Академический Документы

Профессиональный Документы

Культура Документы

Carbon and Low Alloy Steels

Загружено:

pratapkumar333Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Carbon and Low Alloy Steels

Загружено:

pratapkumar333Авторское право:

Доступные форматы

Carbon and Low Alloy Steels

1 of 3

http://www.ksh-industries.com/3.htm

Carbon and Low Alloy Steels

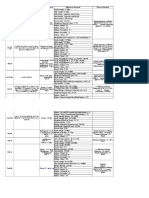

ASTM A 27-91

ASTM A 148-90

ASTM A 216-89

ASTM A 217-91

ASTM A 352-89

ASTM A 426-91

ASTM A 487-89a

ASTM A 597-87

ASTM A 660-91a

Carbon-Steel Castings for General Application.

High-Strength Steel Castings for Structural Purposes.

Carbon-Steel Castings Suitable for Fusion Welding for High-Temperature Service.

Martensitic Stainless and Alloy Steel Castings for Pressure-Containing Parts Suitable for

High-Temperature Service.

Ferritic and Martensitic Steel Castings for Pressure-Containing Parts Suitable for Low-Temperature

Service.

Centrifugally Cast Ferritic Alloy Steel Pipe for High-Temperature Service.

Steel Castings Suitable for Pressure Service.

Cast Tool Steel

Centifugally Cast Carbon Steel Pipe for High-Temperature Service.

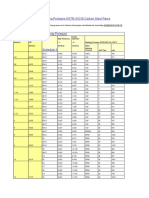

Carbon and Low Alloy Steels

Chemical Composition % -- Maximum

(unless range is given)

Mechanical

Specification PropertiesMinimum

Specification T ensile

Yield

Red

Elong.

of C

And

Strength Point

in 2"%

Area

Grade

ksi

ksi

AST M

A27-93

N-1

----0.25

N-2

----0.35

U-60-30

60

30

22

30 0.25

60-30

60

30

24

35 0.3

65-35

65

35

24

35 0.3

70-36

70

36

22

30 0.35

70-40

70

40

22

30 0.25

Mn

Si

Ni

Cr

Mo

Other

Elements

0.75

0.6

0.75

0.6

0.7

0.7

1.2

0.05

0.05

0.05

0.05

0.05

0.05

0.05

0.06

0.06

0.06

0.06

0.06

0.06

0.06

0.8

0.8

0.8

0.8

0.8

0.8

0.8

--------

--------

--------

--------

AST M

A148-93b

80-40

80-50

90-60

105-85

115-95

130-115

135-125

150-135

160-145

80

80

90

105

115

130

135

150

160

40

50

60

85

95

115

125

135

145

18

22

20

17

14

11

9

7

6

30

35

40

35

30

25

22

18

12

----------

----------

0.05

0.05

0.05

0.05

0.05

0.05

0.05

0.05

0.05

0.06

0.06

0.06

0.06

0.06

0.06

0.06

0.06

0.06

----------

----------

----------

----------

----------

AST M

A216-93

WCA

WCB

WCC

60

70

70

30

36

40

24

22

22

35

35

35

0.25

0.3

0.25

0.7

1

1.2

0.04 0.0450.6

0.04 0.0450.6

0.04 0.0450.6

----

----

----

----

AST M

A217-93

WC1

WC4

WC5

WC6

WC9

C5

C12

CA15

65

70

70

70

70

90

90

90

35

40

40

40

40

60

60

65

24

20

20

20

20

18

18

18

35

35

35

35

35

35

35

30

0.25

.05-.20

.05-.20

.05-.20

.05-.18

0.2

0.2

0.15

.50-.80

.50-.80

.40-.70

.50-.80

.40-.70

.40-.70

.35-.65

1

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

-.70-1.10

.60-1.00

----1

-.50-.80

.50-.90

1.00-1.50

2.00-2.75

4.00-6.50

8.00-10.00

11.5-14.0

.45-.65

.45-.65

.90-1.20

.45-.65

.90-1.20

.45-.65

.90-1.20

0.5

---------

0.0450.6

0.0450.6

0.0450.6

0.0450.6

0.0450.6

0.0450.75

0.0451

0.04 1.5

4/10/2012 3:48 PM

Carbon and Low Alloy Steels

2 of 3

http://www.ksh-industries.com/3.htm

Mechanical

Specification PropertiesMinimum

Specification T ensile

Yield

Red

Elong.

And

Strength Point

of C

in 2"%

Grade

ksi

ksi

Area

Mn

0.0450.6

0.0450.6

0.0450.6

0.0450.6

0.0450.6

0.0450.5

0.0450.6

0.0450.6

AST M

A352-93**

LCA

LCB

LCC

LC1

LC2

LC2-1

LC3

LC4

60

65

70

65

70

105

70

70

30

35

40

35

40

80

40

40

24

24

22

24

24

18

24

24

35

35

35

35

35

30

35

35

0.25

0.3

0.25

0.25

0.25

0.22

0.15

0.15

0.7

1

1.2

.50-.80

.50-.80

.55-.75

.50-.80

.50-.80

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

LC9

85

75

20

30

0.13

0.9

CA6NM

110

80

15

35

0.06

AST M

A426-92+

CP1

CP2

CP5

CP5b

CP9

CP11

CP12

CP15

CP21

CP22

CPCA15

65

60

90

60

90

70

60

60

60

70

90

35

30

60

30

60

40

30

30

30

40

65

24

22

18

22

18

20

22

22

22

20

18

35

35

35

35

35

35

35

35

35

35

30

AST M

A487-93

1B

1C+

2A

2B

2C+

4A

4B

4C+

4D+

4E

6B

90

90

85

90

90

90

105

90

100

115

120

65

65

53

65

65

60

85

60

75

95

95

22

22

22

22

22

18

17

18

17

15

12

7A

115

8A

8B

8C+

9A

9B

9C+

9D+

10A

10B

11A

12A

CA6NMA

85

105

100

90

105

90

100

100

125

70

70

110

Si

Ni

Cr

Mo

Other

Elements

--------2.00-3.00-2.50-3.501.35-1.85

3.00-4.00-4.00-5.00--

---.45-.65

-.30-.60

---

0.04 0.0450.45

8.50-10.00.5

0.2

0.04 0.03 1

3.5-4.5

11.5-14.0

.4-1.0

--------Cu?.30,

?.03

--

0.25

.10-.20

0.2

0.15

0.2

.05-.20

.05-.15

0.15

.05-.15

.05-.15

0.15

.30-.80

.30-.61

.30-.70

.30-.60

.30-.65

.30-.80

.30-.61

.30-.60

.30-.60

.30-.70

1

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.045.10-.50 -0.045.10-.50 -0.0450.75

-0.0451.00-2.00-0.045.25-1.00 -0.0450.6

-0.0450.5

-0.045.15-1.65 -0.0450.5

-0.0450.6

-0.04 1.5

--

-.50-.81

4.00-6.50

4.00-6.00

8.00-10.00

1.00-1.50

.80-1.25

-2.65-3.35

2.00-2.75

11.5-14.0

.44-.65

.44-.65

.45-.65

.45-.65

.90-1.20

.44-.65

.44-.65

.44-.65

.80-1.06

.90-1.20

0.5

------------

45

45

35

40

40

40

35

35

35

35

25

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

.05-.38

1

0.04

1

0.04

1.00-1.400.04

1.00-1.400.04

1.00-1.400.04

1

0.04

1

0.04

1

0.04

1

0.04

1

0.04

1.30-1.700.04

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

-----.40-.80

.40-.80

.40-.80

.40-.80

.40-.80

.40-.80

--.10-.30

.10-.30

.10-.30

.15-.30

.15-.30

.15-.30

.15-.30

.15-.30

.30-.40

100 15

30

.05-.20

.60-1.00 0.04 0.0450.8

.70-1.00 .40-.80

.40-.60

55

85

75

60

85

60

75

70

100

40

40

80

35

30

35

35

35

35

35

35

35

35

35

35

.05-.20

.05-.20

.05-.20

.05-.33

.05-.33

.05-.33

.05-.33

0.3

0.3

.05-.20

.05-.20

0.06

.50-.90

.50-.90

.50-.90

.60-1.00

.60-1.00

.60-1.00

.60-1.00

.60-1.00

.60-1.00

.50-.80

.40-.70

1

-2.00-2.75

-2.00-2.75

-2.00-2.75

-.75-1.10

-.75-1.10

-.75-1.10

-.75-1.10

1.40-2.00.55-.90

1.40-2.00.55-.90

.70-1.10 .50-.80

.60-1.00 .50-.90

3.5-4.5 11.5-14.0

.90-1.10

.90-1.10

.90-1.10

.15-.30

.15-.30

.15-.30

.15-.30

.20-.40

.20-.40

.45-.65

.90-1.20

.4-1.0

V .04-.12

V .04-.12

---------V .03-.10

B

.002-.006

Cu .15-.50

-------------

20

17

17

18

16

18

17

18

15

20

20

15

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.8

0.0450.6

0.0450.6

0.03 1

-----.40-.80

.40-.80

.40-.80

.40-.80

.40-.80

.40-.80

4/10/2012 3:48 PM

Carbon and Low Alloy Steels

3 of 3

http://www.ksh-industries.com/3.htm

Mechanical

Specification PropertiesMinimum

Specification T ensile

Yield

Red

Elong.

And

Strength Point

of C

in 2"%

Grade

ksi

ksi

Area

CA15B

90

65

18

30 0.15

CA15C+

90

60

18

35 0.15

Mn

1

1

0.04 0.04 1.5

0.04 0.04 1.5

AST M

A597-87

CA-2

CD-2

CS-5

CS-7

CH-13

CO-1

-------

-------

-------

-------

.95-1.05 0.75

0.03

1.40-1.601

0.03

.50-.65 .60-1.00 0.03

.45-.55 .40-.80 0.03

.30-.42 0.75

0.03

.85-1.00 1.00-1.300.03

AST M

A660-91a

WCA

WCB

WCC

60

70

70

30

36

40

24

22

22

35

35

35

0.25

0.3

0.25

.70(a)

1

.20(b)

0.03

0.03

0.03

0.03

0.03

0.03

Si

Ni

Cr

Mo

Other

Elements

1

1

11.5-14.0

11.5-14.0

0.5

0.5

---

1.5

-1.5

-1.75-2.25-.60-1.00 -1.5

-1.5

--

0.0350.0350.6

0.0350.0350.6

0.0350.0350.6

----

4.75-5.50 .90-1.40 V 0.20-.50

11.00-13.00.70-1.20 V and Co

0.35

.20-.80 V 0.35

3.00-3.50 1.20-1.60-4.75-5.75 1.25-1.75V .75-1.20

.40-1.00

-V and W

----

----

Notes:

* ASTM A27 Class 1 requiring post-weld heat treatment on all welds is standard from AMERICAN CENTRIFUGAL. Class 2,

which does not require post-weld heat treatment of welds, is not available.

** Impacts (Ft.-Lbs.) to be mutually agreed upon.

+See specification for maximum Brinell hardness after final heat treatment.

The latest revision of a specification shall take precedence in which case the chemical composition may vary from that shown

above.

See the Annual Book of AST M Standards, Section 1, Volume 01.01 and 01.02 for complete

complete details of the

specifications.

AMERICAN also produces material to other ASTM specifications such as A356.

4/10/2012 3:48 PM

Вам также может понравиться

- Stress Analysis ReportДокумент123 страницыStress Analysis ReportNOXOLO PETUNIA SAMBOОценок пока нет

- Yanbu: Export Refinery ProjectДокумент7 страницYanbu: Export Refinery ProjectJanakiraman MalligaОценок пока нет

- Everything You Need to Know About Steel StructuralsДокумент42 страницыEverything You Need to Know About Steel StructuralsJosh Jaymes MasseОценок пока нет

- Yanbu Refinery Hydrogen Injection Piping MaterialsДокумент5 страницYanbu Refinery Hydrogen Injection Piping MaterialsJanakiraman MalligaОценок пока нет

- YANBU REFINERY PROJECT PIPINGДокумент6 страницYANBU REFINERY PROJECT PIPINGJanakiraman MalligaОценок пока нет

- List Files in A FolderДокумент12 страницList Files in A Foldervincent02hk_57881301Оценок пока нет

- T500 VeeyesДокумент5 страницT500 VeeyesTimothy TaylorОценок пока нет

- Numerical investigation of a BFR using OpenFOAMДокумент98 страницNumerical investigation of a BFR using OpenFOAMYuri PaixãoОценок пока нет

- Mechanical, Thermal & Physical Properties of Common Engineering MaterialsДокумент2 страницыMechanical, Thermal & Physical Properties of Common Engineering MaterialsCelineKevinОценок пока нет

- Temperature vs Specific Heat ChartДокумент2 страницыTemperature vs Specific Heat ChartDaud IfadahОценок пока нет

- KIMIA FISIKA HIDROCARBONДокумент9 страницKIMIA FISIKA HIDROCARBONIlhamRifaldiОценок пока нет

- Cahpter 5 Special SteelДокумент50 страницCahpter 5 Special SteelhealgoseОценок пока нет

- Carbon Steel and Alloy Steel FastenersДокумент2 страницыCarbon Steel and Alloy Steel FastenersagnisivadasanОценок пока нет

- Yanbu: Export Refinery ProjectДокумент6 страницYanbu: Export Refinery ProjectJanakiraman MalligaОценок пока нет

- Boundary Layer CalculatorДокумент10 страницBoundary Layer CalculatorTint TigerОценок пока нет

- Material PropertiesДокумент20 страницMaterial Propertiesnikhilpathak16674100% (1)

- Note of Use of The Linear Solver in AsterДокумент28 страницNote of Use of The Linear Solver in AsterTran TuyenОценок пока нет

- MATERIALESДокумент1 страницаMATERIALESRa ClОценок пока нет

- Bolts My SsheetДокумент5 страницBolts My SsheetPiyush TiwariОценок пока нет

- NM MantappisanДокумент224 страницыNM MantappisanRisky Andi0% (1)

- ALPEMA Standards Rev1Документ8 страницALPEMA Standards Rev1nattusharanОценок пока нет

- Jet Reynolds Number Nozzle-Plate SpacingДокумент2 страницыJet Reynolds Number Nozzle-Plate SpacingBurak GülenОценок пока нет

- Bk91 1310 CPF 114 Mef Das 0003 - C - Data Sheet For Stabilizer (CPF 114 C 03cpf 214 C 03)Документ34 страницыBk91 1310 CPF 114 Mef Das 0003 - C - Data Sheet For Stabilizer (CPF 114 C 03cpf 214 C 03)Anonymous bHh1L1Оценок пока нет

- Psychrometric Chart For H 0 (M.a.s.l.) : X KG/KGДокумент16 страницPsychrometric Chart For H 0 (M.a.s.l.) : X KG/KGfisplОценок пока нет

- Yanbu: Export Refinery ProjectДокумент8 страницYanbu: Export Refinery ProjectJanakiraman MalligaОценок пока нет

- Yanbu Export Refinery Piping Materials ChartДокумент7 страницYanbu Export Refinery Piping Materials ChartJanakiraman MalligaОценок пока нет

- EnCal 3000 Gas Chromatograph Software ManualДокумент83 страницыEnCal 3000 Gas Chromatograph Software ManualMostafa NabilОценок пока нет

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesДокумент2 страницыMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamОценок пока нет

- ANSYS AIM DocumentationДокумент306 страницANSYS AIM DocumentationWilder Molina100% (2)

- APEx Tutorial WorkbookДокумент31 страницаAPEx Tutorial WorkbookmusaveerОценок пока нет

- Countercurrent Flow: T1 (F) T2 (F) T3 (F) T4 (F)Документ32 страницыCountercurrent Flow: T1 (F) T2 (F) T3 (F) T4 (F)Partho GiriОценок пока нет

- LPG Physical PropertiesДокумент6 страницLPG Physical PropertiesMugeshОценок пока нет

- Composition and Characteristics of Crude PetroleumДокумент57 страницComposition and Characteristics of Crude PetroleumPrateek Chandra100% (1)

- Materials Properties DatabaseДокумент40 страницMaterials Properties DatabaseJuan Pablo ApazaОценок пока нет

- American Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialДокумент10 страницAmerican Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialjleonosОценок пока нет

- Centre of Stiffness Calculation: Ground FloorДокумент91 страницаCentre of Stiffness Calculation: Ground FloorPoshan DhunganaОценок пока нет

- YANBU PIPINGДокумент7 страницYANBU PIPINGJanakiraman MalligaОценок пока нет

- Deu PointДокумент2 страницыDeu PointP.S.J.SarmaОценок пока нет

- Z - Peng RobinsonДокумент1 страницаZ - Peng RobinsonMuhammadTanzeeLUsmanОценок пока нет

- Pipe Properties FullДокумент16 страницPipe Properties FullJuan P RuizОценок пока нет

- 7335 BulДокумент4 страницы7335 BulSarah DeanОценок пока нет

- Proportional Flow Chart PDFДокумент1 страницаProportional Flow Chart PDFAkyОценок пока нет

- ME 401 Internal Combustion Engines AssignmentДокумент7 страницME 401 Internal Combustion Engines AssignmentRysul Kabir100% (1)

- Gawish SPE Paper PDFДокумент11 страницGawish SPE Paper PDFEdsonОценок пока нет

- Fan Static Pressure CalculationsДокумент3 страницыFan Static Pressure CalculationskarthickОценок пока нет

- Comco Pipe Supply Company Green BookДокумент28 страницComco Pipe Supply Company Green BookinfoОценок пока нет

- Tables and Index Thermodynamics Cengel 7E-2Документ118 страницTables and Index Thermodynamics Cengel 7E-2tomtom9649Оценок пока нет

- SOCKOLETДокумент1 страницаSOCKOLETJOSE DIAZ HERNANDEZОценок пока нет

- Process Heat TransferДокумент327 страницProcess Heat TransferMartin ZaballaОценок пока нет

- System Coupling Tutorials 182Документ114 страницSystem Coupling Tutorials 182Fakhzan Mohd NorОценок пока нет

- Distillation CalculationДокумент9 страницDistillation Calculationraviralagiri020% (1)

- Flange dimensions by pipe size and pressure classДокумент19 страницFlange dimensions by pipe size and pressure classHarish PothepalliОценок пока нет

- Pipe ScheduleДокумент1 страницаPipe SchedulePraveenОценок пока нет

- Distillation Column Separations Homework For Chemical EngineeringДокумент9 страницDistillation Column Separations Homework For Chemical EngineeringkrymxenОценок пока нет

- IPC-TM-650 Test Methods ManualДокумент3 страницыIPC-TM-650 Test Methods ManualRoman MiahОценок пока нет

- Low Voltage Motor Price ListДокумент4 страницыLow Voltage Motor Price ListPARBATIОценок пока нет

- 3Документ4 страницы3Madirley PimentaОценок пока нет

- Chemical Composition of Carbon Steel GuideДокумент2 страницыChemical Composition of Carbon Steel GuideAkilanОценок пока нет

- A 447Документ27 страницA 447superman3kОценок пока нет

- SM SeriesДокумент36 страницSM SeriesGiorgiana RosuОценок пока нет

- New Microsoft Office Word 97 - 2003 Document - 2Документ1 страницаNew Microsoft Office Word 97 - 2003 Document - 2pratapkumar333Оценок пока нет

- BlankДокумент3 страницыBlankpratapkumar333Оценок пока нет

- How To Read Pump CurvesДокумент3 страницыHow To Read Pump CurvesabdurasheediОценок пока нет

- How To Read Pump CurvesДокумент3 страницыHow To Read Pump CurvesabdurasheediОценок пока нет

- How To Make TeaДокумент1 страницаHow To Make Teapratapkumar333Оценок пока нет

- How To Read Pump CurvesДокумент3 страницыHow To Read Pump CurvesabdurasheediОценок пока нет

- S.T.D. Codes: Station Code Station Code Station CodeДокумент4 страницыS.T.D. Codes: Station Code Station Code Station CodeAtul BhardwajОценок пока нет

- Vessel Dimension TerminologyДокумент1 страницаVessel Dimension Terminologypratapkumar333Оценок пока нет

- Script For XPДокумент1 страницаScript For XPpratapkumar333Оценок пока нет

- Vessel Dimension TerminologyДокумент1 страницаVessel Dimension Terminologypratapkumar333Оценок пока нет

- Technip Germany Coke Calcining ExpertiseДокумент17 страницTechnip Germany Coke Calcining ExpertiseSimin Coke Co.Оценок пока нет

- Ethylene Polymers LLDPE PDFДокумент42 страницыEthylene Polymers LLDPE PDFDadadaОценок пока нет

- Agma Ep Gear OilДокумент2 страницыAgma Ep Gear OilMauricioОценок пока нет

- Science 8 3RD Quater Exam ReviewerДокумент6 страницScience 8 3RD Quater Exam ReviewerCrafter CaptsОценок пока нет

- Ozone Solubility ChartДокумент0 страницOzone Solubility ChartWONG TSОценок пока нет

- Zwitterionic Polymers and Hydrogels ForДокумент15 страницZwitterionic Polymers and Hydrogels ForIoana-Alexandra TrofinОценок пока нет

- Phytochemical and Antioxidant Activity of Avocado Leaf Extract (Persea Americana Mill.)Документ1 страницаPhytochemical and Antioxidant Activity of Avocado Leaf Extract (Persea Americana Mill.)Jeff AlbaОценок пока нет

- Macromolecules WorksheetДокумент3 страницыMacromolecules WorksheetSharmaine Durango100% (1)

- PharmpediaДокумент56 страницPharmpediaShyam Singh DasОценок пока нет

- PPTДокумент28 страницPPTRaj KumarОценок пока нет

- TW BF 01 - Barstock Flanged Type Thermowell (Straight) : TWBF - 01Документ17 страницTW BF 01 - Barstock Flanged Type Thermowell (Straight) : TWBF - 01Mangesh MohiteОценок пока нет

- Gram Equivalent Concept: Sunil Kumar SinghДокумент9 страницGram Equivalent Concept: Sunil Kumar Singhnitesh004Оценок пока нет

- Tack Welder Level 3 Question Bank I Fill in The BlanksДокумент6 страницTack Welder Level 3 Question Bank I Fill in The BlanksVigneshwaran VijayakumarОценок пока нет

- Japanies PharmacopieaДокумент254 страницыJapanies PharmacopieaakramuddaulaОценок пока нет

- Carbon and Alloy Steel Properties GuideДокумент51 страницаCarbon and Alloy Steel Properties Guidebs2002Оценок пока нет

- Biomolecules Activity 1.1Документ1 страницаBiomolecules Activity 1.1Kimberly Ann Castro VitugОценок пока нет

- BOC IPRM S08-ConsumablesДокумент187 страницBOC IPRM S08-ConsumablesEduard Lupus Lobo100% (1)

- Process Safety Beacon - March 2023Документ1 страницаProcess Safety Beacon - March 2023Ashish MehtaОценок пока нет

- EFEMA Index of Food EmulsifiersДокумент150 страницEFEMA Index of Food EmulsifiersPhạm Trung HiếuОценок пока нет

- Flashcards - Topic 18 Organic Chemistry - Arenes - Edexcel IAL Chemistry A-LevelДокумент27 страницFlashcards - Topic 18 Organic Chemistry - Arenes - Edexcel IAL Chemistry A-LevelzuveriaОценок пока нет

- Balbach DSC Carbon enДокумент12 страницBalbach DSC Carbon encachoОценок пока нет

- 13.ionic Equilibria NotesДокумент37 страниц13.ionic Equilibria Notesgeoboom12100% (15)

- List of EDLДокумент57 страницList of EDLHerianto P SiregarОценок пока нет

- Process for Producing Ammonium Nitrate from Ammonia OxidationДокумент20 страницProcess for Producing Ammonium Nitrate from Ammonia OxidationGracia ManurungОценок пока нет

- UHLF Liquid FertilizerДокумент1 страницаUHLF Liquid FertilizerGrignionОценок пока нет

- Kaynak Gazı Karışımları en 14175Документ4 страницыKaynak Gazı Karışımları en 14175İbrahimErenОценок пока нет

- Steam ReformersДокумент95 страницSteam Reformersassadeq100% (2)

- DAFTAR PUSTAKA PcttthayДокумент2 страницыDAFTAR PUSTAKA PcttthayNur Utami PakayaОценок пока нет

- Formation of Zein Micro Phases in Ethanol-Water - Wang and Padua 2010Документ5 страницFormation of Zein Micro Phases in Ethanol-Water - Wang and Padua 2010Joeska HyОценок пока нет

- AQA 8464 C 1H Final MS Jun23 v1.0Документ20 страницAQA 8464 C 1H Final MS Jun23 v1.0meherun.hamzaОценок пока нет