Академический Документы

Профессиональный Документы

Культура Документы

SCH4U Butyl Ethanoate Esterification

Загружено:

Afiq AsriИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SCH4U Butyl Ethanoate Esterification

Загружено:

Afiq AsriАвторское право:

Доступные форматы

Asri 1

Synthesis and Purification of 1-Butyl Ethanoate in Laboratory for Organic Chemistry

Mohd Afiq Mohd Asri Chemistry 12 Period 3, International Canadian Pre-University, Taylors College, Wisma Subang Jaya, Jalan SS 15/4, 47500 Subang Jaya, Selangor Darul Ehsan. mohdafiq.mohdasri@sd.taylors.edu.my

Completed on 30 November 2010.

Abstract: Synthesis of butyl ethanoate through esterification is a common laboratory exercise in organic chemistry. The objective of the laboratory is to enlighten Chemistry 12 students about the reactions of organic compounds from functional groups ester, alcohols and carboxylic acid. Students also receive handson experience handling esterification reaction as well as purification via separation and distillation.

Introduction Esters are one of the functional groups of organic chemistry learned in the Chemistry 12 course. Esters are chemical compounds derived by reacting an oxoacid with a hydroxyl compound. Basically, esters are formed by condensing an acid with an alcohol.[1] In this process, the hydroxyl group (-OH) of the carboxylic acid is replaced by an alkoxy group (RO) of the alcohol. Esters have special properties compared to other chemical compounds; notably the fragrance it produces depending on what chemical composition it is made from. The classic synthesis is the Fischer esterification, which involves treating a carboxylic acid with an alcohol in the presence of a dehydrating agent:

RCOOH + R'OH RCOOR' + H2O

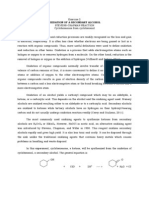

The mechanism of the Fischer esterification is as shown below. The mineral acid used as catalyst in the following example is concentration hydrochloric acid.

Asri 2

The first step involves protonation (addition of H+) of the carbonyl oxygen which increases the electrophilicity of carbonyl carbon, followed by the nucleophillic attack of the alcohol, finished off with the loss of a proton. Again protonation of one of the alcohols occur and followed by loss of water. Electrons from the oxygen come down to form the double bond. The loss of a proton yields the ester.[2] In simpler words, the RC=O in the ester originates from the carboxylic acid and the OR comes from the alcohol. For this experiment, the alcohol used is butanol and the carboxylic acid used is ethanoic acid. Concentrated sulphuric acid is used as the catalyst. The chemical equation for the esterification of butanol and ethanoic acid is given as the following:

CH3COOH + CH3CH2CH2CH2OH CH3COOCH3CH2CH2CH3 + H2O

The experiment should provide students with a deeper understanding on organic chemistry; particularly on the physical and chemical properties esters, alcohols and carboxylic acids.

Background The name ester is derived from the German Essig-ther (literal: vinegar ester), an old name for ethyl acetate. [3] Fischer esterification is a type of esterification by refluxing carboxylic acid and alcohol in the presence of an acid catalyst. The reaction was first described by Emil Fischer and Arthur Speier in 1895.[4] It is the most common type esterification procedure done in school laboratories. The process of esterification is not new in our modern industry as it was dated back about 100 years ago. However, at that time, they had no modern technology to equip themselves to carry out this experiment easily. 1-butyl ethanoate, is an organic compound commonly used as a solvent in the production of lacquers and other products. It is also used as synthetic fruit flavouring in foods such as candy, ice cream, cheeses, and baked goods.

Asri 3

1-butyl ethanoate, CH3COOCH3CH2CH2CH3 has the following molecular structures:

Diagram 1.0 line skeletal formula for 1-butyl ethanoate

Diagram 1.1 structural formula for 1-butyl ethanoate

Butyl ethanoate is found in many types of fruit, where along with other chemicals it imparts characteristic flavours. Apples, especially of the Red Delicious variety[5], are flavored in part by this chemical. It is a colourless flammable liquid with a sweet smell of banana.

Experimental Supplies. 1.0M butanol, C4H9OH; 1.0M ethanoic acid, CH3COOH, 1.0M concentrated sulphuric acid, H2SO4, 100.00 mL distilled water, H2O; anhydrous calcium chloride chips, CaCl2; 0.5M sodium carbonate, Na2CO3; boiling chips, Bunsen burner, retort stand, measuring cylinder, 100 mL round-bottom flask, Liebig condenser, quickfit apparatus, thermometer, beaker, reagent bottle, separatory funnel, filter funnel, filter papers, Vaseline lubricant. Hazards. Safety goggles are to be worn at all times. Do not point the tip of the separatory funnel to anyone when releasing gas pressure during purification process. Joints of the Liebig condenser may break when detached after experiment if not properly lubricated. Boiling chips is used during heating to reduce vigorousness of the reaction to ensure the glassware does not break. Handle sulphuric acid and sodium bicarbonate with care as they are corrosive. Reading of the temperature at purification must be taken immediately as the purified ester begins to form during reflux. Procedures. Step A. The Liebig condenser is to be set-up as following:

Asri 4

Diagram 1.2 set-up of Liebig condenser[6]

20 mL butanol and 20 mL of ethanoic acid are measured using measuring cylinders. The measured solutions are then added into a round bottomed flask containing 3 pieces of boiling chips. 1 mL concentrated sulphuric acid is added into the mixture. The solution is heated and refluxed for 30 minutes. The heat source is then removed and solution is allowed to cool. Impure 1-butyl ethanoate produced is then filtered and transferred into a reagent bottle. Step B. Impure 1-butyl ethanoate is added into a separatory funnel. 40 mL of distilled water is added to the ester. The separatory funnel is stopped and the mixture is shaken. Tilt the funnel so that the tip is pointed upwards. Turn the stopcock to release gas pressure accumulating in the funnel. The stopcock is then closed and the funnel is set upright. As two separate layers are formed in the separatory funnel, the lower layer is removed. 40 mL of sodium carbonate is added into the remaining mixture. The mixture is shaken and gas pressure is released. Two separate layers are formed in the separatory funnel and the lower layer is again removed. 40 mL of water is added into the remaining mixture. The mixture is shaken and gas pressure is released. Two separate layers are formed in the separatory funnel. The lower layer is removed and the remaining mixture is extracted into a beaker. Step C. The extract is poured into a beaker and anhydrous calcium chloride chips are added into the flask. The beaker is swirled and the extract is filtered into a round bottom flask. The extract is then refluxed using a Liebig condenser and pure 1-butyl ethanoate is retrieved. The temperature at the time when the pure ester starts to form is recorded. The colour and odour of the extract is observed.

Asri 5

Results The product yielded from the experiment was 1-butyl ethanoate. The temperature when the pure ester flows out of the condenser is 124C. The first reaction produces a purplish coloured liquid while the extract is colourless after the purification process. Butyl ethanoate has a pungent odour similar to thinner.

Discussions H2SO4 acts as a catalyst to the reaction. The acid provides the H+ ions required for the protonation mechanism as explained in introduction. Esterification reaction is a reversible process that obeys the Le Chateliers principle. As the reaction is reversible, the yield of 1-butyl ethanoate cannot achieve 100%, especially under standard temperature and pressure. At equilibrium, the product yielded is an impure ester containing mixture of 1-butyl ethanoate with unreacted butanol and ethanoic acid. The yield of ester may be increased by having one of the reactants in excess amount, as the equilibrium is favoured towards the product side. The impurities in the mixture need to be removed in order to obtain pure 1-butyl ethanoate, hence the purification process is required. In the purification process, the mixture was washed thrice using different chemical compounds. During the separation step of the purification process, an understanding of the difference in densities of butyl ethanoate, sodium ethanoate and water is essential. Butyl ethanoate has the density of 0.88 g/cm3 [1], water has density of 1.00 g/cm3 and sodium ethanoate has density of 1.53 g/cm3 [7]. The differences in densities are vital in forming the separated layers of the mixture during the separation. The purpose of the first wash using distilled water is to dissolve the excess butanol. Butanol is soluble in water. Butanol-water solution is denser than butyl ethanoate and forms the lower layer. The dissolved butanol is then removed from the separatory funnel. The purpose of washing the ester mixture with sodium carbonate, Na2CO3 is to make it react with ethanoic acid to form sodium ethanoate, CH3COONa; water, H2O and carbon dioxide gas, CO2:

Na2CO3 + 2CH3COOH 2CH3COONa + H2O + CO2

The second wash using distilled water is to separate the layers of sodium ethanoate and the 1butyl ethanoate. The difference in densities causes the water to act as the middle layer that separates the denser sodium ethanoate and the lesser dense 1-butyl ethanoate. This allows the sodium ethanoate to be removed. Anhydrous calcium chloride is added to the extract to remove the remaining water residue from the extract. The beaker is swirled to ensure the dehydration is even and thorough. Also, during the separation process, the stopcock had to be opened a few times at regular intervals to release gas pressure. The pressure is caused by the production of carbon dioxide gas, CO2 which is a by-product of the reaction of the mixture in the separatory funnel. If the separatory funnel is not opened at regular interval, glassware will break due to accumulated pressure.

Asri 6

The boiling point of 1-butyl ethanoate is 126C[5]. At the boiling point, the ester begins to vaporise into gas. The vapour is condensed by the Liebig condenser, reverting the vapour back into liquid pure 1-butyl ethanoate and flows out of the condenser. The difference between the actual boiling point and the value obtained from the experiment is due to the presence of impurities in the extract which lowers the boiling point of the solution. The difference is also due to the fact that human error could have occurred when the temperature was taken.

Conclusion 1-butyl ethanoate can be synthesized in a laboratory by esterification reaction of butanol and ethanoic acid using concentrated sulphuric acid as a catalyst. The reaction must be done using a condenser. The experiment does not yield 100% 1-butyl ethanoate hence the product has to be purified to obtain pure ester. This method of ester synthesis is suitable for the purpose of educating Chemistry 12 students regarding organic reactions as it can be carried out easily in a school laboratory and is economical.

References 1. Ester. Wikipedia, the free encyclopedia. Wikimedia Foundation, 19 Nov. 2010. Web. 28 Nov. 2010. 2. Clark, Jim. The Mechanism for Esterification Reaction. ChemGuide.co.uk, 2004. Web. 29 Nov. 2010. 3. Ester. WorldLingo, n.d. Web. 29 Nov. 2010. 4. Fischer-Speier esterification. Wikipedia, the free encyclopedia. Wikimedia Foundation, 21 Oct. 2010. Web. 26 Nov. 2010. 5. Butyl ethanoate. Wikipedia, the free encyclopedia. Wikimedia Foundation, 22 Nov. 2010. Web. 26 Nov. 2010. 6. Figure 11-1.jpg. Blenders and Beakers. 16 May 2009. Web. 29 Nov. 2010. 7. Sodium ethanoate. Wikipedia, the free encyclopedia. Wikimedia Foundation, 23 Nov. 2010. Web. 30 Nov. 2010.

Вам также может понравиться

- Determination of Ka Value of A Weak AcidДокумент15 страницDetermination of Ka Value of A Weak AcidMyaIdzaharОценок пока нет

- AP Chemistry - Acid-Base Titration LabДокумент3 страницыAP Chemistry - Acid-Base Titration LabJonathan Chen0% (1)

- Spectrophotometric Determination of IronДокумент2 страницыSpectrophotometric Determination of IronNiaz Ali KhanОценок пока нет

- Glass Industry Qazi M. OmarДокумент37 страницGlass Industry Qazi M. OmarHassan BashirОценок пока нет

- Midterm Exam Reviewer (Mas Malala Talaga Ang Real Exam)Документ3 страницыMidterm Exam Reviewer (Mas Malala Talaga Ang Real Exam)Ying YangОценок пока нет

- 10 Homemade Laundry Soap Detergent RecipesДокумент4 страницы10 Homemade Laundry Soap Detergent RecipesOuchaoua UcifОценок пока нет

- Chem 26.1 Experiment 11 Formal ReportДокумент6 страницChem 26.1 Experiment 11 Formal ReportMary Joyce100% (1)

- PHY180 Formal Lab Report - Newton's Third LawДокумент4 страницыPHY180 Formal Lab Report - Newton's Third LawAfiq Asri100% (3)

- How To Process Color and Black-And - White Reversal and Negative Films and PapersДокумент20 страницHow To Process Color and Black-And - White Reversal and Negative Films and PapersErden SizgekОценок пока нет

- Determination of Ka of Unknown AcidДокумент23 страницыDetermination of Ka of Unknown AcidShasha0% (1)

- Chem 40.1 SyllabusДокумент5 страницChem 40.1 SyllabusgraceОценок пока нет

- Biology Lab Report 4Документ5 страницBiology Lab Report 4ai_eiОценок пока нет

- Anthranilic acid: precursor to tryptophanДокумент20 страницAnthranilic acid: precursor to tryptophanGlibОценок пока нет

- Lab Report 7 (Chem 26.1)Документ12 страницLab Report 7 (Chem 26.1)Richelle Mae PadillaОценок пока нет

- Determination of Available Chlorine in Bleach by IodometryДокумент6 страницDetermination of Available Chlorine in Bleach by IodometryKartik Pillay100% (1)

- Energy BalanceДокумент11 страницEnergy BalanceBharat VaajОценок пока нет

- Chem 40.1 Lab PoliciesandBufferReviewДокумент12 страницChem 40.1 Lab PoliciesandBufferReviewYshaReyesОценок пока нет

- KHP LabДокумент5 страницKHP LabSantino MusaОценок пока нет

- Absorption Spectrum of A Conjugated DyeДокумент6 страницAbsorption Spectrum of A Conjugated DyeKing Everest100% (1)

- Introduction/Theory:: EXPERIMENT 3: The Determination of Calcium in Milk by EDTA TitrationДокумент5 страницIntroduction/Theory:: EXPERIMENT 3: The Determination of Calcium in Milk by EDTA TitrationAqilah Mahabir100% (1)

- Lab Report (Final Editied)Документ8 страницLab Report (Final Editied)Alexia Channer100% (4)

- Nucleophlic Acyl Substitution - The Synthesis of Ethyl ButanoateДокумент5 страницNucleophlic Acyl Substitution - The Synthesis of Ethyl ButanoateRuther Cabral67% (3)

- ASTM D 1347 - 72 (Reapproved 1995) MethylcelluloseДокумент6 страницASTM D 1347 - 72 (Reapproved 1995) Methylcellulosealin2005Оценок пока нет

- PH and Buffer LabДокумент13 страницPH and Buffer LabAdellaine Lois GreyОценок пока нет

- Salt MethodsДокумент105 страницSalt MethodsRaj100% (1)

- Insumos de PerfuraçãoДокумент626 страницInsumos de PerfuraçãoyariosОценок пока нет

- Standardization of Acid and Alkali SolutionsДокумент84 страницыStandardization of Acid and Alkali SolutionsRichel Silao73% (15)

- LabДокумент7 страницLabLiz HackettОценок пока нет

- SCH4U - Esters LabДокумент1 страницаSCH4U - Esters LabVictoria WiebeОценок пока нет

- Ester Synthesis LabДокумент6 страницEster Synthesis LabMuhammad Abdur RokhimОценок пока нет

- Organic Chemistry Assignment #2 - SCH4U h5, Chemistry, 12, UniversityДокумент4 страницыOrganic Chemistry Assignment #2 - SCH4U h5, Chemistry, 12, UniversityAnonymous iadge07t0% (3)

- Silly Putty Inorganic Chem LabДокумент6 страницSilly Putty Inorganic Chem LabyesbutidontuseitОценок пока нет

- Organic Chemistry-Reaction To HydrocarbonsДокумент6 страницOrganic Chemistry-Reaction To HydrocarbonsbdidolОценок пока нет

- Ester of Carboxylic AcidsДокумент6 страницEster of Carboxylic Acidsmaryam_m_chemОценок пока нет

- Experiment 8Документ4 страницыExperiment 8Joone Xyron CreenciaОценок пока нет

- Dms 111 Manual by Michael K. Chirchir and Githii WainainaДокумент173 страницыDms 111 Manual by Michael K. Chirchir and Githii WainainaAdventist NaturopathyОценок пока нет

- CHEM1280 2012 13 Midterm Exam Solution PDFДокумент5 страницCHEM1280 2012 13 Midterm Exam Solution PDFLouisОценок пока нет

- Identification of Alcohols and Phenols Using Chemical TestsДокумент6 страницIdentification of Alcohols and Phenols Using Chemical Testsh1iraqОценок пока нет

- Hexane and Toluene Simple and Fractional DistillationДокумент12 страницHexane and Toluene Simple and Fractional Distillationrodneyperu0% (1)

- Exer2 PrelabДокумент3 страницыExer2 Prelabkarinadegoma100% (1)

- Oxidation of Cyclohexanol To CyclohexanoneДокумент5 страницOxidation of Cyclohexanol To CyclohexanoneChandrani Chakraborti100% (1)

- Phase Diagram of Three-Component Liquid SystemДокумент11 страницPhase Diagram of Three-Component Liquid SystemVanessa Denise Aguilar100% (2)

- Aldehydes and KetonesДокумент1 страницаAldehydes and KetonesThea Mae Dino0% (1)

- Experiment 8: Determination of An Equilibrium Constant: PurposeДокумент10 страницExperiment 8: Determination of An Equilibrium Constant: PurposeJohn Joseph0% (1)

- Determination of The Solubility Product Constant of Calcium HydroxideДокумент2 страницыDetermination of The Solubility Product Constant of Calcium HydroxideJunko TsukudaОценок пока нет

- Acid-Base Indicators Spectrophotometric Ka LabДокумент6 страницAcid-Base Indicators Spectrophotometric Ka Labmuskaan0% (2)

- To Synthesize Potassium Tri Oxalato Ferr PDFДокумент5 страницTo Synthesize Potassium Tri Oxalato Ferr PDFApheleleОценок пока нет

- 09 - Flinn - Stoichiometric Ratio of A ReactionДокумент8 страниц09 - Flinn - Stoichiometric Ratio of A ReactionDerek Hammons100% (1)

- Solubility of Organic CompoundsДокумент4 страницыSolubility of Organic CompoundsJeremy Noceda100% (1)

- Oxidation of AlcoholsДокумент5 страницOxidation of AlcoholsAna Sofia Guzman FernandezОценок пока нет

- Acid Base Titration Lab 6Документ11 страницAcid Base Titration Lab 6Jose Cencič0% (1)

- Fischer EsterificationДокумент3 страницыFischer EsterificationDenisse Watt Cuarteros100% (1)

- Separate Salt from Sand Using Filtration and EvaporationДокумент3 страницыSeparate Salt from Sand Using Filtration and EvaporationTonyDiazОценок пока нет

- Analysis of A Mixture of Carbonate and BicarbonateДокумент2 страницыAnalysis of A Mixture of Carbonate and BicarbonateCharles Trono RacadioОценок пока нет

- Esterification of Methyl BenzoateДокумент5 страницEsterification of Methyl BenzoateCyrene MBolaños100% (1)

- Chem Lab - A Velocity Constant TitrationДокумент6 страницChem Lab - A Velocity Constant TitrationMiguel Ackah-Yensu50% (2)

- Experiment 3: Le Chatelier's PrincipleДокумент4 страницыExperiment 3: Le Chatelier's PrinciplespaghetticurlersОценок пока нет

- Phase Diagram of a Three-Component Liquid SystemДокумент7 страницPhase Diagram of a Three-Component Liquid SystemEllaine TejadaОценок пока нет

- Workbook - AcidsДокумент132 страницыWorkbook - AcidsAgustina Itin100% (1)

- Chem 31 (Upm)Документ7 страницChem 31 (Upm)Patricia Gayle JacildoОценок пока нет

- ProteinДокумент16 страницProteinRosnadia RosliОценок пока нет

- Determination of The Equilibrium Constant For The Formation of Tri-Iodide Ion (I)Документ7 страницDetermination of The Equilibrium Constant For The Formation of Tri-Iodide Ion (I)Mehul KhimaniОценок пока нет

- Stereochemistry Qs: Fischer, R/S, ID pairs, Optical ActivityДокумент2 страницыStereochemistry Qs: Fischer, R/S, ID pairs, Optical ActivityShilajit BaruaОценок пока нет

- Lab Report Exp 2Документ8 страницLab Report Exp 2api-384913960Оценок пока нет

- Aldehyde & Ketone ReactionsДокумент21 страницаAldehyde & Ketone ReactionsAinsssОценок пока нет

- Coordination Chemistry: Invited Lectures Presented at the 20th International Conference on Coordination Chemistry, Calcutta, India, 10-14 December 1979От EverandCoordination Chemistry: Invited Lectures Presented at the 20th International Conference on Coordination Chemistry, Calcutta, India, 10-14 December 1979D. BanerjeaОценок пока нет

- Preparation of Butyl Acetate PDFДокумент6 страницPreparation of Butyl Acetate PDFjoiya100133% (3)

- Jasmin Malhotra - Esters PracДокумент7 страницJasmin Malhotra - Esters Pracapi-287665202100% (2)

- Key Design Features: Click To Edit Master Subtitle StyleДокумент7 страницKey Design Features: Click To Edit Master Subtitle StyleAfiq AsriОценок пока нет

- Abstract FinalДокумент1 страницаAbstract FinalAfiq AsriОценок пока нет

- Abstract FinalДокумент1 страницаAbstract FinalAfiq AsriОценок пока нет

- (PDF Revised) Request For Proposal - Vertical EMS Response Time For High Rise Buildings in Church-Yonge Corridor Neighbour HoodДокумент20 страниц(PDF Revised) Request For Proposal - Vertical EMS Response Time For High Rise Buildings in Church-Yonge Corridor Neighbour HoodAfiq AsriОценок пока нет

- QrcodeДокумент6 страницQrcodeAfiq AsriОценок пока нет

- Praxis Showcase - All SketchesДокумент9 страницPraxis Showcase - All SketchesAfiq AsriОценок пока нет

- (PDF) Attachable Vacuum Pads For Enhancing Walker StabilityДокумент1 страница(PDF) Attachable Vacuum Pads For Enhancing Walker StabilityAfiq AsriОценок пока нет

- Chang Chemistry - Assessment Chapter 3Документ14 страницChang Chemistry - Assessment Chapter 3haha_le12100% (2)

- Hardness SoalДокумент2 страницыHardness SoalSarah Winda FauziahОценок пока нет

- Developing a Community Development Plan for Magadi Soda's ExpansionДокумент6 страницDeveloping a Community Development Plan for Magadi Soda's ExpansionRitesh ChaubeyОценок пока нет

- Phchem 1a - Activity #2 - Pharmaceutical Aids and NecessitiesДокумент2 страницыPhchem 1a - Activity #2 - Pharmaceutical Aids and NecessitiesHercy AlintonОценок пока нет

- Rahul Singh Bisht ProjectДокумент51 страницаRahul Singh Bisht ProjectyashОценок пока нет

- STOICHIOMETRYДокумент3 страницыSTOICHIOMETRYSanjana Arora100% (1)

- 8th Science Class Exam QuestionsДокумент4 страницы8th Science Class Exam QuestionsOWAIS AHMEDОценок пока нет

- The Synthesis of Azo DyesДокумент12 страницThe Synthesis of Azo DyesJaveed GanaieОценок пока нет

- Sera Print M-STRДокумент3 страницыSera Print M-STRMohammad shahriar jinnahОценок пока нет

- Initial Treatment With Heat LoadДокумент15 страницInitial Treatment With Heat LoadSunny OoiОценок пока нет

- P-Block ElementsДокумент38 страницP-Block Elementskaushik247Оценок пока нет

- dw95 Asko DishwasherДокумент18 страницdw95 Asko DishwasherZeigtОценок пока нет

- CLASS - X CHEMISTRY Important QuestionsДокумент17 страницCLASS - X CHEMISTRY Important Questionsvt654009Оценок пока нет

- SAM Organic Chemistry Carboxylic AcidsДокумент8 страницSAM Organic Chemistry Carboxylic AcidsChangWeiTanОценок пока нет

- Soda Ash and Energy EfficiencyДокумент7 страницSoda Ash and Energy Efficiencyanandrings100% (1)

- Acid Bases and Salt New 2017Документ1 страницаAcid Bases and Salt New 2017Shubham DeepОценок пока нет

- InorganicДокумент137 страницInorganicShaswata Roy50% (2)

- Drugs Acting On The Gastrointestinal SystemДокумент6 страницDrugs Acting On The Gastrointestinal SystemSubhram Kumar PandaОценок пока нет

- Chemistry: Edexcel GCEДокумент24 страницыChemistry: Edexcel GCEFuzzbuzz95Оценок пока нет

- Solvay Process PresentationДокумент19 страницSolvay Process PresentationRiki Mandol67% (3)

- Chemistry Project: Name: Azad Abdullahi Class: Ss3S Teacher: Mr. AdekunleДокумент14 страницChemistry Project: Name: Azad Abdullahi Class: Ss3S Teacher: Mr. Adekunleapi-383198550% (2)

- Science NotesДокумент244 страницыScience NotesA. PradeepaОценок пока нет