Академический Документы

Профессиональный Документы

Культура Документы

Comparison of Core and Cube Compressive Strength of Hardened Concrete

Загружено:

Rajmonda RamaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Comparison of Core and Cube Compressive Strength of Hardened Concrete

Загружено:

Rajmonda RamaАвторское право:

Доступные форматы

COMPARISON OF CORE AND CUBE COMPRESSIVE STRENGTH OF HARDENED CONCRETE

M. Yaqub*, University of Engineering and Technology Taxila, Pakistan M. Anjum Javed, Concordia University, Canada

31st Conference on OUR WORLD IN CONCRETE & STRUCTURES: 16 - 17 August 2006, Singapore

Article Online Id: 100031053 The online version of this article can be found at: http://cipremier.com/100031053

Thisarticleisbroughttoyouwiththesupportof SingaporeConcreteInstitute www.scinst.org.sg AllRightsreservedforCIPremierPTELTD YouarenotAllowedtoredistributeorresalethearticleinanyformatwithoutwrittenapprovalof CIPremierPTELTD VisitOurWebsiteformoreinformation www.cipremier.com

31st Conference on OUR WORLD IN CONCRETE & STRUCTURES: 16 17 August 2006, Singapore

COMPARISON OF CORE AND CUBE COMPRESSIVE STRENGTH OF HARDENED CONCRETE

M. Yaqub*, University of Engineering and Technology Taxila, Pakistan M. Anjum Javed, Concordia University, Canada

Abstract This paper presents the result of core and cube compressive strength of hardened concrete. Non destructive test methods are used to investigate the properties and strength of hardened concrete. In existing concrete structures there was no direct relation between the results of non-destructive tests. This paper describes the relation between core compressive strength and cube compressive strength of hardened concrete in existing structures. Sixteen cores (diameter 75mm) were extracted from the hardened concrete of 12years old building. Twelve cores (48mm diameter) were also extracted from the same hardened concrete building. Two sizes of cubes (150mm x 150 x 150mm) and (100mm x 100mm x 100mm) were made from the hardened concrete from stone pieces which were taken from the structural members of building with help of stone cutting machine. The cores and cubes compressive strength was determined in compression testing machine. It was found that smaller size cubes (100mm x 100mm x 100mm) and cores (48mm diameter) show greater strength as compared to larger size cubes (150mm x 150 x 150mm) and cores (diameter 75mm). It was also found that the cubes (150mm x 150 x 150mm) compressive strength is 76% the cubes (100mm x 100mm x 100mm) compressive strength. The 75mm diameter cores compressive strength is sixty nine percent the compressive strength of cubes (150mm x 150 x 150mm).

Keyword: Compressive strength, core strength, cube strength, Non-destructive tests. 1. Introduction Once concrete has hardened it can be subjected to wide range of tests to prove its ability to perform as planned or to discover its characteristics if its history is unknown. For new concrete this usually involves casting specimens from fresh concrete and testing them for various properties as the concrete matures. The concrete cube tests, concrete cylinder tests are the most familiar tests and are used as the standard method of measuring compressive strength for quality control purposes. Concrete beam specimens are cast to test for flexural strength and cast cylinder cone be used for tensile strength. Specimens for many other tests can be made at the same time to assess other properties.

For existing concrete samples will need to be taken from the structure. Non destructive testing methods are useful in some instances and can help identify areas from which samples should be taken. The normal method of concrete sampling is by coring although same chemical analysis techniques can be carried out on drilling dust samples. In laboratory many techniques can be used to examine and test hardened concrete to assess a wide Varity of properties. Non destructive and semi-destructive methods play an important role in evaluating the existing structure conditions [1, 2]. Non destructive test methods are used to indicate properties other than strength [3, 4]. British Standard defined non destructive testing as a test that does not impair the intended performance of the element or member under investigation [5]. The nondestructive evaluation techniques are used to assess the condition of concrete structures, to predict future performance and allow minor repair system. The best known non destructive evaluation techniques use ultrasonic waves, core testing, Schmidt hammer test. The estimation of in place concrete strength requires that a known relationship between the results of in-situ testing and the strength of concrete. For existing construction the relationship has to be assessed on site correlating non-destructive test results to strength of core. There was no any relation between core strength and cube strength of hardened concrete. In this research work a relationship between core strength and cube strength was developed. This paper also describes the effect of diameter of core on compressive strength of concrete and effect of size of cube on compressive strength of concrete. 2. Objectives The objectives of this research were: (1) (2) (3) To develop a relationship between core compressive strength and cube compressive strength. To study the effect of core diameter on the compressive strength of concrete. To study the effect of cube size on compressive strength of concrete.

3. Experimental Program Sixteen and eleven cores of 75mm diameters and 48mm diameters were extracted from the 12-years old concrete buildings at different locations of the structural members. Some cores were taken from columns, beams and some cores were taken from base slab, floor slabs and walls. In the same location concrete stone pieces were taken. The length of cores was variable as shown in the table 1 & 2. The concrete stones were made into the regular cube shape of size 150mm x 150mm x 150mm and 100mm x100mm x 100mm by stone cutting machine. The cores were extracted by using rotary cutting machine with diamond bits. The extracted cores were trimmed to make smooth edges parallel and then capped with sulphur to make the ends smooth. After capping, cores were tested in compression testing machine in the concrete laboratory. No rebars were found in the cores. The results of cores are shown in table 1 & 2. After making the regular shape of cubes of sizes 150mm x150mm x 150mm and 100mm x100mm x 100mm they were tested in compression testing machine. The results of cubes are shown in table 3. The average compressive strength of 150mm x 150mm x 150mm cubes was 24MPa [3508psi] and the average compressive strength of 100mm x 100mm x 100mm was found to be 32MP [4608psi]. The average corrected compressive strength of cores having diameter 75mm was 17MPa [2466psi]. The average compressive strength of cores having diameter of 48mm was 18MPa [2611psi]. All cores were tested in dry condition. The strength of cores was calculated after applying all the factors given in ASTM C42-90.

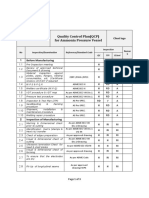

Table 1 Results of Cores (75mm diameter) Sr. No. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Location RCC Column RCC Column RCC Column RCC Column RCC Slab RCC Slab RCC Slab RCC Slab RCC Wall RCC Beam RCC Beam RCC Slab RCC Wall RCC Column RCC Beam RCC Beam Weight (gm) 1524 1516 1608 1572 1500 1448 1196 1138 1480 1568 1564 1124 1546 1562 1518 1486 Dia (mm) 75 75 75 75 75 75 75 75 75 75 75 74.93 74.93 74.93 74.93 74.93 Length (mm) 150 150 150 150 150 140.462 121.41 114.046 150 150 150 4.78 113.79 113.79 113.79 150 Area (mm2) 4418 4418 4418 4418 4418 4418 4418 4418 4418 4418 4418 4418 4418 4418 4418 4418 Corrected Compressive Strength of core (MPai) 12.627 10.885 19.158 19.375 14.1509 26.930 23.2198 25.749 7.619 21.770 21.537 14.142 13.596 16.733 12.550 10.0145

Table 2 Results of Core (48mm diameter) Sr. No. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Location CS-3 BS-2 BS-1 CS-1 GS-2 CS-2 R-7 R-3 BS-4 R-3 (RAFT) R-3 Weight (gm) 360.91 392.92 389.93 400.53 385.97 398.36 300 258.52 250.31 239.72 212.62 Dia (mm) 48 48 48 48 48 48 48 48 48 48 48 Length (mm) 92.40 96.64 97.18 100.12 98.17 100.15 77.26 64.77 64.70 61.69 52.64 Area (mm2) 1809.557 1809.557 1809.557 1809.557 1809.557 1809.557 1809.557 1809.557 1809.557 1809.557 1809.557 Corrected Compressive Strength of core (MPa) 15.840 22.3117 23.3710 22.3117 13.810 19.120 12.352 15.507 12.00 15.877 21.347

Sr. No . 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15.

Cube size 150 x 150 x 150 150 x 150 x 150 150 x 150 x 150 100 x 100 x 100 100 x 100 x 100 100 x 100 x 100 100 x 100 x 100 100 x 100 x 100 100 x 100 x 100 100 x 100 x 100 100 x 100 x 100 100 x 100 x 100 100 x 100 x 100 100 x 100 x 100 100 x 100 x 100

Table 3 Results of Cubes Location Corrected Compressive Strength of core (MPa) Column Column Column Slab Slab Slab Slab Slab Wall Wall Wall Wall Slab Slab Slab 25. 20 28 33 33 28 35 32 32 26 27 35 31 35 36

4. Results and Discussion The cores (diameter 48mm) show greater compressive strength of concrete as compared to the cores (diameter 75mm). The cubes (100mm x 100mm x 100mm) show greater compressive strength as compared to cubes (150mm x 150mm x 150mm). The smaller size cores have smaller cross-sectional area. The compressive strength is load per unit area. Due to smaller size, the strength of smaller diameter cores was greater as compared to the larger size diameter of cores. Similarly the smaller size cubes give greater strength as compared to larger size cubes. 5. Relation between Core Compressive Strength and Cube Strength It was found from the result; the compressive strength of cores (75mm diameter) is 0.693 times the compressive strength of cubes (150mm x 150mm x150mm). The compressive strength of cores (75mm diameter) is 0.528 times the compressive strength of cubes (100mm x 100mm x 100mm). The core (48mm diameter) compressive strength is 0.724 times the compressive strength of cubes (150mm x 150mm x 150mm). The compressive strength of cores (48mm diameter) is 0.552 times the compressive strength of cubes (100mm x 100mm x 100mm). 6. Conclusion From the results of the tested specimen the following conclusion were made. 1. The compare strength of cubes was greater than the compressive strength of cores. 2. The smaller size cubes (100mm x 100mm x 100mm) give greater compressive strength of cubes as compared to larger size (150mm x 150mm x 150mm). 3. The smaller size cubes strength is 1.311 times larger size cube compressive strength. 4. The strength of cores (48mm) is 5% greater than cores (75mm). 7. Reference [1]. British standard institution, Guide to the use of non-destructive methods of test for hardened concrete, BS, 881, 1986, part 201. [2]. Fookes P.G concrete in the middle test past, present ad future , review Damage Assessment Repair Techniques and strategies for reinforcement concrete Macmillan, G.L ed. Bahrain society of Engineers 1991. [3]. Pocock ,D.C the selection o cost-effective repair strategies for corrosion damage concrete an determination and respire of reinforced concrete In the Persian Gulf , oct,1997, Bahrain vol. ,PP147161. [4]. Rasheed uzzafar , D and Gahtani, A.S corrosion of reinforcement in concrete structure in the middle of east concrete international , American concrete institute , vol., 7. No 9. Sep.1985, PP , 4855. [5]. Rasheed uzzafar Dakhil , F.H and Bader,A.M toward solving the concrete determination problem in the gulf region, the Arabian , Journal of science and Engineering , theme issue on concrete durability vol.11nov

Вам также может понравиться

- Comparison of Core and Cube Compressive Strength of Hardened Concrete 02 JuneДокумент6 страницComparison of Core and Cube Compressive Strength of Hardened Concrete 02 JuneGJESRОценок пока нет

- Data Full Papers 112 DelДокумент8 страницData Full Papers 112 DelDBW Quality Control JVACCОценок пока нет

- Split Tensile Strength-Flexural TestДокумент15 страницSplit Tensile Strength-Flexural TestHVRANAОценок пока нет

- 37101-92051-1-PBKantileverДокумент7 страниц37101-92051-1-PBKantileverslametbasuki11878Оценок пока нет

- Prediction of Shear Strength of PPFRC Moderate Deep Beams Using Strut-and-Tie ModelsДокумент4 страницыPrediction of Shear Strength of PPFRC Moderate Deep Beams Using Strut-and-Tie Modelschetan2042Оценок пока нет

- Shear Behaviour of Steel Fibre Reinforced Self-Compacting ConcreteДокумент8 страницShear Behaviour of Steel Fibre Reinforced Self-Compacting Concretejack21abОценок пока нет

- Shear Behavior of Self Compacting R.C. I-BeamsДокумент16 страницShear Behavior of Self Compacting R.C. I-BeamsThomás LimaОценок пока нет

- 7.ISCA JEngS 2012 026Документ5 страниц7.ISCA JEngS 2012 026Turcu Catalin NicolaeОценок пока нет

- Flexural Test On Concrete Based On The ASTM Standards Are ExplainedДокумент9 страницFlexural Test On Concrete Based On The ASTM Standards Are ExplainedTesfayeОценок пока нет

- MAnsur PDFДокумент14 страницMAnsur PDFDogo HeinemanОценок пока нет

- Ferrocement PaperДокумент8 страницFerrocement PaperClassic11Оценок пока нет

- Effects of Unconfined Concrete Strength On FRP Confinement of ConcreteДокумент8 страницEffects of Unconfined Concrete Strength On FRP Confinement of Concretecaojin259Оценок пока нет

- Lifting Eyes Ara Paper 8mayДокумент14 страницLifting Eyes Ara Paper 8mayiuliandurdureanuОценок пока нет

- Evaluation of The Tensile Strength of SFRC As Derived From Inverse Analysis of Notched Bending TestsДокумент9 страницEvaluation of The Tensile Strength of SFRC As Derived From Inverse Analysis of Notched Bending TestsJakob FiskerОценок пока нет

- 86-S60confinement of Reinforced Concrete Columns With Welded Wire FabricДокумент9 страниц86-S60confinement of Reinforced Concrete Columns With Welded Wire Fabricshuangyaksa100% (1)

- Performance of Steel Fiber Reinforced Self Compacting ConcreteДокумент5 страницPerformance of Steel Fiber Reinforced Self Compacting ConcreteInternational Journal of computational Engineering research (IJCER)Оценок пока нет

- A Review of Relation Between Cube Strength and Core Strength of Hardened Concrete in The Light of IS456:2000and IS516:1959Документ4 страницыA Review of Relation Between Cube Strength and Core Strength of Hardened Concrete in The Light of IS456:2000and IS516:1959Rohit RaiОценок пока нет

- Proiect ConstructiiДокумент7 страницProiect ConstructiiAsofii CosminaОценок пока нет

- 1 Experiments Investigating Concrete Floor Punching PDFДокумент17 страниц1 Experiments Investigating Concrete Floor Punching PDFMelissa PungtilanОценок пока нет

- MalikДокумент1 страницаMalikm yousafОценок пока нет

- s2.0 S1877705817X0026X1 s2.0 S1877705817327406main - PDFX Amz Security Token IQoJbДокумент8 страницs2.0 S1877705817X0026X1 s2.0 S1877705817327406main - PDFX Amz Security Token IQoJbkx54fdyzgjОценок пока нет

- 193 PDFДокумент8 страниц193 PDFEmily OchoaОценок пока нет

- Experimental Investigation of Rectangular Spiral Reinforced Concrete BeamsДокумент5 страницExperimental Investigation of Rectangular Spiral Reinforced Concrete BeamsAbel MulugetaОценок пока нет

- Retrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysДокумент12 страницRetrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysSudha JОценок пока нет

- MICROPILE CAP TEST REVEALS BEARING PLATES UNNECESSARYДокумент11 страницMICROPILE CAP TEST REVEALS BEARING PLATES UNNECESSARYrowatersОценок пока нет

- Attachment - 1 - SOP On Core Sample TestingДокумент7 страницAttachment - 1 - SOP On Core Sample TestingNVLNNAGEОценок пока нет

- Retrofitting of Columns of An Existing Building byДокумент8 страницRetrofitting of Columns of An Existing Building bysp thipathiОценок пока нет

- Effect of Small Circular Opening On The Shear and Flextural Behavior and Ultimate Strength of Reinforced Concrete Beams Using Normal and High Strength ConcreteДокумент14 страницEffect of Small Circular Opening On The Shear and Flextural Behavior and Ultimate Strength of Reinforced Concrete Beams Using Normal and High Strength ConcreteSandeep ShridharОценок пока нет

- Experimental and Analytical Study On Funicular Concrete Shell Foundation Under Ultimate LoadingДокумент16 страницExperimental and Analytical Study On Funicular Concrete Shell Foundation Under Ultimate LoadingLudmylla FreitasОценок пока нет

- Thickness and Density of Sprayed Fire-Resistive Material (SFRM) Applied To Structural MembersДокумент5 страницThickness and Density of Sprayed Fire-Resistive Material (SFRM) Applied To Structural MembersBeymerBustamanteMejía100% (2)

- Shear Behavior of Thick Slabs-ACIДокумент12 страницShear Behavior of Thick Slabs-ACIJoão Paulo MendesОценок пока нет

- Behaviour of Glass Fiber Wrapped ConcreteДокумент10 страницBehaviour of Glass Fiber Wrapped ConcreteB.r. AnirudhОценок пока нет

- 20174-Hzrina AIP1.5011494Документ10 страниц20174-Hzrina AIP1.5011494Ehsan WasimОценок пока нет

- For My Students:: Always Treat Your Parents With Utmost Respect and KindnessДокумент36 страницFor My Students:: Always Treat Your Parents With Utmost Respect and KindnessHefon MarketerОценок пока нет

- JUST Concrete Mix Design Lab ReportДокумент12 страницJUST Concrete Mix Design Lab ReportAhmad O KhasawnehОценок пока нет

- Estudio Del Comportamiento de Columnas de Hormigon PretensadoДокумент17 страницEstudio Del Comportamiento de Columnas de Hormigon PretensadoReivax50Оценок пока нет

- Hemanth PPT NewДокумент59 страницHemanth PPT NewhemrajbmsОценок пока нет

- Short ColumnsДокумент15 страницShort ColumnssrividyaОценок пока нет

- Cover Meter Research PaperДокумент7 страницCover Meter Research PaperMrinal AgarwalОценок пока нет

- Tensil Headed Anchors With Large Diameter and Deep Embedment in ConcreteДокумент7 страницTensil Headed Anchors With Large Diameter and Deep Embedment in ConcreteJack SmithОценок пока нет

- Experimental Investigations On CompressiДокумент18 страницExperimental Investigations On Compressiyaj leumas seyerОценок пока нет

- Reconfirmation Notice: AS 1012.3.4-1998 (Reconfirmed) 2014-10-24Документ9 страницReconfirmation Notice: AS 1012.3.4-1998 (Reconfirmed) 2014-10-24heyh jdjОценок пока нет

- Experimental Setup and Procedures for Testing Concrete and RCC ElementsДокумент26 страницExperimental Setup and Procedures for Testing Concrete and RCC ElementsNitish SinghОценок пока нет

- CFRP Bridge BeamsДокумент5 страницCFRP Bridge BeamsAnonymous nQ9RqmОценок пока нет

- Connection For Roundwood Timber Members Using Multiple Glue-In Rods - Final - PaperДокумент7 страницConnection For Roundwood Timber Members Using Multiple Glue-In Rods - Final - PaperTelmo MorgadoОценок пока нет

- Experimental Model for Steel Fibre Concrete SlabДокумент24 страницыExperimental Model for Steel Fibre Concrete Slabdisha847Оценок пока нет

- What Is Flexure StrengthДокумент5 страницWhat Is Flexure Strengthhimanshu tonkОценок пока нет

- Steel StrengthДокумент10 страницSteel StrengthjjОценок пока нет

- Cyclic Behaviour of Beam Column Joint Retrofitted With Simcon LaminatesДокумент20 страницCyclic Behaviour of Beam Column Joint Retrofitted With Simcon LaminatesJay PatelОценок пока нет

- Testing and Design of Gravity-Loaded Steel Purlins Restrained by SheetingДокумент10 страницTesting and Design of Gravity-Loaded Steel Purlins Restrained by SheetingamokeОценок пока нет

- Birkle, Dilger - 2008Документ9 страницBirkle, Dilger - 2008David VillalobosОценок пока нет

- Properties of Anchor Grouts in A Confined State A D Barley Ice Conference London March 1997Документ10 страницProperties of Anchor Grouts in A Confined State A D Barley Ice Conference London March 1997Kenny CasillaОценок пока нет

- Tests On Hardened Concrete: Compressive Strength TestДокумент3 страницыTests On Hardened Concrete: Compressive Strength TestNora ElansaryОценок пока нет

- FIBRE REINFORCED CONCRETE USING DOMESTIC WASTE PLASTICS AS FIBRES by R. Kandasamy and R. MurugesanДокумент8 страницFIBRE REINFORCED CONCRETE USING DOMESTIC WASTE PLASTICS AS FIBRES by R. Kandasamy and R. MurugesanIvan KotОценок пока нет

- Beam Jacketing MSДокумент10 страницBeam Jacketing MSdraganugОценок пока нет

- Reinforced Concrete Buildings: Behavior and DesignОт EverandReinforced Concrete Buildings: Behavior and DesignРейтинг: 5 из 5 звезд5/5 (1)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryОт EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryОценок пока нет

- A. Parties To The 1949 Road Traffic Convention and The 1943 Inter-American Automotive Traffic ConventionДокумент3 страницыA. Parties To The 1949 Road Traffic Convention and The 1943 Inter-American Automotive Traffic ConventionRajmonda RamaОценок пока нет

- Assessing The Relationship Between The Compressive Strength of Concrete Cores and Molded SpecimensДокумент14 страницAssessing The Relationship Between The Compressive Strength of Concrete Cores and Molded SpecimensRajmonda RamaОценок пока нет

- 1 s2.0 S0958946502000136 Main LibreДокумент8 страниц1 s2.0 S0958946502000136 Main LibreRajmonda RamaОценок пока нет

- Plate Bearing Test Data AnalysisДокумент21 страницаPlate Bearing Test Data Analysisjkedar_78100% (3)

- Acceptance of Concrete Compressive StrengthДокумент19 страницAcceptance of Concrete Compressive Strengthwayne1925Оценок пока нет

- Testi I Konit Ne PilotaДокумент115 страницTesti I Konit Ne PilotaRajmonda RamaОценок пока нет

- Guidelines For Testing Fresh Self-Compacting Concrete: Principal Author: G. DE SCHUTTERДокумент24 страницыGuidelines For Testing Fresh Self-Compacting Concrete: Principal Author: G. DE SCHUTTERGeorge CarmelОценок пока нет

- AAC 2017 NotesДокумент5 страницAAC 2017 NotesAnoop singhОценок пока нет

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Документ2 страницыNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserОценок пока нет

- API 1169 Pipeline Construction Inspector Certification Exam PrepДокумент7 страницAPI 1169 Pipeline Construction Inspector Certification Exam PrepYasser Abd El FattahОценок пока нет

- Note CHP 6 Material Science 281 Uitm Em110Документ45 страницNote CHP 6 Material Science 281 Uitm Em110bino_ryeОценок пока нет

- en 12680 32011ok PDFДокумент6 страницen 12680 32011ok PDFUtkarsh GautamОценок пока нет

- Airframe Maintenance and RepairДокумент2 страницыAirframe Maintenance and RepairTamil SelvanОценок пока нет

- Arp 1333Документ15 страницArp 1333Oottuparambil Krishnakumar RamakrishnanОценок пока нет

- Petronas Technical Standards: Onshore Pipeline Construction (Amendments / Supplements To ASME B31.8 and ASME B31.4)Документ15 страницPetronas Technical Standards: Onshore Pipeline Construction (Amendments / Supplements To ASME B31.8 and ASME B31.4)tang weng waiОценок пока нет

- Insulation QAPДокумент2 страницыInsulation QAPPavul RajОценок пока нет

- Shop Welding InspectionДокумент4 страницыShop Welding InspectionIndra Nath MishraОценок пока нет

- Fluorescent Magnetic Particles Product Data SheetДокумент3 страницыFluorescent Magnetic Particles Product Data Sheetஅன்புடன் அஸ்வின்Оценок пока нет

- Magnetic Praticle Inspection ProcedureДокумент9 страницMagnetic Praticle Inspection ProcedureTouil HoussemОценок пока нет

- BP GUPCO Book 2 PT 3 PDFДокумент28 страницBP GUPCO Book 2 PT 3 PDFIbrahimОценок пока нет

- VA1 LSC 00100 QA M8 TPD 0006 (Steel Structure Fabrication Procedure) Rev.1Документ20 страницVA1 LSC 00100 QA M8 TPD 0006 (Steel Structure Fabrication Procedure) Rev.1MungNguyenDinhОценок пока нет

- Part 14 - Crane & HoistsДокумент11 страницPart 14 - Crane & HoistsrickymmaОценок пока нет

- HELLING 2013 (En)Документ95 страницHELLING 2013 (En)Jessi JohnsonОценок пока нет

- 1978-06 Successful Applications of NDT Techniques To Mining Equipment Maintenance - Sutcliffe, Cottier (#MNG)Документ3 страницы1978-06 Successful Applications of NDT Techniques To Mining Equipment Maintenance - Sutcliffe, Cottier (#MNG)rhinemine100% (1)

- Quality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingДокумент3 страницыQuality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingFaisal Awad100% (1)

- 8 RT ProcedureДокумент8 страниц8 RT ProcedureMagesh VenuОценок пока нет

- DNV OS C103 Column StabilДокумент24 страницыDNV OS C103 Column StabilSaid ElhamydyОценок пока нет

- Senarai Tajuk FYP Dan Nama Pelajar Sidang 2022-2023-Program Elektronik 2nd RoundДокумент19 страницSenarai Tajuk FYP Dan Nama Pelajar Sidang 2022-2023-Program Elektronik 2nd RoundAzmi Shah Alias KhooОценок пока нет

- Iso 22232-2-2020Документ64 страницыIso 22232-2-2020AnrStuk100% (4)

- TP-01Hydrostatic Test Cover SheetДокумент4 страницыTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- MT ProcedureДокумент9 страницMT ProcedureTouil Houssem100% (1)

- Supplier Document Cover Page: Greater Enfield Subsea EPCIДокумент29 страницSupplier Document Cover Page: Greater Enfield Subsea EPCIKarthikeyan GanesanОценок пока нет

- DEKRA Nuclear Presentation 2011-05-09Документ22 страницыDEKRA Nuclear Presentation 2011-05-09hocimtmОценок пока нет

- Advanced NDT Techniques Presentation 1572625262Документ12 страницAdvanced NDT Techniques Presentation 1572625262Ali100% (1)

- 02-729-Pt5 Iss2Документ80 страниц02-729-Pt5 Iss2br1ggsyОценок пока нет

- Engineering Physics - DR Sutar M AДокумент2 страницыEngineering Physics - DR Sutar M Agotu123Оценок пока нет

- Spec Unloading Arms IIДокумент221 страницаSpec Unloading Arms IIOmiros Aggelides100% (3)