Академический Документы

Профессиональный Документы

Культура Документы

Annex Euro III-petrol Final

Загружено:

Omar DananИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Annex Euro III-petrol Final

Загружено:

Omar DananАвторское право:

Доступные форматы

Information document to the vehicle type approval

Pursuant to Annex II council directive 70/220/EEC

MINIATOR (S81)

Vehicle Engineering Aug 2009

European Union: 70/220/EEC

Exhaust Emissions

ANNEX II INFORMATION DOCUMENT NO........

Pursuant to Annex I of Directive 70/156/EEC (*) relating to EEC type-approval of a vehicle with respect to the measures to be taken against air pollution by emissions from motor vehicles (Directive 70/220/EEC, as last amended by Directive ... /.../EC) The following information, if applicable, must be supplied in triplicate and include a list of contents. Any drawings must be supplied in appropriate scale and in sufficient detail on size A4 or on a folder of A4 format. Photographs, if any, must show sufficient detail. If the systems, components or separate technical units have electronic controls, information concerning their performance must be supplied. 0. GENERAL 0.1. Make (trade name of manufacturer): SAIPA 0.2. Type and general commercial description(s): Saipa 231 (Miniator) 0.3. Means of identification of type, if marked on the vehicle: See Attachment S81-TA-0001 0.3.1. Location of that marking: See Attachment S81-TA-0002 0.4. Category of vehicle: M1 0.5. Name and address of manufacturer: SAIPA, 15 Km Karaj Special Road, Tehran, Iran 0.8. Address(s) of assembly plant(s): 10th Km Kashan-Natanz Old Road, Kashan, Iran 1. GENERAL CONSTRUCTION CHARACTERISTICS OF THE VEHICLE 1.1. Photographs and/or drawings of a representative vehicle: See Attachment S81-TA-0003 1.3.3. Powered axles (numbers, position, interconnection): 1 axle, Front Wheel Drive, Gearbox (Integrated Differential) 2. MASSES AND DIMENSION (in kg and mm) (Refer to drawing where applicable) 2.6. Mass of vehicle with bodywork in running order, or mass of the chassis with cab if the manufacturer does not fit the bodywork (with standard equipment, including coolant, oils, fuel, tools, spare wheel and driver) (maximum and minimum): 2.8. Technically permissible maximum laden mass stated by the manufacturer (Maximum and minimum): Max= 1350 kg, Min=1000 kg

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

3. POWER PLANT 3.1. Manufacturer: Mega Motors 3.1.1. Manufacturer's engine code (as marked on the engine or other means of identification): SE7M15 3.2. Internal combustion engine 3.2.1.1. Working principle: positive ignition/compression ignition, four stroke/two stroke 3.2.1.2. Number and arrangements of cylinders: 4 in line 3.2.1.2.1. Bore: 75.6 mm 3.2.1.2.2. Stroke: 83.7 mm 3.2.1.2.3. Firing order: 1342 3.2.1.3. Engine capacity(s): 1503cm3 3.2.1.4. Volumetric compression ratio: 9.7 3.2.1.5. Drawings of combustion chamber, piston crown and, in the case of positive ignition engine, piston rings: See Attachment S81-TA-0004 3.2.1.6. Normal engine idling speed (including tolerance): 850 rpm 3.2.1.6.1. High idle engine speed (including tolerance): 5600 rpm 3.2.1.7. Carbon monoxide content by volume in the exhaust gas with the engine idling : % as stated by the manufacturer (positive ignition engines only): Approximately Zero 3.2.1.8. Maximum net power: 58.9 KW at 5000 rpm (manufacturers declared value) 3.2.2. Fuel: diesel oil/Petrol/LPG/NG 3.2.2.1. RON, leaded: No 3.2.2.2. RON, unleaded: 89 3.2.2.3. Fuel tank inlet: restricted orifice/label 3.2.4. Fuel feed 3.2.4.1. By carburettor(s): yes/no 3.2.4.1.1. Make(s): NA 3.2.4.1.2. Type(s): NA 3.2.4.1.3. Number fitted: NA

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

3.2.4.1.4. Adjustments 3.2.4.1.4.1. Jets: NA 3.2.4.1.4.2. Venturis: NA 3.2.4.1.4.3. Float-chamber level: NA Or the curve of fuel delivery plotted against the air flow and settings required keeping to the curve 3.2.4.1.4.4. Mass of float: NA 3.2.4.1.4.5. Float needle: NA 3.2.4.1.5. Cold start system: manual/automatic 3.2.4.1.5.1. Operating principle(s): NA 3.2.4.1.5.2. Operating limits/settings: NA 3.2.4.2. By fuel injection (compression ignition only): yes/no 3.2.4.2.1. System description: NA 3.2.4.2.2. Working principle: direct injection/pre-chamber/swirl chamber: NA 3.2.4.2.3. Injection pump 3.2.4.2.3.1. Make(s): NA 3.2.4.2.3.2. Type(s): NA 3.2.4.2.3.3. Maximum fuel delivery: NA mm3/stroke or cycle at a pump speed of: ..................min-1 or, alternatively, a characteristic diagram: ..................................................... 3.2.4.2.3.4. Injection timing: NA 3.2.4.2.3.5. Injection advance curve: NA 3.2.4.2.3.6. Calibration procedure: test bench/engine NA 3.2.4.2.4. Governor 3.2.4.2.4.1. Type: NA 3.2.4.2.4.2. Cut-off point: NA 3.2.4.2.4.2.1. Cut-off point under load: .............. NA.............min-1 3.2.4.2.4.2.2. Cut-off point without load: .......... NA............. min-1

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

3.2.4.2.6. Injector(s) 3.2.4.2.6.1. Make(s): NA 3.2.4.2.6.2. Type(s): NA 3.2.4.2.6.3. Opening pressure (2): NA kPa or characteristic diagram (2): NA 3.2.4.2.7. Cold start system 3.2.4.2.7.1. Make(s): NA 3.2.4.2.7.2. Type(s): NA 3.2.4.2.7.3. Description: NA 3.2.4.2.8. Auxiliary starting aid 3.2.4.2.8.1. Make(s): NA 3.2.4.2.8.2. Type(s): NA 3.2.4.2.8.3. System description: NA 3.2.4.3. By fuel injection (positive ignition only): yes/no 3.2.4.3.1. Working principle: Intake manifold (single-/multi-point)/direct injection/other (Specify): 3.2.4.3.2. Make(s): CASCO (Continental) 3.2.4.3.3 Type(s): Multi Point Fuel Injector 3.2.4.3.4. System description: 3.2.4.3.4.1. Type or number of the control unit: A Unit for the engine 3.2.4.3.4.2. Type of fuel regulator: Membrane type 3.2.4.3.4.3. Type of air-flow sensor: NA 3.2.4.3.4.4. Type of fuel distributor: Return Less system (In the case of systems) 3.2.4.3.4.5. Type of pressure regulator: Diaphragm Type (other than continuous) 3.2.4.3.4.6. Type of microswich: NA (injection give equivalent) 3.2.4.3.4.7. Type of idling adjustment screw: NA (details) 3.2.4.3.4.8. Type of throttle housing: Mechanical throttle Body 3.2.4.3.4.9. Type of water temperature sensor: NTC 3.2.4.3.4.10. Type of air temperature sensor: NTC

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

3.2.4.3.4.11. Type of temperature switch: NO 3.2.4.3.5. Injectors: opening pressure: kPa or characteristic diagram: Flow (N-Heptanes) @ 300 Kpa- Static: 1.63 gr/s & Dynamic: 3.6 gr/s 3.2.4.3.6. Injection timing: Idle/Part load, Relative air/Fuel-ratio: =1.0 End of injection 480 CA ABDC combustion 3.2.4.3.7. Cold start system: 3.2.4.3.7.1. Operating principle(s): Full load, Relative air/Fuel-ratio: =0.9 End of injection 600 CA ABDC combustion 3.2.4.3.7.2. Operating limits/settings: -23~ 47 3.2.4.4. Feed pump 3.2.4.4.1. Pressure: .......... kPa or characteristic diagram: ............................ 3.2.6. Ignition 3.2.6.1. Make(s): Continental 3.2.6.2. Type(s): Dual Coil 3.2.6.3. Working principle: Electro Magnetic 3.2.6.4. Ignition advance curve: NA 3.2.6.5. Static ignition timing: 7.5 degrees before TDC 3.2.6.6. Contact-point gap: mm 3.2.6.7. Dwell-angle: degrees 3.2.7. Cooling system (liquid/air) 3.2.8. Intake system 3.2.8.1. Pressure charger yes/no 3.2.8.1.1. Make(s): NA 3.2.8.1.2. Type(s): NA 3.2.8.1.3. Description of the system (e.g. maximum charge pressure NA kPa, wastegate if applicable): NA 3.2.8.2. Intercooler yes/no 3.2.8.4. Description and drawings of the inlet pipes and their accessories (plenum chamber, heating device, additional air intakes, etc.):

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

3.2.8.4.1. Intake manifold description (include drawings and/or photos): See Attachment S81-TA-0005 3.2.8.4.2. Air filter, drawings: See Attachment S81-TA-0006 or 3.2.8.4.2.1. Make(s): Mojdeh vasl shiraz Co. 3.2.8.4.2.2. Type(s): Dry, paper type 3.2.8.4.3. Intake silencer, drawings: Yes, See Attachment S81-TA-0007 3.2.8.4.3.1. Make(s): Mojdeh vasl shiraz Co. 3.2.8.4.3.2. Type(s): 3.2.9. Exhaust system 3.2.9.2. Description and/or drawing of the exhaust system: See Attachment S81-TA-0008 3.2.11. Valve timing or equivalent data: IVC: 13 BTDC, IVO: 66 ABDC, EVO: 41 BBDC, EVC: 23 ATDC 3.2.11.1. Maximum lift of valve, angles of opening and closing, or timing details of alternative distribution system, in relation to dead centers: Intake : 9.3 mm & exhaust 8.3 mm, angles of opening and closing = 20 degree 3.2.11.2. Reference and/or setting ranges: 3.2.12. Measures taken against air pollution 3.2.12.1. Device for recycling crankcase gases (description and drawings): Yes, See Attachment S81-TA-0009 3.2.12.2. Additional anti-pollution devices (if any, and if not covered by another heading) 3.2.12.2.1. Catalytic converter yes/no 3.2.12.2.1.1. Number of catalytic converters and elements: one (1) 3.2.12.2.1.2. Dimensions, shape and volume of the catalytic converter(s): Volume of the catalytic=1580 cc, See Attachment S81-TA-0010 3.2.12.2.1.3. Type of catalytic action: 3 Way-CCC 3.2.12.2.1.4. Total charge of precious metals: 1.765 gr/dm3 3.2.12.2.1.5. Relative concentration: PT:PD:RH 0:5:1 3.2.12.2.1.6. Substrate (structure and material): 0.1651 mm 3.2.12.2.1.7. Cell density: 600 CPSI 3.2.12.2.1.8. Type of casing for the catalytic converter(s): Circular or

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

3.2.12.2.1.9. Location of the catalytic converter(s) (place and reference distance in the exhaust line): See Attachment S81-TA-0008 (Exhaust System) 3.2.12.2.1.10. Heat shield: yes/no 3.2.12.2.2. Oxygen sensor: yes/no 3.2.12.2.2.1. Type: Narrow Band 3.2.12.2.2.2. Location: See Attachment S81-TA-0011 3.2.12.2.2.3. Control range: 0-1 V 3.2.12.2.3. Air injection: yes/no 3.2.12.2.3.1. Type (pulse air, air pump etc.): NA 3.2.12.2.4. Exhaust gas re-circulation: yes/no 3.2.12.2.4.1. Characteristics (flow rate etc.): NA 3.2.12.2.5. Evaporative emissions control system: yes/no 3.2.12.2.5.1. Detailed description of the devices ant their state of tune: ........................ 3.2.12.2.5.2. Drawing of the evaporative control system: See Attachment S81-TA-0012 3.2.12.2.5.3. Drawing of the carbon canister: See Attachment S81-TA-0013 3.2.12.2.5.4. Mass of dry charcoal: g 3.2.12.2.5.5. Schematic drawing of the fuel tank with indication of capacity and material: 3.2.12.2.5.6. Drawing of the heat shields between tank and exhaust system: 3.2.12.2.6. Particulate trap: yes/no 3.2.12.2.6.1. Dimensions, shape and capacity of the particulate trap: 3.2.12.2.6.2. Type and design of the particulate trap: 3.2.12.2.6.3. Location (reference distance in the exhaust line): 3.2.12.2.6.4. Method or system of regeneration, description and/or drawing: 3.2.12.2.7. Other systems (description and operation): 3.2.12.2.8. On-board-diagnostic (OBD) system: Yes 3.2.12.2.8.1. Written description and/or drawing of the Ml: See Attachment S81-TA-0014 3.2.12.2.8.2. List and purpose of all components monitored by the OBD system: See Attachment S81-TA0014

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

3.2.12.2.8.3. Written description (general working principles) for: 3.2.12.2.8.3.1. Positive-ignition engines: 3.2.12.2.8.3.1.1. Catalyst monitoring: NA 3.2.12.2.8.3.1.2. Misfire detection: NA 3.2.12.2.8.3.1.3. Oxygen sensor monitoring: NA 3.2.12.2.8.3.1.4. Other components monitored by the OBD system: NA 3.2.12.2.8.3.2. Compression-ignition engines: NA 3.2.12.2.8.3.2.1. Catalyst monitoring: NA 3.2.12.2.8.3.2.2. Particulate trap monitoring: NA 3.2.12.2.8.3.2.3. Electronic fuelling system monitoring: NA 3.2.12.2.8.3.2.4. Other components monitored by the OBD system: NA 3.2.12.2.8.4. Criteria for Ml activation (fixed number of driving cycles or statistical method): 3.2.12.2.8.5. List of all OBD output codes and formats used (with explanation of each): See Attachment S81-TA-0014 3.2.12.2.8.6. The following additional information must be provided by the vehicle manufacturer for the purposes of enabling the manufacture of OBD-compatible replacement or service parts and diagnostic tools and test equipment, unless such information is covered by intellectual property rights or constitutes specific know-how of the manufacturer or the OEM supplier(s). The information given in this section shall be repeated in Appendix 2 to the EC type-approval certificate (Annex X to this Directive): 3.2.12.2.8.6.1. A description of the type and number of the pre-conditioning cycles used for the original type approval of the vehicle. 3.2.12.2.8.6.2. A description of the type of the OBD demonstration cycle used for the original type-approval of the vehicle for the component monitored by the OBD system. 3.2.12.2.8.6.3. A comprehensive document describing all sensed components with the strategy for fault detection and MI activation (fixed number of driving cycles or statistical method), including a list of relevant secondary sensed parameters for each component monitored by the OBD system. A list of all OBD output codes and format used (with an explanation of each) associated with individual emission related power-train components and individual non-emission related components, where monitoring of the component is used to determine MI activation.

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

In particular, a comprehensive explanation for the data given in service $05 Test ID $21 to FF and the data given in service $06 must be provided. In the case of vehicle types that use a communication link in accordance with ISO 15765-4 Road vehicles, diagnostics on controller area network (CAN) part 4: requirements for emissions-related systems, a comprehensive explanation for the data given in service $06 Test ID $00 to FF, for each OBD monitor ID supported, must be provided. 3.2.12.2.8.6.4. The information required by this section may, for example, be defined by Componen t Fault code Monitoring strategy Oxygen sensor 1and 2signals Fault detection criteria Difference between sensor 1 and sensor 2signals MI activation criteria Secondary parameters Engine speed,engine load,A/F mode,catalys t temperature Preconditionin g Demonstration test

Catalyst

P0420

3rd cycle

Two i TypI cycles

Typ I

3.2.15. LPG fuelling system: yes/no 3.2.15.1. Approval number according to Directive 70/221/EEC: NA 3.2.15.2. Electronic engine management control unit for LPG fuelling: NA 3.2.15.2.1. Make(s): NA 3.2.15.2.2. Type(s): NA 3.2.15.2.3. Emission-related adjustment possibilities: NA 3.2.15.3. Further documentation: NA 3.2.15.3.1. Description of the safeguarding of the catalyst at switch-over from petrol to LPG or back: NA 3.2.15.3.2. System lay-out (electrical connections, vacuum connections compensation hoses, etc.): NA 3.2.15.3.3. Drawing of the symbol: NA 3.2.16. NG fuelling system: yes/no 3.2.16.1. Approval number according to Directive 70/221/EEC:NA 3.2.16.2. Electronic engine management control unit for NG fuelling 3.2.16.2.1. Make(s): NA 3.2.16.2.2. Type(s): NA 3.2.16.2.3. Emission-related adjustment possibilities: NA 3.2.16.3. Further documentations: 3.2.16.3.1. Description of the safeguarding of the catalyst at switch-over from petrol To NG or back:

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

10

3.2.16.3.2. System lay-out (electrical connections, vacuum connections compensation hoses, etc.):......... 3.2.16.3.3. Drawing of the symbol: 4. TRANSMISSION (V) 4.4. Clutch (type): Single Plate push-type clutch 4.4.1. Maximum torque conversion: 16.3 kgf.m 4.5. Gearbox 4.5.1. Type (manual/automatic/CVT): manual 4.6. Gear ratios: 1st:3.454, 2nd:1.944, 3rd:1.3, 4th:0.972, 5th:0.784 Internal gearbox ratios(ratios of engine to gearbox output shaft revolutions 3.454 1.944 1.30 0.972 0.784 3.545 3.895 Final drive ratio(s) (ratio output shaft to driven wheel revolutions Total gear ratios 13.453 7.572 5.063 3.786 3.054 13.83

Gear

Maximum for CVT 1 2 3 4 5 Minimum for CVT Reverse 6. SUSPENSION

3.895

6.6. Tyres and wheels: 2 axles; 4 wheels (2 per axle) 6.6.1. Tyre / wheel combination(s) (for tyres indicate size designation, minimum load capacity index, minimum speed category symbol; for wheels indicate rim size(s) and off-set(s)) 6.6.1.1. Axles 6.6.1.1.1. Axle 1: indicate size designation 175/70 R13 (HK), minimum load-capacity index 82T, rim size 13X5J, off-set 40mm 6.6.1.1.2. Axle 2: As Axle 1 6.6.1.1.3. Axle 3: NA 6.6.1.1.4. Axle 4: NA .etc. 6.6.2. Upper and lower limits of rolling radii 6.6.2.1. Axle 1: 285mm

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

11

6.6.2.2. Axle 2: 6.6.2.3. Axle 3: NA 6.6.2.4. Axle 4: NA etc. 6.6.3. Tyre pressure(s) as recommended by the vehicle manufacturer: ......... kPa 9. BODYWORK 9.10.3. Seats 9.10.3.1. Number: 2 front, 1 Bench Rear

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

12

Appendix INFORMATION ON TEST CONDITIONS 1. Spark plugs 1.1. Make: Bosch (Mico) 1.2. Type: FR8DE 1.3. Spark-gap setting: 0.8 mm 2. Ignition coil 2.1. Make: Continental (Korea) 2.2. Type: Dual ignition coil 3. Ignition condenser 3.1. Make: N.A. 3.2. Type: N.A. 4. Lubricant used 4.1. Make: Behran 4.2. Type: SAE 15W40 A.P.I SJ

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

13

Attachments

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

14

Attachment S81-TA-0001

Means of identification of type

NAS81002281******

1-3 (Manufacturer)

4-5 (Body Type)

8 (Engine) 9 (Gear box)

10 (Year of Manufacture)

12-17 (Serial Number)

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

15

Attachment S81-TA-0002

Location of marking

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

16

Attachment S81-TA-0003

Photographs of a representative vehicle

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

17

Attachment S81-TA-0004

Piston rings

1. Top & Second

2. Oil Ring

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

18

Piston

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

19

Attachment S81-TA-0005

Intake Manifold

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

20

Attachment S81-TA-0006

Air filter

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

21

Attachment S81-TA-0007

Intake Silencer

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

22

Attachment S81-TA-0008

Exhaust Manifold

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

23

Exhaust System

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

24

Attachment S81-TA-0009

Device for recycling crankcase gases

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

25

Attachment S81-TA-0010

Catalytic Convertors

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

26

Attachment S81-TA-0011

Location of Oxygen Sensor

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

27

Attachment S81-TA-0012

Schematic Drawing of the evaporative Control system

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

28

Attachment S81-TA-0013

Carbon canister

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

29

Specification canister Specification

Item

Type of canister Amount of activated carbon Air restriction

Specification

Activated carbon 670 cc Max.60 mm AQ

Test Condition

Mitsubishi DIA-HOPE CZ X OR Kuraary chemical KG-DK At dry condition (150 *3hr) Purge air flow from nipple A 10 L/min Test (absorb-degas) %6 cycle.

Working capacity

Effective activity min 65 gr

Average valve of 4-6TH CYC. Effective activity (test code Toore TES H911 Vibration acceleration 4.4 G

Air Vibration strength (at resonance point)

restriction specified.

working Above

Frequency 0-250 Hz (find resonance point if any within this range total number of cycle, 10 direction of vibration, up -down Vibration acceleration 4.4 G

capacity

hust is satisfied

Vibration strength (when resonance point doesnt exit)

No activated carbon leak permitted

Frequency 34 Hz total number of cycle, 10 direction of vibration, up -down

Thermal shock

No deformation or breakage of case- ASSY permitted

20 Cycles Exposure to hot temperature Exposure to cold temperature Color Plastic part Material Thickness Weight Appearance remarks About 500 gr black Designated item equivalent to p-AM-ABSZ (Refer to MES MN200) t=1.5 mm At dry condition 100 c %100 hr -40 c %100 hr

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

30

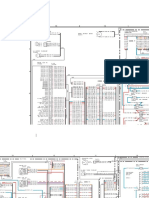

Attachment S81-TA-0014

S81- Fault Codes

Automotive Industries Research & Innovation Center of SAIPA

European Union: 70/220/EEC

Exhaust Emissions

31

Automotive Industries Research & Innovation Center of SAIPA

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Test Poh 172rДокумент3 страницыTest Poh 172rAmit SharmaОценок пока нет

- D 51 Ex PX-22 Código de Peças PDFДокумент495 страницD 51 Ex PX-22 Código de Peças PDFJulia Coitinho SilvaОценок пока нет

- Engine SpecificationsДокумент3 страницыEngine SpecificationsGabriel Andres ValenciaОценок пока нет

- Repair Information gx50 enДокумент1 страницаRepair Information gx50 engeorge e.bayОценок пока нет

- Workshop Manual Volvo - TAD760VEДокумент30 страницWorkshop Manual Volvo - TAD760VEANH LÊОценок пока нет

- Engine Failures 98Документ58 страницEngine Failures 98Abd ElGhanY AwdОценок пока нет

- Starting/Charging ConnectorДокумент15 страницStarting/Charging ConnectorRenato BautistaОценок пока нет

- Daewoo Lanos y NubiraДокумент15 страницDaewoo Lanos y NubiraJøta PerozoОценок пока нет

- Jac 1040-1035Документ107 страницJac 1040-1035Elguaro MecánicoОценок пока нет

- Indian Oil Corp monthly vibration readingsДокумент16 страницIndian Oil Corp monthly vibration readingsHITESHОценок пока нет

- NASCAR Late ModelДокумент14 страницNASCAR Late ModelAnderson ZambrzyckiОценок пока нет

- DeltaHawk Brochure - 2018Документ4 страницыDeltaHawk Brochure - 2018Pablo De FelipeОценок пока нет

- Volkswagen Jetta, Golf, GTI 1999, 2000 2.8 Liter VR6 2V Engine Mechanical, Engine Code(s) : AFPДокумент48 страницVolkswagen Jetta, Golf, GTI 1999, 2000 2.8 Liter VR6 2V Engine Mechanical, Engine Code(s) : AFPifu62319Оценок пока нет

- Ems PDFДокумент294 страницыEms PDFautoin100% (1)

- Eh1100 12V 2000 MtuДокумент121 страницаEh1100 12V 2000 MtuRicardo Yhonatan Lopez Vergara100% (1)

- Triplex PUmp 01 ChecklistДокумент7 страницTriplex PUmp 01 ChecklistMarizon ZulkarnainiОценок пока нет

- SSP 211 New BeetleДокумент12 страницSSP 211 New Beetleภูเก็ต เป็นเกาะ100% (2)

- Smi 15Документ383 страницыSmi 15jaciel leonОценок пока нет

- New Parts CTPДокумент2 страницыNew Parts CTPUB HeavypartsОценок пока нет

- ENGINE LUBRICATION OVERVIEWFДокумент16 страницENGINE LUBRICATION OVERVIEWFhoman83Оценок пока нет

- 02EN0780 Yd25 PDFДокумент2 страницы02EN0780 Yd25 PDFKevin TtitoОценок пока нет

- Technical Data: 4000 Series 4012-46TWG2A 4012-46TWG3AДокумент8 страницTechnical Data: 4000 Series 4012-46TWG2A 4012-46TWG3Aabo omrОценок пока нет

- Fiche Mot Essence-Eb2 Fa Flex FuelДокумент2 страницыFiche Mot Essence-Eb2 Fa Flex FuelRui MendesОценок пока нет

- Attention-: Buick Parts: Group NumbersДокумент16 страницAttention-: Buick Parts: Group NumbersCarlos Diaz TabaresОценок пока нет

- PCED On Board Diagnostics Misfire Detection MonitorДокумент5 страницPCED On Board Diagnostics Misfire Detection MonitorJosé AntonioОценок пока нет

- Vdocuments - MX - Naza Ria MPV PDFДокумент93 страницыVdocuments - MX - Naza Ria MPV PDFalangku09100% (2)

- Thunderbolt IgnitionДокумент18 страницThunderbolt IgnitionChristoffer ChristiansenОценок пока нет

- Fe170 DatasheetДокумент2 страницыFe170 DatasheetduconОценок пока нет

- Crankcase Pressure, CheckДокумент7 страницCrankcase Pressure, CheckIzz BaharОценок пока нет

- How To Check The Turbocharger Oil Leakage ConditionДокумент11 страницHow To Check The Turbocharger Oil Leakage ConditionMyo minОценок пока нет