Академический Документы

Профессиональный Документы

Культура Документы

U.S. Steel blast furnace charge model

Загружено:

rajnguptaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

U.S. Steel blast furnace charge model

Загружено:

rajnguptaАвторское право:

Доступные форматы

_ Hot Metal Production at U. S.

Steel, Mon Valley Works

Page 1 of 13

BLAST FURNACE CHARGING AT U.S. STEEL

Leon S. Lasdon The University of Texas at Austin McCombs School of Business Management Science and Information Systems Dept., B6500 Austin, Texas 78712-0212 Debra L. McCrady (Senior Systems Engineer, Process Control, Blast Furnace), Jon Hermansderfer (Quality Assurance, Blast Furnace), William T. Bennett (Manager, Process Control, Blast Furnace), Sandra D. Feltmate (Manager, Process Control, Blast Furnace) U.S. Steel Mon Valley Works Braddock, Pennsylvania 15044 Allan D. Waren Computer and Information Sciences Department James J. Nance College of Business Administration Cleveland State University Cleveland, Ohio 44115 MAY 13, 1998

ACKNOWLEDGEMENTS

The authors wish to thank the following people for their valuable contributions to this effort: Pete Yanief, Senior Process Leader, Blast Furnace Operations; Gene Bromberg, Quality Engineering; Dave Murphy, Administrator, Process Control; Tom Oshnock, Research Engineer; Jay Rosser, Operator, Blast Furnace; Gene Trudell, General Manager, Computer Systems; Ed Vojtek, Manager, Systems and Process Control; Ted Mills, Manager, Process Control; Bob Zeigler, Senior Systems Engineer, Process Control.

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 2 of 13

ABSTRACT

The process of extracting iron from iron ore in a blast furnace to produce pig iron is a critical steel-making operation. It is the first step in creating slabs at the U. S. Steel Edgar Thomson (ET) Plant in Braddock, PA - the hot end of USXs Mon Valley Works. In an effort to improve the quality, quantity, and cost of the product made in the plants two furnaces, the process control group responsible for maintaining the software in the blast furnace area pursued a modeling approach. The end result of these efforts, which began in the early 1990s, was a charge model which predicts the properties of pig iron produced in the furnaces, given the quantities and composition of solid input materials and the flow rates and composition of gaseous fuels. A nonlinear optimizer was coupled to the model to maximize production while meeting specified quality constraints. The model and solver now act as the controller in an on-line blast furnace control system. Blast furnace operators have used the new process control system since February 27, 1997 and its use has led to improved, more stable product quality.

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 3 of 13

STEEL-MAKING AND BLAST FURNACE OPERATIONS

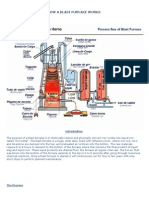

Figure 1 depicts steel-making operations in a modern blast furnace. Iron ore and other raw materials are hoisted to the top of the blast furnace via skip cars, and loaded or charged into the furnace. Heated air, the blast, is injected at high speed into the furnace near the bottom of the stack. Molten pig iron, the hot metal", and slag, a waste product, are drawn or cast from a single tap hole at the bottom.

Figure 1 The Modern Blast Furnace*

* American Iron and Steel Institute, The Making of Steel

Hot metal is transported by sub car to a Basic Oxygen Process (BOP) facility, where it is heated, chemically adjusted, and converted to liquid steel. Its composition and temperature are further modified at a ladle metallurgy facility and/or vacuum degassing facility, in order to meet specifications. The molten steel is then transported by ladle to the dual strand slab caster, where it is placed on a rotating turret. Once in position, the steel flows from the ladle into the tundish below. As it moves down through the molds, the steel cools, solidifies, and slabs are formed. The solid slabs are cut to length by torches, then stacked to await transportation by rail to the U.S. Steel Irvin Works finishing end, where they are rolled, treated and formed into coils. Several authors have described OR/MS models used in the operations subsequent to hot metal production. The most recent work of which we are aware is the Edelman prize finalist paper by Sinha et al. (1995). This paper describes a plant-wide mixed integer linear programming model for the Indian manufacturer Tata Steel that allocates electrical energy and oxygen to multiple finished products. Its references include papers describing related models published in 1987 by Bethlehem Steel and another by a Japanese steel manufacturer. There are two other recent Edelman finalists. Vasko et al. (1989) at Bethlehem Steel consider problems arising in ingot-based casting, an older, less efficient but less capital-intensive technology compared to continuous casting. They select ingot and ingot mold dimensions in a 2 phase process, the second using a set-covering integer programming model. Box and Herbe (1988) at LTV Steel develop a heuristic procedure to sequence customer orders through a dual-strand continuous caster while considering setup costs and order due dates. In other Interfaces articles, Diaz et al. (1991) discuss a system for sequencing heats of molten steel emerging from a BOP facility through the continuous casting operations of a Spanish steel producer. Vasko et al. (1991) present an algorithm for cutting steel plates into customer orders at Bethlehem Steel using a two dimensional cutting stock framework. Bielefeld et al. (1986) describe an LP-based supply chain planning model which plans purchasing, production, and distribution

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 4 of 13

for many products in many plants on an annual basis for Hoesch, a German steel-maker. In blast furnace operations, Deitz (1997), in a product review, describes a system developed by Voest-Alpine Stahl, an Austrian firm, for controlling blast furnace performance. The system consists of a series of computer models for various phases of blast furnace operation. It includes a burden optimization model for determining the optimal mix of inputs, the subject of this paper, while other models determine control settings and hot metal qualities. This automation package includes an expert system that interprets the process, proposes remedial actions, and details how results were obtained. Other Artificial Intelligence applications to blast furnace modeling and control are described in several other papers. Zuo et al. (1998) report on the design of three models based on neural networks for recognition of top gas distribution, distributions of the heat fluxes through the furnace wall, and for the prediction of slips in the blast furnace. Inkala et al. (1995) describes the application of an expert system, at the Finnish firm Rautaruukki Oy, to blast furnace control. Iida et al. (1995) describes several AI applications at Kawasaki Steel including fuzzy inference applied to stove heat control and a neural network application to blast furnace burden distribution control. Angstenberger (1996) describes the application of fuzzy clustering and neural networks to blast furnace modeling and control at a German steel producer. Hogan and Koelble (1996) studied the current capacity, condition, and outlook of coke ovens and blast furnaces in the U.S. They found that the number of U.S. blast furnaces had dropped from 197 to 43 since 1975 and that three of the remaining blast furnaces were designated as "standby" and were unlikely to operate again. Additional environmental requirements were expected to further constrain blast furnace operations. It is clear that improved productivity and reduced emissions are critical requirements for U.S. steel makers. The production of hot metal in the blast furnace is the first and most crucial step in making steel products. Inputs charged into the furnace at its top, the "burden, fall into four categories. The first category, iron-bearing materials, such as iron ore, sinter, pellets, mill scale, and steel scrap, contribute to tonnage and quality of the hot metal. The second category, coke, which serves as fuel, provides the carbon required for the iron bearing materials to be reduced. The final two categories, fluxes and trims, separate the impurities from the hot metal following the reduction phase. Examples of fluxes and trims are limestone, dolomite, gravel and various manufactured materials. For all of these materials, their pH determines their classification as fluxes or trims. Heated air, enriched with natural gas and/or coke oven gas, is injected into the furnace through jets called tuyeres, resulting in the combustion of carbon in the coke. This exothermic reaction reduces the burden and facilitates several chemical reactions, resulting in the melting and reduction of the iron ore and the formation of liquid slag. In normal operation, the furnace contains three casts at different height levels; the cast at the bottom is being tapped, the middle two are descending and are undergoing reduction, and the charge for a new cast is being added. The materials in a cast descend more rapidly near the furnace center where the hot air is directed. Hence there is some mixing of the materials in adjacent casts. The charged materials comprising a cast pass through the furnace in approximately 8 hours. Some of the slag, containing trace amounts of desirable elements, may be recycled into the furnace after processing. In some cases, the slag that is not recycled is sold for such uses as road repair. One ton of hot metal requires about 1.7 tons of iron-bearing materials, 0.5 to 0.65 tons of coke and other fuel, 0.25 tons of fluxes and trims, and 1.8 to 2.0 tons of air. In addition, for each ton of hot metal produced, the process creates 0.2 to 0.4 tons of slag, 0.05 tons or less of flue dust, and 2.5 to 3.5 tons of blast furnace gasses. The final product, hot metal, is about 93% iron, with other trace ingredients including Sulfur, Silicon, Phosphorus and Manganese. Materials are continuously charged to replace the descending burden and to maintain a specific level of solid materials (the stockline-see Figure 1). The stockline is controlled to keep gas pressure from rising too high in the upper part of the furnace. Approximately 10-14 charges are required to maintain the proper stockline during a charging and casting period. The mix of raw materials in each charge is intended to be the same, although some difference between charges is unavoidable due to errors in weighing and to variation in properties within a pile of raw material. Dust is produced as solid materials are charged, totaling about 0.66% of the total input by weight. It is collected, weighed, and chemically analyzed. We use the analysis results to update model coefficients

CHARGE MODEL VARIABLES

We developed a single-period charging model which determines the best mix of input materials to use in each of the 10-14 charges of the blast furnace, in order to meet a set of quality constraints for the hot metal and slag outputs. Some of the decision variables used are shown in Table 1 below. Units for all variables are pounds per charge.

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 5 of 13

1. 2. 3. 4. 5. 6. 7. 8.

Variable Type Iron Bearing Iron Bearing Iron Bearing Trim Fluxes Fuel Fuel Fuel

Variable Name Ore Pellets Acid Pellets Scrap materials (Recycled) Purchased Trim product Flux Pellets Nut Coke Clairton Coke (USS-produced) Natural Gas

Table 1 - Variable Types and Names

CHARGE MODEL CONSTRAINTS AND OBJECTIVE FUNCTION

The model constraints, ranked in order of importance, are shown in Table 2. Most important is an equality constraint on total carbon weight in the inputs. The right hand side of this constraint, the carbon "aim", is used to control the hot metal temperature, the location of the cohesive zone in the furnace, and the adiabatic flame temperature. The cohesive zone is the level in the furnace where the burden reaches its temperature of softening and melting, while the coke, retaining its shape, permits gas flow. The adiabatic flame temperature is the temperature just above the tuyeres. The carbon aim is adjusted to compensate for variations in other less controllable inputs such as the moisture content of injectants (e.g., coke oven gas), blast temperature, scrap usage, and coke characteristics. The operator's manual contains rules for adjusting this carbon aim for various measured values of these less controllable inputs. As the charge model was developed, improvements were made in these control rules, and these play an important part in the performance improvements described later. Importance 1 2 3 4 5 6 7 8 9 10 11 12 Constraint Name Total Carbon Slag Basicity Slag Volume Hot Metal Produced SiO2 Al2O3 CaO MgO TiO2 K2O Cu Molybdenum

Table 2 - Hot Metal Material and Basicity Constraints The next constraint is an upper and lower bound on slag basicity. Slag, which floats on the surface of the hot metal, is a waste product, but is crucial to the removal of impurities from the hot metal. Slag basicity is the weight of MgO and CaO in the slag divided by the weight of SiO2 in the slag. It controls the viscosity and melting point of the slag, which in turn affect the hearth temperatures and grade of iron produced. The slag basicity constraint is the only one that does not have units of pounds. The slag volume constraint is an equality constraint on slag "volume". However slag volume, a term long used in steel making, is not in fact a volume but is the weight of slag per ton of hot metal produced. Constraint 4, the weight of hot metal to be produced, is often set to one ton. The remaining constraints are all upper and lower limits on compounds or elements found in the hot metal, measured in pounds per ton of hot metal produced. Only a subset is shown, since the number of these constraints can vary from run to run. Typically, in addition to the constraints shown, 10 more constraints of this type are included at the Mon Valley works blast furnace facility. The objective function used most often is the minimization of the total weight of input materials. Since the hot metal produced is usually constrained to be equal to one ton, this is equivalent to maximizing the productivity of the furnace. Another option is to minimize the total cost of the burden.

SYSTEM HISTORY AND DEVELOPMENT

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 6 of 13

In the 1960s, an optimization-based blast furnace blending model was developed at the U.S. Steel Research Facility and distributed to the Mon Valley Works. It calculated the best mix of raw materials, based upon the current furnace conditions and quality constraints for the final products. Its decision variables and constraints were very similar to those in tables one and two, and the form of the constraint functions was the same as described below - this is industry standard. However, it was written in an early version of FORTRAN for the DEC PDP-11 computer, which restricted variable names to 8 characters or less, and did not include many modern programming constructs. It was poorly structured, not sufficiently modular, and lacked a clean top-down design, making it difficult to understand and modify. The process control group supporting the software at the blast furnace could not add or delete variables or constraints easily, and maintenance was an ordeal. Over the next 20+ years, the model code was ported from one computing platform to another, compounding the maintenance problems. The platform migrations often required software rewrites or translations, which frequently led to losses of important functionality. Code modifications were usually poorly documented, and output reports were overly complex, incomplete, and difficult to modify. In addition, the reconciliation factors f(q) described below were updated after each cast, which caused too much variation in model outputs from one charge to the next. The more cautious statistical approach to updating these factors described in the next section has led to much more stable operation of the furnace. The replacement of the old system became essential when the Mon Valley Works decided to use Coke Oven Gas (COG), a waste product of their coke plant, as a fuel in the blast furnace. Modifications to the old system to accommodate the new COG input were not considered to be a cost-effective solution. Additional requests to vary the number of materials and constraints from one cast run to the next only hastened the decision to replace the aging system. Further motivation for a new system came from changes in the economic environment. Due to increases in foreign competition in the 1980s, the steel industry in the United States was pushed to lower costs and raise quality. In response, U.S. Steel initiated the APEX program (All People, Products, and Processes - in EXcellence) and a program of Continuous Improvements (CI). Under these programs, departments form teams and develop improvement strategies, selecting projects that will complement associated department activities. In the blast furnace area, various teams began work related to material loading. Operations fine-tuned the loading sequence, Quality Assurance concentrated on Coke Oven Gas injections and the natural gas enrichment process, Research investigated moveable armor and coal injection, and Process Control concentrated on material selections. As of February 1998, most of the aforementioned CI projects have been completed and are operational. The Mon Valley Works is injecting Coke Oven Gas, using the new charge model for all material selections, the moveable armor to direct the charged materials to specific locations in the furnace, and a charging sequence that has resulted in record production periods. The results shown in Figures 3-5 follow the installation of the new charge model. In keeping with the continuous improvement philosophy in effect at the Mon Valley Works, results at the blast furnace have continued to improve, partially because of the charge model and partially due to the other innovations.

CHARGE MODEL STRUCTURE, SOLUTION, AND UPDATING

The constraint functions in the charge model are based on the assumption that all input materials blend linearly. That is, each property of slag and hot metal is a weighted average of the corresponding properties of the charged inputs with nonnegative weight coefficients. To define the model structure precisely, let R = set of raw material inputs (see Table 1 for examples) Q = set of hot metal and slag material and basicity constraints-see Table 2 for examples)

xr = pounds of raw material r charged into the furnace for all r R (decision

x = vector of all xr s.

g q (x) = hot metal or slag material or basicity q Q resulting from input mix x.

variables)

a(q,r) = number of pounds of material q in one pound of raw material r (model data). f(q) = reconciliation factor for material q (model data). These are revised after each cast, based on actual measurement of product properties, to increase model accuracy. Details are described later. c1 = constant factor in equation for tons of hot metal produced (model data) The total weight of material q in the charged inputs is

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 7 of 13

w(q,x) =

a ( q, r ) * x

r R

(1)

Using these definitions, constraint function 1 in table 2, the total weight of input carbon, is

g1 ( x) = w(Carbon,x)

Constraint function 4, the number of tons of hot metal produced, is

(2)

g 4 ( x) = c1*w(Fe,x)/2000

(3)

where the constant c1>1 accounts for the fact that the hot metal is only about 93% iron (Fe), so the weight of hot metal produced is greater than the weight of the iron in the input. All hot metal properties (all those in Table 2 except numbers 2 and 3) have the form

g q (x) = w(q,x)/ g 4 ( x)

q 2,3

(4)

The formula for slag basicity is

g 2 ( x) = ( qSB

f (q) * w(q, x)

)/f(SiO2)*w(SiO2,x)

(5)

where the index set SB = (CaO, MgO). The formula for slag volume is

g 3 ( x) = ( q SV f (q ) * w(q, x )

)/ g 4 ( x)

(6)

where the index set SV is (CaO,MgO,SiO2,AL2O3) Constraint 1 is linear, and each of the other constraints is a ratio of linear functions of the decision variables, where each function in the denominator is positive.Any system of equality or inequality constraints involving such ratios can be transformed into an equivalent system of linear constraints by multiplying both sides of each constraint by the denominator. For the Mon Valley Works, the problems are small enough that they solve very quickly as nonlinear problems, and it was easier and more natural for US Steel to develop the FORTRAN code for these constraint functions using their nonlinear form. Additionally, in this form, the Lagrange multipliers of the constraints are equal to the sensitivity of the optimal objective with respect to the constraint limits. This would not be true if the problem were converted into linear form. To increase model accuracy, the reconciliation factors f(q) for q = SiO2, CaO, MgO, Al2O3, Si, and Fe are recomputed after each cast. During charging, measurements of actual material inputs (which may differ somewhat from those recommended by the charge model for reasons described earlier) are gathered. Eight hours later, when these materials reach the hearth and are cast from the furnace as hot metal and slag, output samples are sent to the chemistry laboratory for analysis. If the vector of values of the measured inputs is called xm, and the measured weights of the output materials are wm(q), the factors are recomputed to make the predicted and measured material weights equal, i.e. f(q)*w(q,xm) = wm(q) (7)

The factors f(q) are stored and trends are generated and reviewed on a regular basis by quality assurance (QA) personnel. A factor value of 1.0 indicates that all material chemistries are correct and the reduction is occurring as expected. As factors deviate from 1.0, QA personnel determine whether the results are transitional, are indicative of inaccurate raw material chemistries a(q,r), or result from some other change in furnace operating conditions. When factor values fall between 0.95 and 1.05, they are considered normal and are used in the charge model. Values falling outside this range for an extended period of time initiate further investigation into the causes of the errors. This includes examination of material chemistries, evaluation of flue dust, and examination of furnace instrumentation and operational practices. This off-line tuning continues until all factors return to within the acceptable range. In our experience thus far, factor values have usually remained well within range, which is attributable to both QAs persistence in reviewing them regularly, and the special attention given by Operations and Maintenance personnel to furnace performance.

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 8 of 13

This models structure is simpler than that of most gasoline blending models, which involve several gasoline properties, like octane number and distillation points, which blend nonlinearly (See the appendix of [DeWitt et. al., 1989]). The primary reason for the relative simplicity of this model is that the linear blending assumption is quite accurate for the hot metal properties of concern, when the reconciliation factors f(q) are included and updated as described above. Other reasons arise from basic differences between blending petroleum products and blending hot metal in a blast furnace. Petroleum product blending can be measured and controlled much more precisely than hot metal production in a blast furnace, where measurement is difficult and the underlying physical processes are more complicated and not as easily controlled. Hence, in petroleum product blending, controlled experiments can be performed, accurate measurements taken, and expressions for nonlinear phenomena can be fit to this experimental data with high accuracy. We selected the GRG2 nonlinear optimization system [Lasdon, et. al., 1978] to optimize the charge model. A Generalized Reduced Gradient (GRG) algorithm has several advantages over other nonlinear programming (NLP) methods in on-line control applications. GRG uses a two-phase approach, first attaining feasibility in phase 1, then retaining feasibility while striving for optimality in phase 2. This approach is suitable for real-time control applications, where computation time is limited, since the optimization process can be stopped at any point in phase two with a feasible, although sub-optimal solution. This two-phase process is also less likely to return a false diagnosis of infeasibility than are competing algorithms like Successive Quadratic Programming (SQP) [Luenberger, 1984], which attain feasibility and optimality simultaneously. Infeasible problems occurred often in this application, especially in early tuning phases. Software factors also influenced the selection of GRG2. These include pseudo-dynamic allocation of working storage. In GRG2, all working arrays are allocated by partitioning three main arrays, whose dimensions are easily modified by the user, thus permitting relatively simple configuration for problems of different sizes. GRG2 is callable from a user-provided main program, and is written in ANSI-standard FORTRAN 77, which runs on a VAX and most other platforms. The developers of GRG2 provide FORTRAN source code to enable in-house modifications, an important consideration to U.S. Steel due to ISO 9000 Certification requirements. The wellstructured and documented source code simplified such modifications. Finally, assistance from the GRG2 authors during model development and tuning was very important. It is common for problems to arise during this phase, which are difficult for users who are not experienced with NLP software to solve. For example, an early problem was caused by the use of single precision arithmetic to calculate the constraint functions. GRG2 used first order finite difference estimates of the first partial derivatives of these functions, with a finite difference perturbation parameter set to its default value of the square root of the machine precision, about 1.d-8. The correct value for single precision functions is the square root of the function precision, about 1.d-4. This mismatch caused estimated derivatives to be nearly zero, and GRG2 was declaring that the initial point was optimal. Changing to double precision throughout the function evaluation routine eliminated this difficulty.

CONTROL SYSTEM DESIGN AND DEVELOPMENT

The overall control system for the blast furnace consists of the charge model and its associated optimizer, the operators who use it, several measurement modules, data collection and storage activities, and feedback loops. A diagram of the systems major components is shown in Figure 2.

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 9 of 13

F u rn a c e

M a te ria l S y stem

C hem Lab P I S y stem S to c k Y a rd

M a te ria l C h e m istry D B

G o b a l S e ctio n s

L ab In fo M a teria l In fo C o n s tra in ts

F u rn a ce In fo rm a tio n C h a rg e W eig h ts

C o e ffic ien ts M odel M odel R un R equest

O p e ra to r c a n o rd e r m a te ria ls o r re -s u b m it re q u e s t.

R ec o m m en d atio n s R un R e p o rt R e p o rt W rite r D a ily Rpt Q u a lity Rpt M isc . R p ts.

A rch iv e D B

Figure 2 - Control System - Major Components

The new system runs under the VAX/VMS operating system and is written in VAX FORTRAN using DECForms for the graphical user interfaces. To enhance the speed of disk access, the system uses global sections disk areas accessible by all linked modules - for data storage. Furnace information resides in Oil Systems PI (Plant Information System) database. DECMessageQ is the communication link used to gather data from the chemistry lab, and Oracle RDB - a relational database - is used for archiving data and for generating overnight reports. Overnight reports include a daily summary, daily quality, and monthly total report, generated each night at 1:00 am and sent to the printers of the blast furnace managers. Each morning at 7:30 am, the reports are reviewed and decisions are made for adjustments concerning the production for the rest of the day. In 1994, the process control department began design work on the portions of the system that acquire, store, and display the information affecting the choice of input materials. These model inputs include the current conditions of the furnace (e.g., temperatures, pressures, flow rates), the chemical analysis of the previous casts metal and slag, and the composition and physical attributes of the materials available for selection. The system has several screens providing access to the current constraint settings and clearly shows all calculations affecting the current fuel requirements. By reviewing documents developed at U. S. Steel, such as [U. S. Steel, 1964] and consulting with experts in the field, we selected initial upper and lower limits on the constraint functions. We chose the raw materials to be included from the previous years purchasing plan, which established delivery schedules for these materials. System development was completed over the next 18 months. This was followed by a preliminary testing/tuning phase that lasted about 2 months, when attention was focused on proper adjustment of the right hand side of the carbon constraint, which is the most important. Other constraints were relaxed to reduce their effect. The new charge model was brought on-line to run in parallel with the old model for final tuning and evaluation. During the final tuning period, quality assurance personnel worked closely with the process control department and with the GRG2 authors to determine which furnace fluctuations would require fuel adjustments and which would simply be ignored. Changes in the Coke Oven Gas constituents and casting times were deemed too minor for adjustment. We subsequently fixed fuel injection parameters, and established a base cast time and fuel injection level. Operators at the blast furnace adjusted many of the constraint ranges, including the molybdenum constraint, since the original limits for that constraint did not permit loading of materials that had proved to be acceptable in previous production runs. As transitional changes were ignored and reasonable limits were set on output properties, the new charge models recommendations led to a more stable loading schedule than was previously available with the old model. Since the furnace operators run the model most often, we submitted initial designs of the screens to them for their

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 10 of 13

input. They worked with the process control department to develop user-friendly interface designs and report layouts. Extensive detail is provided on the run report which clearly outlines why each decision was made, giving the operator the ability to agree or choose to overlook certain conditions which he may deem transitional. As understanding of the models output grew, better control followed. Constraints were tightened or relaxed to meet the changing furnace environment, and experience was acquired regarding the proper frequency of changes in model parameters. For example, rather than adjusting the reconciliation factors in the model after each cast, they are adjusted based on their trends over time as described earlier.

USES AND BENEFITS

On February 27, 1997, the blending model was put into production mode on both furnaces, and since then furnace operators have been following its recommendations for charging. U.S. Steel has experienced increased, sustainable quality levels, including lower deviations in hot metal Si, Sulfur, and temperatures. This is illustrated in Figure 3 through Figure 5 below, showing standard deviations for these properties for all casts within each month, just before and after the system went on line.

S ta n d a rd D e via tio n fo r H o t M e ta l S ilic o n

0 .3 5 0 .3 0 0 .3 0 0 .2 5 0 .2 0 0 .1 5 0 .1 0 0 .0 5 0 .0 0 0 .2 4 0 .3 0 0 .2 8 0 .2 6 0 .2 5 0 .1 9 0 .2 1 0 .1 8 0 .1 6

Figure 3 - Improved Hot Metal Si Deviations

Standard De viation for Hot M e tal T e mpe rature

45 40 35 30 25 20 15 10 5 0 42 38 36 38 34 33

32

30

28

30

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 11 of 13

Figure 4 - Improved Hot Metal Temperature Deviations

Standard Deviation for Hot Metal Sulfur

0.035 0.031 0.030 0.025 0.020 0.015 0.010 0.005 0.000 0.024 0.019 0.019 0.017 0.020 0.017 0.013 0.013 0.020

Figure 5 - Improved Hot Metal Sulfur Deviations A problem arose about one year after the system went into production mode, characterized by charging recommendations varying much more widely than usual. The need for solution persistence in optimization-based decision support applications intended for repeated use in an operating environment has been recognized frequently in the Operations Research/Management Science (OR/MS) literature, most recently by Brown, Dell, and Wood, [1997]. Upon investigation, it was recognized that, model instances solved over the past year had in fact been infeasible, but the infeasibilities were small and the solutions had been persistent until the problem arose. The new solutions had larger infeasibilities in the copper, molybdenum, and carbon constraints. Apparently this was caused by the recent introduction of some input materials with high copper and molybdenum content. At the same time, changed input conditions required an increase in the right hand side of the carbon constraint. To reduce problem infeasibilities, the copper and molybdenum constraints were relaxed, the GRG2 feasibility tolerance was loosened, and its optimality tolerance was tightened. These changes produced a feasible model and GRG2 converged to an optimal solution. Recent solutions have tended to be at vertices, with as many active constraints as decision variables. The first feasible solution produced is usually optimal. Over the past year, the new charge model has been used successfully in atypical situations, such as shutting down (blowing-down) and starting up (blowing-in) the furnaces, because it produces accurate outputs over a much wider range of furnace operating conditions than the old model did. For example, material additions are key to product removal prior to shutting down the furnace. Burden changes are made which alter the slag composition drastically. Highly siliceous slag is developed to remove as much lime as possible from the hearth and bosh walls. Eventually, iron bearing components are removed from the burden and coke is substituted until all iron is reduced, which eases the job of cleaning the furnace following the final cast. Blowing-in a furnace is equally tedious. Reference to actual burden practice is avoided here because of variations in materials and furnace sizes. In general a heavy coke burden is used initially to heat the hearth and bosh (the furnace level where it reaches its widest and then begins to narrow), while minimum slag is desired to allow hot gases to warm the hearth sufficiently. Next, a rather high volume of slag is required to prepare the hearth for the increasing temperatures and volumes of hot metal. Caution is used when introducing the ore-bearing material into the burden to decrease

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 12 of 13

the chances of the ore solidifying in the stack, termed freezing the furnace . The new system is also useful in making off-line decisions. In the latter part of 1997, an Optimum Burden team was formed. The charge model was used to study the tradeoffs between material compositions, costs, and resulting fuel requirements of alternative materials. As a result, the material purchasing team was better able to acquire a beneficial material mix for the upcoming year, considering cost, quantity, and quality. In another instance, quality assurance and operations personnel used the playground feature of the charge model, which simulates the production system environment, to experiment with new approaches for running the furnaces. These included changes to blast moisture, temperature, flow rate, and enrichments. Some experiments have yielded improved control approaches. For example, BOC-Gases has installed an Oxygen plant next to the U. S. Steel Plant. Blast furnace personnel are preparing to take advantage of the increased oxygen supply by manipulating the above-mentioned blast characteristics. The new charge model is easily maintained and adapted. Current values of all model parameters are readily available to the operators. By updating the reconciliation factors as previously described, model accuracy is maintained despite changes in furnace operating conditions or inaccurate model parameters. The offline tuning procedures indicate when material chemistries are inaccurate, flag problems in dust generation factors, and provide access to controllable fuel adjustments. This robust charging model has proven so beneficial to U. S. Steel that its sales division has been actively marketing it. The blast furnace teams at the Mon Valley Works continue to develop new projects based on continued use of the charge model, and continue to reap the benefits of improved control of their process.

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

_ Hot Metal Production at U. S. Steel, Mon Valley Works

Page 13 of 13

REFERENCES

American Iron and Steel Institute, The Making of Steel, Communications and Education Services Department. 26. Angstenberger, J. 1996. Blast Furnace Analysis with Neural Networks. Artificial Neural Networks - ICANN 96, Springer-Verlag, Berlin, Germany. 203-208. Box, R.E., and D. Herbe Jr. 1988. A Scheduling Model for LTV Steels Cleveland Works Twin Strand Continuous Slab Caster. Interfaces, 18, 1, 42-56. Bielefeld, F. W., K. Walter, and R. Wartmann. 1986. A Computer-Based Strategic Planning System for Steel Production. Interfaces, 16, 4, 41-46. Brown, G. G., R. F. Dell, and R. Kevin Wood. 1997. Optimization and Persistence. Interfaces, 27, 5, 15-38. DeWitt, C., L. Lasdon, A. Waren, D. Brenner, and S. Melhem. 1989. OMEGA: An Improved Gasoline Blending System for Texaco. Interfaces, 19, 1, 85-101. Diaz, A. et al. A Dynamic Scheduling and Control System in an ENSIDESA Steel Plant. Interfaces, 21, 5, 5362. Deitz, D. 1997, Modeling Furnace Performance. Mechanical Engineering, 119 (Dec), 16-17. Hogan, W. T. and F. T. Koelble. 1996. Fewer Blast Furnaces but Higher Productivity. New Steel, 12, (Nov.), 62-66. Inkala, P., A. Karppinen, and M. Seppanen. 1995. Computer Systems for Controlling Blast Furnace Operations at Rautaruukki. Iron and Steel Engineer, 72, 8, 44-48. Iida, O. and U. Yuichi. 1995. Application of AI Techniques to Blast Furnace Operations. Iron and Steel Engineer, 72, 10, 24-28. Lasdon, L. S., A. D. Waren, A. Jain, and M. Ratner. 1978. Design and Testing of a Generalized Reduced Gradient Code for Nonlinear Programming. ACM Transactions on Mathematical Software, 4, 34-50. Luenberger, D. G. 1984. Linear and Nonlinear Programming, Second Edition, Addison-Wesley Publishing Co. Sinha, G. P. et al. 1995. Strategic and Operational Management with Optimization at Tata Steel. Interfaces 25,1, 6-19. United States Steel, 1964. The Making, Shaping, and Treating of Steel, Berne and Pan-American International, 8th addition. United States Steel, The Blast Furnace Course Instruction Manual, U.S.Steel Technical Center. Dino Raviso Section VII Blast Furnace Burdening. Vasko, F. et al. 1991. An Efficient Heuristic for Planning Mother Plate Requirements at Bethlehem Steel. Interfaces 21, 2, 1-7. Vasko, F. et al. 1989. Selecting Optimal Ingot Sizes for Bethlehem Steel. Interfaces 19, 1, 68-84. Zuo, G., J. Ma, and B. Bjorkman. 1998. Some Applications of Neural Networks for the Prediction of Blast Furnace Irregularities. Steel Research, 69, 2, 41-48.

http://www.utexas.edu/courses/lasdon/blast5.htm

11/01/2012

Вам также может понравиться

- Effect of Nut Coke On The Performance of The Ironmaking Blast Furnace Qingshi SongДокумент159 страницEffect of Nut Coke On The Performance of The Ironmaking Blast Furnace Qingshi SongGaurav SrivastavaОценок пока нет

- Developments in Blast Furnace Process Control at Port Kembla BaseДокумент13 страницDevelopments in Blast Furnace Process Control at Port Kembla BaseBinod Kumar PadhiОценок пока нет

- Abnormality Prediction During Furnace Operation (C) Rev1Документ35 страницAbnormality Prediction During Furnace Operation (C) Rev1Shauvik Roy100% (1)

- CupolaДокумент5 страницCupolaRajan Goyal100% (2)

- BLTДокумент10 страницBLTRajesh KumarОценок пока нет

- Operation Manual FurnaceДокумент21 страницаOperation Manual FurnaceAshutosh SinghОценок пока нет

- BFДокумент56 страницBFvikrantsingh2908Оценок пока нет

- Coke properties at tuyere level with pulverized coal injectionДокумент7 страницCoke properties at tuyere level with pulverized coal injectionsinghbasant12100% (1)

- IRREGULARITIES AND REMEDIES IN BLAST FURNACESДокумент2 страницыIRREGULARITIES AND REMEDIES IN BLAST FURNACESSk BeheraОценок пока нет

- Standard Operating Procedures for BF Blowing-InДокумент18 страницStandard Operating Procedures for BF Blowing-InTheleapInoblivionОценок пока нет

- Blast Furnace IronmakingДокумент83 страницыBlast Furnace IronmakingKumar Varun100% (1)

- Cupola Furnace: Types, Parts, Working and ApplicationsДокумент23 страницыCupola Furnace: Types, Parts, Working and Applicationssayan halderОценок пока нет

- Blast Furnace DesignДокумент9 страницBlast Furnace Designmakarsk2007Оценок пока нет

- Cupola Furnace Project ReportДокумент32 страницыCupola Furnace Project Reportadelina ednandaОценок пока нет

- How Cupola Furnaces Melt Cast IronДокумент13 страницHow Cupola Furnaces Melt Cast IronRahul RaiОценок пока нет

- Numerical Analysis Blast Furnace PDFДокумент9 страницNumerical Analysis Blast Furnace PDFLTE002Оценок пока нет

- (Ksw?Tl3Utlon QF This Document Is Unlim!TedДокумент9 страниц(Ksw?Tl3Utlon QF This Document Is Unlim!TedAlfian PangestuОценок пока нет

- Optimizing Blast Furnace Slag Flow via Experimental InvestigationДокумент56 страницOptimizing Blast Furnace Slag Flow via Experimental Investigationdevidutta4uОценок пока нет

- Energy Conservation in Cupola FurnaceДокумент32 страницыEnergy Conservation in Cupola Furnacenayan patel100% (1)

- HIsmelt - The TechnologyДокумент3 страницыHIsmelt - The Technologyrockstar_raphОценок пока нет

- NIPPON STEEL TECHNICAL REPORT No. 89 JANUARY 2004 Development of Visual Evaluation and Numerical Analysis System of Blast FurnaceДокумент8 страницNIPPON STEEL TECHNICAL REPORT No. 89 JANUARY 2004 Development of Visual Evaluation and Numerical Analysis System of Blast Furnacescribdaccount0Оценок пока нет

- Ironmaking and Steelmaking Theory and PracticeДокумент9 страницIronmaking and Steelmaking Theory and PracticeRasul BzОценок пока нет

- Pig Iron - Blast Furnace RouteДокумент3 страницыPig Iron - Blast Furnace RouteRaden Pambudi PratamaОценок пока нет

- Blast Furnace - Material TeknikДокумент8 страницBlast Furnace - Material TeknikDaniel Parsaoran Hamonangan SinagaОценок пока нет

- BSSL Blow-In Plan r1 PDFДокумент37 страницBSSL Blow-In Plan r1 PDFROWHEIT100% (1)

- Kalugin Shaftless Hot Stoves For Blast Furnaces (KSS)Документ3 страницыKalugin Shaftless Hot Stoves For Blast Furnaces (KSS)Maheswar SethiОценок пока нет

- Sintering PlantДокумент24 страницыSintering PlantB R Manikyala Rao100% (1)

- Some Ironfounding Cupola Furnace in Asia and EuropeДокумент4 страницыSome Ironfounding Cupola Furnace in Asia and EuropeKhin Aung ShweОценок пока нет

- Unit 4 v3 PDFДокумент12 страницUnit 4 v3 PDFCh RajuОценок пока нет

- BF Alkali ProblemДокумент6 страницBF Alkali ProblemSuresh BabuОценок пока нет

- Causes and Prevention of Tuyere BurningДокумент4 страницыCauses and Prevention of Tuyere Burningsatya7960100% (1)

- Micro Pellet Sintering Method-CIE 20150414Документ10 страницMicro Pellet Sintering Method-CIE 20150414honeygupta121Оценок пока нет

- Cupola Furnaces Case StudyДокумент5 страницCupola Furnaces Case StudyPutt LaLuОценок пока нет

- Mathematical Modelling of A Cupola FurnaceДокумент2 страницыMathematical Modelling of A Cupola FurnaceLokesh DahiyaОценок пока нет

- Iron Making2Документ54 страницыIron Making2richa_msmeОценок пока нет

- BF SlagДокумент9 страницBF SlagSuresh BabuОценок пока нет

- How A Blast Furnace WorksДокумент7 страницHow A Blast Furnace WorksprasenjitsayantanОценок пока нет

- Decreasing Blast Furnace Process Costs at Iscor Long ProductsДокумент6 страницDecreasing Blast Furnace Process Costs at Iscor Long ProductsPaul VermeulenОценок пока нет

- The Sintering Process of Iron Ore FinesДокумент6 страницThe Sintering Process of Iron Ore FinesAbdullah Aljabir100% (1)

- Mill ScaleДокумент6 страницMill ScaleJhovanny RendónОценок пока нет

- Cupola and Blast FurnaceДокумент26 страницCupola and Blast FurnaceGurjinder SinghОценок пока нет

- Construction of Blast FurnaceДокумент90 страницConstruction of Blast FurnacesuvraОценок пока нет

- How's Steel Manufactured?: Raw Materials For IronmakingДокумент6 страницHow's Steel Manufactured?: Raw Materials For IronmakingUpendra93Оценок пока нет

- Blast Furnace Gas CleaningДокумент25 страницBlast Furnace Gas CleaningSalil JainОценок пока нет

- Impact of Pci in Blast FurnaceДокумент11 страницImpact of Pci in Blast FurnaceSableen SinghОценок пока нет

- Comparing Byproduct and Heat-Recovery CokemakingДокумент9 страницComparing Byproduct and Heat-Recovery Cokemakingkselvan_1100% (1)

- Reverberatory Furnace: By: Walid Khalid AbdulkaderДокумент9 страницReverberatory Furnace: By: Walid Khalid Abdulkaderanon_665535262Оценок пока нет

- Blast Furnace: How Iron is ExtractedДокумент17 страницBlast Furnace: How Iron is ExtractedAnonymous mRBbdopMKfОценок пока нет

- Iron MakingДокумент26 страницIron Makingsumit ranjanОценок пока нет

- Nut CokeДокумент10 страницNut Cokescribdaccount0Оценок пока нет

- Modern Blast Furnace Ironmaking Technology PotentiДокумент36 страницModern Blast Furnace Ironmaking Technology PotentiHicham Cheikh100% (1)

- Electric Arc Furnace Injection System For OxygenДокумент7 страницElectric Arc Furnace Injection System For OxygenIcilma LiraОценок пока нет

- Blast Furnace Design of The FutureДокумент10 страницBlast Furnace Design of The FutureSamanway DasОценок пока нет

- State of The Art and Future of The Blast FurnaceДокумент16 страницState of The Art and Future of The Blast Furnacesaibal_silОценок пока нет

- OTE Outotec Pallet Cars For Sintering and PelletizДокумент4 страницыOTE Outotec Pallet Cars For Sintering and PelletizShukla SuyashОценок пока нет

- Energy Optimizing FurnaceДокумент4 страницыEnergy Optimizing Furnacesourajpatel100% (1)

- Indian Steel Making ProcessesДокумент10 страницIndian Steel Making ProcessesSarbajitManna100% (1)

- BLAST FURNACE MAIN RUNNER DESIGN OPTIMIZATIONДокумент11 страницBLAST FURNACE MAIN RUNNER DESIGN OPTIMIZATIONSaptarshi SenguptaОценок пока нет

- Sinter Plant JSPL, RaigarhДокумент14 страницSinter Plant JSPL, RaigarhJatin BangaliОценок пока нет

- Drive CarДокумент7 страницDrive CarrajnguptaОценок пока нет

- Key Concepts 2 Heat InputДокумент4 страницыKey Concepts 2 Heat InputBama RamachandranОценок пока нет

- Drive CarДокумент7 страницDrive CarrajnguptaОценок пока нет

- Aqueous Processing of WC-Co PowdersДокумент78 страницAqueous Processing of WC-Co PowdersrajnguptaОценок пока нет

- Diseño SismicoДокумент330 страницDiseño SismicoMarco SaraviaОценок пока нет

- ElectrostaticsДокумент79 страницElectrostaticsHead Department of PhysicsОценок пока нет

- D 2718 - 00 Rdi3mtgtmda - PDFДокумент6 страницD 2718 - 00 Rdi3mtgtmda - PDFRufo CascoОценок пока нет

- Magik Language PracticesДокумент3 страницыMagik Language PracticesBada Sainath100% (1)

- Effect of Attenuation and Distortion in Transmission LineДокумент16 страницEffect of Attenuation and Distortion in Transmission Lineமணி பிரபுОценок пока нет

- Summer 2022Документ20 страницSummer 2022GAMING PLUS TECHОценок пока нет

- Corrrelation AnalysisДокумент17 страницCorrrelation AnalysisRaghavendra JeevaОценок пока нет

- Note On Backpropagation John Hull: Ith Observation, and yДокумент2 страницыNote On Backpropagation John Hull: Ith Observation, and yOmar BairanОценок пока нет

- Basic Review CardДокумент6 страницBasic Review CardSheena LeavittОценок пока нет

- Rational Numbers on the Number LineДокумент4 страницыRational Numbers on the Number LineESTEPHANIE TUMAGANОценок пока нет

- TNPSC GROUP I PRELIM EXAM SOLUTIONSДокумент18 страницTNPSC GROUP I PRELIM EXAM SOLUTIONSMONNISH G. MB11564Оценок пока нет

- Chapter 8Документ20 страницChapter 8keshav TyagiОценок пока нет

- Module 1: Nature of StatisticsДокумент47 страницModule 1: Nature of StatisticsHannah Bea LindoОценок пока нет

- Quality Assurance in The Analytical Chemistry Laboratory PDFДокумент321 страницаQuality Assurance in The Analytical Chemistry Laboratory PDFaqeel1970Оценок пока нет

- PDEbookДокумент295 страницPDEbookPrince KayОценок пока нет

- 5DOF Manipulator Simulation Based On MATLAB-Simulink MethodologyДокумент7 страниц5DOF Manipulator Simulation Based On MATLAB-Simulink MethodologySasha NarvaezОценок пока нет

- Singapore IGF Parallax Betwn Science & GitaДокумент116 страницSingapore IGF Parallax Betwn Science & GitasathviksraoОценок пока нет

- GATE Geology GeophysicsДокумент3 страницыGATE Geology GeophysicsstudyurselfОценок пока нет

- 10 Jan Slot 2 SolutionsДокумент40 страниц10 Jan Slot 2 SolutionsBabita MishraОценок пока нет

- Welcome To CMSC 250 Discrete StructuresДокумент13 страницWelcome To CMSC 250 Discrete StructuresKyle HerockОценок пока нет

- LLVM Reference CardДокумент2 страницыLLVM Reference CardPranay DevisettyОценок пока нет

- SME QA Answering Directions General PDFДокумент20 страницSME QA Answering Directions General PDFSagan AlamОценок пока нет

- PRINCIPLES OF MATHEMATICS CURRICULUM DESIGNДокумент3 страницыPRINCIPLES OF MATHEMATICS CURRICULUM DESIGNKhadga Shrestha50% (2)

- MAFE208IU-L7 InterpolationДокумент35 страницMAFE208IU-L7 InterpolationThy VũОценок пока нет

- Advanced Practical Physics Worsnop-Flint PDFДокумент694 страницыAdvanced Practical Physics Worsnop-Flint PDFTanvir Hossain Fahim100% (1)

- Gumbel DistributionДокумент5 страницGumbel DistributionAdrian IosifОценок пока нет

- DLL Quarter 4 Week 6 MATHEMATICS 3Документ4 страницыDLL Quarter 4 Week 6 MATHEMATICS 3Cherry ursuaОценок пока нет

- Digital Notes: (Department of Computer Applications)Документ14 страницDigital Notes: (Department of Computer Applications)Anuj PrajapatiОценок пока нет

- Structural and Design Specific of Space Grid SystemДокумент11 страницStructural and Design Specific of Space Grid SystemClaudia Kristell Mattos RivasОценок пока нет

- Quarter 3 Week 9 Math DLL by MpuhiДокумент25 страницQuarter 3 Week 9 Math DLL by MpuhiCristy AmorОценок пока нет