimum surface tension, reached at the solubility limit of 5, was close to the value found for the C1113E40 surfactants at their CMC, and the surface tension was similar at low concentrations. The calculated minimum area/molecule was lower for 5 (0.95 nm2) than for the C1113E40 surfactants (1.4 nm2). Similarly, 3 and 4 had a smaller area than C12E17. The low solubility limit of 5 at about 400 mg/L showed that micelles were unable to form. The large size and the rigid structure of the dehydroabietic acid hydrophobe seemed to impose a large

TABLE 1 Critical Micelle Concentration (CMC), Surface Tension at the CMC, and Area/Moleculea of Surfactants 35 and Some Suitable Reference Surfactantsb Surfactant 3 4 5 C11E40e C13E40e C15E40e C17E40e ChI-EO13f ChI-EO30g ChI-EO35f ChI-EO50f NP-EO9.5 NP-EO15 NP-EO20 NP-EO30

a

CMC (mg/L) 60 73 6 35 239 1554 191 38 31 100g 199g 316g 631g

CMC (mM) 0.071 0.069 0.0032 0.018 0.12 0.77 0.112 0.0196 0.0121 0.157 0.226 0.287 0.409

CMC (mN/m) 36.1 36.1 48.4d 50 49 48 49 46 52

CMC (mol/m2) 2.85 2.91 1.7

Area/moleculec (2) 58 57 95d 150 140 140 150 72 100 120 151 55h 72h 82g 101h

SCHEME 1

Values derived from the surface tension isotherms in Figure 2 and references. Temperature is 25C. b Surfactants denoted as CnEm are polyoxyethylene-based ether surfactants consisting of n number of linear alkyl hydrophobic carbons and m number of ethylene oxide (EO) units. The surfactants ChI-EOm are polyoxyethylene cholesteryl ethers of m number of EO units via an ether bond. The surfactants NP-EOm are traditional, commercial polyoxyethylenated p-nonylphenol of m number of EO units via an ether bond. c Mean value of area/molecule. d Solubility limit. e Data from Reference 30. f Data from Reference 31. g Data from Reference 32. h Data from Reference 33.

Journal of Surfactants and Detergents, Vol. 6, No. 2 (April 2003)

128

P.S. PIISPANEN ET AL.

micelle size, larger than that of the corresponding surfactant with a more flexible alkyl chain. This meant that the curvature of the micelle surface of DeHab(E)m surfactants was lower and that the head group of 5 was probably too large to be compatible with such a micelle. Hence, no efficient packing into micelles was possible since the hydrophobic and hydrophilic parts had conflicting requirements on the micellar curvature. The packing and solubility properties may also have originated to some degree from the lack of a terminal hydroxyl group at the end of the polyoxyethylene chain of surfactants 35, in contrast to the reference surfactants. Cloud point. The cloud points for 2 wt% samples of compounds 3 and 4 as a function of sodium chloride concentration are shown in Figure 2. The cloud point decreased in a roughly linear fashion with 2C for each additional 0.1 M added salt. The same behavior was found for the ethoxylated dehydroabietic acid DeHab(E)22, which has a cloud point of 72C in water (17), and for poly(ethylene oxide) polymer systems (35). The cloud point increased with the head group chain length, which is commonly found for other ethoxylated surfactants (34,36), and it decreased by only about 0.5C when the concentration was decreased to 1 wt% (see Table 2). The role of the dehydroabietic acid hydrophobe is to signicantly reduce the cloud point compared to, for example, a dodecyl chain surfactant with the same head groups (34,36). For example, the cloud points for C12E8 and C12E12 are 77 and 98C, respectively (36). In comparison to other large alicyclic surfactants, the cholesteryl ether (ChI)-EOn series, the title surfactants again had surprisingly low cloud points. This indicates that the size and shape of the DeHab(E)m micelles are larger, which, among other things, gives rise to a stronger van der Waals force between the micelles and reduces the importance of the mixing entropy. Both these effects will promote the formation of the concentrated surfactant phase, which gives rise to the clouding phenomenon. Foaming. Figure 3 shows the foaming behavior for compounds 3 and 4 as a function of concentration and time. The foamability for compound 5 is extremely low because of the high surface tension at the solubility limit and because of the large head group, which prevents packing at a planar interface. The concentrations 0.1 and 1.0 wt% in Figure 3 are both above the CMC, which are 0.007 wt% for compounds 3 and 4. The foam volume at t = 0 (the measure of foamabil-

TABLE 2 Cloud Points of Surfactants 35 and Some Suitable Reference Surfactantsa Surfactant 3 4 5 ChI-EO10d ChI-EO13d ChI-EO35d ChI-EO50d

a

Cloud point (C) 44 63 50 84 130 130

Surfactant NP-EO9.5b NP-EO15b C12E4.4c C12E6.5c C12E8e C12E9.7c C12E12e C12E15.3c

Cloud point (C) 60 95 25 46 77 88 98 88+

Surfactants denoted as CnEm are polyoxyethylene-based ether surfactants consisting of n number of linear alkyl hydrophobic carbons and m number of EO units. The surfactants ChI-EOm are polyoxyethylene cholesteryl ethers of m number of EO units via an ether bond. The surfactants NP-EOm are traditional, commercial polyoxyethylenated p-nonylphenol of m number of EO units via an ether bond. All cloud points are measured from 1 wt/vol% surfactant solutions. For abbreviation see Table 1. b Data from Reference 33. c Data from Reference 30. d Data from Reference 31. e Data from Reference 36.

ity), as well as the foam stability, increases when the EOchain length is increased from 12 to 17 and with concentration. This behavior has been found for other oligo(ethylene oxide) surfactants (34) as well as for C8 to C18 alkyl chain lengths with the number of EO units ranging from about 3 to 15. However, at a sufficiently high EO content the foamability starts to decrease (34,37). The foamability and foam stability were lower for C12E7 than for C12E5. For a dodecyl hydrophobe, the maximum foaming already is passed when the oxide chain reaches 7 units (37). This demonstrates that the foaming behavior is dependent on the size of the EO group in relation to the size of the hydrophobic group. The higher foamability and foam stability for compound 4 (17 EO) than for compound 3 (12 EO) are related to the larger size of the hydrophobic groups in these compounds compared to the dodecyl chain. In comparison to a sugar surfactant with a dodecyl chain (lactose monododecanoate), the foamability and the foam stability were higher for the sugar surfactant (38). The foam height of a 1 wt% lactose monododecanoate solution is 170 mm and decreases to 160 mm after 30 min. In addition, the foaming behavior for the sugar

FIG. 2. Cloud point as a function of NaCl concentration (c) for compounds 3 () and 4 () at 2 wt%. For comparison, the cloud points of 3 ( ) and 4 () at 1 wt% are included.

FIG. 3. Foam height as a function of surfactant concentration (c) and time for compounds 3 and 4.

Journal of Surfactants and Detergents, Vol. 6, No. 2 (April 2003)

SURFACTANTS FROM DEHYDROABIETIC ACID

129

surfactant is less dependent on the concentration, and is unchanged when the concentration is lowered to 0.1 wt% (38). We noted that the CMC for lactose monododecanoate (0.43 mM) and those of compounds 3 and 4 were about the same, which means that the differences in the foaming behavior cannot be explained by differences in the CMC, but rather are related to the packing at the interface. The common observation is that better interfacial packing results in a higher surface elasticity, which increases the foam stability. Wetting. Table 3 shows the contact angles of compounds 3 and 4 and, for comparison, some other surfactants on a hydrophobic glass slide. Since there is a notable lack of wetting data on polyethoxylated sterols, nonionic sugar surfactants were used as reference surfactants instead. All contact angles were measured at concentrations at or above the CMC value when the contact angle had reached its minimum. It has been reported that the contact angle is dependent only on the surface tension of the solution (39,40). This is perhaps true for structurally similar substances such as a series of CnEm surfactants with different alkyl and EO chain lengths. However, a comparison of the contact angles of different sugar surfactants with those of CnEm surfactants clearly showed that the latter are better wetting agents with lower contact angles, even at the same surface tensions (10,41). The contact angles at concentrations above the CMC for compounds 3 and 4 were much lower than those of C12-maltose and LABA (N-lauryl lactobionamide). They had better wetting abilities than TEDAd [(tetra(ethyleneoxide) dodecyl amide] and C12E5 at the same surface tensions. For example, at 37 mN/m the advancing contact angles were 64, 63, 71, and 71 degrees for surfactants 3, 4, TEDAd (32), and C12E5 (41), respectively. The reason for this might be better packing of the dehydroabietic hydrophobe on the surface. The contact angles for TEDAd and C12E5 above the CMC were lower than these, however, because of the lower surface tension of the solution. The present investigation has demonstrated that polyoxyethylene esters of dehydroabietic acid possess CMC values equal to the equivalent linear dodecyl polyoxyethylene ethers. The cloud point, however, is signicantly lower than those of both the corresponding dodecyl-based surfactant and the equivalent cholesterol-based surfactant, indicating a

TABLE 3 Contact Angles of 3, 4, and Other Surfactants on a Hydrophobized Glass Slidea Surfactant Water 3 4 Octyl--glucosideb C12-Maltose esterb LABAb TEDAdc C12E5c

a b

use as low-temperature solubilizers. The wetting results indicate that the title surfactants are better wetting agents than both sugar-based surfactants and linear alkyl-based surfactants. Thus, the surfactants should be useful detergents in washing products since they also possess the foaming properties often desired by consumers. The wetting properties should also be able to improve substrate wetting in painting products and would be useful additives in mineral otation.

ACKNOWLEDGMENTS

The study was performed within the Competence Centre for Surfactants Based on Natural Products (SNAP), Stockholm, Sweden, and was supported by the Royal Institute of Technology (KTH), Stockholm, Sweden, NUTEK, and industry. Professor Per Claesson, Surface Chemistry, KTH, Stockholm, is gratefully acknowledged for discussions and comments.

REFERENCES

1. Rico-Lattes, I., and A. Lattes, Synthesis of New Sugar-Based Surfactants Having Biological Applications: Key Role of Their SelfAssociation, Colloids Surf. A 123124:37 (1997). 2. Sderberg, I., C.J. Drummond, D.N. Furlong, S. Godkin, and B. Matthews, Non-ionic Sugar-Based Surfactants: Self-Assembly and Air/Water Interfacial Activity, Colloids Surf. A 102:91 (1995). 3. Aveyard, R., B.P. Binks, J. Chen, J. Esquena, P.D.I. Fletcher, B.R. Buscall, and S. Davies, Surface and Colloid Chemistry of Systems Containing Pure Sugar Surfactants, Langmuir 14:4699 (1998). 4. Retailleau, L., A. Laplace, H. Fensterbank, and C. Larpent, Synthesis, Structural Analysis, and Properties of N-Alkylglucosyl(meth)acrylamides: New Reactive Sugar Surfactants, J. Org. Chem. 63:608 (1998). 5. Garofalakis, G., B.S. Murray, and D.B. Sarnay, Surface Activity and Critical Aggregation Concentration of Pure Sugar Esters with Different Sugar Headgroups, J. Colloid Interface Sci. 229:391 (2000). 6. Sarney, D.B., H. Kapeller, G. Fregapane, and E.N. Vulfson, Chemo-enzymatic Synthesis of Disaccharide Fatty Acid Esters, J. Am. Oil Chem. Soc. 71:711 (1994). 7. Balzer, D., Cloud Point Phenomena in the Phase Behavior of Alkyl Polyglucosides in Water, Langmuir 9:3375 (1993). 8. Boyd, B.J., C.J. Drummond, I. Krodkiewska, and F. Grieser, How Chain Length, Headgroup Polymerization, and Anomeric Conguration Govern the Thermotropic and Lyotropic Liquid Crystalline Phase Behavior and the AirWater Interfacial Adsorption of Glucose-Based Surfactants, Langmuir 16:7359 (2000). 9. Zhang, T., and R.E. Marchant, Novel Polysaccharide Surfactants: The Effect of Hydrophobic and Hydrophilic Chain Length on Surface Active Properties, J. Colloid Interface Sci. 177:419 (1996). 10. Kjellin, U.R.M., P.M. Claesson, and E.N. Vulfson, Studies of NDodecyllactobionamide, Maltose 6-O-Dodecanoate, and Octyl-glucoside with Surface Tension, Surface Force, and Wetting Techniques, Langmuir 17:1941 (2001). 11. Folmer, B.M., M. Svensson, K. Holmberg, and W. Brown, The Physicochemical Behavior of Phytosterol Ethoxylates, J. Colloid Interface Sci. 213:112 (1999). 12. Folmer, B.M., K. Holmberg, E. Gottberg-Klingskog, and K. Bergstrm, Fatty Amide Ethoxylates: Synthesis and Self-Assembly, J. Surfact. Deterg. 4:175 (2001). 13. Khachadurian, A., C.H. Fung, T. van Es, and F.F. Davis, Polyoxyethylated Cholesterol DerivativesOrganic Synthesis, Cellular Uptake, and Effect on Lipid Metabolism in Cultured Skin Fibroblasts, Biochim. Biophys. Acta 665:434 (1981).

CMC (mM) N/A 0.3 0.3 22.0 0.33 0.35 0.5 0.064

(mN/m) 72.2 37 37 32 39 37 31 30

adv (degrees) 108 64 63 61 80 79 54 46

rec (degrees) 94 22 20 21 19 14 20 24

All concentrations are above their respective CMC. From Reference 10. C12-maltose ester, maltose 6-O-dodecanoate; LABA, N-lauryl lactobionamide. c From Reference 41. TEDAd, tetra(ethylene oxide) dodecyl amide; for other abbreviation see Table 1.

Journal of Surfactants and Detergents, Vol. 6, No. 2 (April 2003)

130

P.S. PIISPANEN ET AL.

14. Mueller-Goymann, C., Liquid Crystals in Emulsions, Creams, and Gels Containing Ethoxylated Sterols as Surfactant, Pharm. Res. 4:154 (1984). 15. Shibamoto, T., M. Fukushima, and T. Suzuki, Cosmetic, Japanese Patent JP-62,187,404, Pola Chemical Industries Inc. (1987). 16. Barla, P., K. Larsson, H. Ljusberg-Wahren, T. Norin, and K. Roberts, Phase Equilibria in a Ternary System SaponinSunflower Oil MonoglyceridesWater: Interactions Between Aliphatic and Alicyclic Amphiphiles, J. Sci. Food Agric. 30:864 (1979). 17. Persson, M., P. Stenius, G. Strm, L. dberg, I. Bolmgren, H. Ljusberg-Wahren, and T. Norin, Solubilization, Micellization, and Phase Equilibria of Polyoxyethylene Derivatives of Dehydroabietic Acid, J. Phys. Chem. 84:1557 (1980). 18. Piispanen, P.S., S. Bystrm, M. Svensson, B. Kronberg, I. Blute, and T. Norin, Synthesis and Characterization of Surface-Active Compounds Derived from Cholesterol Derivatives and Glucose, J. Surfact. Deterg. 345:351 (2002). 19. Goossens, A., M.H. Beck, E. Haneke, J.P. McFadden, S. Nolting, G. Durupt, and G. Ries, Adverse Cutaneous Reactions to Cosmetic Allergens, Contact Dermatitis 40 :112 (1999). 20. Amorosa, L.F., C.P. Martucci, N.R. Stevenson, and A.K. Khachadurian, The Effects of Polyethylated Cholesterol on Fecal Bile Acids and Nitrogen and on Cholesterol Balance in Rats, Lipids 26:209 (1991). 21. Hamunen, A., and A. Hirschfeldt, Sterols from Unsaponiable Constituents of Tall OilA Wood-Based Raw Material for the Cosmetic, Pharmaceutical, and Food Industries, Seifen, Oele, Fette, Wachse 112:261 (1986). 22. Kaluza, U., and K. Taeger, Struktur und Eigenschaften von Alkanol-Ethoxylaten, Tenside Surfact. Deterg. 33:46 (1996). 23. Matsumura, S., K. Imai, S. Yoshikawa, K. Kawada, and T. Uchibori, Surface Activities, Biodegradability and Antimicrobial Properties of n-Alkyl Glucosides, Mannosides and Galactosides, J. Am. Oil Chem. Soc. 67:996 (1990). 24. Matsumura, S., Y. Kawamura, S. Yoshikawa, K. Kawada, and T. Uchibori, Surface Activities, Biodegradability and Antimicrobial Properties of Glucosamine Derivatives Containing Alkyl Chains, J. Am. Oil Chem. Soc. 70 :17 (1993). 25. Hedman, B.E.O., Tall Oil Products as Raw Materials for Surfactant Synthesis, Licensiate Thesis, Royal Institute of Technology (KTH), Stockholm, Sweden, 2000, p. 25. 26. Akatsuka, T., O. Kodama, K. Matsuo, and Y. Esaki, Agent to Control Rice Blast, Japanese Patent JP-63,017,806, Arakawa Chem. Ind. Co. Ltd. (1986). 27. Akatsuka, T., O. Kodama, K. Matsuo, and Y. Esaki, Agent to Control Rice Blast, Japanese Patent JP-19,880,125 Arkawa Chem. Ind. Co. Ltd. (1986). 28. American Standard Test Methods, a Standard Test Method for Foaming Properties of Surface-Active Agents, D1173-53 (2001). 29. Ross, J., and G.D. Miles, An Apparatus for Comparison of Foaming Properties of Soaps and Detergents, Oil Soap 18:99 (1941). 30. Ameri, M., D. Attwood, J. Collett, and C. Booth, Self-Assembly of Alcohol Ethoxylate Non-ionic Surfactants in Aqueous Solution, J. Chem. Soc., Faraday Trans. 93:2545 (1997). 31. Sderlund, H., J. Sjblom, T. Wrnheim, Phase Diagrams and Solution Properties of Ethoxylated Cholesterols, J. Dispersion Sci. Technol. 10 :131 (1989). 32. Svensson, M., Surfactants Based on Sterols and Other Alicyclic Compounds, in Novel Surfactants, edited by K. Holmberg, Marcel Dekker, New York, 1998, p. 179. 33. Schick, M. (ed.), Nonionic Surfactants, Marcel Dekker, New York, 1966. 34. Cox, M.F., Effect of Alkyl Carbon Chain Length and Ethylene Oxide Content on the Performance of Linear Alcohol Ethoxylates, J. Am. Oil Chem. Soc. 66:367 (1989). 35. Florin, E., R. Kjellander, and J.C. Eriksson, Salt Effects on the

36.

37.

38.

39.

40.

41.

Cloud Point of the Poly(ethylene oxide) + Water System, J. Chem. Soc., Faraday Trans. 80:2889 (1984). Mitchell, D.J., G.J.T. Tiddy, L. Waring, T. Bostock, and M.P. McDonald, Phase Behaviour of Polyoxyethylene Surfactants with Water, J. Chem. Soc., Faraday Trans. 1 79 :975 (1983). Garrett, P.R., and P.L. Gratton, Dynamic Surface Tensions, Foam and the Transition from Micellar Solution to Lamellar Phase Dispersion, Colloids Surf. A 103:127 (1995). Drummond, C.J., and D. Wells, Nonionic Lactose and LactitolBased Surfactants: Comparison of Some Physico-chemical Properties, Colloids Surf. A 141:131 (1998). Gau, C.-S., and G. Zografi, Relationships Between Adsorption and Wetting of Surfactant Solutions, J. Colloid Interface Sci.140 :1 (1990). Bargeman, D., and F. Van Voorst Vader, Effect of Surfactants on Contact Angles at Nonpolar Solids, J. Colloid Interface Sci.42:467 (1972). Kjellin, U.R.M., P.M. Claesson, and P. Linse, Surface Properties of Tetra(ethylene oxide)dodecyl Amide Compared with Poly(ethylene oxide) Surfactants. 1. Effect of the Headgroup on Adsorption, Langmuir 18:6745 (2002). [Received October 15, 2001; accepted October 30, 2002]

Peter S. Piispanen, born in 1972, received his B.Sc. from the Royal Institute of Technology (KTH), Stockholm, in 1996. A position as a Ph.D. student, under the Department of Organic Chemistry at the KTH, started immediately and the dissertation was completed in June of 2002. The thesis work concentrated on the synthesis and the physical/surface characterization of surfactants based on natural products. U.R. Mikael Kjellin, born in 1970, received his M.Sc. in Engineering from the KTH, Stockholm, in 1996. A position as a Ph.D. student, under the Department of Chemistry, Surface Chemistry, at KTH began in July 1996. He completed his Ph.D. dissertation in January of 2002. The thesis work concentrated on the structure/ property relationships of surfactants based on natural products. Bjrn Hedman was born in 1967 and received his M.Sc. in Chemistry and Chemical Engineering from the KTH, Stockholm, in 1994. He worked as an industrial researcher and was a part-time Ph.D. student at Arizona Chemical AB during 19962000. A Licensiate in Organic Chemistry was obtained in 2000 with the thesis Tall Oil Products as Raw Materials for Surfactant Synthesis. Hedman is currently employed as a production manager at Vallviks Bruk AB, Vallvik, Sweden, and his main research interest is tall oil chemistry, especially rosin acids and derivatives. Torbjrn Norin retired as Professor of Organic Chemistry at the KTH in Stockholm, Sweden, in 2000 and is now acting as professor emeritus. Norin is a fellow of the Royal Swedish Academy of Sciences, the Royal Swedish Academy of Engineering Sciences, the Academia Europaea, and the Royal Norwegian Society of Sciences and Letters. He has served and serves on many boards and councils, both nationally and internationally. He is President of the Organic and Biomolecular Chemistry Division of IUPAC. He has, for 10 years (19891999), served as President of the Swedish Chemical Society and has also served as Chairman of the chemistry section of the Royal Swedish Academy of Sciences. At present he is a member of the board (Akademinmnden) of the Royal Swedish Academy of Sciences. He has been a member of the board of directors of the Institute of Surface Chemistry, Stockholm, Sweden (19742001; 19912001 as chairman). His research interests are within organic chemistry (natural product chemistry, synthetic organic chemistry, asymmetric synthesis, and biocatalysis). He is the author or co-author of more than 200 scientic publications and two textbooks.

Journal of Surfactants and Detergents, Vol. 6, No. 2 (April 2003)

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Hydroponic Cheat SheetДокумент3 страницыHydroponic Cheat SheetNarcisMarin100% (12)

- Ss2 Chemistry Exam Questions For Second TermДокумент8 страницSs2 Chemistry Exam Questions For Second TermPeter Anga100% (3)

- NDT Method SummaryДокумент3 страницыNDT Method SummaryNguyen Anh TungОценок пока нет

- Concrete ClothДокумент20 страницConcrete ClothShrinivasОценок пока нет

- Tensile TestДокумент11 страницTensile TestOsura GunasenaОценок пока нет

- Metodo XenosepДокумент12 страницMetodo XenosepJenny Chavez AlarconОценок пока нет

- Ec101 Semi ConductorsДокумент68 страницEc101 Semi ConductorsCaptain Tech8Оценок пока нет

- Elevation 01 Elevation 04: C03 C01 C02 D01 D02 D03 D04 D05 D06 D07Документ1 страницаElevation 01 Elevation 04: C03 C01 C02 D01 D02 D03 D04 D05 D06 D07Abid AyubОценок пока нет

- A Brief Guide To Calculating Embodied CarbonДокумент6 страницA Brief Guide To Calculating Embodied Carbonmatt calvertОценок пока нет

- Technological Result of Decomposition Sodium Aluminate SolutionДокумент10 страницTechnological Result of Decomposition Sodium Aluminate SolutionDragana Dragojlović SmiljanicОценок пока нет

- Test Bank The Human Body Health Illness 5th Edition HerlihyДокумент15 страницTest Bank The Human Body Health Illness 5th Edition HerlihyRhonda Mosholder100% (22)

- 50CДокумент6 страниц50Cjhacademyhyd89% (9)

- Project Black Cotton Soil Bricks-1Документ18 страницProject Black Cotton Soil Bricks-1Anusha SajjanОценок пока нет

- Adsorption Modeling With The Esd Equation of State: Aaron D. Soule, Cassandra A. Smith, Xiaoning Yang Carl T. LiraДокумент38 страницAdsorption Modeling With The Esd Equation of State: Aaron D. Soule, Cassandra A. Smith, Xiaoning Yang Carl T. LiraSanjeeva YedavalliОценок пока нет

- Photoinduced Degradation of 2,4-Dichlorophenol in Water - Influence of Various Fe (III) CarboxylatesДокумент8 страницPhotoinduced Degradation of 2,4-Dichlorophenol in Water - Influence of Various Fe (III) CarboxylatesLilith angieОценок пока нет

- Simple DistillationДокумент5 страницSimple DistillationJheian Christian TubleОценок пока нет

- 5.6 DisinfectionДокумент23 страницы5.6 DisinfectionZul ImiОценок пока нет

- Yield Strength Yield Point Stress Yield Point Stress Elastic Limit Elastic LimitДокумент1 страницаYield Strength Yield Point Stress Yield Point Stress Elastic Limit Elastic LimitCarlito Jr JavilloОценок пока нет

- 12CHEM Long Response Dot PointsДокумент11 страниц12CHEM Long Response Dot PointsJane YooОценок пока нет

- ChemДокумент2 страницыChemDBANJAN MAITYОценок пока нет

- Design of CPP Manufacturing Plant and Study Its DefectsДокумент33 страницыDesign of CPP Manufacturing Plant and Study Its DefectsAbdullah AbbasОценок пока нет

- Optical Brightener Uvitex OB Msds Baoxu ChemicalДокумент11 страницOptical Brightener Uvitex OB Msds Baoxu ChemicalBhaumik ParmarОценок пока нет

- Water Softener ResinДокумент3 страницыWater Softener Resinmkgchem100% (1)

- Winsheld PDFДокумент34 страницыWinsheld PDFAnonymous FAa4A3akdОценок пока нет

- Material Selection Guide: Magnetic FlowmeterДокумент24 страницыMaterial Selection Guide: Magnetic Flowmeteryrdna nawaiteosОценок пока нет

- Slide 11 Extrusion and Wire DrawingДокумент53 страницыSlide 11 Extrusion and Wire Drawingjohn doeОценок пока нет

- 2023 Productcatalogue 2Документ35 страниц2023 Productcatalogue 2Trevor NaidooОценок пока нет

- Glazed Alum Curtain Wall - Vendors ListДокумент3 страницыGlazed Alum Curtain Wall - Vendors ListKiran Kumar AkulaОценок пока нет

- AbcdДокумент3 страницыAbcdNikesh ShahОценок пока нет

- Quiz 1 InorgДокумент5 страницQuiz 1 InorgDanielle Lois AbagОценок пока нет