Академический Документы

Профессиональный Документы

Культура Документы

Carbopol - 934 - Ficha Tecnica

Загружено:

Luis Alvaro Montoya SantiyanesИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Carbopol - 934 - Ficha Tecnica

Загружено:

Luis Alvaro Montoya SantiyanesАвторское право:

Доступные форматы

Product Specification

CARBOPOL* 934 NF POLYMER

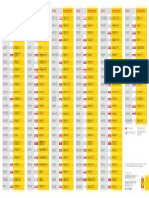

Carbopol 934 NF polymer meets the current edition of the following monographs: United States Pharmacopeia/National Formulary (USP/NF) monograph for Carbomer 934 Japanese Pharmaceutical Excipients (JPE) monograph for Carboxyvinyl Polymer General Product Characteristics Appearance: White, fluffy powder Odor: Slightly acetic Test Identification Colorimetric test Gel formation test Infrared spectrum Precipitate test Carboxylic Acid Content, Assay % Viscosity, cP, 25C Brookfield RVT, 20 rpm, neutralized to pH 7.3 - 7.8 0.2 wt% mucilage, spindle #4 0.5 wt% mucilage, spindle #6 Loss on Drying, % Heavy Metals, ppm Total heavy metals, as Pb Specific metals: Hg, Pb, As, Sb Residual Solvent6, ppm Benzene Residual Monomer, ppm Free acrylic acid Sulphated Ash, % (Residue on ignition) pH, 0.2% Dispersion

1

Specification Pass Pass Pass Pass 56.0 - 68.04

Lot Test Frequency1 1:200 1:1 ---3 1:200 1:1

Test Procedure2 USP/NF USP/NF JPE JPE USP/NF

2,050 - 5,450 30,500 - 39,400 2.0 max 20 max 10 max 1,000 max 2,500 max 2.5 max 2.5 - 4.0

1:1 1:1 1:1 1:200 1:200 1:1 1:1 1:200 1:200

Lubrizol 430-I5 USP/NF USP/NF USP/NF Lubrizol SA-012 Lubrizol SA-006 Lubrizol SA-005 JPE JPE

Where lot test frequency is less than 1:1, statistical quality control determines the parameter to be within specification limits. Actual values are not reported on the COA, but compliance within established limits is assured. Lubrizol test procedures have been cross-validated to specified compendial procedure(s) if they are included in the monograph. Infrared reference spectra available upon request. Lots requiring compliance to JPE standards will meet a specification of 58.0 63.0%. Lubrizol test procedure 430-I is the same test procedure that is noted in USP/NF, except for the concentration. No other residual solvents as listed in USP/NF <467> (Class 1, 2 or 3) are used or are an expected by-product in the manufacturing process of this product. Since the monograph specifies a limit for benzene, the Residual Solvents test <467> limit for benzene is superseded by the monograph limit.

2 3 4 5 6

Lubrizol Advanced Materials, Inc. / 9911 Brecksville Road, Cleveland, Ohio 44141-3247 / TEL: 800.379.5389 or 216.447.5000

Lubrizol Advanced Materials, Inc. cannot guarantee how the product(s) will perform in combination with other substances or in the users process. Therefore, no representations, guarantees or warranties of any kind are made as to the suitability of this product(s) for particular applications. End product performance is the responsibility of the user. Lubrizol Advanced Materials, Inc. shall not be liable for and the customer assumes all risk and liability of any use or handling of any material beyond Lubrizol Advanced Materials direct control. The SELLER MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTIBILITY AND FITNESS FOR A PARTICULAR PURPOSE. Nothing contained herein is to be considered as permission, recommendation, nor as an inducement to practice any patented invention without permission of the patent owner.

For further information, please visit www.pharma.lubrizol.com

Lubrizol Advanced Materials, Inc. is a wholly owned subsidiary of The Lubrizol Corporation * Trademark owned by The Lubrizol Corporation Copyright 2007 / The Lubrizol Corporation

Issue date: June 14, 2007

Вам также может понравиться

- Msds SC 4000Документ9 страницMsds SC 4000Cristián RojasОценок пока нет

- LSG007 - Automated System DesignДокумент6 страницLSG007 - Automated System DesignwilmerОценок пока нет

- Tabla de EquivalenciasДокумент1 страницаTabla de EquivalenciasyamilmrОценок пока нет

- PH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)Документ4 страницыPH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)dfbdfbfdbfbОценок пока нет

- 2 - 15B Ah-5vomДокумент1 страница2 - 15B Ah-5vomMamiherintsoa Issaia RanaivoarimananaОценок пока нет

- PB 300 Parts Manual 2013 1001Документ15 страницPB 300 Parts Manual 2013 1001Duvan MoralesОценок пока нет

- Checkllist Mecánico - Filtro Prensa Dorr OliverДокумент12 страницCheckllist Mecánico - Filtro Prensa Dorr OliverMarco Valverde MorenoОценок пока нет

- MCO 9 EVO Touchpanel MCO 9 EVO TouchpanelДокумент34 страницыMCO 9 EVO Touchpanel MCO 9 EVO TouchpanelTEKLEWEYNI Tsegay100% (1)

- FR92809 6cta8 3-M220 Datasheet en 00Документ4 страницыFR92809 6cta8 3-M220 Datasheet en 00narisОценок пока нет

- 205 Rotary RigДокумент4 страницы205 Rotary RigBungleBugarlisОценок пока нет

- Kane 458 Operating ManualДокумент64 страницыKane 458 Operating ManualP_Davies0% (1)

- 3M 6800 Full Face MaskДокумент6 страниц3M 6800 Full Face MaskAlvarioОценок пока нет

- SNL 517 + 2217 K + HA 317 Soporte de Pie Con Rodamiento y Manguito PDFДокумент4 страницыSNL 517 + 2217 K + HA 317 Soporte de Pie Con Rodamiento y Manguito PDFLeandro SienraОценок пока нет

- SKF Epb Pump en MMДокумент4 страницыSKF Epb Pump en MMEbied Yousif AlyОценок пока нет

- Nuevos Productos ShellДокумент1 страницаNuevos Productos ShellCara GutierrezОценок пока нет

- Astm d7720 PDFДокумент14 страницAstm d7720 PDFRodrigo Andres Vallejo Castro100% (1)

- Manual de Tuerca Hidraulica-Desbloqueado-editadoДокумент37 страницManual de Tuerca Hidraulica-Desbloqueado-editadomauriciojjОценок пока нет

- Manual Montacargas Caterpillar PDFДокумент38 страницManual Montacargas Caterpillar PDFFederico VarelaОценок пока нет

- Robotrac ManualДокумент202 страницыRobotrac ManualadasrafalskiОценок пока нет

- SLV XL PDFДокумент8 страницSLV XL PDFFaidh Maulana Aksyar Faidh100% (1)

- Sumitomo HSMДокумент68 страницSumitomo HSMEdisson Yanqui VivancoОценок пока нет

- Every Ton.: For Mining ApplicationsДокумент4 страницыEvery Ton.: For Mining ApplicationsRafaelОценок пока нет

- Eaton AxisPro Servo-Performance Directional Valve User ManualДокумент254 страницыEaton AxisPro Servo-Performance Directional Valve User ManualMICKEОценок пока нет

- Stock List PDFДокумент4 страницыStock List PDFAL Wahid SpareОценок пока нет

- PTK1 Oil Analysis Patch Test KitДокумент2 страницыPTK1 Oil Analysis Patch Test KitВалерия КорнееваОценок пока нет

- REHS9597-19 Repair of Large Wheel Loader Lift Arms and LeversДокумент26 страницREHS9597-19 Repair of Large Wheel Loader Lift Arms and LeversCarlosОценок пока нет

- Ah 18851Документ89 страницAh 18851Valeria MartinezОценок пока нет

- Ic-0014 Kit Refrifluid B Uc-0020-1700 (En)Документ2 страницыIc-0014 Kit Refrifluid B Uc-0020-1700 (En)Lluis Cuevas EstradaОценок пока нет

- EX 1200-5D Kit Part NumbersДокумент4 страницыEX 1200-5D Kit Part NumbersVinod GuptaОценок пока нет

- MSDS Paroil EДокумент13 страницMSDS Paroil Ewillhansen kamargaОценок пока нет

- SPEK fh230 PDFДокумент2 страницыSPEK fh230 PDFSeptaDoresОценок пока нет

- MD6420 - Procedimiento de Cambio de Compresor - Manual de Servicio (EM005781)Документ16 страницMD6420 - Procedimiento de Cambio de Compresor - Manual de Servicio (EM005781)Victor ArceОценок пока нет

- Lux M10Документ40 страницLux M10simonОценок пока нет

- Ficha Tecnica - HP-2402Документ10 страницFicha Tecnica - HP-2402Benjamin MillerОценок пока нет

- Pm-Clinic Data Sheet Wd900-3 Base Information: Customer Name LocationДокумент3 страницыPm-Clinic Data Sheet Wd900-3 Base Information: Customer Name LocationJuan Pablo Muñante Palacin100% (1)

- MacRoy D IOMДокумент60 страницMacRoy D IOMRicardo VeraОценок пока нет

- 120SXJ Maintenance and Service ManualДокумент112 страниц120SXJ Maintenance and Service ManualTecnico Reach Stacker Tecnico Reach StackerОценок пока нет

- Pinch Valves General TechДокумент7 страницPinch Valves General TechPrakashОценок пока нет

- Battery - Paccar P27-6100 A 01: CompanyДокумент2 страницыBattery - Paccar P27-6100 A 01: Companyjohn jairo guzman100% (1)

- Guide Service de Balde AlemiteДокумент14 страницGuide Service de Balde AlemiteAH SergioОценок пока нет

- Catálogo Gradall 534D6Документ2 страницыCatálogo Gradall 534D6Adriano Alves Silva0% (1)

- MetalSamples General Catalog XIIIДокумент40 страницMetalSamples General Catalog XIIIDavid Cruz ZamoraОценок пока нет

- Catalogo Alemite PDFДокумент134 страницыCatalogo Alemite PDFRodrigo UlloaОценок пока нет

- AFBMA Bearing InterchangeДокумент1 страницаAFBMA Bearing InterchangevandoОценок пока нет

- Refrentador de Caras - Bb5000Документ4 страницыRefrentador de Caras - Bb5000Marco BacianОценок пока нет

- Peerless Pump CompanyДокумент33 страницыPeerless Pump CompanyDamian CFОценок пока нет

- Tabla de Equivalencias: Lubrax Puma YPF Castrol Shell Total / Elf MobilДокумент1 страницаTabla de Equivalencias: Lubrax Puma YPF Castrol Shell Total / Elf MobilLankaster Flórez Ch100% (1)

- 1 - Southern Cross - Iso Pump - 50 X 32 - 160 - 1410-2880 RPM PDFДокумент1 страница1 - Southern Cross - Iso Pump - 50 X 32 - 160 - 1410-2880 RPM PDFIra LtrОценок пока нет

- Datasheet Bateria CATДокумент3 страницыDatasheet Bateria CATOrlando Vazquez PuertaОценок пока нет

- WEB bbb4 Catalog PDFДокумент128 страницWEB bbb4 Catalog PDFDiego PascualОценок пока нет

- AscoДокумент1 страницаAscoSudipto MajumderОценок пока нет

- Cotta Transfer Case Lube PlanДокумент3 страницыCotta Transfer Case Lube PlanMatias Alfredo Contreras KöbrichОценок пока нет

- Tabla AGMA Open GearДокумент1 страницаTabla AGMA Open GearEsteban Fernando Meza Ibaceta100% (1)

- Manual de Partes Reed B50V08 - B50HPv08 - PartsДокумент72 страницыManual de Partes Reed B50V08 - B50HPv08 - PartsNestor Oyaga Barrios0% (1)

- RT10 Torque ChartДокумент2 страницыRT10 Torque ChartRoy Ramos100% (1)

- Erapol EHP95AДокумент2 страницыErapol EHP95AMohammad Doost MohammadiОценок пока нет

- Regular Grade Anti-Seize & Lubricating Compound: Never SeezДокумент2 страницыRegular Grade Anti-Seize & Lubricating Compound: Never SeezGregory Alan Francisco IIОценок пока нет

- Pi - Cassida FM Compound SG 720Документ2 страницыPi - Cassida FM Compound SG 720Milena GonzalezОценок пока нет

- SPEC Carbopol Ultrez 10 NFДокумент1 страницаSPEC Carbopol Ultrez 10 NFNataly Morón100% (1)

- Rules 6-10 CasesДокумент21 страницаRules 6-10 CasesannedefrancoОценок пока нет

- Data Privacy Notice For StudentsДокумент4 страницыData Privacy Notice For StudentsUthred RagnarsonОценок пока нет

- Rule of Law Sample AnswerДокумент3 страницыRule of Law Sample Answermaksuda monirОценок пока нет

- Montelius AffidavitДокумент6 страницMontelius Affidavitkaimin.editorОценок пока нет

- Law of Property Assignment 1Документ8 страницLaw of Property Assignment 1Utjiua TjavaraОценок пока нет

- Go ToДокумент3 страницыGo ToNadine Malaya NadiasanОценок пока нет

- United States v. Roy Terry Bennett, AKA Terry King Roy Terry Bennett, 100 F.3d 1105, 3rd Cir. (1996)Документ9 страницUnited States v. Roy Terry Bennett, AKA Terry King Roy Terry Bennett, 100 F.3d 1105, 3rd Cir. (1996)Scribd Government DocsОценок пока нет

- 2.CivRev2 - Padua V RoblesДокумент6 страниц2.CivRev2 - Padua V RoblesAnonymous yisZNKXОценок пока нет

- Bunkley v. Wolfenbarger - Document No. 2Документ3 страницыBunkley v. Wolfenbarger - Document No. 2Justia.comОценок пока нет

- Rule: Guidance Necessary To Facilitate Electronic Tax AdministrationUpdating of Section 7216 RegulationsДокумент18 страницRule: Guidance Necessary To Facilitate Electronic Tax AdministrationUpdating of Section 7216 RegulationsJustia.com100% (1)

- Full Download Strategic Management Concepts and Cases Competitiveness and Globalization 12th Edition Hitt Test BankДокумент36 страницFull Download Strategic Management Concepts and Cases Competitiveness and Globalization 12th Edition Hitt Test Bankowen4ljoh100% (23)

- Mary M. Perry v. The Hearst Corporation, 334 F.2d 800, 1st Cir. (1964)Документ4 страницыMary M. Perry v. The Hearst Corporation, 334 F.2d 800, 1st Cir. (1964)Scribd Government DocsОценок пока нет

- Signature Not VerifiedДокумент6 страницSignature Not VerifiedVikas SareenОценок пока нет

- Case Study On Euthanasia PleaДокумент10 страницCase Study On Euthanasia PleapoddaranilshrutiОценок пока нет

- Sec 24 To 50Документ28 страницSec 24 To 50Felip MatОценок пока нет

- Nursing Practice and The LawДокумент19 страницNursing Practice and The Lawapi-534059022100% (2)

- M13 An Intro To Abstract MathДокумент166 страницM13 An Intro To Abstract MathMengrui JiangОценок пока нет

- Eric Lindros - Statement of ClaimДокумент15 страницEric Lindros - Statement of ClaimPhiladelphiaMagazineОценок пока нет

- Confederation of Coconut Vs Aquino DigestДокумент3 страницыConfederation of Coconut Vs Aquino DigestPrincess Rosshien HortalОценок пока нет

- Michael MooreДокумент4 страницыMichael MooreAnantha KrishnanОценок пока нет

- Withholding Tax Remittance Return: Kawanihan NG Rentas InternasДокумент4 страницыWithholding Tax Remittance Return: Kawanihan NG Rentas InternasArlyn De Las AlasОценок пока нет

- Red BookДокумент16 страницRed BookbsheehanОценок пока нет

- Selecting Suppliers - The Use of Post Tender Price NegotiationДокумент4 страницыSelecting Suppliers - The Use of Post Tender Price NegotiationJohn N. ConstanceОценок пока нет

- Constitution of India NotesДокумент4 страницыConstitution of India NotesRee QОценок пока нет

- NSE Circular 02112021-SOPДокумент2 страницыNSE Circular 02112021-SOPSwapnita RaneОценок пока нет

- Rose, Rand, Ray, Winfrey & Gregory, P.A. v. Bruce Salter, Defndant-Appellant, Randy David Salter, 877 F.2d 60, 4th Cir. (1989)Документ4 страницыRose, Rand, Ray, Winfrey & Gregory, P.A. v. Bruce Salter, Defndant-Appellant, Randy David Salter, 877 F.2d 60, 4th Cir. (1989)Scribd Government DocsОценок пока нет

- UN Declaration On Human Rights Education and Training PDFДокумент6 страницUN Declaration On Human Rights Education and Training PDFprem101Оценок пока нет

- Vic Roads Mass LimitsДокумент2 страницыVic Roads Mass LimitsJames Mizzi100% (1)

- Sasan vs. NLRC, G.R. No 176240 (2008)Документ19 страницSasan vs. NLRC, G.R. No 176240 (2008)Christiaan CastilloОценок пока нет

- Motor Policy Wording UaeДокумент64 страницыMotor Policy Wording UaeBassam MustafaОценок пока нет