Академический Документы

Профессиональный Документы

Культура Документы

An 095

Загружено:

tazzo2Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

An 095

Загружено:

tazzo2Авторское право:

Доступные форматы

In-System Programmability

in MAX Devices

Application Note 95

September 2005, ver. 1.5

Introduction

MAX devices are programmable logic devices (PLDs), based on the Altera Multiple Array MatriX (MAX) architecture that and supports the IEEE Std. 1149.1 Joint Test Action Group (JTAG) interface. MAX devices are also in-system programmable, which adds programming flexibility and provides benefits in many phases of product development, manufacturing, and field use. This application note provides background information on in-system programmability (ISP) and the IEEE Std. 1149.1 JTAG interface and discusses the advantages of using ISP-capable MAX devices. In-system design, prototyping, and manufacturing, reduces cost, shortens development time, and provides a wider range of programming options than standard device programming methods. With ISP, you can:

Features & Benefits

Program and reprogram devices after they are soldered onto the printed circuit board (PCB), minimizing the possibility of lead damage or electrostatic discharge (ESD) exposure. Manufacture systems before you finalize device configuration. Perform boundary-scan test (BST) procedures and program devices using in-circuit testers. Upgrade systems in the field after they have been shipped.

Altera Corporation

A-AN-095-1.5

AN 95: In-System Programmability in MAX Devices

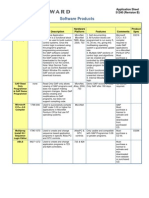

Table 1 describes the features and benefits of using ISP-capable MAX devices. Table 1. ISP-Capable MAX Device Features & Benefits Product Development Phase

Device prototyping

Features

Benefits

Devices are programmed with a VCC-level Eliminates the need for a 12.0-V programming voltage. programming voltage and the possibility of accidental damage to lower voltage parts. Also reduces system power requirements. Devices can be programmed while soldered to a PCB. Prototype systems can be assembled before the device configuration is finalized. Minimizes device handling, thereby protecting devices from ESD and lead damage. Cuts prototype development time and saves development costs. Simplifies manufacturing, saves time, and protects devices from ESD and lead damage.

System manufacturing PLDs can be treated the same way as other board-level devices because they can be programmed after the PCB is assembled. ISP is implemented using the IEEE Std. 1149.1 (JTAG) interface; therefore, circuit testing and device programming can be combined into a single manufacturing step using a standard in-circuit tester. Programming data can be downloaded from in-circuit testers, PCs, or workstations during final PCB test. Devices can be programmed with test configurations. In-field programming

Enhances design debugging and boardlevel testing capabilities.

Devices can be reprogrammed in the field. Adds versatility and reduces service costs, thereby making products more attractive to the consumer.

VCC-Level Programming

ISP-capable MAX devices support ISP through a VCC-level programming voltage. The devices generate a 12.0-V programming voltage internally to program, verify, and erase the devices EEPROM cells, eliminating the need for the external 12.0-V programming voltage typically required for programming. ISP-capable MAX devices are guaranteed for 100 erase and programming cycles with 100% programming and functional yields.

Altera Corporation

AN 95: In-System Programmability in MAX Devices

Programming Systems

In Altera devices, ISP is implemented using the IEEE Std.1149.1 JTAG interface, which streamlines PCB testing and device programming operations into a single manufacturing step. ISP-capable MAX devices are supported by the following systems:

MAX+PLUS II development system In-circuit testers Embedded processors

MAX+PLUS II Development System

You can use a PC or UNIX workstation, the MAX+PLUS II Programmer, and the BitBlaster serial or ByteBlasterMV parallel port download cable to download Programmer Object Files (.pof), Jam Files (.jam), or Jam Byte-Code Files (.jbc)from the MAX+PLUS II software to ISPcapable MAX devices mounted on a PCB. This method is more costeffective than other programming methods because design, simulation, and prototyping can be performed using the same PC- or UNIX workstation-based system. For production, you can implement ISP using Alteras free stand-alone programming software and the BitBlasterMV cable to download POFs. 1 PC-based stand-alone programming software, asap2.exe, is available from Alteras FTP site at ftp.altera.com in the \pub\misc directory.

Figure 1 shows the 10-pin female plug dimensions for the BitBlaster or ByteBlasterMV download cable.

Altera Corporation

AN 95: In-System Programmability in MAX Devices

Figure 1. 10-Pin Female Plug Dimensions

Dimensions are shown in inches. The spacing between pin centers is 0.1 inch.

0.425 Typ.

Color Strip

1 0.250 Typ. 2 4 6 8 10 3 5 7 9

0.100 Sq. 0.700 Typ.

0.025 Sq.

Table 2 identifies the 10-pin female plugs pin names for the corresponding download mode. Table 2. Female Plugs Pin Names & Download Modes Pin JTAG Mode Signal Name

1 2 3 4 5 6 7 8 9 10 TCK GND TDO VCC TMS TDI GND

PS Mode Signal Name

DCLK GND CONFIG_DONE VCC nCONFIG nSTATUS DATA0 GND

Description

Clock signal Signal ground Data from device Power supply JTAG state machine control No connect No connect No connect Data to device Signal ground

Description

Clock signal Signal ground Configuration control Power supply Configuration control No connect Configuration status No connect Data to device Signal ground

The circuit board must supply VCC and ground to the ByteBlasterMV cable.

Altera Corporation

AN 95: In-System Programmability in MAX Devices

ISP-capable devices are programmed via a devices JTAG pins: TCK, TMS, TDI, and TDO. Figure 2 shows how the BitBlaster or ByteBlasterMV download cable interfaces with an ISP-capable device. The I/O pins are tri-stated during in-system programming. Figure 2. ISP-Capable MAX Device Programming with the BitBlaster or ByteBlasterMV Download Cable

VCC

VCC

1 k

VCC

1 k 1 k

GND

Target Altera Device

TCK TDO TMS TDI

1 k

10-Pin Male Header (Top View)

VCC

Pin 1

GND

GND

Search for Programming a Single Device with the BitBlaster or ByteBlasterMV in MAX+PLUS II Help, or go to the BitBlaster Serial Download Cable Data Sheet and ByteBlasterMV Parallel Port Download Cable Data Sheet in this handbook for more information.

In-Circuit Test Programming

You can program ISP-capable MAX devices during the final PCB testing stage using in-circuit testers and the IEEE Std. 1149.1 (JTAG) interface. To program a device using in-circuit testers, create a Jam or SVF File with the MAX+PLUS II software and download this file from an in-circuit test station to one or more ISP-capable MAX devices.

Embedded Processor Programming

You can program ISP-capable MAX devices in-system using an embedded processor. For example, programming information can be stored in an EPROM and shifted into the ISP-capable MAX device using a 4-bit interface from the processor to the devices JTAG pins. This method lets you program devices during burn-in and upgrade devices in the field.

Altera Corporation

AN 95: In-System Programmability in MAX Devices

You can program MAX devices with an embedded processor by creating a Jam File from the MAX+PLUS II software and downloading it with the Jam Player.

f IEEE Std. 1149.1 Interface

Refer to AN 122: Using Jam STAPL for ISP & ICR via an Embedded Processor for more information on embedded processor programming. MAX device JTAG pins and functions are described in Table 3.

Table 3. JTAG Pins Pin

TDI

Description

Test data input

Function

Serial input pin for data and instructions, which are shifted in on the rising edge of TCK. This signal needs to be externally pulled high during normal operation. Serial data output pin for instructions and data. Data is shifted out on the falling edge of TCK. This signal is tri-stated if data is not being shifted out of the device.

TDO

Test data output

TMS

Test mode select Input pin controls the IEEE Std. 1149.1 JTAG state machine and is evaluated on the rising edge of TCK. This signal needs to be externally pulled high during normal operation. Test clock Provides the clock signal for the JTAG circuits. The maximum operating frequency is 10 MHz. This signal needs to be externally pulled low during normal operation.

TCK

During erasure, programming, and verification, all device I/O pins are tri-stated to eliminate interference from other devices on the PCB. Devices are programmed by applying the appropriate signals on the TMS and TCK inputs and shifting data into and out of the devices on the TDI and TDO pins, respectively. After programming, the IEEE Std. 1149.1 JTAG Test Access Port (TAP) controller state machine must be advanced to the RESET state, which is maintained by external pull-up resistors on the TCK, TMS, and TDI pins. During normal operation, the pull-up resistors prevent the device from entering other modes. Figure 3 shows the timing waveforms for the IEEE Std. 1149.1 JTAG TAP controller state machine.

Altera Corporation

AN 95: In-System Programmability in MAX Devices

Figure 3. JTAG Waveforms for MAX Devices

TMS

TDI

tJCP tJCH tJCL tJPSU tJPH

TCK

tJPZX tJPCO tJPXZ

TDO

tJSSU tJSH

Signal to Be Captured Signal to Be Driven

tJSZX

tJSCO

tJSXZ

Table 4 shows the JTAG timing parameters and values for ISP-capable MAX devices. Table 4. JTAG Timing Parameters & Values for MAX Devices Symbol

tJCP tJCH tJCL tJPSU tJPH tJPCO tJPZX tJPXZ tJSSU tJSH tJSCO tJSZX tJSXZ TCK clock period TCK clock high time TCK clock low time JTAG port setup time JTAG port hold time JTAG port clock to output JTAG port high impedance to valid output JTAG port valid output to high impedance Capture register setup time Capture register hold time Update register clock to output Update register high impedance to valid output Update register valid output to high impedance 20 45 25 25 25

Parameter

Min

100 50 50 20 45

Max

Unit

ns ns ns ns ns

25 25 25

ns ns ns ns ns ns ns ns

Go to AN 39: IEEE Std.1149.1 (JTAG) Boundary-Scan Testing in Altera Devices for information on the IEEE Std.1149.1 JTAG TAP controller state machine.

7

Altera Corporation

AN 95: In-System Programmability in MAX Devices

Programming ISP-Capable MAX Devices

You can use an IEEE Std.1149.1 JTAG-compatible header to program a single device or a chain of devices, depending on the layout of your PCB.

Single-Device Programming

For PCBs that contain a single ISP-capable MAX device, a JTAG-compatible headersuch as the 10-pin BitBlaster or ByteBlasterMV headercan be used to program the device. See Figure 4.

Altera Corporation

AN 95: In-System Programmability in MAX Devices

Figure 4. Single-Device Programming

VCC

1 k

VCC

1 k

ISP Target Device

TDI

VCC

TDI

TDO TCK

TMS

IEEE Std. 1149.1 JTAG Interface

1 k

TMS TCK TDO

1 k

JTAG-Chain Device Programming

When programming a chain of devices, one JTAG-compatible plug, such as a BitBlaster or ByteBlasterMV 10-pin male plug, is connected to several devices. The number of devices in the JTAG chain is limited only by the drive capability of the BitBlaster or ByteBlasterMV download cable. However, when three or more devices are connected in a JTAG chain, Altera recommends buffering the TDO,TCK, TDI, and TMS pins. JTAG-chain device programming is ideal when the circuit board contains multiple devices, or when the circuit board is tested using JTAG BST. See Figure 5.

Altera Corporation

AN 95: In-System Programmability in MAX Devices

Figure 5. JTAG-Chain Device Programming with a BitBlaster or ByteBlasterMV Cable

VCC

ByteBlaster 10-Pin Male Header

VCC

VCC

1 k 1 k

1 k

Other IEEE Std. 1149.1 JTAGCompliant Device TDI TMS TDO TCK

Target Altera Device TDI TMS TDO TCK

Other IEEE Std. 1149.1 JTAGCompliant Device TDI TMS TDO TCK

1 k

To program a single ISP-capable MAX device in a JTAG chain, the programming software puts all other devices in the JTAG chain in BYPASS mode. When in BYPASS mode, devices pass programming data from the TDI pin to the TDO pin through a single bypass register. Bypassed devices are not affected internally, thereby enabling the programming software to erase, program, or verify the target device.

f Conclusion

Go toAN 39: IEEE 1149.1 (JTAG) Boundary-Scan Testing in Altera Devices for more information on the BYPASS mode. ISP-capable MAX devices offer benefits in product design, prototyping, and manufacturing. ISP simplifies the manufacturing flow by allowing the devices to be mounted on a PCB with standard pick-and-place equipment before they are programmed. ISP-capable MAX devices can be programmed by downloading the information via in-circuit testers, embedded processors, or the BitBlaster or ByteBlasterMV download cables. In addition, programming these devices after they are placed on the board eliminates lead damage on high pin-count packages, e.g., quad flat pack (QFP) packages, due to device handling. These devices can also be reprogrammed in the field (i.e., product upgrades can be performed in the field via software or modem).

10

Altera Corporation

AN 95: In-System Programmability in MAX Devices

101 Innovation Drive San Jose, CA 95134 (408) 544-7000 www.altera.com Applications Hotline: (800) 800-EPLD Literature Services: literature@altera.com 11

Printed on Recycled Paper.

Copyright 2005 Altera Corporation. All rights reserved. Altera, The Programmable Solutions Company, the stylized Altera logo, specific device designations, and all other words and logos that are identified as trademarks and/or service marks are, unless noted otherwise, the trademarks and service marks of Altera Corporation in the U.S. and other countries. All other product or service names are the property of their respective holders. Altera products are protected under numerous U.S. and foreign patents and pending applications, maskwork rights, and copyrights. Altera warrants performance of its semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make changes to any products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information, product, or service described herein except as expressly agreed to in writing by Altera Corporation. Altera customers are advised to obtain the latest version of device specifications before relying on any published information and before placing orders for products or services.

Altera Corporation

Вам также может понравиться

- Coca-Cola Vending MachineДокумент27 страницCoca-Cola Vending MachineAbel MeketaОценок пока нет

- Debugging With JTAGДокумент43 страницыDebugging With JTAGGlen MonetteОценок пока нет

- ATM Terminal Design Based On Figure Print Recognition DocuДокумент115 страницATM Terminal Design Based On Figure Print Recognition DocuPraveen NaiduОценок пока нет

- STM 1 ConfigurationДокумент11 страницSTM 1 Configurationrohit0072260% (5)

- Siemens s7-300 ProgrammingДокумент94 страницыSiemens s7-300 ProgrammingPrittam Kumar Jena100% (6)

- ChipMax ManualДокумент68 страницChipMax ManualRaul E. SoliОценок пока нет

- Integrated Control System: Prepared By: Guided By: Rajyaguru Maulik M. D.M. Patel (General Manage, Inst)Документ31 страницаIntegrated Control System: Prepared By: Guided By: Rajyaguru Maulik M. D.M. Patel (General Manage, Inst)Sunil PillaiОценок пока нет

- Practical Data Acquisition for Instrumentation and Control SystemsОт EverandPractical Data Acquisition for Instrumentation and Control SystemsОценок пока нет

- A Master-Slave DSP Board For Digital ControlДокумент5 страницA Master-Slave DSP Board For Digital Controlfurious143Оценок пока нет

- Ajax CNC Installation ManualДокумент27 страницAjax CNC Installation ManualsunhuynhОценок пока нет

- IJTAG B Ravi Kishore 2017HT80522Документ10 страницIJTAG B Ravi Kishore 2017HT80522RaviKishoreBonalaОценок пока нет

- Micronet SoftwaresДокумент4 страницыMicronet SoftwaresHasan FarooqОценок пока нет

- PLC ScadaДокумент30 страницPLC ScadaNeeraj Mishra100% (1)

- (1 Introduction To Laboratory Hardware and ToolsДокумент12 страниц(1 Introduction To Laboratory Hardware and ToolsMalix ismОценок пока нет

- Xport TCP IpДокумент5 страницXport TCP IpKarthick Vijayan100% (1)

- Programming Cable Users GuideДокумент13 страницProgramming Cable Users GuideSahal AhammedОценок пока нет

- Mark Vi术语表Документ9 страницMark Vi术语表meirangongОценок пока нет

- Industrial Security System Using Microcontroller Regulated Power SupplyДокумент6 страницIndustrial Security System Using Microcontroller Regulated Power Supplynaveenraj111Оценок пока нет

- Xilinx In-System Programming Using An Embedded MicrocontrollerДокумент38 страницXilinx In-System Programming Using An Embedded Microcontrollerusmancheema81Оценок пока нет

- DSAUTAZ008901Документ5 страницDSAUTAZ008901chengchung liОценок пока нет

- Tems ConfigurationДокумент21 страницаTems ConfigurationPoetri Sagitarius LoveLy BlueОценок пока нет

- XPort DS-220314Документ6 страницXPort DS-220314snobic9379Оценок пока нет

- Vanguard Product BrochureДокумент6 страницVanguard Product BrochurescribdkhatnОценок пока нет

- PCT Manual 2.3.1Документ115 страницPCT Manual 2.3.1SzefElityОценок пока нет

- Manual For Cycle 1Документ193 страницыManual For Cycle 1Seth GreeneОценок пока нет

- Microcontroller Ethernet Interfacing Purpose: MAE 285 Laboratory #5Документ11 страницMicrocontroller Ethernet Interfacing Purpose: MAE 285 Laboratory #5Avik SarkarОценок пока нет

- TGA-B RP Test ProcedureДокумент27 страницTGA-B RP Test ProcedureAlberto VegaОценок пока нет

- Gui Based Liquid Indicator Using Cortex M3 For Industry Monitoring SystemДокумент9 страницGui Based Liquid Indicator Using Cortex M3 For Industry Monitoring SystemeditorijaiemОценок пока нет

- D.Sai Dutt: Phone No: - 09030772232. Location: - Hyderabad Professional SkillsДокумент4 страницыD.Sai Dutt: Phone No: - 09030772232. Location: - Hyderabad Professional SkillsReshma VlsiОценок пока нет

- ESA DeviceNet ConfigДокумент10 страницESA DeviceNet ConfigCalin CucОценок пока нет

- Xilinx Answer 73361 PCIe Link Training Debug Guide For US and US PlusДокумент54 страницыXilinx Answer 73361 PCIe Link Training Debug Guide For US and US PlusEvamGilotraОценок пока нет

- Debugger UserДокумент109 страницDebugger Usercarver_uaОценок пока нет

- In System Programming With 8051Документ7 страницIn System Programming With 8051vmateixeiraОценок пока нет

- Introduction of MTK Tools V2 PDFДокумент81 страницаIntroduction of MTK Tools V2 PDFJoao Carlos RamosОценок пока нет

- E-Notice Board Using GSM and Microcontroller: Project Presentation OnДокумент25 страницE-Notice Board Using GSM and Microcontroller: Project Presentation OnBandesh KumarОценок пока нет

- JTAG & Microcontroller FeaturesДокумент6 страницJTAG & Microcontroller FeaturesJMОценок пока нет

- Objective and AimДокумент6 страницObjective and AimSaadat ZaidiОценок пока нет

- MP & DSP Lab ManualДокумент122 страницыMP & DSP Lab ManualShiva RamОценок пока нет

- MKS Base Datasheet PDFДокумент7 страницMKS Base Datasheet PDFJeyson GuanoluisaОценок пока нет

- ASSIGNMENT 1 (Embd&IOmT)Документ9 страницASSIGNMENT 1 (Embd&IOmT)rakesh.jОценок пока нет

- PWM-Inverter Drive Control Operating With A Standard Personal ComputerДокумент6 страницPWM-Inverter Drive Control Operating With A Standard Personal Computeralpha1ahОценок пока нет

- M7000a (Epm7256ae)Документ64 страницыM7000a (Epm7256ae)marcelgrandoОценок пока нет

- Atca 6101Документ3 страницыAtca 6101Karanja SamОценок пока нет

- Honeywell ALerton LTBT-VLXДокумент2 страницыHoneywell ALerton LTBT-VLXVo Dai NgocОценок пока нет

- InteliCompact NT Datasheet 2011-11 CPLEICNTДокумент6 страницInteliCompact NT Datasheet 2011-11 CPLEICNTThao Nguyen XuanОценок пока нет

- Harsh AlДокумент81 страницаHarsh AlSmit VahalkarОценок пока нет

- 8 JTAG Unit 8Документ19 страниц8 JTAG Unit 8nareshОценок пока нет

- Embedded Design of A Remote Voice Control and Security SystemДокумент6 страницEmbedded Design of A Remote Voice Control and Security SystemSooraj PuthiyaveetilОценок пока нет

- USER MANUAL Mab - 51Документ93 страницыUSER MANUAL Mab - 51Pushpinder Singh KhalsaОценок пока нет

- Etherlink Plus Adapter Technical Reference Manual: A Member of The Etherlink Product FamilyДокумент84 страницыEtherlink Plus Adapter Technical Reference Manual: A Member of The Etherlink Product FamilyInterested PersonОценок пока нет

- 05-6709A02 RevA Orbit ECR Setup Guide PDFДокумент5 страниц05-6709A02 RevA Orbit ECR Setup Guide PDFHaider AliОценок пока нет

- ENC28J60 Ethernet ModuleДокумент7 страницENC28J60 Ethernet ModuleNeha MahoreОценок пока нет

- Evaluates: MAX78000 MAX78000FTHR Application Platform: General Description FeaturesДокумент16 страницEvaluates: MAX78000 MAX78000FTHR Application Platform: General Description Featuresduval fortesОценок пока нет

- Exaopc GS36J02A10-01E PDFДокумент11 страницExaopc GS36J02A10-01E PDFsina20795Оценок пока нет

- Experiment: 1: Government Engineering College Sector-28, GandhinagarДокумент7 страницExperiment: 1: Government Engineering College Sector-28, GandhinagarDhrumil ManiyarОценок пока нет

- AT29C020Документ11 страницAT29C020hajarОценок пока нет

- DSA00340765Документ6 страницDSA00340765chengchung liОценок пока нет

- JTAGulator Product Brief 1.1Документ2 страницыJTAGulator Product Brief 1.1Josemar M. FerreiraОценок пока нет

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.От EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.Оценок пока нет

- ABX00053 DatasheetДокумент19 страницABX00053 DatasheeteduardlopezОценок пока нет

- c10lp Eval A1 SCHДокумент56 страницc10lp Eval A1 SCHVienNgocQuangОценок пока нет

- Dvi 0027a Arm7tdmi PoДокумент22 страницыDvi 0027a Arm7tdmi PoMahavirsinh GohilОценок пока нет

- Evk1000 User Manual v107Документ25 страницEvk1000 User Manual v107truonggiang_mtgОценок пока нет

- Jarvis ResumeДокумент4 страницыJarvis ResumeRakshaОценок пока нет

- Automotive MCUs and MPUs 8 16 e 32 Bits Devices FreescaleДокумент2 страницыAutomotive MCUs and MPUs 8 16 e 32 Bits Devices FreescaleJoão JoséОценок пока нет

- US-NRC Document On QualificationДокумент98 страницUS-NRC Document On QualificationParidhi AggarwalОценок пока нет

- Stm32 Flash ProgrammingДокумент31 страницаStm32 Flash ProgrammingeemkutayОценок пока нет

- Tmx-r1000 Service ManualДокумент61 страницаTmx-r1000 Service Manualroca9o100% (1)

- Tutorial For Quartus' Signaltap Ii Logic AnalyzerДокумент7 страницTutorial For Quartus' Signaltap Ii Logic AnalyzerbittibssiОценок пока нет

- EZ Board Manual Rev 1Документ111 страницEZ Board Manual Rev 1Top Hat ElectronicsОценок пока нет

- Azure Sphere MT3620 Starter KitДокумент2 страницыAzure Sphere MT3620 Starter KitRP1996Оценок пока нет

- Unit - 6 Embedded System Implementation and TestingДокумент23 страницыUnit - 6 Embedded System Implementation and TestingMurali Dhara Sesha Giri Rao GoddantiОценок пока нет

- List of ARM Cortex-M Development ToolsДокумент8 страницList of ARM Cortex-M Development Toolsscience pathОценок пока нет

- MNAV100CA Users ManualДокумент50 страницMNAV100CA Users ManualYirui TangОценок пока нет

- Infineon-FM4 S6E2G-Series Pioneer Kit Guide-UserManual-v01 00-ENДокумент82 страницыInfineon-FM4 S6E2G-Series Pioneer Kit Guide-UserManual-v01 00-ENCrazyGamer SLОценок пока нет

- ALTERA - In-System Programmability GuidelinesДокумент18 страницALTERA - In-System Programmability GuidelinesRobert GuzmanОценок пока нет

- Iot Security 1.1 Chapter 3 Quiz: Attempt HistoryДокумент11 страницIot Security 1.1 Chapter 3 Quiz: Attempt HistoryJaime QuishpeОценок пока нет

- Path Planning of Mobile Robot Using ROSДокумент8 страницPath Planning of Mobile Robot Using ROSInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Programmable System-On-Chip (Psoc) : General DescriptionДокумент137 страницProgrammable System-On-Chip (Psoc) : General DescriptionPrabhuKiranОценок пока нет

- Atmel 42051 SAM BA For SAM4L Application Note AVR10005Документ13 страницAtmel 42051 SAM BA For SAM4L Application Note AVR10005bibloiОценок пока нет

- Ordb2a Ep4ce22 User ManualДокумент19 страницOrdb2a Ep4ce22 User ManualbwsparxzОценок пока нет

- Jtag & BscanДокумент18 страницJtag & Bscankarthikp207Оценок пока нет

- LG GT500 GT505 Service ManualДокумент242 страницыLG GT500 GT505 Service ManualMatei FlorinОценок пока нет

- Byte Blaster MVДокумент12 страницByte Blaster MVapi-3712916100% (1)

- 60001290e PDFДокумент382 страницы60001290e PDFBryanMonangWienerОценок пока нет

- ARM Cortex-M3: An Improvement Overview: January 2011Документ7 страницARM Cortex-M3: An Improvement Overview: January 2011RoopaNarsiОценок пока нет

- Cascade 5700 5.7" Panel Mount HMI Specification: Model: FBDA9031-50Документ12 страницCascade 5700 5.7" Panel Mount HMI Specification: Model: FBDA9031-50plopiessОценок пока нет